Stove heating is considered one of the most common, economical and simple ways of autonomous heating for private homes .

Especially for heating large rooms, well-known manufacturers have developed many thoughtful models of wood-burning stoves for every taste and budget.

Modern devices are safe to use and do not require lining or strengthening the foundation, which means that the user will not have any problems during the installation and operation of heating equipment.

The lineup

Today there are many models of the Butakov stove on the market. Below we will consider the main ones.

- The Gymnasist device, with a power of only 7 kW, is capable of heating up to 100 m² of area. The height of the chimney is 5 m.

- The Student stove (9 kW) can heat a room up to 150 m². The maximum fuel volume is up to 20 kg. The height of the chimney is 5 m.

- Professor Butakov’s “Engineer” unit (15 kW) will heat a room up to 250 m². The maximum fuel volume is 40 kg. The height of the chimney is 5 m.

- The Docent stove (25 kW) will heat a home up to 500 m². The design can hold up to 100 kg of flammable substances. The height of the chimney is 6 m.

- The “Professor” device (40 kW) is capable of heating up to 1000 m² of housing. The maximum fuel volume is 200 kg. The height of the chimney is 8 m.

- The Akademik unit (55 kW) can warm up a house with an area of up to 1200 m². The stove can hold up to 240 kg of flammable material.

Each model has its own dimensions. The larger the fuel space and firebox, the larger the dimensions of the stove.

The optimal choice of device depends on its purpose and the area of the premises requiring heating.

The compact stove “Gimnasist” can heat up to 100 square meters. meters. Its chimney goes up, so this unit is suitable for country houses and garage buildings. For other models, the chimney exits to the top or is located at the rear of the structure. They are mainly installed in large rooms.

Rating of the TOP 12 best wood stoves for the home

| Place | Model | Price |

| Small power models up to 50 cc. meters | ||

| #1 | TMF Cinderella 2016 | |

| #2 | Vesuvius Teremok | |

| #3 | TMF Cinderella Light | |

| Models from 60 to 100 cc. meters of heating | ||

| #1 | Vesuvius V5S | |

| #2 | Breneran AOT-06/00 | |

| #3 | Teplodar T-100 | |

| Models from 100 to 300 cc. meters | ||

| #1 | Guca Arina Low | |

| #2 | Professor Butakov Student | |

| #3 | Vesuvius V5S | |

| Models from 300 cc. meters | ||

| #1 | Breneran AOT-14/02 | |

| #2 | Professor Butakov Associate Professor | |

Page navigation:

How to light a stove correctly Engineer

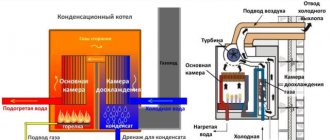

The air-heating boiler Professor Butakov performed by the Engineer, working on wood and coal, a derivative model Hydraulic with a built-in water circuit, have a common structure and principle of operation.

The company has prepared some recommendations regarding the correct firing of stoves:

- Air pockets form in the chimney, especially after a long break in operation. If you immediately turn on the stove at full power, backdraft will appear and smoke will flow into the room. Therefore, to begin with, the stove and chimney duct are heated by burning a small volume of finely chopped splinters. The firebox is started at full power after 10-15 minutes of maintaining a low-intensity flame.

It is wrong to heat a stove exclusively with coal, and the Engineer and Engineer Hydraulic series are not intended for this type of fuel at all. The coal boiler is initially heated with wood. After heating the firebox and creating the required temperature, a portion of coal is poured on top. Some experienced users recommend that the fuel be laid in layers. A layer of firewood, a layer of coal. This prevents overheating of the combustion chamber, and during combustion, the soot burns out at the same time. Learning how to properly fire a Termofor Engineer coal stove is not at all difficult. After 2-3 kindlings in accordance with the instructions set out in the documentation from Termofor, the firebox will become a familiar and everyday activity.

All long-burning wood stoves for the Engineer house operate in gas generation mode. In order to force solid fuels to release flammable carbon dioxide, certain conditions must be created. After heating the combustion chamber to a temperature above 200°C, the gate valve is closed.

