A heat meter is a device for recording consumed coolant, which is currently very profitable, as it allows you to save money by paying only for consumed heat, excluding overpayments.

An important point is the correct choice of the type of device depending on the installation location and design features of the heating network, as well as concluding an agreement with a service organization that will monitor the technical condition of the device.

There are many models of heat meters, differing in design and size, but the principle of how a heating meter works remains the same as with a simple device that measures the temperature and water flow at the inlet and outlet of the pipeline of a heating supply facility. Differences appear only in engineering approaches to solving this issue.

Tachometer heat meters

Tachometer heat meters (vane, turbine, screw) are the simplest devices.

The principle of operation of mechanical heat meters is based on the transformation of the translational motion of the fluid flow into the rotational motion of the measuring part. Mechanical heat meters consist of a heat calculator and mechanical rotary or vane water meters. These are the cheapest heat meters yet, but to their cost it is necessary to add the cost of special filters that are installed in front of each mechanical heat meter. As a result, the price of such kits is 10-15% lower than heat meters of other types, but only for nominal pipeline diameters of no more than 32 mm. For larger diameter pipelines, the price of mechanical and other heat meters is almost equal or even higher. The disadvantages of mechanical heat meters include the impossibility of using them in conditions of increased water hardness, the presence of small particles of scale, rust and scale, which clog filters and mechanical flow meters. For these reasons, throughout almost all of Russia, the installation of mechanical flow meters is permitted only in apartments, small private houses, etc. In addition, mechanical flow meters create the highest water pressure loss compared to other types of flow meters.

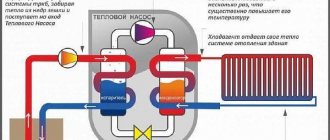

Diagrams of thermal units

If we talk about the schemes of heating points, it should be noted that the most common types are the following:

- Thermal unit is a circuit with a parallel single-stage hot water connection. This scheme is the most common and simple. In this case, the hot water supply is connected in parallel to the same network as the heating system of the building. The coolant is supplied to the heater from the external network, then the cooled liquid flows in the reverse order directly into the heat pipe. The main disadvantage of such a system, compared to other types, is the high consumption of network water, which is used to organize hot water supply.

- Diagram of a heating point with a sequential two-stage connection of hot water. This scheme can be divided into two stages. The first stage is responsible for the return pipeline of the heating system, the second - for the supply pipeline. The main advantage of thermal units connected according to this scheme is the absence of a special supply of network water, which significantly reduces its consumption. As for the disadvantages, this is the need to install an automatic control system to configure and adjust the heat distribution. This connection is recommended to be used if the ratio of the maximum heat consumption for heating and hot water supply is in the range from 0.2 to 1.

- Thermal unit is a circuit with a mixed two-stage connection of a hot water heater. This is the most universal and flexible connection scheme. It can be used not only for normal temperature schedules, but also for elevated ones. The main distinguishing feature is the fact that the heat exchanger is connected to the supply pipeline not in parallel, but in series. The further principle of the structure is similar to the second scheme of the heating point. Thermal units connected according to the third scheme require additional consumption of network water for the heating element.

Electromagnetic heating meter

This is an expensive model of thermal devices, and is one of the most precise devices. The principle of operation of an electromagnetic meter is that the coolant passes through the device, while the electromagnetic field conducts a weak current. This device needs to be maintained, that is, cleaned periodically.

Rice. 4 Electromagnetic heat meters

The electromagnetic device consists of 3 main parts:

- Primary converter;

- An electronic unit that can operate both from batteries and from the mains;

- Temperature sensors.

In this case, the electromagnetic heat device can be installed in any position (horizontal, vertical, or at an angle), but this is only in the case when the area where the meter is installed is constantly filled with coolant.

If the diameter of the pipe does not match the diameter of the device flange, then adapters can be used.

What the law says

The law in 2022 does not oblige the installation of individual heat energy meters in the apartment, but does not prohibit it either. In order to install a meter in an apartment, the meter must also be installed at the entrance to the building. According to Article 13, paragraph 5 of Federal Law No. 261-FZ of November 23, 2009, every apartment building must be equipped with a heat meter. So if the management company adheres to the law, then we can assume that the general building meter is installed by default.

Based on the law, Article 157 of the Housing Code of the Russian Federation, payment is made on the basis of a common building meter, and then the amount received is divided among all residents, taking into account the square footage of the apartment.

If the meter is also installed in the apartment, then the owner pays for the heat consumed by it and for general house consumption for heating the entrance, basement, or attic.

