One of the cheapest types of fuel used to operate heating boilers is waste oil. It can be anything: synthetic or natural. Oil drained from cooking units, cars or diesel locomotives is suitable.

In any case, when burned, it will produce a large amount of heat. Therefore, assembling a waste oil boiler with your own hands is very profitable. Especially if you need to heat a utility room or garage.

We will tell you how the heating device is designed and works, what are the design nuances of a home-made unit, and also describe the step-by-step process of assembling the boiler and the features of its operation.

Exhaust boiler: what are they?

Manufacturers produce three types of liquid fuel heating boilers. Air heaters increase the temperature in a room by directly heating the air. Such devices are characterized by high performance and are able to maintain temperature for a long time even in large rooms.

The fuel tank for such devices is usually located on the floor, and the air heater itself can be mounted on the ceiling or wall.

A heating device during testing can warm up the air in the room or heat up the water circuit, and sometimes both at once

Boilers are designed to heat a coolant, usually water.

There are two types of equipment:

- double-circuit - capable of heating water for domestic needs and heating the coolant;

- single-circuit - “responsible” only for heating.

Automatic heat generators are classified as hot water boilers. They are equipped with an automation system that controls the operation of the device.

Automation for boilers during testing can perform different functions. This can be control over the air temperature in a heated room, control of heating of the coolant, etc.

Boilers for testing with or without automation are made exclusively in the floor-standing version. Their cost varies significantly depending on the functionality. However, in any case, it is quite large, so home craftsmen assemble such devices with their own hands.

Waste oil heating for a private home

Waste heating oil was initially used together with diesel fuel. This method has proven its effectiveness and cost-effectiveness. Then they decided to reduce the cost of the product even more and removed diesel fuel from the composition. Used oil resembles diesel fuel in its characteristics, but is much cheaper.

Photo 1. This is what used oil looks like, which is used for heating. The liquid is dark brown in color.

Features of use

The waste is used as fuel in a special boiler or furnace. Only this guarantees complete combustion of the product without the formation of fumes. Re-equipment of the heating system or installation of a new circuit pays for itself in the first year of use of the product.

Types of fuel. How much heat is produced by burning one liter?

Burning one liter of such fuel produces 10-11 kW of heat per 60 minutes. The pre-treated product has more power. Its combustion produces 25% more heat.

Types of used oils:

- motor oils and lubricants used in various types of transport;

- industrial products.

Advantages and disadvantages

Pros of fuel:

- Economic benefit. Consumers save money on fuel, but businesses benefit the most. The implementation of processing eliminates the costs of storage, transportation and disposal of the product.

- Conservation of energy resources. Refusal to use gas and electricity for heating prevents the depletion of sources.

- Environment protection. Due to the high cost of disposal, business and vehicle owners disposed of oil by dumping it into waterways or into the ground. This had a negative impact on the environment. With the beginning of the use of waste as fuel, such manipulations stopped.

Disadvantages of fuel:

- poses a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- The operation of the boiler leads to the combustion of oxygen and evaporation of moisture from the air.

How is oil processed?

Processing is obtained by burning any type of oil, but for heating the premises, oil refining products from internal combustion engines are usually used.

Also from industrial mechanisms, compressors and power equipment.

What does not apply to such fuel?

List of products not related to waste:

- processed oils of vegetable and animal origin, which are used for household needs;

- solid waste with processing;

- solvents;

- products that are not subject to the same processing as waste;

- natural petroleum fuel from the spill;

- other unused petroleum products.

How does a heating device work?

The design of the boiler is extremely simple. It includes two chamber compartments: evaporation and combustion. In the first, the process of preparing the oil for combustion occurs, in the second, it burns.

Everything happens as follows. From the waste reservoir, the pump supplies used oil to the evaporation chamber, which is located at the bottom of the device. Here, a temperature is maintained sufficient for the waste to heat up and begin to evaporate.

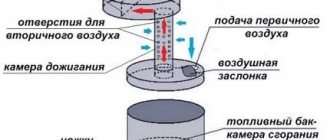

This is how a boiler with oil evaporation and forced air supply works (+)

Oil vapor rises to the upper part of the housing, where the combustion chamber is located. It is equipped with an air duct, which is a pipe with holes. Using a fan, air is supplied through the duct and mixed with oil vapor.

