Even in a house with gas heating, owners often design and install stoves, fireplace stoves, and fireplaces. The reasons for this are home comfort and hearth, color and tradition, open fire, design and decor... And backup heating in case of any outages will not hurt. One of the most popular heating devices in this case is a stove with a stove bench.

Not everyone knows what opportunities there are today for laying stoves with a stove bench. Even fewer stove makers directly admit the shortcomings of classic and modern stoves with stove benches... We are, of course, not talking about a Russian stove with a stove bench. That would be a completely different, separate topic.

But nothing compares to the warmth, comfort and chic of a bed covered with a blanket and pillows. She instantly gathers guests and children around her! But let's talk about everything in order...

Would Emelya take a ride on a modern stove with a stove bench?

I think that Emelya would not ride on modern stoves with a stove bench. The stoves are not right, the stove is low, it gets too hot - you can get burned, and it doesn’t work very well, it’s standing on a foundation. This is not a Russian stove with a stove bench...

Let's dot the T's right away. A modern stove with a stove bench and a Russian stove with a stove bench are different stoves.

Pragmatically choosing a good heating device for their home - a brick stove, many immediately dismiss the Russian classics with a stove bench. And in many ways they are right:

- Low efficiency compared to modern furnaces - once;

- A bulky design that will not fit into any interior - two;

- The high cost of masonry - three and much more.

But some stove makers now know how to make a Russian stove with a stove bench of a more efficient design. Namely, this is a Russian stove with a stove bench - with bottom heating. No flooding, no slab. But read about this in my other articles.

Safety precautions

To cook in a Russian oven and not start a fire or get burned, it is enough to know how to properly heat the oven and follow the rules for cooking in an oven.

How to light a Russian stove:

- It is necessary to stack the firewood in the firebox as closely as possible to each other; add firewood after the first batch has burned out.

- During kindling, the damper must be closed, the stove damper slightly open, and the ventilation damper closed.

- Do not forget to provide access to oxygen in the stove - to do this, just stir the firewood with a poker.

- During combustion, the ash door should be open approximately 7 cm.

How to cook in a Russian oven:

The stove must be heated well and the wood must be allowed to burn out; only coals without open fire and well-heated walls should remain. The first courses are prepared in cast iron pots or ceramic pots without handles. Since the food in the oven simmers and does not boil, pour a little water into the container, no more than one quarter. All dishes except bread can be cooked together

The bread is cooked separately with the door closed until baked. When cooking in the oven, it is important to use oven mitts, towels or gloves to avoid burning your hands. It is better to place and remove dishes with a special wooden shovel or grip.

Modern stoves with a stove bench - what are they?

A modern stove with a stove bench, of course, is very different from the classics and has many advantages. The simplest stove with a stove bench today is a heating stove. But most often they make so-called “Russian heated cars” with a couch. Such ovens are equipped with a hob and a bread chamber (with a door).

The main difference between a modern oven and a classic oven is that it has a baking space with a door and is heated from the main firebox - you don’t need to heat the oven separately to cook - and there is no ash left in it. But this is not the most important thing. It is important that a properly folded stove with a stove bench heats up evenly and quickly enough.

Another feature of modern stoves with a stove bench is its height - it is made low, about 8-12 bricks, on average 11. The height of a brick row with a stove seam is 69-71 mm. The result is about 80 cm tall.

It should be noted that any stove with a stove bench will be more heat-intensive, if only because it contains approximately more bricks per pallet - that’s how many bricks are needed to lay a good - not small - stove bench. Although you can make a warm “chair”.

It is very convenient to heat the stove, oven and bed from one place - from the firebox. This is both economical in terms of wood consumption and time. But there are models with a separate firebox for the bed.

The design of modern stoves with a stove bench is usually laconic; “stoves” have disappeared - this is required by the design of the stove for maximum reliability and heating efficiency. And there is nowhere to “insert” them into such a low bed. There is no woodshed under the grain place, for obvious reasons. And in general, the modern design of stoves, especially double-bell stoves, allows you to save space. And when the oven is small, it’s difficult to come up with any kind of “architecture”. Moreover, all this can worsen its design reliability qualities.