Operating principle of the heat meter

01 January 2015. Written by Super User. Posted in Useful articles

Heat meters, by their nature, come with a mechanical and ultrasonic flow meter, which determines the cost of an apartment heat meter. The heat meter is installed on both the supply and return pipelines of the heating system, which is permitted by the manufacturer. How does a heat meter work, a heat meter for an apartment. The principle of operation is based on the amount of water that passes through the installed heat meter and the difference in coolant temperatures in the supply and return pipelines. As everyone knows, hot water enters the radiators (radiators) and heats the air inside the room, from which we get the difference in water temperatures at the entrance and exit from the apartment.

Q - amount of heat consumed

m—mass flow rate of coolant, [m 3 /hour]

c — heat capacity of the coolant, [Gcal/kg⋅°С]

t1, t2 are the temperatures of the coolant at the entrance to the system and at the exit from it, respectively,

The heat meter data from the water flow sensor is transferred to the computer, and it also receives data from two temperature sensors, which are respectively located in the supply and return pipelines. The computer processes the original data and stores it in the archive. All necessary information for the user is transmitted to the screen and can also be read by a data collection system via radio channel or wired Mbuss.

Generating a report:

You have installed an individual heat meter (heat meter) and the question immediately arises of how to read the information and generate a report for the heat supply organization. It is necessary to study the operating instructions for the installed heat meter, which describes how to correctly view the necessary information. Depending on the manufacturer of the heat meter, thermal energy is displayed on the display in different physical quantities. This is necessary, 1 Gcal = 4.187 GJ = 1163 kW/hour, for the correct transfer of thermal power. The operating organization often issues invoices according to the tariff in Gcal, so the transfer system must be understood.

Each resident who has purchased a heat meter needs to know that, along with the actual readings of the individual heat meter for the apartment, it is necessary to pay for heating of common areas, such as staircases, elevators, basements, on average 0.5 UAH. for 1 m2 of the apartment’s own area.

The methodology for calculating this payment is based on the following legal documents:

Resolution dated 21 June 2005 N 630 About the confirmation of the Rules for the provision of services from centralized burning, cold supply

and hot water and water supply and a standard contract for the provision of services from central heating, supply of cold and hot water and water supply.

Order 31.10.2006 N 359 About the approval of the Methodology for the recovery of the amount of heat generated by the burning of the fireplace of large apartment buildings, and the corresponding payment for their burning

Order 02/22/2008 N 47 About the confirmation of the Recommendation to sterilize the Methodology for the expansion of the amount of heat produced by the scorching of the fireplace of rich apartment buildings, and the increase in payment for their scorching.

Sheet No. D11-10/37466 dated 10/14/2002. Based on the clarifications of the Ukrainian ZNDPI on civil life, 1.2 recommendations are the coefficient for the recovery of the amount of thermal energy spent on the scorched area of the fireplace and on the unfurnished fireplace. and heat losses.

Types of metering units

| Heating - installation of common house and collective heat supply meters. Of course, installing a heat consumption meter is beneficial, since the monthly amount for heating will be calculated according to current tariffs and based on the readings recorded by the collective metering device. Otherwise, the calculation is made according to the standard using a multiplying factor. In addition, residents of an apartment building have the opportunity to regulate heat energy consumption individually using an automatic control system. | |

| Composition of a heating heat meter: Heat meter – 1 pc. Flow meter – 2 pcs. Temperature sensors – 2 pcs. Pressure sensors – 2 pcs. | |

| Hot water - installation of communal and collective hot water metering devices. What is the difference between a hot water supply metering unit and a thermal energy metering unit for heating? Fundamentally, it’s the same thing. Both metering units include a heat meter with associated electronics, flow meters, temperature sensors, and pressure sensors. However, such a metering unit is usually cheaper, since you can use a flow meter on the return pipeline (circulation) of a smaller diameter, or, if agreed by the resource supply organization, use mechanical water flow meters with a pulse output. In certain cases, such a project may be agreed upon with the RSO. There is a nuance: If the hot water is dead-end, then only one metering unit module is installed, this significantly reduces the cost of the DHW heat meter. | |

| Composition of the dead-end hot water metering unit: Heat meter – 1 pc. Flow meter – 1 pc. Temperature sensors – 1 pc. Pressure sensors – 1 pc. | |

| Cold water - installation of common house, collective cold water metering devices. The devices that are included in the water metering unit can be of different quality and modifications.

A special feature of the HVS unit is the presence of a bypass line for fire extinguishing. In normal operating mode, the valve on the bypass line is closed and sealed by an RSO engineer. |

Household heating meter device features

Common house heating meter.

This device is used in residential buildings. At a meeting of residents, the issue of installing a common building heating meter is decided - a common device has a number of advantages over an individual meter. Firstly, a common house meter will be much cheaper. Secondly, the readings of the device will be calculated in accordance with the number of residents, that is, you do not need to pay so much. This utility service is paid for by the responsible person, who is elected at the meeting. This person is also responsible for purchasing the meter. A common house meter costs much more than an individual type of device, but if divided equally between residents, it will be profitable.

You can install a common house meter yourself. To do this, you need to connect it to the central pipe, which provides heating to the house through the house manifold. The second installation method is reverse installation. This pipe removes waste coolant from the radiator. Both methods of connecting the device are not characterized by the complexity of the work.

The radiator, inside which the heat exchange process is regulated, is also a device for connecting the meter. To avoid problems during its installation, invite a specialist. However, you will have to pay an additional amount for the services of a master. A common house heating meter is installed in the radiator: this will make it easier for you to take readings.

Construction of a heating meter for a common building.

An individual type meter is purchased and installed in the apartment by the owner. He pays for everything: the device, the services of the master, receipts. That is, the heat meter belongs to him personally, he is fully responsible for it. A conventional device like this is an ideal solution in case of refusal of a common house meter. The presence of this device greatly simplifies your life: this way you will be calm about the honesty of payment for heating. Therefore, it is necessary to install a heat meter, even if the neighbors are against the common system.

There are some difficulties in installing an individual meter. For example, if your house has vertical wiring, then the work scheme takes place in several stages, since there is no central part of the heat supply. That is, it is necessary to introduce a riser into all rooms of the apartment.

The problem is solved by attaching a heat meter to the radiator. The radiator regulates the heat transfer process, and the attached device regulates the amount of heat produced. At the same time, the meter works efficiently and for a long time. The price of a heating meter for an apartment is much more expensive, since it is considered more reliable and has a warranty from the manufacturer.

How to choose the right Danfoss heat meters

Products manufactured in Denmark have gained universal popularity and fame throughout the world. It will be necessary to meet the installed heating devices. The wide range presented allows everyone in need to make the most of their financial capabilities to achieve the desired result.

- power supply

- measurement accuracy and error level

- dynamic range of measurement

- functional content

- connection method

- price.

Almost the entire model range is quite small in size, which provides additional convenience during installation work.

Metering devices and savings

Installing devices does not guarantee a real reduction in service fees. What needs to be done to ensure that the amounts in payments become smaller? Having installed apartment metering devices, together with control valves, you will receive and pay exactly as much as you need.

With this approach, your dependence on the actions of your housemates will be lower.

Practical installation diagram for heating meters:

- A metering device is installed at the branch point of the common riser. These works must be carried out only by professionals and sealed by specialists from the management company.

- Thermostats are installed at heating radiators. They help regulate the coolant supply. If there is no money for such a solution, then you can install a regular valve. Remember that it is not advisable to use screw versions. Because the gasket can close the pipe at an unexpected moment, which will lead to a drop in temperature in your apartment.

- Ideally, thermostats should be mechanical or electronic. The essence of their work is simple: they have a temperature sensor, which is located outside the zone of air flows ascending from the battery. After proper configuration, they will provide the system throughput that is necessary to maintain the programmed air temperature in the apartment.

What actions can be taken by owners of premises equipped with a standing heating system? Installing equipment that regulates the supply of coolant to each battery is very expensive. Such a project is unlikely to recoup the initial investment. We must not forget about the need for regular maintenance of these facilities. Installation of electronic thermometers can help owners. They are also called heat allocators. It continuously records the temperature of the air and the surface of the battery.

The cost of such a device is low (about 1000 rubles). It must be attached directly to the radiator. There will be a good incentive to save heat, since payment will be for the resource actually received.

Heating system in an apartment building Heat meters for an apartment building How to change the management company in an apartment building

Design and principle of operation

The basis of a water meter with a temperature sensor is the same as a regular one. When the pressure is turned on, the impeller rotates, the revolutions of which are read and converted by the water meter itself into units of volume. In the classic version - cubic meters. In the case of a flow meter with a temperature sensor, the consumption of hot water is taken into account. More subtle mechanisms come into force. The hot water temperature is taken into account continuously. The temperature sensor takes measurements and consumption is calculated.

According to existing rules, the consumption of water resources is fully paid only for heat of 50 degrees and above. If it is 45-49, then you have to pay 90% of the amount spent, if it is colder - 40-44 degrees Celsius, then 70%. Everything that, according to the temperature sensor, has a temperature below 40 degrees is calculated as cold.

This is an excellent opportunity to save on formally hot water using a temperature sensor. Citizens are deterred by the cost of a water appliance with a temperature sensor, because its price is sometimes several times higher than the market average replacement costs, for example (including the work of a technician, the cost of the device, and the journey to the apartment). The profit from the purchase will not be comparable to the losses. Continuing to pay for barely warm water at unreasonably high prices, the consumer loses more money and nerves - from the understanding that he will pay money again.

On the display of a meter with a temperature sensor it will be written in detail and clearly how much was spent. The information content of the displays depends on the complexity of the model with a temperature sensor, but even the simplest one will provide comprehensive information. The Profit RMD water meter model is in demand among city residents.

Length of the straight section of the pipeline.

Many types of flow transducers require long straight runs upstream and downstream of their installation location for correct measurements. This is relevant for ultrasonic and variable pressure flow meters. But in practice, in the absence of suitable premises, it is not always possible to satisfy this requirement.

Measurement channels.

Modern heat meters are complex measuring systems that can simultaneously account for two or more heat inputs and a hot water supply line. In this case, the heat meter becomes universal and can satisfy the requirements of a wide variety of heat consumers.

Availability of a diagnostic system.

Most heat meters are equipped with a self-diagnosis system, which provides periodic automatic checks of the device’s status and provides information about the nature of the failures that have occurred, the time the failures began and their duration. At the same time, the devices can record emergency situations that arise in the heat supply system, such as the current flow rate going beyond the range set for the device or beyond the settings entered into the device memory, power failure, mass imbalance in pipelines, etc.

Energy independence.

Energy independence must be considered from two perspectives: interruptions of the network (220 V) power supply and operational safety. Power interruptions can be dealt with using uninterruptible power supplies, and safety is important when operating heat meters installed in damp and damp rooms (basements), as well as in social facilities: kindergartens, schools, etc.

Terms of Use.

When choosing heat meters, it is necessary to take into account the quality of the coolant. If there is a possibility of mechanical and gas impurities in the water, then it is not recommended to use ultrasonic and tachometer heat meters

In this case, electromagnetic and vortex heat meters are preferable. If there are ferromagnetic impurities in the water, it is not recommended to use tachometer heat meters and vortex meters with electromagnetic signal acquisition. If there are impurities in the network water that form films or deposits on the inner surface of pipelines, it is not recommended to use electromagnetic heat meters, etc.

Completeness of delivery.

When using single heat meters or composite heat meters obtained from one supplier, the compatibility of its blocks and elements and their performance as a whole are guaranteed. Otherwise, there may be problems associated with adapting the heat meter to specific application conditions and not appearing at the commissioning stage.

Intervalidation interval.

Since the verification interval is an economic category (the cost of periodic verification is up to 10% of the cost of the heat meter), heat meters with the largest verification interval should be selected. Currently it ranges from 2 to 5 years for different heat meters.

Availability and depth of the archive.

Almost all modern heat meters archive information with the ability to subsequently retrieve archived data directly from the device or using additional terminals

In this case, the ability to display archived data on the device display is important.

Cost and reliability.

The cost of a set of various heat meters varies over a wide range and depends on the thermal load of the building, the number of heat measurement channels, the need to measure pressure in the pipeline, the presence of additional external equipment (printer, modem), supplier (domestic, foreign) and other factors. The cost of a heat meter directly correlates with reliability.

How to convey testimony correctly

An apartment heat meter is functionally much simpler than a modern mobile phone, but users periodically have misunderstandings about the process of taking and sending display readings.

To prevent such situations, before starting the procedure for taking and transmitting readings, it is recommended to carefully study its passport, which provides answers to most questions related to the characteristics and maintenance of the device.

- From the liquid crystal display by visually capturing readings from various menu sections, which are switched by a button.

- ORTO transmitter, which is included in the basic package of European devices. The method allows you to display and print extended information about the operation of the device on a PC.

- The M-Bus module is included in the delivery of individual meters in order to connect the device to the centralized data collection network of heat supply organizations. Thus, a group of devices is combined into a low-current network using a twisted pair cable and connected to a hub, which periodically polls them. Afterwards, a report is generated and delivered to the heat supply organization, or displayed on a computer display.

- The radio module included in the delivery of some meters transmits data wirelessly over a distance of several hundred meters. When the receiver comes within range of the signal, the readings are recorded and delivered to the heat supply organization. Thus, the receiver is sometimes attached to a garbage truck, which, as it follows a route, collects data from nearby meters.

Installing a heating meter

Any installation work of the heating system (including installation of a heat meter on the battery) is carried out only by specialists. To start installing a heating meter, you will need:

- Order a device installation project.

- Agree on the package containing documents for installation permission with utility companies.

- If the commission approves, then the project is implemented and heating meters are installed in the apartment.

- The meter is registered with the utility service (otherwise it is considered invalid), after which it is given for use.

Scheme for installing meters in an apartment in a heating system.

After the above procedures, you can call specialists. They have to:

- Implement this project.

- Coordinate documentation on heat supply matters.

- Install a metering device.

- Officially register the device.

- Hand over the heat meter for use and transfer it to the supervision of the supervisory organization.

Any counter must have a passport and certificate. The documentation indicates the period for the first verification of the device by the manufacturer.

This period is also indicated on the device itself in the form of a stamp. During use of the heat meter, it is necessary to check its functionality. Meter verification is done depending on the device model. Usually it is carried out once every 4 years. After the expiration date on the stamp, you should contact either Rostest at your place of residence or an organization that specializes in meter inspections. Manufacturers should also check devices (as a rule, each company has a service center).

How to pay for heating using a meter? To pay for utilities, you should look at the number shown on the device. Next, fill out the receipt, in it you will see the difference between the current and previous readings. Finally, you multiply the number on the meter by the current tariff and pay for thermal energy.

Operating principle of the heat meter

This device has 2 sensors, one of which is called a flow sensor, the second is called a temperature sensor. The task of the first is to calculate the amount of heating consumed, the second is to measure the temperature. The main part of any meter is the heat calculator. This is a kind of calculator, it gives calculation results. To do this, the amount of heating spent on the meter is multiplied by the temperature. This way you get readings from which you then pay.

Installation of a heat meter.

Verification of meters. Verification must be performed once every 4 years. The purpose of this procedure is to determine the suitability of the device. The verifier must make a corresponding note in the device’s passport and issue you a certificate, which will confirm the functionality of the meter.

Features of installation and commissioning

The installation of devices must be carried out by a trained specialist, taking into account the specifics of the heating distribution in the apartment building. The correct operation of the device depends on this.

To install the device, you do not need to change the heating circuit. It attaches directly to the battery. Programmable. The installation algorithm may vary slightly depending on the model.

It is prohibited to use recorders where the following are installed:

- Heated floor systems;

- Heaters or convectors with forced air supply;

- Ceiling heaters with outside air intake function;

- Converters where steam is used as a coolant.

How does a heat meter work, types and characteristics of these devices

For this reason, metering the consumption of thermal energy consumed is only possible by installing a separate meter for each radiator, which is not economically feasible. In this case, it is recommended to install a group meter either on the house as a whole, or on a separate entrance (although the latter option is used very rarely).

So, where to start installing a heat energy meter:

- It is necessary to obtain a document called technical conditions from a local organization engaged in the supply of thermal energy.

The technical specifications usually indicate the location and method of installation, requirements for the meter (conditional bore diameter, temperature range and other data), in addition, an installation diagram with certain regulatory requirements for certain dimensions must be attached.Project for installing a heat meter

- Based on the technical conditions, the homeowner himself has the right to decide which meter to install for heating, but making a choice on his own is not recommended.

The fact is that the next document that needs to be obtained is a project for installing a meter for metering the received thermal energy. The development of project documentation must be carried out by a company that has the appropriate license. Be prepared for the fact that it will take a significant amount of time to develop the project, and the cost of this document is commensurate with the price of the purchased meter.

But it’s worth paying tribute to the designers, in many cases they recommend the most suitable metering device for certain conditions, so it’s worth listening to their advice.

The main thing is not to make a mistake in choosing an organization that will develop a project for installing a heat meter; try to give preference to trusted companies that have real reviews.

- The developed project is subject to mandatory agreement with the heat supply organization.

Although, serious designers resolve all these issues themselves thanks to long-established working relationships, however, this may affect the cost of project development services. - Based on the received permits, you can already select a specific meter.

Usually it is possible to purchase 2-3 modifications from different manufacturers. - Installation work should be entrusted to certified companies. Independent installation of a heat meter or the services of dubious specialists can result in problems when putting the meter into operation.

- Upon completion of all installation work, the meter must be accepted by representatives of the heat resource supplier.

On average, the entire procedure associated with installing a heat energy meter can take 1-6 months, it all depends on the amount of money invested and the efficiency of all organizations involved.

The procedure for legal installation of a heat meter

The sequence of actions aimed at installing an individual heat metering device in an apartment consists of several stages.

Let's look at them in more detail:

- A written application to the house management organization for permission to install a heat meter. Copies of documents on ownership of the living space and the technical passport of the apartment must be attached to the letter.

- Obtaining technical specifications for the installation of a heat meter from a heat energy supplier (usually a management company).

- Preparation of a project for individual heat metering and installation technical documentation. Performed by an organization that has the legal right to provide design services.

- Coordination of design documentation with the heat supply company.

You should not purchase a heat meter before receiving an agreed upon thermal energy project, because Failure is possible for various reasons.

Having all the documentation for the project, all that remains is to choose a heat meter - ultrasonic, mechanical or externally installed, for example, a heat calculator.

A device that is required to save up to 50% of heating costs - it must be installed by a professional. And with a guarantee

For the purchased model, you must obtain from the seller receipts (sales and cash receipts), instructions, warranty card and a copy of the current quality certificate.

The company installing the heat meter must have a license for this type of work.

Before choosing a contractor, it is necessary to evaluate the data on the candidates (Unified State Register of Legal Entities, certificates, SRO approvals), the professionalism of the installers (special equipment, list of installation work, availability of an installation kit), guarantees of the work performed.

The quality of the thermostat installed on the heating radiator is important. It is this that will allow you to control the heating of the battery, and therefore the cost of heat. Please note that in addition to the heat meter, you will need additional devices and accessories: bypass, radiator thermostats, pipe filters, tees, etc.

Please note that in addition to the heat meter, you will need additional devices and accessories: bypass, radiator thermostats, pipe filters, tees, etc.

Sealing the heat meter or heat distributor after installation work is mandatory.

The seals are placed by representatives of the heat supply company.

Main technical characteristics

Performance characteristics

Heat meters provide measurement, indication and registration of parameters of the coolant and thermal energy along 1...8 pipelines, their average hourly, average daily and total values, as well as operating time and the duration of emergency situations in its operation. Archive depth – 45 days.

Heat meters provide registration of the specified information on an external device (printer, PC, etc.) via the RS232, RS485, Centronics interface.

The computer is powered from a 220 V AC network.

Metrological characteristics

Heat meters, depending on their configuration with sensors, have the technical characteristics indicated in the table:

| Flow sensor type | Nominal diameter, DN, mm | Limits of flow measurement range, m3/h | Max. temperature value, °C | |

| Gname | Gnaib | |||

| VORTEX | ||||

| VRTK-2000(VPR) | 15-350 | 0.016 Gmax | 4-1600 | 150 |

| VEPS | 25-300 | 0.03 Gmax | 10-1600 | 150 |

| VEPS-TI | 20-200 | 0.04 Gmax | 4-630 | 150 |

| DRC-V | 25-100 | 0.04 Gmax | 10-200 | 150 |

| METRAN-Z00PR | 25-200 | 0.04 Gmax | 9-700 | 150 |

| UPS | 20-200 | 0.04 Gmax | 4-630 | 150 |

| DRG-M | 50-150 | 0.025 Gmax | 160-5000 | 200 |

| ELECTROMAGNETIC | ||||

| PREM | 20-150 | 0.005…0.0067 Gmax | 12-630 | 150 |

| IPRE-1(1M) | 32-200 | 0.05 Gmax | 5,6-900 | 150 |

| IPRE-3 | 32-200 | 0.04 Gmax | 22,7-900 | 150 |

| MP400 | 10-150 | 0.04 Gmax | 3,39-763 | 150 |

| IR-45 | 32-200 | 0.04 Gmax | 22,7-900 | 150 |

| "VOZLET ER" ERSV | 10-200 | 0.012 Gmax | 3,39-1357 | 150 |

| TACHOMETRIC | ||||

| PRMT | 32,50,100 | 0.1 Gmax | 1-100 | 150 |

| VST | 15,20 25-250 | 0.04 Gmax 0.05…0.08 Gmax | 3,5 7-1000 | 90 150 |

| VMG | 50-200 | 0.025 Gmax | 60-500 | 150 |

| OSVI | 25-40 | 0.02 Gmax | 7-20 | 90 |

| WPD, M-T150QN | 20-300 | 0.03… 0.09 Gmax | 3-1000 | 150 |

| M-T, WS, WP | 15-200 | 0.02… 0.05 Gmax | 1,5-600 | 120 |

| ET, WP, MT | 15-250 | 0.04…0.05 Gmax | 3-800 | 90; 120; 130; 150 |

| IMW, MT, E-T, WS, WP | 15-200 | 0.03…0.06 Gmax | 3-600 | 90; 120, 130 |

| ETW, MTW | 15-50 | 0.04…0.1 Gmax | 1,5-30 | 90 |

| ULTRASONIC | ||||

| DRC-S | 50-350 | 0.02 Gmax | 145-1000 | 150 |

| DRC-3 | 80-4000 | 0.01…0.015 Gmax | 18…450000 | 150 |

| EEM-Q | 15-50 | 0.04 Gmax | 1,5-15 | 150 |

| SONOFLO | 25-250 | 0.04 Gmax | 6-1000 | 150 |

| ULTRAFLOW II | 15-250 | 0.03 Gmax | 1,5-1000 | 150 |

| UFM001 | 50-1000 | 0.04 Gmax | 85-34000 | 150 |

| UFM003 | 15-40 | 0.02… 0.04 Gmax | 4,5-30 | 150 |

| UFM005 | 15-1600 | 0.04 Gmax | 2-36200 | 150 |

| UFM500 | >50 | 0.028 Gmax | 31,25-100000 | 150 |

| RU2K | 10-1800 | 0.04 Gmax | 2-110000 | 150 |

| SUR-97 | 25-300 | 0.01 Gmax | 20-2500 | 150 |

| URZH2K | 15-1800 | 0.04 Gmax | 0.034DN2 | 150 |

| UZR-V-M "AKUSTRON" | 50-2000 | 0.03 Gmax | 72-113400 | 150 |

| UFC002R | 50-2000 | 0.04 Gmax | 60-100000 | 150 |

| UFC-003R | 20-50 | 0.025 Gmax | 2,5-25 | 150 |

| UZS-1 | 15-2400 | 0.016 Gmax | 6,3-150000 | 150 |

| UPR-1 | 15-2400 | 0.016 Gmax | 6,3-150000 | 150 |

| URSV-010 | 50-1600 | 0.284DN | 0.028DN2 | 150 |

| URSV-010M “TAKE OFF PC” | 50-4200 | 0.0З Gnaib | 0.03 DN2 | 150 |

| URSV "VZLET MR" | 10-5000 | 0.2Du/r | 0.03 DN2 | 150 |

The calibration interval of the heat meter is 4 years.

Common features and types of equipment

Heat meters are manufactured in Russia and adapted to local conditions of use. Devices for receiving and processing information from NPP TEPLOVODOKHRAN, regardless of type, are distinguished by convenient installation and high accuracy.

Structurally, heat metering equipment is an assembly of one or two flow meters, a set of thermoformers, a computer and pressure sensors. Heat meters have a non-volatile memory in which the received data on the heat generated is recorded for up to 60 days. In addition to the average temperature and coolant volume values, the archive saves an event log with information about the operation of the device, error codes, and parameter changes.

All our models are characterized by:

- Long interval between mandatory checks.

- Resistance to low-quality coolant.

- Long service life.

- Available post-warranty support.

- Convenient and intuitive controls.

- Compact size, laconic design.

- Self-diagnosis function.

Depending on the design features, thermal energy meters are divided into four groups:

- With visual reading - the devices have a convenient and intuitive interface. Information about consumed heat resources is displayed on the screen. The models do not have rotating parts, which prolongs their service life and increases resistance to low-quality coolants.

- With pulse output - a group of heat meters with high measurement accuracy. Transfer of data on consumed resources occurs during a visual inspection or remotely. The devices have diagnostic functions, date recording and determination of thermal power consumption.

- With a digital output - another category of general house heat meters, designed for long-term operation in areas where thermal energy is of poor quality. It is distinguished by its versatility and high accuracy of readings. The recorded information is displayed on the screen and transmitted remotely to the controlling organization.

- With radio output - a wide group of communal heat meters. The received data is remotely transmitted to service organizations, helping to solve emerging problems in a timely manner. The heat meter is highly accurate when reading data.

Residential heat meter operating principle

We also recommend that you consider the benefits of a custom heat control system supplied to your home to reduce the cost of these costs. The best solutions to these savings will be found together as we look at the piping in your home.

Quarterly recording of thermal energy is possible only with a horizontal wiring system for heat supply!!! *

Call us or leave a request on the website, and our manager will contact you.

Our prices

| Installation cost 1 water meter | from 1700 rubles |

| Cost of replacing 1 water meter | from 1400 rubles |

| Meter installation cost | from 12,000 rubles |

| Meter replacement cost | from 7,000 rubles |

| Installing the first radiator | from 3200 rubles |

| Installing the first radiator with 2 1/2" | from 4200 rubles |

| Jumper | 1800 rubles |

| Installing the first radiator by replacing two 3/4" | from 4700 rubles |

| Jumper | 2000 rubles |

| Installing the first radiator by replacing two 1" taps | from 5000 rubles |

| Jumper | 2400 rubles |

Thermal energy calculators and distributors: advantages of use

Heat calculators and allocators are meters that calculate the relative costs of heat energy. They consist of a thermal adapter and two elements characterized by sensitivity to temperature changes. Sensors measure the temperature of the surface of the battery and the air in the room every 3 minutes, determining the difference in indicators. The resulting values for heat consumption are added up and generated on the device screen.

Devices of this type will have to be installed on all batteries in the apartment

Heat calculators on each sensor are set immediately before installing the device and putting it into operation. To do this, all the required coefficients and power indicators are entered into the memory of the thermal energy meter, which then allow the device to display the amount of heat consumed.

Important! The data displayed on the device screen are conventional units, to convert which to kW/h it is necessary to multiply the resulting figures by the power of the heating radiator, which is indicated in the product passport, as well as by the coefficient corresponding to the type of radiator, confirmed by the meter manufacturer.

Due to the fact that distributors and calculators determine the consumption of thermal energy in one radiator, their number must correspond to the number of batteries in the apartment. Both types of heat meters work properly, regardless of the quality of the coolants circulating in the heating system. Other advantages are:

- relatively low price of devices - approximately 2000-3000 rubles;

- long service life - more than 10 years;

- simple and easy installation on the battery surface;

- the presence of a single controller that calculates the sum of indicators read from several devices (the option is not available in all models).

Calculators and distributors can produce an error of up to 12%

Before installing a heating meter in an apartment of this type, you need to take into account that the relative error of the obtained indicators in some cases reaches 12%; heat distributors show a particularly large deviation. You also need to carefully approach the purchase of a kit for installing the device, which must match the type of battery installed. If you choose the wrong kit, the quality of information collection will be significantly reduced, so without a specialized installation kit, it is more advisable to simply install the heat meter near the radiator.

Types of thermal heating devices

The main types of heat meters include:

- Tachometer or mechanical;

- Ultrasonic;

- Electromagnetic;

- Vortex.

There is also a classification by area of application. For example, industrial or individual.

An industrial heating heat meter is a common building (in apartment buildings) device; it is also installed at production facilities. This unit has a large diameter from 2.5 cm to 30 cm. The range of coolant amount is from 0.6 to 2.5 m3 per hour.

An individual heating device is the unit that is installed inside the apartment. It is distinguished by the fact that its channels have a small diameter, namely no more than 2 cm. And also the range of coolant amount is from 0.6 to 2.5 m3 per hour. This meter comes with 2 devices, namely a heat meter and a hot water meter.

General rules for reading and calculating data

For a service provider company, one indicator is important - the amount of heat energy used during the reporting period (usually per month). Payment is calculated based on this indicator. Accordingly, at the end of the reporting period it is necessary to take readings and make a calculation.

On the front panel of the heat meter there is an electronic information board on which all parameters are displayed. The first is the amount of accumulated heat energy. Necessary:

- write down readings from the screen;

- Subtract from this figure the readings taken in the previous reporting period. This will be the amount of heat energy used for the current period.

Saves or not

Every year housing and communal services become more and more expensive, a considerable part of which goes to paying for heating. When calculating the amount, it is often overestimated, using not individual data from each house, but approximate, theoretical ones. In order not to overpay for heat that was not used to heat their home, many install a heating meter.

It is important to immediately note that the thermal energy meter does not save heat itself. It only calculates exactly how much energy was spent on heating. However, in this case, the owner will have to pay not for average indicators, which often include losses from the passage of water through pipes and possible flaws in the network itself, but for the amount of heat actually spent. Thanks to this, costs are reduced.

The meter will allow you to clearly see how much money is spent on heating a particular room. If the temperature is lower than what the service provider agreed to provide under the contract, the latter must return the money paid.

In addition, thanks to the meter and control, homeowners may decide to insulate the premises in order to pay less, for example, by changing windows.

Meter in a private house Source eno-tek.ru

Is it profitable to install individual heat meters?

After you go through all the vicissitudes of paperwork, installation of a heat meter and its commissioning, you will receive the following benefits:

- payment for the heat used specifically by you, and not some average costs throughout the building;

- it will be possible to save thermal energy when it is not required;

- By investing money in insulating the walls of your apartment, you will not only protect your home from the cold, but you will also pay less for heating in fact.

The payback of the project depends on many factors, ranging from how much the heating meter and installation services cost. Practice shows that payment for the device is reduced by an average of 25-30% compared to the tariffs applied in the absence of heat meters.

Advice. There is a simple way to verify the benefits of organizing individual heat energy metering. Analyze how much you paid for centralized heating 2-5 years ago and track the trend in tariff growth. Note that rising energy prices will not stop in the future.

This thermal head allows you not only to regulate the temperature, but also to change it according to the time of day

Controlling actual heat consumption is the first step to saving it. The second is the installation of valves with thermal heads on batteries that limit the heating of air in rooms, which is described in detail in this article. If you buy programmable thermal heads, then during your absence the temperature in the rooms can be reduced by 3-4 °C. The third step is thermal insulation of walls and ceilings with floors (if necessary).