The oil-air mixture burns almost without a residue - the resulting heat warms up the heat exchanger, and the combustion products are sent to the chimney.

Preheating the oil is an essential part of the process. You need to understand that the waste contains a large amount of impurities and toxic substances. All this is broken down into simple carbohydrates, which are subsequently burned.

After which water vapor, carbon dioxide and nitrogen are formed - completely harmless elements. However, this result is only possible if certain temperature conditions are met.

Complete oxidation or combustion of hydrocarbons occurs only at a temperature of +600°C. If it is lower or higher by 150-200°C, then during the combustion process a large number of various toxic substances are formed. They are unsafe for humans, so the combustion temperature must be strictly observed.

Terms of use

In order for the boiler to serve for a long time without service, it is necessary to pay attention to the rules of use

Fuel

Used oil for boiler operation can be used for almost any purpose. The main thing is that it meets a number of requirements set by device manufacturers.

Photo 4. Draining used oil into a special container. The liquid itself is dark brown.

If you have additional filtration systems, feel free to use them. The cleaner the used oil is, the more efficient the combustion process will be. This also affects the fact that you will carry out less preventive maintenance during operation.

If analysis reveals that the fuel contains a large amount of water and antifreeze, then it is necessary to filter the fuel completely. There are special recommendations on how to remove such impurities.

Manufacturers most often recommend using hydraulic, motor, transmission oils, as well as oil from an automatic transmission. But it is not recommended to use fuel oil in the device.

The fuel for the boiler is calculated in accordance with the heat loss for each specific room. It is necessary to take into account data on the insulation of the place, its glazing, the operating mode of the boiler, as well as the required set temperature. Depending on the manufacturer, the calculation will be performed using individual formulas. It is better to contact the manufacturer directly to identify this issue.

The most commonly used formula is:

B = d*(h1-h2) + d*(h1+h2) /qn

Where: h1 - efficiency factor,

h2 is the enthalpy of the fuel,

d is the heat of combustion of fuel,

qn is the temperature and specific heat of the oil.

How to properly and safely pour fuel into the boiler?

Before starting work, you need to carry out a number of actions that will ensure the safety of using the device:

- Open the container with the liquid. This is necessary so that it has time to interact with oxygen.

- After this, disconnect the device from the network and power, check the degree of sealing of the seams.

- Fill the collection pan with oil. You need to pour a 10mm layer. The oil must be clean.

- Add 100 ml of kerosene to this liquid.

- Take the wick and wet it in the ignition.

- Lower to the bottom of the container.

- Set fire to the waste.

- Watch how the seams and oil behave. All actions must be carried out with gloves.

- Close the lid.

- After this, the device will start working, and you can check how efficiently it functions.

Photo 5. Filling a homemade boiler with waste oil. Fuel is poured into the lower part of the unit.

Do not get oil on foreign parts or parts of the device. During operation, all additional sources of oxygen supply, such as doors or windows, must be closed.

Design details of homemade equipment

The most important component of combustion technology is oil preheating. This makes it possible to decompose “heavy” fuel into lighter components. Properly selected parameters allow you to achieve almost smokeless and complete combustion of used oil.

Home craftsmen believe that the easiest way to achieve this result is to use a thick-walled hot metal bowl into which the waste is fed in drops.

One of the possible operating schemes for heating equipment with oil evaporation (+)

When the oil touches the hot metal, it immediately turns into vapor, which is sent into the combustion chamber. For better combustion they need to be mixed with air. An air duct is used for this purpose.

An impeller is installed at its mouth to create the flow turbulence necessary for the oil-air mixture to remain in the combustion chamber for a sufficiently long time. Only in this case will the fuel supplied to the bowl burn completely.

A certain difficulty in the process of activating the operation of the heating device is the heating of the evaporation bowl.

The easiest way to do this is to put a wick soaked in any flammable composition inside the tank. Then pour some gasoline or diesel fuel into the bottom of the bowl and set it on fire. After the metal heats up to the desired temperature, the oil supply begins. This is the simplest, but rather dangerous method.

Another difficult aspect to implement is the oil supply. On the Internet and other open sources you can find many examples of boilers operating on waste oil, where the waste is supplied by a jet.

Yes, such a system is functional, but it is extremely dangerous for the user. The oil supplied by the jet does not have time to burn. A large amount of toxic substances are formed that can enter the room. And this is very dangerous.

