Good time. This morning was really good. The sun was truly spring. It’s warm.. And the first thing I decided to do was... plant onions. It's really unexpected. Don’t make a stove, but plant onions on the greens. Crazy old man, I myself was surprised at my reckless courage. After all, it’s March 7th. But you shouldn’t blame me indiscriminately. I was led to this decision. First, onions in the underground - which have already sprouted. It would be a shame to throw it away, because no matter how little, 3 bags will rot. Second, to my surprise….. sprouts of young onions appeared in the garden, which had not been harvested since the fall… I planted everything, and began to wonder, scratch the top of the head.. What else could I create?. So I went to get some bread. I walked the dog, I have a noble one - with the name Goddess, if translated from Sanskrit. On the way, I told the electrician everything I thought…..and no, he can’t open his mouth. And if it happens, I’ll close it for him myself and sprinkle some earth on him... He confused the phase with zero... It was a good day! The thermometer showed +20 degrees.

Looking at it, my thoughts drew a parallel between degrees and a thermocouple. We need to make a kiln. Project kiln for firing ceramics, day 3 continued under the link..... Using my miracle markings, I marked the barrel for drilling holes for fastening buttons. In the bottom half of the oven, around the entrance (where the burner is) and around the top edge. That is, it turned out, if you look from the side, one line from the edge. Because I think it will be enough. In the Upper half it is also the stove lid, around the outlet, along the edge of the lid, and on the side, in a circle from two edges. Now about cutting out the thermomat. The diameter of the barrel is 60 cm. It’s lucky, because the width of the mat is 60 cm. This means that the circumference of the barrel is 180 cm. I need 3 layers of 60 cm each for the bottom and roof. I cut 180 cm and fold it into a square. You need 2 such squares. But first you need to make the walls. I cut another 360 cm, fold it in half to make a strip 360 x 30 cm and roll it out along the wall. It turns out 4 layers with a slight overlap. Which was cut on both sides and set into each other. Like layers in a Napoleon cake. In total, the total thickness of the layers is 8 cm. The same procedure with the lower part. All this will be sewn with buttons. Now lining the top of the lid or how to fit a square into a circle. Of course you could cut the edges in a circle. But the small, domestic, amphibian pet fiercely grabbed its throat, screaming about the inadmissibility of wasting a valuable resource. I had to bend the edges into the inside of the barrel. It turned out beautiful and weighty. Below is another song. Because I planned to lay an additional layer of fireclay bricks - I had to cut circles out of felt. Cried and cut. Remembering hedgehogs and cacti. Well, the time has finally come to attach the buttons with nichrome wire. And then I realized that I had forgotten where she was. …I searched, searched, searched, searched…. And that’s it….I found a fur-bearing animal…. Now you have to wait until the end of the weekend to buy a spiral for the stove..... Don't tell me until you jump over. Happy holiday dear women..

Source: vk.com

What to look for when choosing a stove?

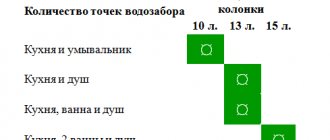

Muffle units are more suitable for amateur ceramists. For professionals engaged in more or less large-scale activities, the best option is camera equipment. When choosing a device, you need to rely on:

- on the volume of daily firing;

- product dimensions;

- electrical wiring requirements (some units are designed for three phases).

The format of loading ceramics is also important. You need to build on your own preferences and financial capabilities. Vertical loading equipment will be appreciated by specialists with a limited budget. Moreover, the result in the “cheap” case is no worse than in the other case. The degree of comfort in viewing products from above depends on individual characteristics.

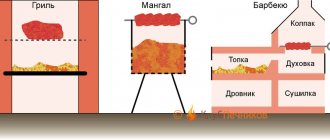

Figure 7. Top-loading wood burning equipment

When loading horizontally, it is not so easy to assess the distance between products, but there is an excellent overview of the tiers. To get a 360-degree view of the ceramics being processed, you should purchase bell-type furnaces. It is also the most expensive.

The cost of budget, “home” models starts from 30,000 rubles. The lower price level for professional options is about 100,000 rubles. The price of powerful, productive furnaces reaches half a million rubles.

Figure 8. Furnace chamber with hot ceramics

Classification

Special kilns are manufactured industrially. Among them there is also professional equipment, which is quite expensive (from 35 thousand rubles). However, it is not necessary to purchase such devices. You can also make them yourself. There are several classifications of kilns. One of the most important criteria is the operating temperature.

The highest category is equipment where heating is carried out to

1400-2000 °C.

The next group is furnaces operating at temperatures of 900-1400 °C. (400-900 °C) operate at moderate rates . And the last group is characterized by low temperature conditions (up to 500 ° C) . The most beneficial are ovens with the ability to regulate the temperature.

Depending on the energy sources used, such firing devices are divided into electric, gas and solid fuel. Industrial designs are only of the first and second types. As for wood-burning equipment, these can only be homemade stoves. The use of solid fuel is not capable of heating to high temperatures.

Another important indicator of the furnace’s performance is its power. For small units with a chamber volume of up to 50 liters, the following rule must be followed: 100 W per liter. If the unit has a large chamber volume (100-500 l), the ratio will be different: 50-70 W per 1 l.

According to their configuration, furnaces are divided into three types:

- Bell bells.

- Tubular with vertical loading.

- Chamber with horizontal loading.

The advantages of tubular devices include the uniform distribution of heat in them. The other two types are more suitable for mass production and firing of large products. For insufficiently experienced craftsmen, furnaces equipped with a viewing window are suitable, allowing them to control the firing process.

Modern units are equipped with fire-resistant elements made of high-quality materials, which are characterized by low weight and low thermal conductivity. Heavy structures using fireclay are already a thing of the past.

Types of furnaces

There are different types of thermal energy sources:

- The oldest is the wood stove. The masters kept the secrets of firing and passed them on only to their students. Today, wood burning is very rare. Technological types have replaced them.

- The most popular is natural gas. With forced air injection, products can easily be heated to temperatures above 1500 °C. Gas equipment is easy to make with your own hands, and gas can be purchased in liquefied form in cylinders.

- The most high-tech is electricity. Electric spirals are evenly laid inside the oven, quickly and accurately heating the chamber with the products. Such equipment is more difficult to manufacture; high voltage requires compliance with safety precautions and electrical installation rules.

Photo 1. Small electric kiln for firing ceramics with evenly laid out spirals inside.

Wood-burning: structure and principle of operation

This is a great option for a beginner potter. It does not require large material costs to manufacture, and dry firewood is available everywhere. Wood stoves come in several types:

Earthen

A descendant of the ancient technology of burning in a fire flame. Above the narrow pit - the firebox - a clay roof is built on which the products are laid. A vault of bricks or strips of clay is built around the products, and a smoke hole is left at the top. The design works like this: charcoal is burned in the firebox, which gives a high temperature and does not smoke.

Hot gases without flames pass through the chamber with the products, heating them, and exit through the hole at the top. The temperature is regulated by the amount of coal and the “latch” on the chimney. After cooling, the stove roof is disassembled and the finished products are taken out.

Such a stove is suitable for one-time work, since each time you have to lay it out again. But, despite the labor intensity, the option is the cheapest - the cost of components is zero.

Brick

They are assembled from fired clay bricks and fire-resistant fireclay bricks. The operating principle is similar to earthen ones. They consist of a firebox with a grate, a chamber for products and a chimney.

Photo 2. Kiln for firing ceramics made of refractory bricks with a chimney and firebox on the street, next to the house.

The difference is that the design is reusable and more efficient. Products are placed into the chamber through a collapsible wall or door; the stove can be heated with wood - the flame does not reach the products.

Reference! It is important to use dry firewood, otherwise the products will pick up moisture and become cracked. Brick has high thermal conductivity, the stove cools down, so this design is voracious

Metal with lining

Thanks to the use of basalt and kaolin insulation, a wood-burning stove becomes more heat-resistant and efficient. Such a stove consists of a firebox on which a metal container is installed.

Photo 3. A ceramic kiln with an unheated metal body and lining has heat-resistant properties.

The walls and roof are insulated with non-flammable material; sometimes the metal frame does not even heat up. The heat from burning wood in the firebox rises, heating the products, and the cooled streams of air descend and rush through the chimney into the chimney. These stoves are much more economical than brick stoves and are easy to manufacture.

The downside is the need to use expensive insulation, the plus is the durability and mobility of the structure.

Gas

Has a number of advantages:

- The gas burns completely and contains no moisture.

- Gas burners develop high temperatures.

- Temperature regulation is easy.

A gas furnace for firing ceramics is made using different technologies:

Muffle. A muffle is a separate sealed chamber in which ceramics are heated and makes it possible to produce earthenware and porcelain, since the workpieces do not come into contact with hot gases - combustion products.

The muffle is placed in the combustion chamber and the flames are distributed evenly over the entire area.

Chamber. Excellent for firing conventional ceramics. Products are loaded into an insulated chamber through which hot gases pass. The burner is installed lower and separated by a partition. The temperature distribution occurs evenly, when cooled, the gases exit into a special hole at the bottom of the chamber.

Device

Regardless of whether you are making a ceramic kiln from a barrel or using an industrial version, each design is made from several main parts:

- The outer casing of the unit can be made of stainless steel or an old refrigerator. Its main task is to create a power frame around the internal firebox and oven. Steel structures are not competitors to brick buildings, which will last a long time. To manufacture the steel outer casing we use steel, sheet thickness from 2 mm.

- Inner layer of thermal insulation. To do this, use fireclay brick or other heat-insulating material that can withstand heating temperatures above 2000. The performance of the device and heat loss depend on the heat-insulating qualities of this layer.

- A layer of thermal insulation between the inner layer and the oven body. Use mineral wool, basalt wool, and perlite. It is not recommended to use sheet asbestos. At high temperatures, the material releases substances harmful to humans.

- Chambers for laying clay products and heating elements. For electric furnaces, nichrome spirals or air heating elements are used. These devices are installed in grooves that are selected in fireclay bricks. Nichrome wire is the best option for electric furnaces. Gas burners are installed for gas.

Lining

The dimensions of the furnace are multiples of the dimensions of lightweight fireclay bricks ШЛ-0.5, standard size No. 5. Brick dimensions 230x113x65. In the photo it is white. Yellow ones are some other refractory brick with slightly different dimensions. But for my needs this is not important. If necessary, I will make everything from ShL-0.5. Since lining a door with bricks is another task, so for lining the door I used a Cerablanket mat (blanket) from the Sukholozhsky plant.

resistance up to 1260 g (in practice, withstands the direct flame of a gas burner). Sold by the meter in rolls 610 mm wide, thickness from 13 to 50 mm. I would like to warn you against some ambushes that may await you when making the lining. First of all, I want to warn you if you are tempted to use asbestos. Yes, it melts at 1500 degrees, but at 800 degrees it loses chemically bound water and turns into powder. Therefore, products made from it, such as cardboard or cord, can work up to this temperature.

Regarding the use of fibrous materials on a mineral (basalt) basis, I will repeat what I wrote on one of the forums. It's almost the same thing. Produced by melt blowing. Holds temperature well. But they have a binder that will not withstand even 250 degrees. But on the Internet, cunning sellers cite the fire resistance of the fiber itself. Formally, they are right. But they don’t write that after the first calcination the binder will burn out and they will fall off in a heap. There are varieties with a refractory binder, but there is very little information. Only indirect signs - for example, intended for baths and fireplaces. And again the fire resistance of the fiber itself is tested. So if there is a risk of flying, it is better to use already tested ones.

Of the ones I have tested, mullite-silica felts are most suitable, for example, MKRVH-250 (1300 g) and this Cerablanket. Since mats still had to be used for the door, the vault was also made from it. If necessary, I will lay out everything with an SHL brick, since the camera is already sized for it. The mats are attached to pins made of stainless electrodes. One end is sharpened, the other is welded to the furnace wall with a stainless electrode. The holders are pieces of stainless steel sheets with cross-cut slits.

Operating rules

The electric oven may only be plugged into a reinforced socket. You can also run a large cross-section wire directly from the shield. In addition, it would be useful to install a circuit breaker.

Since this device model has exposed wires, you need to be extremely careful with it. Do not touch the coils while the oven is running. To avoid accidents, it is recommended to install a limit switch on the door, which will turn off the unit when the door is opened. If you are not very good at electrical work, seek the help of a specialist who can help make the device as safe as possible, including grounding it.

Method two. We make a stove without having a metal casing at hand

The manufacturing process in this case is not much different from that described above, but there are definitely some nuances here. Let's start with the fact that the working volume of the design below will be about 13 liters. The spiral, as mentioned above, can warm up to a thousand degrees in just 1.5 hours, while the temperature of the outer walls of the device will not exceed 100 degrees. The algorithm of actions should be as follows.

Step 1. First, using a 4x2 centimeter profile pipe (with a square cross-section), we build a stand for the device. After this, we paint the finished stand with enamel.

Step 2. We attach a sheet of galvanized steel on top of the stand (its thickness should be approximately 0.1 centimeters), using “metal” self-tapping screws.

Step 3. We make the walls from fireclay bricks and a special fireplace composition (everything is the same as in the previous version). After the solution hardens, we make grooves for the spiral.

Step 4. We assemble the bottom from brick separately, and use the same mortar for fastening. Before continuing work, wait until the structure is completely dry. Do not forget to wet each brick immediately before laying.

Step 5. We lay a thermal insulation layer on top of the metal base (we can use the same basalt wool for this). In order to maximize compaction of this layer, it must be moistened before fixing the brick bottom.

Step 6. We continue the traditional laying of the stove, but we try to ensure that all voids and seams are carefully filled.

Step 7. We traditionally make the lid for the chamber from fireclay bricks, but at the same time we fasten them together with a metal tie.

Step 8. Place the spiral in the prepared grooves and insulate the structure from the outside with thermal insulation material. Next, we cover everything with sheets of galvanized steel, which are cut according to the dimensions of the resulting chamber.

As you can see, this requires knowledge not only in the furnace business, but also in the field of electricity. You can see another possible manufacturing method in the video below.

Video - wood burning stove

How to make a Bubafonya stove yourself

Previously, we talked about how to make a Babufonya stove on your own, in addition to this article, we advise you to read this information, see all the details here

Specifications

Fireclay refractory clay is fired in special drum kilns at a very high temperature. During processing, all moisture will evaporate from it. As a result, it becomes like a stone. At the final stage, pieces of clay are ground in mills to fine or coarse grains. According to the standards, fireclay clay must have the following characteristics:

- moisture absorption – about 7.8%;

- grain size – on average 1.9 mm;

- moisture content – no more than 5%;

- fire resistance – 1530-1839 C.

The main advantage of fireclay clay is that it does not shrink. Consequently, masonry joints and plaster do not crack when dry.

When considering the technical characteristics of fireclay clay for oven plaster, it is necessary to note the following:

- The grain size corresponds to two millimeters.

- Highly fired fireclay absorbs no more than 10% moisture, and low fired fireclay absorbs no more than 25% moisture.

- The maximum temperature that the material can withstand is 1850C.

- The humidity of quality material does not exceed 5%.

When determining the required amount of material, you should know:

- A standard 20 kg package of clay is enough to lay 30 bricks.

- For 1 m3 of masonry, you should purchase 100 clay.

- A solution prepared with precise adherence to technology becomes absolutely solid after 24 hours, provided that the air temperature does not fall below 10C.

How to choose the right camera size

Which oven to choose based on the size of the chamber. Someone immediately thought, the more, the better and immediately passed it by. In fact, it's better to speculate a little. Estimate how much work is approximately being done and how much will be offended at one time. If you buy one that is too small, the firing time will make any ceramist nervous. The work will be idle and deteriorate. This will also happen if the size selected is too large. The energy consumption will be enormous, but only a small part will be fired. The master will begin to put several works aside, which will wait their turn, when at this time I could already paint the finished works and cover some with glaze.

Thermocouple

The thermocouple has been used for measuring the temperature in a furnace for quite some time. At the same time, it has established itself as a reliable measuring device. Essentially, these are two wires consisting of different alloys, which are connected to each other by welding.

When measuring temperature, a current is generated at the ends of the wires, and the higher the oven temperature, the more millivolts we get at the output. Using special devices, you can easily convert millivolts into a temperature indicator.

There are a huge number of types of thermocouples, which consist of different alloys. A type K thermocouple is intended for the muffle furnace. It consists of a chromel-alumel alloy and is designed for temperatures up to 1300 °C. For high temperature environments, it is recommended to use a thick wire thermocouple.

You can measure the temperature inside the furnace with a thermocouple using various devices. We will describe some of them below.

A multimeter is an affordable measuring device; in its design, the function of determining temperature with a K-type thermocouple is immediately thought out. Basically, this type of converter is immediately sold in a set with a multimeter. The only drawback is that the TCA proposed in this version is thin and quickly breaks down at high temperatures.

You can also use type S thermocouples based on platinum-rhodium-platinum alloys. They are more expensive than K-type thermocouple alloys, but withstand high temperatures better as they are rated for 1600 °C and will last longer. According to the standard, such a thermocouple is supplied already in a protective casing.

The thermal converter TPP, like the thermocouple K, is connected to an electronic converting device. Thus, it is possible to easily determine the temperature in the oven and regulate it using a user program.

The TXA converter is another type of meter connected to the controller

It is important here that the length of the wires is sufficient. If the wiring is initially short, then you can use special temperature compensation wires

It is important to understand that the material of the extension wire must consist of the same alloys as the material of the converter itself. But its diameter should be smaller.

By connecting a thermocouple to the controller and connecting them to power, you can immediately find out the temperature in the muffle furnace. To make firing even easier, use the controls and automatically control this process.

On the Tekhnonagrev website you can choose the most suitable thermocouple option and extension wires. If necessary, contact our managers for advice.

When working with a muffle furnace, do not forget about protective equipment. Even when a stove is more than adequately insulated, its outer surface can become hot enough to seriously burn someone if touched with unprotected skin. Therefore, use the following personal protective equipment:

Kiln mitts or gloves: These should be worn when handling any part of the kiln (other than the control panel) while it is firing or cooling. Even after turning off the power, the oven will remain hot for several hours. Do not open or touch it until completely cooled.

Sunglasses. It is recommended to use special safety glasses to observe openings in the oven. They protect your eyes from radiant heat. Regular sunglasses are not suitable for this purpose and can even cause harm, because... not designed for high temperatures. Safety glasses may also allow you to see your cones, if you are using them, more clearly.

Z.Y.

For those who want to suffer, I am posting drawings of the furnace. The pictures are clickable. If you save the drawings via the link, print them and put them together, then there will be a front view drawing on top, and a top view on the bottom of the same drawing. This is me so as not to draw extra lines