Modern stoves with a hob often have a summer valve, and stoves with a stove bench also have a heating control valve. But does this valve always work and can it help us with the main problems of such furnaces?

Preparation of the solution

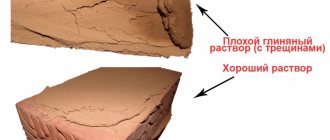

For masonry, a normal type of clay mortar is required, which has good ductility and does not crack. A thin solution is not suitable, as it crumbles a lot, while a fat solution cracks when it dries.

The composition of the masonry clay mortar will be as follows:

- fatty clay, very carefully sifted - 3 parts;

- river sand, also sifted, pre-calcined, - 3-5 parts;

- clean water for mixing - 1 part.

After mixing, you need to get a thick, viscous, greasy solution, but it should not be soft and flowing.

Various methods are used for preparation, the most optimal is soaking the clay and then adding water. When calculating the volume of mortar, it must be taken into account that when laying 50 bricks with a joint thickness of no more than 3-5 mm, approximately 20 liters of mortar are used, but experts recommend increasing this amount by 15%. The proportions of the clay mixture are 1 part sand to 2 parts clay.

When, when kneading, the consistency of the solution becomes similar to sour cream, it can be used for work. If traces of water appear on the surface of the mixture, a small amount of sand must be added. To increase strength, you can use regular salt at the rate of 100-250 grams of salt per bucket of the mixture. When laying a chimney, cement must be added to the solution at the rate of 750 grams per bucket of mixture.

No matter how bad the stove is, it is better with a stove bench.

Firstly, the list of disadvantages of a stove with a stove bench is by no means exhaustive.

Secondly, it, of course, can be taken into account and corrected. You need to keep all this in mind... or give up on it. After all, nothing compares to the warmth and comfort of a bed covered with a blanket and pillows.

The bed is like a magnet that brings together family and guests. It is better to provide a couple more armchairs and a coffee table next to it - mainly for tea. Or fit it into the interior in some other way - as one of the main gathering places, in addition to the places in front of the firebox with a glass door or fireplace. It is from such little things that the life and happiness of a family and children are built. Cozy moments with loved ones can be remembered for years, as often happens. They cannot be overestimated.

Cracks in the oven are generally difficult to completely remove; they appear like “hairs” when heated and disappear when cooled. Some stove makers fundamentally make only double-wall stoves - such stoves have completely fireclay interiors. Fully. Also, the stove bench is not connected to the main stove - only the fireclay core inside is single.

There are many advantages to such ovens, which can be discussed in another article. But, in my opinion, there are two main disadvantages:

- Labor-intensive and expensive masonry;

- They take a long time to get into “regime” - warming up.

I myself live in a house with a complex “Russian heater” - a stove with a stove and an oven. In addition, I made it a combination - with a couch and with a fireplace. I, like no one else, know all its disadvantages and would not trade either the bed or the fireplace for any other stove. Although I would be happy to correct some errors. And I do this, but not for myself, but for my readers and stove customers.

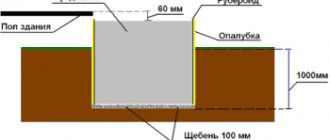

We make the foundation

Before you start building a heavy structure, you need to pour its foundation. But if you make a stove in an already finished house, then you will create the foundation for it right there. It is important to ensure that the base of the house does not come into contact with the stove. The depth of its foundation depends on how large the stove is: the larger the structure, the deeper the foundation needs to be made.

Foundation

Creating a pillow

Before pouring the foundation, it is important to carry out preparatory work. First of all, you need to put markings. Afterwards, you can proceed to digging a pit of the required depth. When you have thoroughly compacted its bottom, add slightly damp sand there and compact it again. The thickness of the compacted sand ball should be 10-20 centimeters. Now fill everything with crushed stone to a height of 15 centimeters. It also needs to be compacted.

We create formwork

Before pouring the solution, you need to build and install the formwork. Any wooden slats are suitable for creating side walls. If there are any gaps, cover them with plastic and secure them with a stapler. The formwork must be higher than the soil and reach the foundation. It can be done right along the edge of the pit.

Fill the solution

When the formwork is installed, fill the foundation with mortar. For it you will need coarse gravel, cement and sand.

Coarse gravel

The minimum fill height is 15 centimeters. When the first layer has been poured, place reinforcing bars vertically in it - this will connect this layer to the concrete mixture.

Fill in the lightweight solution

Fill the reinforcement sheets with lighter concrete, the layer of which should reach the ground. When everything is done, level this mixture and wait until it hardens a little. After this, cover it with steel reinforcing mesh and fill it with concrete to the thickness of the formwork. Level the poured screed and leave to dry for 27-30 days.

Creating a waterproofing surface

When the screed has dried, remove the formwork. Cover the base with a layer of waterproofing made from glued roofing felt balls. When everything is ready, start laying the stove walls.

Can you lay out the stove and stove bench yourself or do you need to contact a specialist?

You can lay out the stove with a stove bench yourself, just like any other stove. Of course, without knowledge, procedures or design, experience in construction (preferably masonry), it will be difficult to adapt to this business.

You can also contact a stove maker. But stove makers are different. There are such stove makers that it would be better for you to take on the masonry yourself, especially if you are concerned about the issue of saving money. Then the option of self-masonry is even more relevant. But it’s still better to turn to specialists - at least for advice. And we will always be happy to help you!

Leave comments on the article, rate it 5 stars and share with friends on social networks if the article was useful to you.

Continuing traditions

A traditional stove with a brick stove bench is a complex heating device with an element for relaxation or household use - a deck chair.

This modern stove will add variety to your interior.

Benefits of the bed:

- Rest and keep warm . After walking in the cold air in winter, such a warm “bed” will delicately restore body temperature, eliminate chills, and prevent colds.

- Health . The heat emanating from the bricks relaxes muscles, has a beneficial effect on the musculoskeletal system, and calms the nervous system. The relaxing effect cannot be overestimated. Our ancestors also used a hearth with a bed for healing purposes. All known diseases were treated with it - from colds to radiculitis.

- Drying berries, herbs, mushrooms . The lounger provides a slow release of heat, due to which the supplies lose moisture gradually, maintaining maximum useful properties.

- Increased efficiency . An additional structural element in the form of a lounger is heated by the stove and slowly releases additional heat to the room.

How to choose the location of the furnace?

It is very important to decide on the choice of place where the Russian stove will be installed. If its location is in a wooden room, be sure to make the distance between the walls of the stove and the house approximately 20 cm

It is best to protect wooden walls for safety using non-combustible material, such as asbestos boards. The created gap will allow for an inspection of the furnace walls, which is done before the onset of the heating season.

If the stove is installed in an opening between two rooms, then it is lined with brickwork, at least 20 cm thick. A gasket of asbestos sheet is made between the masonry and the wooden wall.

https://youtube.com/watch?v=ksIJIivKRlw

Nuances of the stove design

It is advisable to make the outer part of the chimney from sand-lime brick. It is more resistant to moisture and temperature fluctuations. After laying the chimney, fittings that have not yet been installed (cast iron hob, etc.) are installed.

If the goal is simple brickwork, then you can get by with simple cleaning and alignment of the seams. If your plans include decorating a wood-burning stove, you don’t need to pay attention to the joints. Typically, such structures are decorated with heat-resistant ceramic tiles. For example, tiles or clinker.

The first option is preferable from the point of view of heat transfer. The tiles are characterized by a box-shaped back shape, which increases the thermal efficiency of the coating.

Figure 7. Stove lined with tiles

For those who do not want to deal with tiles, but want to somehow decorate the structure, we can recommend painting the stove with heat-resistant paint. You can decorate in a traditional Russian ornamental style.

List of tools

To make work easier when laying a Russian stove with your own hands, you need to prepare working and measuring tools in advance. The working tool set should consist of:

- bayonet shovel;

- containers for preparing masonry mixture. It should be wide enough and have low sides;

- a shovel and two metal sieves with mesh sizes of 2x2 and 1x1 mm. This tool is used to sow clay and sand;

- trowel - a special trowel, which is used to take the mortar and distribute it among the masonry elements, and also remove excess mixture that protrudes beyond the seam;

- hammer - pickaxe. They can be used to divide a whole brick into several parts and trim the resulting surfaces;

- jointing, which helps to seal masonry joints and give them the desired shape;

- scraping - a rubber plate with a handle. It cleans the internal surfaces of the masonry from excess mixture and seals the seams in hard-to-reach places;

- saws - grinders. It can be cut more accurately and bricks can be adjusted for laying curved structural elements;

- rules - for leveling the upper plane of the foundation.

Control of vertical and horizontal masonry joints and geometric parameters of the entire furnace structure is carried out using:

- bubble level;

- plumb line;

- square;

- roulettes.

Final works

You have built an excellent and multifunctional fireplace for your home with a stove bench on your own. Not only is it pleasant to admire, but the fireplace can heat a room and retain heat for a long time even after the combustion process has ended. The credit for this goes entirely to the material. Brick has a high heat capacity and is able to accumulate heat.

The very presence of a stove in the house requires the design of the room to be designed accordingly. A brick stove without finishing looks good against the background of wooden or wood-trimmed structures. In this case, it is necessary to comply with all fire safety rules. When lifting the chimney through the ceiling, you will have to install a heat-protective belt. This will save not only from a possible fire, but also from deformation of the ceiling material.

Modern styles of room decoration will require the same from the fireplace. Here you can use different materials to suit the owner’s taste. The exception is those that are unstable to elevated temperatures. But if one of the main functions of the stove is heating, which is most likely, then it is better not to cover the brick, but to give it the opportunity to fully transfer heat to the room.

Step-by-step description of DIY construction

Building a structure with a hob and a stove bench is quite a difficult task for an inexperienced craftsman, so it is advisable to first consult with a specialist. It is not recommended to change the selected project without permission - careful adherence to the construction plan will help avoid serious mistakes.

Selecting a project, ordering

The choice of design scheme largely depends on existing conditions. When deciding to build a stove with a stove bench in a small room, the dimensions of the furnace and the device itself are calculated so that there is no overheating during operation . If the stove is installed in a large house, it is advisable to build a heating panel and place the structure itself closer to the center of the building. The best option would be to install the stove in the middle of a large combined area , where the kitchen and living room are located simultaneously.

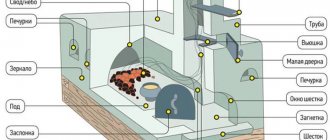

Photo 4. Arrangement of a Russian stove with a stove bench and stove. In total it contains 27 rows.

Materials

To carry out construction with your own hands, you will need the following materials and elements:

- Fire-resistant hardened brick - mainly used for laying out the furnace and chimney channels; most often bricks are made from fireclay clay.

- Ceramic brick - used for laying the external walls of the furnace, as well as elements that are not exposed to heat.

- High-fat clay and fine sand are the components for preparing masonry mortar. In construction stores you can buy ready-made fire-resistant mixture.

- Doors, latches, grilles, hinges for them - metal elements are sold in specialized stores.

- A hob with removable circles - purchased or cast to order according to the required size.

Before starting work on the project scheme, that will be needed is carefully calculated Due to the fact that the device requires uniform drying, it is better to carry out the laying in a short time ( 1-2 days ) without interruption by unforeseen circumstances, such as the purchase of missing materials.

Preparing tools

To perform brickwork, expensive tools are not required; the following set is usually used:

- shovel and container for preparing the solution;

- furnace hammer;

- hammer-pick for splitting bricks;

- hacksaw blade;

- Bulgarian;

- trowel for applying mortar;

- rule for leveling the mixture;

- plumb lines, cords, building level.

For the work to be effective, it is also recommended to prepare all tools in advance.

Selecting a location

The main feature of any brick oven is its large size and significant weight. Therefore, before construction, it is necessary to lay a separate foundation. It is best to place the stove in the center of the room to ensure even heat distribution. If this is not possible, the device is placed in such a way that there is a space of at least 30-40 cm to the nearest walls and partitions.

Be sure to take into account the location of the ceilings and the roof ridge , which is an important point for the correct installation of the chimney. The site for the structure is prepared by covering the walls and ceiling with non-combustible material.

To lay out the foundation, a pit is dug at least half a meter (depending on the density of the soil; the smaller it is, the deeper the hole is made).

Drainage is laid at the bottom of the pit - first sand ( about 15 cm ), which is filled with water and compacted, then a layer of material of a larger fraction - broken brick or crushed stone will do.

Formwork made of boards or reinforcement is installed on the drainage, which is then filled with concrete mixture. The foundation is given several days to dry , after which it is covered with waterproofing (roofing felt).

Masonry

Before starting work, the brick is soaked for several hours - this ensures better adhesion to the mortar and uniform drying of the entire structure.

Next, perform the following steps:

- The bottom of the oven is laid out - the bricks are laid on the waterproofing of the foundation without mortar, the ordering scheme is carefully followed.

- Lay out the rows of the oven - this part will not be heated, so ceramic bricks are used.

- It is laid out under the furnace, the mouth, and the doors of the combustion chamber are installed.

- The hob is installed

- A bed is laid out over the crucible.

- A chimney is installed , and if necessary, a heating shield is laid out.

at least a month to dry After the first two weeks of drying, gradual heating begins. Start with a small amount of fuel, gradually increasing it to the full volume. After a month, the oven is ready for use.

Possible difficulties

When building it yourself and lacking experience, it’s easy to make some mistakes:

- Use of low-quality materials - cheap bricks often have defects or crack when heated to high temperatures.

- If you do not soak the brick before construction , it will draw moisture from the mortar, which will lead to uneven drying and deterioration of the strength and tightness of the masonry.

- The seams between the bricks are filled unevenly and not tightly enough - this later leads to a violation of the seal.

To avoid these and other mistakes, before starting work, it is better to seek advice from an experienced specialist.

Swede with a trestle bed - an option for a small house

The Shvedka heating and cooking stove is popular among fans of stove heating due to its compactness and ease of installation. Modern craftsmen have supplemented the favorite model of country residents with a comfortable couch. This functional design is recommended to be installed between the kitchen-dining room and the bedroom. It easily copes with heating a room of 25 square meters.

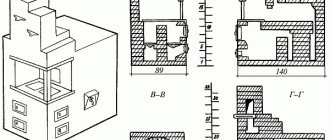

In summer mode, during heating of the stove, both smoke valves are opened, and in winter the second one is closed (marked in diagram “2”), due to which hot gases rush through a long chimney, heating the base of the hearth and the resting place. Base size: 114.8*76.5 cm, trestle bed dimensions: 178.5*63.8 cm. A stove maker with basic skills in laying stove equipment can build this stove-bed with his own hands, using the procedure given below.

To build this structure, 900 pieces of red brick and 200 pieces of fireclay are required. You will also need doors (blower, combustion, cleaning), grate, hob, steel corner.

Explanations for the diagram:

- 1 - main smoke valve,

- 2 - valve for summer use,

- 3 — ceiling fireproof cutting,

- 4 - cast iron hob,

- 5 - grate,

- 6 - combustion door,

- 7 - blower door,

- 8 - cleaning doors,

- 9 - steel corners and strips,

- 10 - niche for cooking,

- 11 - stoves,

- 12 - blind chamber,

- 13 — caps,

- 14 - horizontal chimneys for winter,

- 15 - vertical chimneys of the cooking mode,

- 16 - ventilation hole,

- 17 - entrance of heated gases into vertical chimneys for winter mode,

- 18 - gas inlet into the chimney,

- 19 — inlet,

- 20 - bypass,

- 21 - temperature gaps.

Technology for building a Swedish brick oven

Laying a Swedish stove with your own hands has a number of features that must certainly be taken into account in the work. It is immediately necessary to mention the need not only for waterproofing, but also for thermal insulation of its foundation, otherwise during operation the stove will heat the floor.

Balsat cardboard can be used here, and when laying it in three layers, the foil sheet should be in the middle.

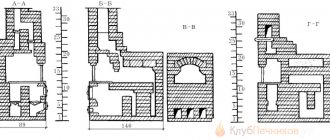

Another diagram of the furnace masonry

We will not dwell on this option in detail. From the previous diagram it is easy to understand what each element in the illustration represents.

Figure 5. Layout diagram of another furnace option

This model is one of the simplest. However, it is effective and efficient. Unlike more complex structures, the execution of this one can also be entrusted to even a relatively unprepared homeowner.

Figure 6. Alternative design with a bed