The characteristics and thermal efficiency of stoves declared by the manufacturer are only possible if the conditions for using firewood with a relative humidity of no higher than 20% are met.

Pros and cons of long-burning stoves

There are many advantages that economical wood stoves have:

- Maximum complete combustion of the solid fuel load. For this reason, boilers that burn wood for a long time have excellent efficiency, reaching 85%.

- These heating units are quite easy to clean and maintain, since after the wood has burned through, there is practically no ash left.

- Environmental friendliness of the pyrolysis process. With complete combustion of natural organic compounds, the only oxidation products are carbon dioxide and water vapor. In a pyrolysis furnace, solid fuel decomposes completely, so all kinds of industrial waste can be used as a source of thermal energy, which under normal conditions is allowed to be burned only at a considerable distance from residential buildings in specially equipped landfills.

- You will need to load the next portion of firewood or other solid fuel much less frequently, or rather once every 10 to 15 hours, which is an undeniable advantage of these units compared to conventional stoves and potbelly stoves. Some models of factory-made pyrolysis boilers are capable of operating for a longer period of time on one bed.

- Fast heating of the coolant, provided there is a heating heat exchange circuit for private houses.

- The ability to perform precise and high-quality adjustment of the unit’s power indicator. Under normal operating conditions, it is quite difficult to control the operation of heating devices using solid fuel compared to analogues that use gaseous or liquid fuel. Since in a long-burning wood-burning stove the gas released during the pyrolysis process is burned in a special compartment, this problem can be solved quite easily.

Pyrolysis plants have a number of disadvantages, including:

- High price for ready-made heating boilers. This negative point can be eliminated if you make economical wood-burning stoves with your own hands.

- Increased requirements for the moisture content of solid fuels. If you decide to use poorly dried firewood and try to put the unit into operation before it is completely dry, the fire will most likely go out and the full pyrolysis process will not be completed.

- Quite large dimensions. In addition to the fact that it is necessary to prepare a place for installing a pyrolysis boiler, it will be necessary to arrange the area where solid fuel will be stored.

- Inability to provide fully automatic operation. Firewood must be loaded into the unit manually.

- When installing an industrial model of a pyrolysis boiler, additional blowing of the combustion chamber is often provided and pumping equipment is installed to circulate the working medium in the heat supply circuit. Therefore, for the uninterrupted operation of the installation, it is necessary to ensure a high-quality power supply.

- There is a risk that the pyrolysis chamber may go out as a result of using too cool coolant coming from the heating circuit. To prevent such a nuisance, a bypass pipe called a bypass is installed in the device. Using it, hot water is added to the cooled working medium. As a result, the design of the heating boiler becomes more complicated and at the same time its price increases. But a self-assembled pyrolysis stove without connecting a heating system does not have this drawback.

Advantages and disadvantages

The devices have a whole list of advantages that are very valuable for products of this kind. Among them it is worth highlighting the main aspects:

- quite convenient installation that does not require specific skills and the construction of additional foundations;

- rapid removal of ash, which can be done even during combustion;

- The design of the heating stove by Professor Butakov “Student” provides for an organic combination with any interior.

- large heating area;

- presence of air cooling;

- sufficient dimensions of the heating surface;

- functional firebox, equipped with control of air supply, as well as combustion intensity;

- replaceable grates.

However, despite such a number of positive qualities, there are also some disadvantages. These include:

- strong surface heating;

- the need to wet the ash before removing it from the firebox;

- requires the use of enhanced thermal insulation for chimneys.

Nevertheless, the Student heating stove has many more advantages than disadvantages that do not affect the functionality of the device.

Characteristics

Considering that the Butakov “Student” furnace has various modifications, their sizes and technical characteristics differ significantly. What these devices have in common is the presence of built-in convective channels used to increase heat transfer. Depending on the type, stoves can work both to heat air and provide water heating.

In this mini-review we will look at stoves from.

Wood burning stove

This device is characterized by maximum thermal efficiency and high efficiency, in comparison with coal analogues. It has the following features:

- Tightness of the combustion chamber - the door closes securely, eliminating the formation of cracks.

- Improved control of air supply - the unique design of the gate valve allows you to set gas generation or simply combustion modes.

