How to detect a defective area

First, visually assess the condition of the battery. If it is old, worn out, with a lot of rusty spots that have already leaked, it is easier to buy and install a new one. If there are no obvious signs of wear, it is advisable to repair and restore it. Only defective items can be replaced.

Inspect everything carefully, paying attention to the joints, connections and the entrance area of the heating pipe. Hard-to-reach areas are inspected using a flashlight and mirror.

Sometimes the cause of poor or uneven heating is an air lock. To remove it, open the tap and drain a small amount of liquid. The airiness will disappear. If this does not happen, you need to look for damage.

If no defect is found, remove the housing and place it in a filled bath. Air bubbles will appear in areas of depressurization. After inspection, it will become clear what kind of damage occurred.

Cellular repair

Repairing the aluminum honeycombs themselves always caused a severe headache for both car owners and craftsmen. The main reason is the sometimes very complex and almost unrepairable design, and the rather thin metal of the radiators, which do not have “weak points” in the design, so to speak. But let's consider everything in order.

Prefabricated radiators

The first type that we will describe is a prefabricated car radiator, which, as mentioned above, is inexpensive, but its high-quality repair requires quite large material investments, but at the same time it is quite possible with the hands of professionals. The design consists of a honeycomb part , which, by the way, if it breaks, it is not often; as a rule, the rubber seals are the first to fail.

Round honeycombs are fixed to the mesh using rolling, through a rubber seal, which is plastic at the beginning of its life. But this is only at first, and only when pouring high-quality antifreeze, then the gasket simply turns into a terrible sight. For example, the lifespan of a German radiator, which is operated with high-quality antifreeze, is approximately 11-16 years, a Soviet one - 7-11 years, a lifespan of modern and Chinese ones - can sometimes be from 20 minutes to several years .

If soldering the central part of this radiator (well, rubbed, or pierced with a screwdriver) is possible with the help of special solders, then it is beneficial and high-quality for both parties; repairing the “sinister connection” is almost impossible. Some workshops at one time developed a composition that makes it possible to solder aluminum honeycombs to a steel mesh, but, naturally, it is not practical to use it in repairing, for example, products for the VAZ-2107; this option is only good for repairing “foreign cars”.

How to replace gaskets in case of leakage

The connections between the battery and the pipes, at the joints and between sections, are sealed with O-rings sealing the system. Most often they are made from paronite or other heat-resistant polymer. However, over time, this material wears out, becomes deformed, and coolant begins to leak through the worn ring. Sometimes the nipples connecting the parts of the unit are damaged.

The outer gasket is easy to replace. Turn off the supply tap, drain the water, unscrew the cap with a radiator wrench, remove the defective element and replace it with a new one.

It is more difficult to change sealing elements and nipples at intersectional joints. In this case, you will have to dismantle and disassemble sections with leaking joints. A radiator key is useful for this.

When disassembling, remember two subtleties:

- The thread can be either right-handed or left-handed, with equal probability. The products of many manufacturers are marked - right - D, and left - S.

- Each section is equipped with two heads. If you twist and move only one of them, distortion and deformation of the metal will occur. Therefore, loosen the fastenings parallel to the top and bottom, and move the disconnected elements strictly parallel.

Once you get to the damage, replace the torn O-ring or damaged nipple, and then put everything back in place.

Do-it-yourself aluminum cooling radiator repair in a car

The repair of aluminum radiators has always caused a stir, both from car owners and from craftsmen. The former constantly wanted to eliminate all problems, the latter to earn money. In this article we will try to consider all aspects of repairing aluminum radiators. Everything described below applies equally to both cooling radiators and stove radiators.

The most common radiator malfunctions:

- the appearance of cracks in the area of radiator outlet and inlet pipes;

- violation of the tightness of the tubes;

- violation of the tightness of the seals;

- the appearance of holes and cracks as a result of mechanical damage;

- weak passage of liquid, as a result of clogged tubes.

Construction of aluminum radiators

First, let's look at the design of aluminum radiators and what composite materials are used during their production. The first type is a traditional aluminum radiator with plastic tanks ; depending on the model, it may differ in the way the tanks are clamped and the core is made. As a rule, the tanks are clamped with wave rolling or teeth.

Sometimes it may seem that the only difference is in the rolling method, but this is not true. Without going into details, we note that the type of gasket used between the bottom of the radiator and the tank imposes certain restrictions, or, in other words, entails the use of a specific type of rolling. Now let's look at the types of cores.

typesetting

Stacked cores are divided into:

- all-soldered;

- typesetting (or prefabricated).

Solid soldered

These radiators are more complex to produce, and, accordingly, they cost much more than prefabricated ones. The meaning of the core is that it is collected, like copper, but then sent to a special furnace with an inert gas environment and a strictly defined temperature for sintering. Then, when the core is ready, plastic tanks are connected to it using wave rolling. Naturally, in nature there are combinations of the above methods.

Prefabricated

As a rule, prefabricated models are based on round tubes with a cross-section of 7-11 millimeters, and stacked heat sink plates; they are not welded to the tubes, but simply tightly placed on them. The advantage of this design is its low cost, since almost all work is carried out mechanically, without the help of welding. But there is still one type of prefabricated radiators, where the tubes are not rolled through silicone gaskets to a metal mesh, but are soldered to an aluminum one. In 99 percent of cases, the tanks are connected to these radiators using a certain type of gear rolling.

A little different are all-aluminum radiators, in which both the cores and tanks are made of aluminum. The cores of these radiators are always made using solid-soldered technology .

But, surprisingly, not a single cooling radiator from a large manufacturer uses this technology, since the tanks may require the same amount of material as the core itself. The only exceptions are exclusive American radiators; they are produced to order by the capricious owner of a “drag” or a restored “classic”.

In our country, this technology is found either in stove radiators from some manufacturers (for example, Daewoo Nubira, Lanos), or in models from a frankly Chinese or domestic manufacturer. But these two described options, although cheaper than a copper-brass radiator, the quality of their assembly and design is completely copied from brass models, and inherits all the “innate” shortcomings. In addition to the above, it must be said about aluminum stoves, their tanks are not welded to the mesh, as they should be, but glued, and even with glue, which is dangerous to use even with a garden watering can, let alone a heating radiator.

That is, in order to produce a high-quality aluminum radiator, which, in addition to good heat dissipation, can also withstand mechanical and hydrodynamic loads for a long time, requires careful design and the use of complex equipment during production. And this increases the cost of the final product, which will immediately transfer it from the category of leaders, in comparison with the “copper” product, to the level of expensive outsiders.

Since, for example, in a GAZelle, on our roads, a brass radiator rarely travels 40,000 km without breakdowns, and this is about a year with a daily load of 100 km. After overhauling the radiator with our own hands, we can double its lifespan, unlike the factory one, but doing this with an aluminum analogue is quite difficult, and most importantly, not very profitable financially. Here is a reason to think about whether you need to save money when buying between an aluminum and a brass radiator?

"Exotic"

As a rule, craftsmen call stoves and radiators exotic, which can be very rarely found. 1992 Opel Omega heater ; it is made of a completely plastic mesh (bottom) and tanks, made monolithically, and connected to a stacked core, which has oval tubes, with a welded turbulator. Besides this example, there are also a number of rarely seen varieties, but again, these are rare.

It should be noted that the more exotic the radiator is on your car, the more difficult it is for car mechanics to repair it, and not only because of the complexity of combining different materials, but also because the experience of many craftsmen simply does not make it possible to use a tried and true one the first time. repair option. That is, an inexperienced technician will carry out repairs at random, while simultaneously learning the intricacies, so to speak, practicing with his own hands on your radiator, gaining experience.

Plastic tanks

As mentioned above, plastic tanks lighten the weight and reduce the cost of construction. But we need to make a reservation, the term “plastic” when considering tanks is not very correct, since they are based on polypropylene, and no one will disclose other additives and impurities; survival in a competitive environment depends on this. Here you can find fiberglass reinforcement, fillers, and other tricks.

After a certain time, plastic tanks dry out, the base of the plastic changes under the influence of a constant temperature difference and they become brittle and form a leak. In this case, the best option would be to replace the radiator with a new one, because replacing the tank is not always cost-effective. But sometimes, if we consider exclusive models, there is nothing you can do to repair cracks in the tank with your own hands, but here the second question arises - which repair option is better?

There are three main repair options:

- replacing the tank with a metal one, which is welded or soldered in place of the plastic one;

- soldering the tank with plastic;

- use of special polymers.

How to fix housing leaks

When inspecting the metal, cracks and holes are often found that need to be repaired. In such cases, the battery will have to be removed and repaired.

Fix the defect in one of two ways:

- Cold – clean the area around the defect with sandpaper. To remove thick layers of rust and dirt, use soapy water or citric acid. Then seal the hole with high-temperature cold welding. In appearance it resembles plasticine, and after drying it forms a durable patch. You can use epoxy resin to which aluminum or bronze powder has been added; it seals holes in the metal well.

- Hot - the defect can be soldered with a soldering iron. A patch of flux, iron and rosin coated with solder will restore the seal. Please note that aluminum is difficult to solder without experience. The most effective hot method is argon welding, which provides reliable sealing of defects. In this case, you will have to contact specialists.

It is recommended to replace seals that have lost their strength and shape. This will allow you to avoid having to deal with dismantling and disassembling once again.

Battery Features

Despite all its attractiveness, this type of heater is in the least demand among consumers due to the prevailing opinion that the service life of aluminum radiators is short, and they have many shortcomings and “claims”.

This is not entirely true. Aluminum heating radiators have a number of attractive features that have won the hearts of many customers.

Among them:

- They are able to withstand pressure drops of up to 20 atmospheres and above. If they are intended to be installed in a house with centralized heating, then you should carefully study the operating system and, when choosing radiators, familiarize yourself with their technical characteristics specified in the data sheet.

- Aluminum radiators weigh little , so they are easy to both transport and install.

- Their device is so simple that, if necessary, it allows you to repair aluminum heating radiators with your own hands if you have the necessary tools .

- High heat transfer ensures rapid heating of the room while saving energy resources .

- A small volume of coolant provides almost instantaneous heating of the entire radiator area.

- Aluminum radiators have a stylish design and fit perfectly into any environment.

Such a number of advantages could make them leaders in sales on the heating systems market, if not for the fact that they “feel” best in individual heating systems.

This is due to the fact that aluminum is susceptible to corrosion in the absence of a coolant for a long time (as is known, in centralized systems it is drained in the warm season) and its purity and alkaline balance.

If with autonomous heating the quality of the media can be monitored and left in the system, then in an apartment building with central heating it is very difficult to do this.

If aluminum batteries are installed correctly and operated in the conditions required for them, then their service life significantly exceeds the warranty (10 years) from the manufacturer. Repairing an aluminum heating radiator will not be as difficult as adding additional sections.

Causes of holes and leaks

- Incorrect choice of heating system components and disruption of the installation process. Sometimes such errors emerge only during operation.

- External corrosion of the housing, which occurs from the outside with high humidity in the room. This often happens in bathrooms and showers.

- Incorrect physical and chemical parameters of the coolant that reacts with the metal. The aluminum or silumin body is destroyed.

- Draining the media for a long time - air accumulates inside the case, reacting with metals and alloys.

- Destruction of gaskets - the material from which they are made loses strength over time and does not seal.

- Damage to shut-off valves. Reasons: pressure surges, resource depletion.

What can happen if there is a lack of coolant?

If the radiator leaks or the pipe ruptures, the following may happen:

- The engine will overheat;

- The cylinder head gasket is deformed;

- When attempting to examine the problem, pressurized liquid may splash into the face, causing burns;

- The engine will seize.

All these troubles can lead to expensive repairs, and damage to health can be irreparable.

Useful tips

In order not to engage in restoration, you need to buy only high-quality radiators, and trust the installation of the heating system to trusted companies. You should not skimp on quality - constant repairs will cost more.

In order for the purchased product to serve for a long time, it should be used correctly - do not leave the heating system empty for a long time, fill only with a suitable coolant.

When repairing radiators, it is necessary to check the integrity of all elements. Perhaps there are still areas on the body that need to be restored, require replacement, or the shut-off valves or nipples are worn out.

Leak test

The quality of the repair can be checked using air or water pumped into the radiator under pressure. The air method has been previously described.

Pressurized water can only be checked during the heating season. To do this, a plug is placed on one side of the battery, and the other is connected to the supply through the Mayevsky tap. Having slightly unscrewed the tap and bypass, fill the radiator with water. To facilitate observations, a strip of white paper is placed under the battery.

If after 10-15 minutes the paper remains dry, the leak has been eliminated and the radiator can be connected to the general system.

If it is not possible to create pressure, then fill the radiator with colored water and leave it for several hours. Usually after 3-4 hours the leak manifests itself.

You might be interested

Connecting heating batteries with bottom supply

Drywall battery box

Heating area of an aluminum radiator (heating radiator power per 1 m2)

How to choose bimetallic heating radiators for an apartment

Dimensions of bimetallic heating radiators

How to connect aluminum radiators

How much water is in one section of an aluminum radiator

The best aluminum heating radiators for a private home

Replacing heating radiators: how to avoid mistakes

Hidden wiring pipes are leaking

When laying hidden pipes, reliable ones are used. But even in this case, leaks may occur. Breaking walls or floors is, to put it mildly, a “not very good” option. There are two ways to eliminate this heating leak:

- The method is old-fashioned, but it works. By the way, it will also help in cases of open wiring - if there is a leak somewhere, but it’s difficult to get to. Fixing a leak in the heating system in this case is simple: pour a couple of packs of mustard powder into the expansion tank and start the system with this coolant. After a couple of hours, the leaks heal: they become clogged with suspension. This way you can plug up small leaks in the boiler. Then the mustard coolant is drained, the system is washed and it is restarted with clean water. The method works, but is risky: something else may get clogged at the same time, and filters and dirt traps will have to be cleaned.

- The work of factory sealants for heating systems is based on the same principle, but only with the use of polymers. They are poured into the system for a certain period of time. As polymers circulate through the system, they settle on the walls; in places where there are leaks, they are not carried away by the coolant flow. Gradually a traffic jam forms there. When the leaks are blocked, the composition is drained, clean water is poured into the system and the heating continues to operate.

Heating system sealants seal all leaks

Of course, it is cheaper to use mustard, and significantly cheaper: a 1 liter canister of such sealant (added at the rate of 1*100) costs from 6 thousand rubles. But the result may be different: mustard is organic, and the sealant contains a suspension of polymers. Moreover, there are ready-made sealants for antifreeze, for water, and for leaks of varying intensity.

And, by the way, this is almost the only way to eliminate an antifreeze leak: it is very fluid, and often also poisonous (ethylene glycol) and you need to work with it extremely carefully. You cannot live in a room where ethylene glycol flows: its vapors are also toxic.

https://www.youtube.com/embed/kax7LBUmZ2c. There are enough ways to eliminate a leak in the heating system

But everything except replacing a damaged part only provides some respite - to survive until the end of the heating season. Then you need to change the pipes or radiators, and re-seal the connections. Read about how to change radiators here

There are enough ways to eliminate a leak in the heating system. But everything except replacing a damaged part only provides some respite - to survive until the end of the heating season. Then you need to change the pipes or radiators, and re-seal the connections. Read about how to change radiators here.

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

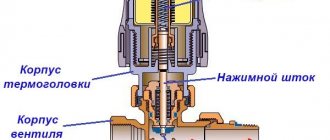

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device.

If the radiator plate is leaking

The occurrence of fistulas on plate radiators is a fairly common problem and is associated with the instability of the metal to corrosion or with insufficient wall thickness.

As a rule, it is better to replace leaking plates with new ones, but not everyone has this opportunity. In this case, the plate can be repaired by cold welding - epoxy glue, following the instructions that come with the product.

All of the above methods can be used to eliminate leaks in the heating system, but in the case of a more global problem or a complete lack of experience and necessary information, it is still recommended to seek help from qualified specialists. And it doesn’t have to be a plumber from a service company. To speed up the process, preference can also be given to private enterprises engaged in the repair of heating systems.

April 11, 2016, 11:28 Home and Life 3054

Scheduled Maintenance

All of the above methods are mostly used in winter, when something urgently needs to be done. During the warm period of the year, you can carry out scheduled maintenance of risers and batteries so that leaks do not occur in winter. The battery is completely removed from its place and unrolled into sections. All threaded connections are cleaned of old sealant. If necessary, nipples are replaced with new ones. Intersectional gaskets are also completely replaceable. The detected fistulas are welded or sealed, and the battery is installed in its place. In the video below you can see other ways to eliminate leaks.

Recommendations - where to call if a pipe burst in your apartment

Emergency situations usually arise unexpectedly, so information about where to call if a pipe has burst should be in a visible place: in the apartment or on your mobile phone.

Any person develops an algorithm of actions in critical conditions - he is directed towards a specific goal and consistently achieves it.

The direction is clear: stop the flow, and establishing who is to blame will not be difficult. Emergency phone It is important to know where to call if there is a water leak. The purpose of the telephone call is to notify the emergency repair team of an accident as soon as possible.

Such units are organized in all housing management companies and city utilities.

An accident occurs at any time of the day or night, and therefore available for contact

We recommend reading: How the market value of a land plot is determined

Soldering the radiator: method 1

It includes the following steps:

- Surface preparation. This process must be done carefully. It consists of cleaning the treated area from all dirt and paint residues. Clean the aluminum surface using emery cloth and solvent. Preparation also includes degreasing the treated area (for this, preparations containing alcohol are used), as well as wiping the metal dry.

- Preparation of iron rosin flux. To do this, the crucible is placed on a gas stove and heated. You can heat it with a blowtorch. A piece of rosin is placed in a heated crucible. It needs to be completely melted. Next, add iron filings little by little and immediately stir the mixture. The ratio of rosin and sawdust should be 2:1.

- Applying flux to the prepared area. The solution is applied so that the desired part of the radiator surface is completely covered. Otherwise, oxygen will have access to the aluminum, and the hole will not be soldered well. At the end, the entire soldering surface should be under a layer of flux.

- Soldering. It involves introducing solder into a liquid flux environment. You need to take small portions of solder onto the soldering iron. Solder is applied to the soldering area so that it is under the flux layer. At the same time, perform circular movements. During these movements, the soldering iron constantly dislodges some particles of solder. The displacement of iron particles leads to the destruction of the oxide film. Rosin prevents air from penetrating the aluminum.

This method should be used to eliminate small defects. If the damage is large, then you can only solder the radiator using homemade flux.