This way you can organize a drip feed of used oil into the evaporation bowl. A nipple, tees and a fragment of a medical dropper are used

For efficient smokeless combustion of waste, it is necessary to organize a drip supply of oil. This is quite difficult, but quite solvable. The optimal method of drip supply, according to home craftsmen, is as follows.

You need to take a hose that will act as an oil line. A filter must be attached to one end to clean the fed waste from impurities and contaminants.

This should be a full filtration automobile oil filter. The latter is very important. Not partial, but complete. You need to be prepared for the fact that you will have to change it often. On average once every 30 days, or even more often. Everything will depend on the quality of the fuel used.

Some difficulty may arise in the process of attaching the unit. It is equipped with a thread with which it is fixed in the car.

You can do the following. You should find a small piece of oil-resistant hose, the diameter of which will coincide with the thread cross-section, and put it on the filter. The resulting unit is connected to the oil pipeline using a fitting.

It is very important that excess oil does not accumulate in the oil supply hose, otherwise drip feed will be impossible.

Pyrolysis type boiler. Due to the presence of an afterburner, the burning time of one portion of fuel significantly increases

As an option, you can select a pump of such power that it delivers only the required amount of waste. But it is so hard. A simpler option is used in industrially assembled boilers. This is a simple design of tees, fittings and nipples.

With its help, you can easily adjust the supply of the required amount of oil. The excess will be returned to the fuel tank.

The last element of the drip feed system is a fragment of a medical dropper. You need to take a section with a wheel-regulator. The element will allow you to control the speed and frequency of fuel supply to the bowl. The dropper fragment is securely fixed to the fitting.

It is optimal that the waste does not smoke and burns steadily. This is only possible if the oil has normal fluidity. To do this, its temperature must be within 10-20°C.

You need to know that with each change in the composition of the waste or its temperature, you will have to reselect the frequency and speed of the droplet supply of oil. It will not be possible to supply fuel directly from the dropper to the combustion chamber. It is directed into a funnel connected to a pipe that supplies fuel to the bowl.

In this simple way, you can organize a uniform supply of oil into the chamber and thereby extend the burning time of one loaded portion of fuel (+)

The design of the boiler may vary. It can be connected to the heating system pipes. A prerequisite in this case is the installation of a pump to ensure efficient circulation of the coolant.

If you arrange a so-called water jacket around the device, it will heat the water. If there is only one water circuit, the boiler will only serve heating. If there are two circuits, hot water will also be supplied.

Image gallery

Photo from

Stove in operation with a water circuit

Tank for periodic topping up of fuel

Oiler welded into the lower chamber

Lower chamber drawer

Another option is a built-in heat exchanger in the shape of the letter U. It is placed in the upper part of the firebox and connects to a remote tank that will contain hot water. An alternative option is to place the heat exchanger on the chimney.

The exhaust boiler can be pyrolysis. Its main feature is the ability to operate for a long time on one load of fuel. Structurally, such a model will differ in the presence of an afterburner chamber.

This is where the final combustion of all the chemical elements that make up the used oil takes place. Due to the presence of an afterburning chamber, the operating time of the pyrolysis boiler on one portion of oil increases significantly.

What is good about a brick oven with a water boiler?

How can you not enjoy the sounds of peacefully crackling logs in a bathhouse? And what if, besides, there was an original wicker firewood basket nearby, with logs lying comfortably in it? Modern wickerwork used for these purposes is made from wicker, birch bark and even metal. Woven into a trough shape, they allow firewood to be neatly stacked and beautifully complement the design of the sauna.

This is not only an aesthetic pleasure, it is also “natural” warmth, heat and a unique aroma. How to save firewood, since it takes a lot of it to kindle? Every year the popularity of standard or Russian stoves with water heating boilers is growing. A brick kiln with a water circuit is characterized by good heat transfer, reliability and high efficiency. This design will be effective both in a small and in a bath room with an area of up to 100 sq.m.

It is not too difficult to make such a design, the main thing is to take into account all the features and recommendations. For example, the pipe must not only be thick-walled, but also seamless, the welding seam must match the thickness of the pipe walls, and the feed is welded only to the edge of the upper thick pipe. The oven is laid out with ordinary and refractory bricks; for masonry, ordinary and refractory mortar are used. Such bath heating will be reliable, durable and comfortable.

