How nice it is to return from the street, where there is frost and wind, to a warm and cozy home! But what to do if it's cold in your home? TO

Of course, you can approach the issue globally. Get involved in replacing heating radiators or contact the appropriate authorities so that your apartment can be heated better.

But all this requires a considerable investment of time, effort and money. But now you want warmth. I suggest the most obvious solution: install a heater.

Today we will discuss how to choose an oil heater for an apartment or house.

Principle of operation

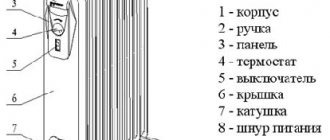

An oil heater consists of a metal body that visually resembles a stationary battery, special mineral oil and a heating element.

After turning on the device, the heating element begins to work, heating the oil to the desired temperature. Next, the oil transfers its heat to the metal shell, which gradually heats the surrounding air.

All modern models have several operating modes, thanks to which you can choose the intensity of heating the air in the room.

To prevent overheating and breakdown, modern models are equipped with a special sensor that turns off the device if such a threat arises.

The built-in timer helps regulate the temperature: when the air is heated at a given temperature, the device turns off, and when it gets cold, it turns on.

WE MEASURE TECHNICAL PARAMETERS

This stage of the test was carried out at a network voltage of 220 V.

Power

Measuring the actual power consumption at a voltage of 220 V revealed a deviation from the nominal one declared by the manufacturer. The minimum difference in percentage was shown by the Beko BRZ-2009 and Vitek VT-1729 BK heaters (3.28% each), the maximum - Timberk TOR 21.2009 HA (-21.2%).

Heater warm-up time

At this stage, the time it took for the device to warm up to operating temperature was measured. The heating time depends on the design of the heaters, the location of the heating elements, the brand of oil and other features of the devices.

The initial temperature is room 23 +/–2°С.

This test is carried out at maximum heater power. The fastest was Beko BRZ-2009 (6 min 40 sec), the slowest was Scarlett SC-1167 (15 min 30 sec). The temperature was measured according to the standard, at the hottest point of the case (the hottest point is located for each heater, as a rule, at the bottom, closer to the heating element).

Heat radiation efficiency

This is a very tricky parameter. Due to convection, the radiation of oil heaters is predominantly directed upward, and only a small part is directed sideways. And this part, in fact, determines how warm we will be next to the device.

Radiant heat efficiency is the temperature difference in front of and behind a black plywood test bench located a meter to the side of the heater. The maximum efficiency is for Aeronik PO-1123M - 3.85? C, the minimum for Timberk TOR 21.2009 HA - 2.05? C.

Types and characteristics of oil heaters

All radiators operate according to the same algorithm, but differ in the set of additional functions, type of mounting and price. Depending on the goals set for the device and its location, oil radiators are divided into:

- Wall-mounted – economical in terms of electricity consumption.

- Floor-standing ones are popular because of their mobility.

- Tabletop - low level of heat transfer.

- For cots.

- Ceiling.

Some models are equipped with a fan that disperses flows of warm heated air throughout the room. The disadvantage of such a device is noise during operation. The developers of some companies have included a humidifier in their models.

This device is especially relevant in the cold season, when the air outside becomes much drier, and the heater itself gradually dries it out further. Some units have a delayed start function.

WHAT TO CHOOSE?

The question of choice is not an easy one. We sincerely hope that the test will help you find “your” heater. We ordered the testing in the accredited testing laboratory TESTBET.

| Tested models | |||

| Trademark | Model/type | A country | Place of production |

| Aeronik | PO-1123M | no data | China |

| Beko | BRZ-2009 | Türkiye | China |

| DeLonghi | TRD 0820 ER/K 082071 ER | Italy | China |

| Scarlett | SC-1167 | no data | China |

| Timberk | TOR 21.2009 HA | Sweden | China |

| Unit | UOR-920 | Austria | no data |

| Vitek | VT-1729 BK | no data | China |

The selected devices belong to the same class, have the same rated power -2000 W (with the exception of PO-1123 from Aeronik, 2300 W), are similar in appearance, but behave differently when tested. The more interesting it is to get to know each other!

Advantages of oil heaters

- High level of device security. In an oil radiator, all heating elements are hidden inside, and the outer shell heats up to a temperature of no more than 60 degrees.

This eliminates the possibility of a fire due to a fall or burns to the skin surface due to tactile contact. The last factor is important in families with small children.

- Long service life. The device is designed in such a way that the components do not burn out due to long continuous operation. The device can work without turning off for up to three days.

- The compact size of the device and its mobility allow you to move it to different parts of the house or apartment. And quiet operation will not cause any discomfort.

- The price of oil radiators is affordable. The cost depends on the number of sections that the device has.

- No foreign odors are emitted during operation of the device. Radiators do not dry out the air in the room, which means that you do not have to spend extra money on purchasing a humidifier.

- To install such a heater, you do not need special knowledge or tools. You simply plug in the device and enjoy the warmth.

Selecting an oil cooler according to parameters

It is impossible to clearly say which heater from which company is better. There is a huge selection of models on the market. The best manufacturers will always offer reliable housings and trouble-free safety and adjustment systems. But it is important to know how to choose an oil radiator based on the main parameters.

Power

The main criterion when choosing an oil heater is power. The recommended rate is calculated based on the area of the heated room at the rate of 100 watts per 1 sq. m. But this is the maximum selection rate.

In practice, to comfortably heat a room of 20 square meters, 1500 watts of heater is enough. Moreover, the greater the number of sections (the area of contact with air), the faster the room will warm up and the more stable and economical the operation of the device will be.

Radiator type

The radiator is chosen according to personal preference. The flat heater fits conveniently against the wall, can be located behind the back of the sofa or even mounted on the wall. A sectional device with simple soldering is more compact and can be easily placed next to your favorite place in the room. A device with safe ribs or a tubular double body is the optimal solution for a nursery or apartment where little fidgets are constantly running around.

Disadvantages of oil heaters

An oil cooler has several negative aspects that you need to be aware of before purchasing. They are quite controversial and can be easily eliminated:

- Heavy radiator weight. It will not cause any difficulties when moving, since each model is equipped with wheels, and there is no need to lift the unit at all.

- Long room heating time. First, the heating element inside the device heats the oil, and only after that does it heat the outer shell of the radiator.

But this drawback can be easily eliminated if you initially purchase a radiator with a built-in fan, which will disperse warm air around the room, thus heating it up faster.

Installation method

Oil heaters can be mounted on a wall, installed on the floor or on a table.

Wall mounted

Wall heaters are flat in shape and light in weight. They are mounted on the wall in the place where there is a protective screen so that the heat from it is reflected and returned to the room. Typically, such devices are more expensive due to the reduced temperature system, which is necessary to reduce the risk of fire; increased demands on performance as well as beautiful appearance.

Floor-standing

A floor-mounted oil heater is often bulky and heavy, as it is made of steel. The device cannot be mounted on a wall due to its large weight, volumetric shape, and loss of heat transfer from the side of the attached wall. Floor-standing options are stationary, but many models have legs if you need to move them to another room.

Tabletop

The desktop version is the weakest in terms of power. Very rare and very unpopular.

How to choose an oil heater

Consider simple rules:

- Heater power. To heat 10 square meters of area you need about 1 kW of power. The manufacturer does not produce radiators with a power exceeding 3 kW. To heat larger rooms, you will need several copies.

- Size. The number of sections ranges from 5 to 14. The more sections in the radiator, the faster it will heat the room and the more electricity it will consume.

The best option is a heater with 6-8 sections. This wave is considered to be enough to heat a medium-sized room.

- Model design . When purchasing, pay attention to the presence of a light indicator, temperature controller and several operating modes. There should also be protection against overheating of the device, which will protect you from unforeseen situations.

With several modes, you can independently regulate the temperature that the device produces, and thus save the energy it consumes.

- Timer , with which you program the radiator to turn on or off for a certain time.

- Built-in air humidifier . During the cold season, the air becomes dry, which negatively affects the skin. The built-in air humidifier operates while the heater itself is operating, bringing the humidity in the room back to normal.

- Built-in fan. It will speed up the process of heating the room, but models with this function are much more expensive.

Also pay attention to the following aspects:

- Give preference to radiators with narrow sections. They heat up faster and transfer heat to the room. When reducing the size of sections, increase their number.

- Large sections take a long time to heat up and cool down, this provides additional heat, but requires additional electricity costs.

- If the device is lightweight, but at the same time large in size, it means that the manufacturer has saved on materials.

- Radiators of dark color give off heat better.

Main advantages and disadvantages

It is not for nothing that an oil-fired appliance is considered the best means of heating for the home. It has an impressive list of advantages:

- does not dry out the air;

- provides smooth and constant heat transfer;

- does not require maintenance;

- fireproof;

- equipped with reliable mechanical and electrical protection systems;

- durable, housed in a corrosion-resistant housing;

- consumes power acceptable even for average wiring in an apartment;

- you can purchase a heater for a nursery, made in a protective casing, with safe section ribs;

- no dust is burned, no unpleasant odors;

- does not make noise, except for a short period of the first start;

- a good device moves on wheels, some models can be attached to the wall.

When making a personal choice which oil heater is best, you should pay attention to some of the disadvantages of individual models.

- Cheap room heaters equipped with a fan warm the air quickly, but the noise is a nuisance.

- It is worth choosing a device in a reliable design, with radiator walls anodized, galvanized or made of stainless alloys. Inexpensive models are often susceptible to corrosion.

- Narrow and tall models do not always have good stability.

- The most powerful appliance is not always the best choice for heating a room. A device with multi-stage temperature control is much more convenient.

If we describe how to choose the right oil heater, we can confidently say: the device should be about 50-65 cm in height, on a wide wheel support, with reliable radiator walls, and have multi-stage temperature control. By making such a purchase, you can immediately compensate for most of the shortcomings of inexpensive oil heaters.

Which is better

Before purchasing a radiator, you should calculate how much area it will need to heat. The heating function depends on the power of the radiator and the number of sections.

The power is selected depending on the size of the room in which the radiator will operate: for 10 square meters of room you need 1 kW of generated electricity.

The formula applies to rooms where the ceiling height is no more than 2.75 m. If the ceilings are located higher, the required power can be calculated using the following algorithm:

- Multiply the length of the room by the width to get the area.

- Multiply the resulting number by the height of the room, this way you will get the required volume.

- Divide the resulting figure by 25, because 1 kW of energy per 25 m3 is calculated. The result obtained is the power needed to heat the room.

Then it’s a matter of individual taste and financial capabilities. A simple oil heater has a standard set of functions and is inexpensive.

Models equipped with fans, timers, humidifiers and remote controls are more expensive, but more comfortable to use.

Self-production of an oil-filled heating radiator

In rooms where the requirements for the aesthetics of heating equipment are not high (garage, workshop), you can save on heating by making your own electric heater filled with waste oil. Let's take a closer look at this possibility.

Homemade oil heater made from steel pipes

Like an industrially manufactured unit, such a heater must include:

- radiator (register) with supporting structure;

- Heating element with power cable;

- oil;

- control system.

Making a radiator and inserting heating elements

The dimensions of this component of the heater are selected based on the dimensions of the room. As a rule, the register is made of two or three sections of steel pipes, which will be located horizontally, communicating with each other by piping smaller diameter pipes.

Manufacturing option.

From a seamless steel pipe with a diameter of 100 mm, 3 sections 2-2.5 m long are cut, the sections of which are butted. On a lathe, 6 internal plugs are turned from sheet steel 4-6 mm thick. Four of them are inserted from both ends into 2 elements of the weaving pipe and carefully welded around the perimeter, that is, the elements are jammed.

Considering the significant dimensions of the heater design, for its efficient operation it is more advisable to use two heating elements of medium power (1.5 - 3.5 kW), which should be installed at the ends of the third fragment of the weaving pipe. You can limit yourself to one, but more powerful heater (3-5 kW), but then it would be advisable to embed a pump into the radiator for better oil circulation, or install additional piping of the sections with pipes of a smaller diameter.

Important! For steel pipes, heating elements should be chosen from copper or stainless steel, and the presence or absence of a magnesium anode does not matter - it is not needed in an oil environment.

In the case of using two heating elements, two couplings 5-7 cm long with internal threads corresponding to the external threads of the heaters are also turned from steel on a lathe. The couplings are welded at the centers into plugs, which are then installed from the ends into the third element of the weaving pipe and thoroughly welded.

Then, depending on the number of heating elements in the structure, the register sections are tied with steel pipes with a diameter of 40-50 mm, using or without mounting connections, and the heater legs are installed. A pipe with a plug is welded into the upper element of the register, into which a safety valve is installed - to allow emergency relief of excess pressure.

Heating elements are screwed into the couplings from the ends of the lower section of the register using sealing gaskets made of paronite or oil-resistant rubber. Power cables are connected to the heaters, which must have grounding conductors.

Using the formula for determining the volume of a cylinder (the product of the base area and the height), the capacity of each element of the manufactured radiator is calculated, after which the obtained values are summed up - the need for used oil will be 90% of the sum of the volumes.

Characteristics of oil for a homemade heater

The ideal option for filling a home-made oil heater is new transformer oil. But, based on the fact that the goal of making such a unit yourself is to save money, using expensive high-grade oil in it would be contrary to the idea. Therefore, we will consider options for using the material used, that is, how to choose the right material.

You can buy used transformer oil for next to nothing, which is drained at electrical substations when the transformers are replaced with new ones. After the new filler, this is the second best rated option.

Used automobile engine oil is also suitable for refilling, but the following nuances should be taken into account:

- Any organic motor or transmission oil is suitable for an oil heater, preferably viscous;

- synthetic oil is liquid, and its convective movement in the radiator will be accompanied by noise;

- It is not recommended to mix synthetic oil with organic oil, since the consistency of the mixture may become unpredictably heterogeneous when heated, the movement of convective flows in the radiator will slow down, and the surface of the heater will be heated unevenly during operation.

The selected oil is poured into the radiator in an amount of 85-90% of its volume through the filler neck in the upper section, after which a plug with a safety valve is screwed onto the pipe.

Security system design

If oil is poured into a radiator made of steel pipes correctly - in the right quantity, then the presence of a safety valve is more of an additional safety measure than a necessity, since steel can withstand high tensile loads. As for the temperature of the heater, it is first measured at various points of the radiator and the efficiency of the heater is assessed. If the temperature is low, you need to replace the heating elements with more powerful ones. If the radiator heats up excessively, then there are two ways out of the situation:

- install lower power heaters;

- Add thermostats to the heating element circuit (according to the number of heaters), placing them on the radiator in close proximity.

Thermostats must be selected with a suitable temperature range. A device from a household iron, for example, is of little use for this, since the lower threshold of its temperature control is still too high for an oil radiator.

Important! The heating unit must be grounded. In the absence of professional knowledge and skills, it is better to entrust the design and installation of a homemade oil radiator safety system to a specialist who will minimize the risk of using a homemade electric heating device.

Oil heater made of cast iron radiator

If you have an old cast iron battery from a water or steam heating system, then a homemade electric heater using waste oil can be made from it without buying steel pipes.

However, it should be taken into account that the amount of work in this case, at a minimum, will not decrease, and certain professional skills will be needed.

First of all, the radiator needs to be inspected for cracks and chips. Then it must be inspected - disassembled into separate sections, cleaned of scale from their insides and threaded connections, and then reassembled using sealants that seal the threads. This is done because oil, especially hot oil, has a much higher penetration rate than water.

To perform a battery inspection, you will need a special key, which is used to unscrew the connecting nipples of the sections, and, if this operation is performed for the first time, help or at least consultation from a heating engineer.

The heating element is inserted into a cast iron radiator in the same way as into a steel pipe radiator - from below, instead of the standard plug.

A safety valve is installed in the upper diagonal liner of the cast iron radiator - a valve with the possibility of emergency pressure relief.

Important! Cast iron works less well under tension, so higher requirements are placed on the system for protecting a cast iron radiator from excess pressure than on a heater made from steel pipes.

Based on the above, it is better to entrust the manufacture of an oil heater from a cast iron radiator of a central heating system, especially a security system, to a specialist who has practical skills in performing this type of work.

Exploitation

Precautionary measures:

- Before you start using the device, make sure that the voltage in the apartment outlet corresponds to that recommended by the manufacturers.

- If you are not using the device, unplug it from the outlet.

- Do not leave the device on when there is no one in the room.

- Do not cover the device with clothing, this will cause overheating or a fire. It is better to place it at a safe distance from flammable substances.

- Keep the device clean.

- In the event of a breakdown, do not try to disassemble the radiator parts yourself; it is better to leave this work to professionals.

- Supervise children closely if they are in the same room as the device is in use. Do not allow them to play with the cord or appliance, as this may result in short circuit, electric shock or fire.

- Carefully monitor the condition of the device itself, the wire and the plug. Do not use the heater if the cord or plug is damaged.

- The device is intended exclusively for indoor home use.

Preparing for work

If the device was purchased in the cold season, then it must be carefully unpacked, placed on wheels and left for at least 3 hours.

After this, plug the radiator into a grounded outlet and leave it to work for 1 hour in a ventilated area. This will evaporate all foreign odors that may appear at the initial stage.

Oil Cooler Maintenance

Oil heaters do not require special maintenance during their service life, unless there are any complaints or complaints.

- If you need to store the device for a long time, wipe it with a slightly damp cloth to remove dust and dirt, disconnect the cord, and roll it up carefully. Remove the support wheels and put them in a box, which you close tightly.

- When you need the heater again, take it out of the box, wipe it off again from dust, and reassemble it. Carefully inspect the device for any deformation or oil leakage.

Remember, special oil is used for radiators.

Carefully inspect the cord for cracks and damage. If the components are in order, you can start using it as usual.

Oil cooler disposal

When the oil heater becomes unusable, it must be disposed of according to the following scheme:

- Cut off the power cord from the unit.

- Drain the oil, which is dangerous for humans, and hand it over to a special collection point.

- The body can be sold for scrap.

WE MEASURE FUNCTIONAL PARAMETERS

This part of the test is one of the most interesting. We will find out how efficiently the devices heat, how the temperature will change while maintaining the set value, how many kilowatts we will use, and we will be able to understand how much additional heat will cost us.

Heating the room

How were the measurements taken? To correctly compare the heating capabilities of the heaters, they were placed in a test chamber: an unheated room with an area of 10 sq.m. Each device was tested separately. The heater had both heating elements turned on, i.e. it worked at the maximum heating level. The time it took to heat the room by 10°C and the energy consumption of this process were measured.

The conditions were as close as possible to real ones: after all, in winter there are constant heat leaks in the house both through the windows and through the walls. The more interesting!

The Scarlett SC-1167 heated the air the fastest (65 min), the slowest was the Beko BRZ-2009 (2 hours 51 min). Why is this happening?

For each heater, the thermostat is configured differently: for some, “overclocking” occurs with continuous operation of two heating elements, while for others, with periodic shutdown of one or two heating elements.

Keep the temperature

The second important task of any oil heater is to be able to maintain the temperature in the room while spending a minimum of energy. After the set temperature was reached, it was fixed by smoothly turning the thermostat knob until it clicked. After this, the devices worked, trying to maintain the set temperature.

The operating algorithm for different devices was different: some devices (Aeronik PO-1123M, Scarlett SC-1167, Timberk TOR 21/2009 HA, Unit UOR-920) worked for some time at maximum mode, turning off the heating for a short period of time (from 2 up to 5 min); De'Longhi TRD0820ER alternated operation in maximum and medium modes, and VitekVT-1729 BK - in maximum and minimum modes, Beko BRZ-2009 maintained the temperature, including only the middle heating stage.

Such on/off modes lead to some temperature fluctuations. The smaller this range, the better. The measured fluctuations turned out to be very small. After all, oil radiators are inert: after switching off, hot oil is in no hurry to cool down. The minimum range for De'Longhi TRD0820ER and Unit UOR-920 is only half a degree, the maximum - 1.33? C - for Scarlett SC-1167. Such deviations are absolutely invisible without special measurements.

In addition, the change in temperature was recorded while maintaining a given heating level - i.e. deviation from the set temperature after a long period of time (several hours of operation until a steady state when the temperature no longer changes). The fact is that heaters tend to slightly “overheat” the room over time. All models passed the test with dignity; the maximum increase of +1.83? C for the Scarlett SC-1167 is very small and imperceptible to humans.

Economical

How much energy will we spend to ensure that in a room of 10 sq.m. Has it become 10*C warmer? It turned out that the Vitek model (1.75 kW) spends the least amount of energy on heating, while the Beko BRZ-2009 (2.6 kW) and Aeronic PO-1123M (2.5 kW) are the most wasteful.

In addition, the energy consumption when maintaining the temperature in the room was also measured. The most economical heater turned out to be the Beko BRZ-200 (0.88 kW*h), and the most “expensive” were the De'Longhi TRD0820ER (1.56 kW*h) and Scarlett SC-1167 (1.43 kW*h).

Ease of use and ergonomics

It would seem that the oil radiator is conceptually simple: plug the plug into the socket, and it becomes warm. But this is only at first glance. There are a lot of little things that make working with the device pleasant, and vice versa. This part of the test is intended to introduce us to the ease of use of oil heaters.

Preparing for work

The first thing you have to do after removing the device from the box is installing the supports. A rare specimen does not require screwing on the legs and wheels. In our set, such an extraordinary device was the De'Longhi TRD0820 with its “Easy Wheel” system (see the instructions for the exact name). For other models, the roller bearings are attached to the body with U-shaped holders with wing nuts.

Switching on-switching heating stages

Heating levels are controlled primarily by keys. This is characteristic not only of the devices being tested, but reflects the situation on the market as a whole. In our seven heaters, the De'Longhi TRD0820 and Vitek VK-1729 BK turned out to have a more convenient and expensive design, electronic, which allows you to see on the display what exactly is being switched.

Thermostat control

What should be the adjustment? Smooth, with easy movement of the rotary wheel, if there is one, with a clear click. A click is produced by the bimetallic strip at a certain set temperature level when the heating stops. Aeronik PO-1123M and Scarlett SC-1167 turned out to be close to ideal.

The De'Longhi TRD0820 and Vitek VK-1729 BK were unbeatable with their electronics: both models allow you to set temperature values accurate to a degree. The De'Longhi TRD0820 allows you to adjust the temperature using the remote control.

On the Timberk TOR 21.2009 heater, unfortunately, the handle touches the body when adjusting.

Operation indication

The indicator must be bright! Same as De'Longhi TRD0820 and Vitek VK-1729 BK. These heaters received the maximum score, the rest had a “good” rating.

Marking

What is required from labeling? Visibility, durability, contrast. In general, the devices performed well during testing, but no one earned maximum marks.

Moving the heater

Fortunately, our home heat carrier is not stationary. And if so, he must easily move around the room on rollers. The handle by which you will transport it should be comfortable. The Timberk TOR 21.2009 had the best rollers and handle - the heater received the highest score.

Power cord storage

To wind the cord, as a rule, a special reel is provided at the end. How should the cord be stored? For example, like the Unit, in which it is located on a wide, convenient device, and the plug is clearly attached to the top.

Cleaning and care

The issue of hygiene for a heating device is very, very relevant. A smooth body and a minimum of nooks and crannies where dirt and dust can hide distinguish four of the seven heaters. The De'Longhi TRD0820 protective cover, which added points to the model at other stages of testing, let it down here. There are plenty of hard-to-reach places to clean!

Instructions

Reading instructions is a fun and useful activity. Thanks to him, you can get closer to the acquired miracle of technology, find out what is necessary for it to serve faithfully. Well, or, at least, how to assemble this miracle. The description should be well illustrated, detailed, intelligible and logical, for example, like the De'Longhi TRD0820 and Aeronic PO-1123M. If the font, like the Beko BRZ-2009, is small, it becomes difficult to get to know the device. What can we say about the instructions for Vitek VK-1729 BK, whose font is pale blue and vanishingly small, and the paper is high-quality, glossy... and reflective?

Guarantee

The warranty period for storage of oil radiators is 1 year, and for use - 2 years.

During the warranty period, the manufacturer guarantees satisfaction of the buyer's requirements related to problems in the operation of the radiator, subject to the rules of operation, transportation and storage of the device.

Warranty obligations are fulfilled only if the fact of purchase is confirmed by a receipt, where the date of purchase is clearly visible.

Warranty obligations are not fulfilled in case of mechanical damage to the device, such as dents, scratches, or other defects.

Malfunctions

The most common problems with oil radiators are:

- A cracking noise is heard when turned on and during the first 10-15 minutes of operation. If after this time the cracking disappears, it’s okay. It occurs when the oil inside the radiator heats up.

Perhaps drops of water got into it, which causes such a reaction. This is possible if the device was assembled in conditions of high humidity.

- The radiator does not turn on. First, carefully inspect the cord and plug for cracks or creases. If they are not found, try plugging the heater into a different outlet.

If this does not work, then the problem is in the contact, which has come loose. Try to repair the device yourself or send it to a service center, where experienced technicians will solve the problem.

- The device turns on, but does not heat up. At the same time, indicator lights, a fan and other additional devices on the case work.

The cause of such a breakdown is problems with the thermal relay; it cannot be eliminated without special tools. Contact the service center.

- Oil is leaking. Such a breakdown occurs due to a manufacturing defect (poorly sealed seam) or a long period of use of the device.

Over time, the metal at the joints burns out and becomes thinner, which leads to this type of failure. Unfortunately, it is impossible to repair an oil leak either independently or at a service center.

If the breakdown is serious, you should carefully consider the prospect of buying a new radiator, because sometimes repairs cost more than a new device.

Additional features

- Almost every heater has a light indicator. It shows when the heating element is working. When the room temperature reaches the desired temperature, the heating element stops heating and, accordingly, the indicator goes off;

- The thermostat can be mechanical or electronic.

The mechanical option is more reliable and in case of malfunction it can be easily and quickly repaired without large financial costs. An electronic temperature controller is more expensive, as its functionality is much wider. For example, you can program operation at certain times of the day or even days of the week. In addition, it more accurately maintains the set temperature; Mechanical thermostat Electronic thermostat - Overheating protection will prevent fire. If the heating element starts to overheat, the protection will automatically turn it off;

- When heated, the oil expands and if it heats up above the permissible temperature, the radiator may rupture. To prevent this from happening, good heaters are equipped with boil protection. The protection itself is a two-component sensor, which, when overheated, breaks the circuit and disables the fuse, the replacement of which will not hurt your pocket;

- The timer allows you to set the operating time of the device. If you want to come home from work to an already heated house, you need to set the timer for the work time two hours before returning;

- An air humidifier solves one of the main problems of heaters - air dehumidification. The design is very simple - there is a container with water on the radiator. When heated, the water begins to evaporate and due to this the air is slightly humidified;

- The fan heater allows you to warm up the air faster. It is installed inside the device and releases streams of warm air during operation;

- Many users dry things directly on the heater, but this is prohibited by safety rules. Therefore, a removable clothes dryer solves this issue.

Important! You cannot turn on the heater if the overheat sensor does not work. The unit will increase in temperature without stopping, which can lead to rupture of the housing. If you ignore this rule, there is a risk of fire.

Manufacturers of oil heaters

Ballu

The company is known for high-quality products with a matte textured coating, which increases heat transfer by 20%. The products are coated with an anti-corrosion compound, which prevents the device from rusting.

The new generation thermostat closely monitors the room temperature. Among the distinctive features, it is necessary to highlight the special design of the legs, which make it impossible for the heater to fall.

De'Longhi

The advantages are absolute noiselessness when the heaters operate, uniform heating of the rooms and the absence of open heating elements that can cause burns.

The combination of efficiency, functionality and quality makes the heaters of this company in demand.

Oasis

The main direction is the production of high-quality heating equipment, among which a special place is occupied by oil radiators of various types: cast aluminum, steel, panel and bimetallic radiators.

Recahta

A Russian brand that has won a large number of fans in a short time.

The company is constantly moving forward, making oil radiators more and more advanced and of higher quality, providing them with a large number of additional features.

Scarlett

The company does not specialize exclusively in heaters, but has a wide selection of products for the home.

Sinbo

The company has been in the heating equipment market for more than 30 years, but does not have a huge number of oil radiator models.

Among 5 models that differ in appearance, power and number of sections, everyone can choose the option that suits them perfectly.

Design Features

Let's consider what elements the design of an oil heater consists of. The radiator housing is made of metal with a thickness of 0.8-1 mm. The section plates are securely soldered to each other, ensuring tightness. On the outside, the metal of the case is coated with heat-resistant paint and white or black enamel.

The heating element (heating element) runs on electricity. It is located inside the device, which is filled with mineral oil to 85-90% of the internal volume. This is due to the fact that when heated, the liquid expands, filling the empty space.

The design of the oil heater is equipped with additional elements:

- Temperature regulator,

- thermostat,

- protective device that protects against overheating.

The radiator heating element is connected to the network using an electrical wire. Legs with wheels are attached to the lower part of the body, which are responsible for stability and convenience when moving the heater.

Some models have a plastic casing. It protects against burns if you accidentally touch the hot body of a working device. The protective cover is included or purchased separately.