- High-quality materials - thick-walled structural steel was used to make the body, cast iron was used for the grates and doors.

In addition, the device is characterized by relatively small dimensions, which are:

- 530*780*370 mm;

- chimney pipe diameter 120 mm;

- weight of the entire oven is 77 kg;

- firebox volume 74 l;

- power reaches 9 kW;

- Efficiency is 85%.

The Student stove has an amazing ability to prevent soot from contaminating work surfaces. Even long-term use will not affect the cleanliness of the glass. The burning duration allows you to make bookmarks no more than once every 6-7 hours. The device is equipped with a replaceable grate, which allows air flows to be evenly distributed in the fuel chamber. This eliminates the formation of soot. The design of the ash box allows it to be cleaned without interrupting the combustion process.

Coal furnace

When designing these heating furnaces, the intensity of the thermal load was taken into account. The device has the following characteristics:

- weight – 77 kg;

- firebox volume – 70 l;

- dimensions – 530*370*780 mm;

- Efficiency – 85%;

- Power – 9 kW.

Burning coal requires more oxygen than wood, but produces significantly more heat. Thanks to the 5 mm wall thickness, metal deformation, which can cause rapid breakdown of the furnace, is eliminated. The tightness and thoughtfulness of the design can significantly reduce coal consumption. A similar stove by Professor Butakov “Student”, operating on coal, is an ideal option for systematic heating.

Hydraulic

Thanks to the unique design of the heat exchanger, the long-burning Student water-heating stove has a fairly high heat output. The usual coils in it were replaced with convective channels, partially recessed into the firebox. Thanks to these features, the liquid is intensely heated and enters the heating system. This large-sized device has the following characteristics:

- weight - 90 kg;

- power - 16 kW;

- firebox – 70 l;

- dimensions – 720*370*770 mm;

- Efficiency – 85%.

In addition, the design provides for the installation of heating elements, which allows you to maintain the temperature of the coolant for a long time.

Features of the “Student” furnace design Hydraulic

Attention! Electric heaters can be installed independently or purchased together with the boiler

Types of long-burning stoves

There are many varieties of such units:

- By purpose - heating, bath, universal, cooking.

- By type of fuel.

- According to the material of the body - steel, cast iron, brick, combined.

Among the most popular long-burning stoves are:

- Buleryan;

- Bubafonya;

- Potbelly stove;

- Stove hybrid;

- Furnace type heat generator.

Types of fuel used:

- coal;

- firewood;

- pellets/briquettes.

All about stove installation Engineer

To facilitate installation, each Termofor oven comes with detailed installation instructions. The company has thought out a convenient and simple design that facilitates installation work.

To begin installing the Engineer furnace with your own hands, you should begin by determining the location. It will not be unimportant to decide which chimney to use when connecting.

To heat adjacent rooms, a heat sink is installed on air heating furnaces for routing air ducts, and a heating system pipeline is connected to water heating models. After installation, the stove will be able to effectively heat the entire building, and not just the room in which it is installed.

Requirements for placement

The efficiency and uniformity of heating largely depend on the correct location of the stove. For normal operation, the Engineer stove needs a large volume of air and no obstacles in the way of convection currents.

An essential condition is compliance with fire safety rules. Some points that must be followed are contained in the instruction manual. In particular, it states:

- The stove is installed on a non-combustible base.

Protection is provided for walls and ceilings (where the chimney passes) when installed in a wooden house. The section of the wall adjacent to the stove is insulated with non-flammable insulation, and then covered with steel sheet or brick.

The surface of the chimney is heated to a temperature of over 200°C, which, according to the rules of PPB, requires the use of a special passage unit filled with mineral insulation when passing through floor slabs and roofing.

The special design and the use of a special base simplifies the installation of the Engineer furnace and makes it possible to do the connection yourself.

Which chimney is better

Solid fuel heating equipment belongs to the class of furnaces with high flue gas temperatures. During combustion, inside the combustion chamber, the heating intensity reaches 450-550°C. Although due to the use of gas generation, the smoke at the outlet cools significantly, the temperature still remains sufficient to lead to burnout and deformation of a conventional steel chimney.

Additional requirements apply to traction characteristics. Insufficient pressure leads to backdraft, air locks and other operational difficulties.

Reviews from owners and practice have shown that the optimal choice for convection and water heating stoves is a sandwich pipe and a ceramic chimney. An additional advantage of the systems is the simple installation of the chimney yourself. Sandwich pipes and ceramics are assembled like a construction kit and do not require special skills for installation.

On the Internet you can find negative reviews about the stoves of Professor Butakov Engineer, but they are rather the exception to the rule. Basically, owners point out the advantages of Termofor products:

- Affordable price.

Long service life.

A simple design that allows for independent installation of the stove in the house.

Thermal efficiency due to the ability to connect to a water heating system and air ducts.

All of the above factors ensure uninterrupted and comfortable operation of the Butakov stoves of the Engineer series and explain the popularity of the models among Russian consumers.

How to choose a wood stove for your home?

The range of wood-burning stoves impresses even experienced buyers, so the choice of equipment should be taken with full responsibility, paying special attention to a number of the most important technical parameters.

Keep in mind! When choosing a suitable device for your home or garden, you must consider:

- maximum power. The power of the unit should be sufficient to fully and quickly heat the building. The optimal indicator can be determined from the ratio of 1 kW per 10 sq.m. area +10-15% reserve. This is an ideal option for high-quality heating;

- heated volume. Some models of wood stoves are tied to a certain volume, while other devices allow you to vary the power by changing the intensity of combustion. In the second case, it is important that the calculated value for the heated room falls within the range of the heated volume;

- combustion chamber volume. A spacious firebox will be able to accommodate a fairly large amount of firewood, so the owner will not have to add it often. According to reviews, working with a device equipped with a small combustion chamber is less convenient;

- heat transfer method. Based on the method of heat transfer, wood-burning stoves are divided into convection stoves and models with a liquid heat exchanger. The best solution would be a unit with a water circuit, since it can heat a large room more efficiently and quickly;

- connection to the chimney. The device can be connected from behind or from above, but in some models this option is not available at all. Many users choose a universal option, in which the unit can be connected both from behind and from above, while the alternative connection will be plugged. Experts do not recommend purchasing equipment without connectivity;

- material. The structure can be made of cast iron, steel, ceramics or brick. If a buyer is looking for a compact device, a cast iron model would be a good solution. For quick heating, a steel unit is suitable, but if design is important, you should give preference to a ceramic stove. The most reliable and expensive option are brick devices;

- dimensions of the structure. When choosing a unit, it is important to remember that it should not take up too much space in the room. On average, devices are produced with a width of 51-105 cm, a length of 30-80 cm and a depth of 40-75 cm. But a wide range of models allows you to choose a device based on your own preferences.

Furnace installation

Before installation, you should prepare a place for the heating stove. This does not require the installation of an additional foundation.

The stove is installed on the floor, on a flat, insulated surface (metal sheets on asbestos cardboard can serve as such a surface).

The base of the Butakov stove design is equipped with holes for fixing, so it can be fixed to the floor.

Adjacent walls also need to be insulated to a level 25 cm above the top edge of the stove. Plaster on a metal mesh or asbestos cardboard with a metal sheet serves as thermal insulation.

The distance from the wall to the stove must be at least 38 cm.

A metal sheet must be laid in front of the oven door.

The hole for the chimney should be thermally insulated.

The Butakov heating stove is installed in a prepared place made of non-combustible materials (for example, on a brick stand).

The last step in the installation is connecting the chimney to the tee and the stove.

Important! All pipe joints should be treated with heat-resistant sealant. Important! The chimney pipe should protrude 50 cm above the roof ridge

In this case, the part of the chimney located in open space must be insulated with material that can withstand temperatures up to +400 °C

Important! The chimney pipe must protrude 50 cm above the roof ridge. In this case, the part of the chimney located in the open space must be insulated with material that can withstand temperatures up to +400 °C

Be sure to insulate the hole in the roof with special material.

The space around the structure can be equipped with any heat-resistant and non-flammable material.

Long-burning furnaces with a water circuit

Long-burning heating stoves with a water circuit will be the best heating option for a home if it is not possible to supply gas to it, and electric heating is too expensive.

Such heating devices not only allow you to increase the interval between fuel loads, but also make it possible to heat several rooms or the entire house at once.

Heating stoves with a water circuit are universal devices for heating rooms, combining the functions of a boiler and titanium. These stoves are the optimal choice for heating country houses and cottages.

In heating stoves with a water circuit, the heat exchanger is built into the chimney duct or firebox. Some types of furnaces operate in hot steam circulation mode, which is not available in a standard hot water circulation system.

This design is designed to solve problems with providing heat in houses that require autonomous heating. Due to the fact that water actively circulates in various heat exchange systems, for example, in radiators, several rooms can be heated at once.

As a result, the entire house is heated. In addition, using a stove with water heating allows you to significantly save on wood, and the room warms up very quickly.

It is worth remembering that if you do not heat this stove in severe frosts, then there is a high probability of the coolant freezing, and this can happen very quickly.

Therefore, if no one lives in a house with such a design on a permanent basis, experts advise adding special additives to distilled water. Thanks to them, the system will not freeze.

Such heating stoves may differ in the material they are made of. So they could be:

- metal - steel or cast iron;

- brick;

- combined - when a ready-made metal firebox with a heat exchanger for the water circuit is used as a basis, and the outer casing is made of brick.

Advantages and disadvantages of water-heated furnaces

Main advantages:

- Available fuel. If necessary, firewood can be collected on your country plot.

- Small sizes.

- Easy to operate and maintain.

- Firewood is considered an environmentally friendly raw material that is not capable of causing harm to the human body. When they are burned, a minimal amount of harmful substances is produced and released into the environment.

- Relative autonomy. In the absence of electricity, a water-heated structure will heat the room for a long time with its hot body.

- For the manufacture of wood-burning stoves, materials are used that are characterized by increased strength. This allows the structure to serve for a very long time, practically without undergoing repair.

- In addition, such a design for the home may have a hob on which it is easy to prepare any dish. It heats up from a direct burning flame.

Disadvantages of water-heated stoves:

- Low efficiency. This design will be inferior in efficiency to diesel and gas boilers.

- Manual control. There is no automatic adjustment of the fuel supply and maintenance of normal control of its operation.

When purchasing a stove with a water circuit, you need to pay attention to the power of the stove and the number of additional kilowatts from the heat exchanger. For example, for 25 cu. m. of room requires a 1 kW oven.

Analogues of furnaces with a water circuit

Solid fuel boilers with a water circuit - the use of a combined or solid fuel boiler makes it possible to heat a room with an area of up to 170 square meters. m. The boiler runs on wood or electricity. Made from strong steel. Equipped with a built-in electrical unit.

Fireplaces with water circuit and stove/oven. Solid fuel thermofireplaces can be connected to solar collectors and other heating systems. A device that combines the qualities of a traditional fireplace and the functional properties of a solid fuel boiler. Designed for heating water using circulation pumps in all types of heating systems.

Advantages and disadvantages of the design

The undeniable advantages of this heating device include:

- No negative impact on the environment and humans. The design feature of the fuel chamber creates conditions for complete burnout of the fuel used. Therefore, no harmful substances or combustion waste are observed.

- Any detail of the design of such a furnace is endowed with high functionality and helps to increase efficiency.

- High fire safety is based on two circumstances - the absence of an open flame and smoldering fuel (incomplete combustion).

- High-quality materials used to make the body of the heating device and the hermetic design of the firebox ensure excellent reliability.

- One portion of fuel provides a long operating cycle - from 8 to 12 hours.

- These heaters take up little space in the room due to their optimal dimensions.

- The extended service life, combined with an affordable price, is a good recommendation for purchasing and using the stove.

You may find this article about long-burning heating stoves useful.

Read an article on how to assemble a pyrolysis oven with your own hands here.

Butakov’s brainchild, the “Professor” stove, has certain disadvantages that do not have a significant effect on the process of heating the room:

- There is a risk of burns from the extremely hot housing.

- Increased dehumidification of the air space during the heating process requires artificial, forced humidification of the air in the room.

- Short-term cooling of the combustion chamber leads to a rapid decrease in the temperature in the room.

The decision made to heat your own home or industrial premises with the Professor heating device will not allow you to experience disappointment when choosing this model. And the stove’s undemanding nature of fuel types will allow you not to bother with just one type of fuel.

Watch the video in which the user shares his impressions of the operation of the furnace Professor Butakov Associate Professor:

Design Feature

But not only high performance is the advantage of this design.

The whole point of long-term burning is that not the entire stack of firewood burns out at the same time, as happens in a classic stove, but only the top layer.

Principle of operation

This becomes possible due to air intake from above, and not from below through the ash pan. Thus, fuel combustion occurs gradually, in its upper layer. When this layer burns out, a new portion of oxygen is supplied through the regulator, and exactly as much as is needed for the combustion of the top layer. This ensures such a burning duration and the ability to control the process.

The main point in a fireplace stove is maintaining long-term combustion, during which the fuel elements completely disintegrate. As a result of this process, large volumes of hot gases are formed and a large amount of heat is steadily released.

The implementation of secondary afterburning occurs in the second chamber (upper).

In the fuel chamber, where the firewood is placed, the primary combustion of the fuel occurs. Hot smoke rises up the pipe and burns out completely. To stimulate the secondary combustion of wood, the design provides for the presence of pipes through which oxygen flows.

Today, two long-term combustion systems implemented in such devices have become widespread. These are the Canadian system Buleryan and the Baltic Stropuva. At the same time, the Burelyan system is very popular in our country due to its small dimensions and low price. But the Stropuva system is less common due to its high price and large number of technical parameters.

Traditionally, the Burelyan system (this is the technology that will be used in the long-burning stove-fireplace we are describing) is a small stove consisting of two chambers.

The main combustion of wood occurs in the lower chamber, resulting in the formation of wood gas. When heated, it rises and enters the second chamber, which is located above the first.

Scheme of a stove with a long-burning hob

Here, diffusion of hot gas with air and secondary combustion occur.

Another difference from a traditional fireplace stove is the location of the firebox door. If it is usually attached from below, then here the design will be slightly different.

The burning time itself suggests that the process will require a large amount of firewood, which must be located somewhere.

It is for this purpose that the lower chamber (or firebox) should be large, and the door through which firewood is placed should be located high enough.

Features of a long-burning stove

In a fireplace stove, the ash pan plays a purely technical role and is intended to clean the stove from residual ash, of which very little remains after double combustion of the fuel. Considering the fact that air enters through a special hole located in the upper part of the furnace, the ash pan door must be absolutely sealed.

Otherwise, there will be no question of any long-term combustion if oxygen comes from below the stove.

So, summarizing the design features of a long-burning fireplace stove, we can highlight the following points:

- large volume of combustion (loading) chamber;

- dividing the main firebox into two parts: upper and lower chambers;

- lack of blower;

- adjustable oxygen supply from above.

The higher the humidity of the wood, the lower the efficiency of the stove will be. Therefore, for combustion it is recommended to use fuel with a moisture content of no more than 20%.

Device

Design of the "Engineer" furnace. (Click to enlarge)

In terms of design and principle of operation, the “Engineer” is practically no different from other models of heating stoves “PROFESSOR BUTAKOV”.

The body of the furnace-boiler is an all-welded structure of an original shape (truncated parallelepiped), made of steel and coated with black anthracite-colored silicone paint.

Inside the housing, in the front and rear parts, there are built-in convection pipes, through the lower part of which cold air is drawn in, passing along the housing, heated, rises, exits through the upper part of the pipe and is distributed throughout the room through special openings-air ducts.

The presence of a large replaceable grate ensures uniformity and duration of combustion of the firebox over its entire area. The bottom of the firebox is protected from burnout by a heat-resistant grate. As a result, all surfaces of the stove participate in heating the room.

The door rotates on hinges 120 degrees, has a special seal and a reliable locking mechanism.

These stoves use solid fuel as fuel - pressed cardboard, firewood, wood waste, peat, brown coal. At the bottom of the furnace there is a capacious box for ash, which is poured into it through the slits of the grate, and which can be emptied of ash without interrupting the operation of the furnace.

The base of the boiler has mounting holes for fixing the stove to the floor.

At the same time, the Engineer stove has a number of distinctive (besides the above) features and characteristics:

- she weighs 100 kg;

- its dimensions are 440×645×800 mm;

- firebox volume -120 liters;

- chimney pipe diameter is 120 mm;

- efficiency factor (efficiency) - about 85% (increased heat transfer is achieved through the use, like the Student furnace, of pipes with a large diameter and thinner walls.)

In addition, the Engineer series has 2 modifications:

- with steel door;

- with a cast iron door with heat-resistant glass.

Accordingly, prices for each model also differ: in different stores they vary between 14,000-16,000 rubles. and 18,000-20,000 rubles.

Criteria for selecting long-burning stoves

When choosing a long-burning stove, you should give preference only to trusted manufacturers from various European brands, since their products are always marked with quality and safety certificates.

It is worth noting that today there are a large number of different types and styles that are expanded with additional functions, have special cladding and are installed in different ways. There are various options that are equipped with fans, an oven, compartments for solid fuel, etc.

The main criterion when choosing a heating device with a long combustion cycle using solid (wood) fuel is its power.

It must correspond to the volume of the heated room. There is no point in installing a high-power stove in a small room, since part of the heating material will burn irrationally. In addition, a large device will take up a lot of space, and the room temperature will be too high.

On the contrary, a low-power stove in large rooms will work at the limit of its capabilities, which will quickly cause it to fail.

When choosing, you should decide on the type of fuel that is supposed to be used - firewood, pellets, coal, fuel briquettes, etc.

You should know that the moisture content of wood fuel is of great importance, since water vapor diluting the gases interferes with combustion, reduces the power of the device and promotes the formation of condensation.

In some cases, excessive moisture in the burned material can lead to spontaneous extinguishing of the furnace. Firewood for long-burning fireboxes, for example, should have a moisture content no higher than 20-35%.

The metal or alloy from which the long-burning furnace is made is also an important selection criteria. The thicker the material of the device body, the slower the device cools and the longer its service life.

Some models of long-burning stoves made of cast iron last up to 50 years and, moreover, are not subject to corrosion.

Elements of many modern stoves - firebox, hob, trim, door - are made from different materials (cast iron, vermiculite, steel, stainless steel, heat-resistant glass, etc.), which allows to increase service life, improve design, improve ease of use and long lasting time to maintain appearance.

The appearance of the heating device often plays no less important role than other factors. A stove for a living space should have a modern design and fit harmoniously into the interior.

There are many imported models on the market, from which you can choose a ready-made stove for any home.

All long-burning stoves are supplied with instructions, but they often do not mention some nuances that must be taken into account:

- It is necessary to provide free space around the stove and protection from fire;

- for easy maintenance (cleaning), the chimney should have a collapsible design if possible;

- pipes must be installed in the direction of gas movement;

- due to low draft, the chimney should not have a curved shape;

- During operation, condensation may form in the chimney.

It should also be noted that liquid fuel cannot be used in long-burning stoves; some models are quite difficult to set up and require constant supervision.

Preparing pipes and parts

The oven has an outlet of 14 convection pipes. The diameter of the chimney outlet is 200 mm; we purchase it ready-made from a corrugated ventilation pipe.

For manufacturing we will need to prepare several parts. From 4 mm sheet steel we cut out:

- 2 side parts measuring 800/950 mm. The second dimension is the height of the structure;

- For the front and rear walls, we use a grinder to cut out parts 1110/670 mm. After final assembly, the protruding metal will be cut off and can be used as reinforcement for the base;

- for the top we cut out a piece measuring 350/950 mm. It is necessary to mark 6 holes of three pieces on the narrow sides and drill or cut them by welding. Pipes with a diameter of 40 mm will come out of them;

- for 2 side jibs, cut the workpiece to a size of 200/950 mm;

- for the base you can use a corner with a 100 mm shelf or a channel. 2 pieces 950 mm and 2 lintels 470 mm each. It is necessary to make holes in the base for the pipes, which must be coaxial with the top ones;

- For convection pipes we use steel parts with a cross section of 40 mm. 6 of them are straight, they run along the front and back walls. There are 4 holes on the jibs. 8 pipes will need to be bent to a certain angle. It is better to do this on a pipe bender.

You will also need to leave a sheet for making a door and an ash drawer. To make a grate, you can use a sheet 10 mm thick, making longitudinal grooves in it with a grinder. You can weld a grid from reinforcement or a rod with a diameter of 8-10 mm.

To install the grate, we will prepare several pieces of corner. It is better not to secure the grate tightly; this will make it easier to replace and maintain the stove. A hole is marked on the top part and made for connection to the outlet pipe. You will need to prepare a section with a cross-section of 180-190 mm and a length of 170 mm.

User manual

Some consumers complain about the rapid combustion of solid fuel in the stove. But experts insist that they install and operate the unit incorrectly. The fuel must not only be placed correctly, but also ignited correctly.

Stack firewood correctly

In order for it to smolder as long as possible, you first need to set fire to a small amount of wood and obtain coals. Then add solid fuel, after which it will smolder for 8-10 hours and give off a large amount of heat.

Basic recommendations:

- Before putting the boiler into operation, it needs to be tested. This will help determine the optimal method for operating the structure.

- To prevent objects from igniting from the hot stove body, it is installed at a distance of at least 40 cm from them.

- During boiler operation, slag appears on the damper and inside the chimney. To get rid of it you need to use special cleaning agents “Miracle Log” or “Umbrella Pipe”, which increase the movement of the air mass in the chimney.

- It is not recommended to use fuel from coniferous trees, as it emits an unpleasant odor or smoke, while fuel from deciduous trees (birch, aspen, etc.) fill the room with pleasant and environmentally friendly warm air.

- The chimney must be open. Fuel can be placed horizontally or vertically in the firebox.

Design and principle of operation

Professor Butakov’s “Associate Professor” stove has a simple but original design, consisting of:

- all-welded 2-chamber body;

- straight and curved convective pipes built into it;

- gas guide screen;

- jets for dosing the intake of secondary air;

- firebox;

- grate;

- ash pan, where there is a special container for collecting ash;

- metal door of the combustion chamber or combined with heat-resistant glass;

- gate welded to the body;

- chimney.

The operation of the furnace is carried out with the simultaneous flow of pyrolysis and convection processes:

- The pyrolysis process is carried out directly in the combustion chamber in smoldering fuel mode. The gas released when wood burns enters the second chamber, where it mixes with oxygen and burns completely;

- the convection process occurs in special air ducts that pass through the firebox and have ends protruding outward. Cold air enters them from below the structure. Then it passes under the influence of natural draft through the combustion chamber and comes out to the top in a heated state.

The firebox door also has a special design. There is a convection chamber inside it, which also participates in heating the room.

Principle of operation

Main processes:

- Pyrolysis. This function is performed directly behind the flow door inside the firebox.

- Convection. It occurs inside the pipes installed in the structure, generating hot air. Moving along the pipes, he enters the room.

The principle of operation of the furnace is that the fuel in the combustion chamber smolders and does not burn. This happens because the oxygen content in the chamber is low. It allows you to avoid adding a second batch of solid fuel for a long period of time from 8 to 12 hours. Smoldering fuel produces the same amount of heat as during normal combustion. This is the main effect of the Engineer boiler.

What to make it from?

Several variants of furnace designs have been developed. This can be a simple barrel in which firewood is placed on top and the air flow is blocked by a gate valve. It will take more time to produce an analogue of industrial samples with a system of convection pipes and a separate gas combustion chamber.

The simplest and most uncomplicated scheme is a Butakov stove made from a gas cylinder. In this option, you can do without convection pipes or use 2-3 convection inserts.

We will examine in more detail the production of an analogue of an industrial design with a rectangular shape and a complete circuit of convection tubes and a system for long-term pyrolysis burning of wood. This design is the most productive and economical.

But during the manufacturing process it will be necessary to perform turning and drilling work. You can take the dimensions and bend angle from industrial sample pipes. The amount of material required for work depends on the chosen option and the dimensions of the furnace.