Pellet stoves are an economical and convenient device that allows you to save on fuel. Pellet units operate on special compressed pellets made from wood shavings, which are easily combustible. The main advantage of the work is that the pellet burner is able to burn fuel as efficiently as possible thanks to unique supply algorithms, as well as the flow of air, which helps regulate combustion.

A wood burning stove with a water circuit is efficient and reliable. Such designs make it possible to heat large rooms, even at low outside temperatures. Their advantage is an environmentally friendly combustion process and good efficiency. In the process of their work, they produce process water at high temperatures, which is also used. At the same time, fuel costs are minimal, and the heating rate of the room is fast. The stove looks like a steel firebox with a wall thickness of 4-6 mm. The heat exchanger tubes are located between the walls.

Each of the described options is a universal solution for heating a bathhouse or other country house. Having decided to purchase a stove of a certain type, you need not only to study the options for modern models offered by manufacturers, but also to think through everything thoroughly and take into account the parameters of the actual room where it will be installed, its area, and functional features.

Advice from the master!

Making a product yourself must take into account all the necessary requirements and recommendations for its safe operation. And only then will the waste oil stove not only fulfill its main function - heating the room, but will also harmoniously complement the sophisticated style of any home or bathhouse.

https://youtube.com/watch?v=oyWnB-cS1M8

A little about safe operation

Heating devices operating during mining are quite dangerous in operation. This must always be remembered.

To avoid trouble, you should strictly follow a few simple rules:

- The room where the heating device is installed must be equipped with effective ventilation.

- The boiler must be equipped with a well-designed and executed chimney that removes combustion products without residue. It must have a damper.

- The passage of the smoke exhaust through the roof is carried out by installing a special casing.

- The boiler must be installed in accordance with fire safety requirements.

- Storing flammable and flammable materials near the heating device is strictly prohibited.

The boiler during testing, like any other heating device, must be treated with care. Carry out all necessary preventive work in a timely manner, then problems with operation and its safety will not arise.

Pros and cons of waste oil furnaces

Advantages

- the extreme simplicity and reliability of the design practically eliminates or minimizes the possibility of breakdowns;

- possibility of uninterrupted operation at severe subzero temperatures;

- high speed of heating of small rooms;

- absence of dependence on the availability of electricity in simple models;

- no need to develop a project and have it approved by regulatory authorities;

- possibility of alternative use in the form of a hob;

- possibility of self-production;

- mobility and ease of transportation.

Balance of advantages and disadvantages

It would seem that the idea is practically devoid of shortcomings, but this is not so. To make an informed decision about using such heating in your home, you need to see not only the advantages of its use, but also the disadvantages.

Let's start with the advantages of the method. So, if you have regular access to waste fuel, which essentially is waste fuel, then you can effectively use and at the same time dispose of this material. Proper use of technology allows you to obtain heat with complete combustion of the material without releasing harmful substances into the atmosphere.

Other advantages include:

- simple design of the heating unit;

- low costs for fuel and equipment;

- the possibility of using any oil that is available on the farm: vegetable, organic, synthetic;

- flammable material can be used even if contaminants make up a tenth of its volume;

- high efficiency.

The disadvantages of the method should be taken seriously. If the process technology is not followed, incomplete combustion of the fuel may occur. Its fumes are dangerous to others.

If there were more disadvantages to heating during development than advantages, such factory-produced products would not appear on sale, which are sold like hot cakes, despite the fairly high prices

It is not for nothing that the main requirement when arranging heating during testing is the presence of ventilation in the room where the boiler will be operated.

We list other disadvantages:

- since good draft requires a high-quality chimney, it must be straight and its length must be at least five meters;

- the chimney and plasma bowl must be cleaned regularly and thoroughly;

- the difficulty of drip technology lies in the problematic ignition: at the time of fuel supply, the bowl should already be red-hot;

- operation of the boiler causes air drying and oxygen burnout;

- independent creation and use of hot water structures can help lower the temperature in the combustion zone, which jeopardizes the efficiency of the process as a whole.

To solve the last of the above problems, you can install a water jacket where it cannot affect the quality of combustion - on the chimney. The listed shortcomings have led to the fact that the product, without significant modifications, is practically not used for heating residential premises.

If you don’t have the desire or time to build a unit with your own hands, you can take advantage of numerous offers from workshops engaged in the production and installation of metal structures of various sizes: