If you see that water is leaking from a gas boiler, do not put off solving this problem. After all, you don’t want to replace the entire boiler because of a small crack in the heat exchanger, do you? Let’s say right away that coolant leaks occur for other reasons and in other places. How to detect and eliminate them is the topic of our article.

We will tell you what signs you can use to quickly identify a leak. We will tell you which structural components are most susceptible to loss of tightness. Our recommendations will help you quickly identify the cause in order to eliminate it without waiting for breakdowns beyond repair.

What are the dangers of a boiler leak?

In most cases, further operation of a leaking boiler is impossible.

Even if it continues to heat water, you should not use it. The liquid contained in the heating system can extinguish the burner, which will lead to the filling of the home with gas. And if electrical appliances are located in the immediate vicinity of the boiler, a short circuit may occur. As a temporary solution to eliminate the leak until the repair team arrives, you can use cold welding or sealant. This option is not suitable as a permanent solution: after a short time, the leak will appear again. Therefore, if your boiler is leaking, call us urgently!

We use the boiler correctly. How to extend the service life?

The first thing we must do is check the pressure in the system. If this indicator exceeds 3 atmospheres, then you will have to additionally install a gearbox that can reduce it. As you know, the cause of an increase in pressure can be an increase in temperature, and this is also very dangerous for the boiler

The reducer itself must be installed in front of the device; it is important that the system pressure is no more than 2 atmospheres. It is also undesirable to set the temperature of the water heater too high. Ideally, it should not exceed 50 degrees. The boiler needs periodic cleaning, moreover, we need to constantly monitor the condition of the rod (at least every two to three years)

If this rod becomes unusable, we immediately install a new one, otherwise it will negatively affect the functionality of the heating element. Finally, experts advise installing a special filter in front of the water heater, also made of magnesium. Thanks to this filter, the hardness of the incoming liquid will noticeably decrease.

Note! It is recommended to configure the water heater so that you can take a shower without diluting the water. This will not only save time, but also extend the service life of the equipment.

Why is water flowing from the heating boiler?

Water leaks from the boiler for several reasons, so before you start repairing it, you should figure out what exactly needs to be fixed:

- Corrosion. Gas boilers are made of steel or cast iron. These materials are not resistant to corrosion, and if we take into account that the unit operates with constant circulation of water in it, then this cause of failure can easily be considered the most common.

- Marriage. A poorly made boiler can leak at the welding seams.

- Burnout of the walls is another common cause of failure. Steel and cast iron can only burn when exposed to open fire. If you operate the boiler following all the recommendations in the instructions provided for it, then this cause of failure is unlikely to occur.

The following factors can lead to a malfunction of a gas boiler:

- Long-term operation at maximum temperatures;

- Inconsistency between the power of the device and the area of the heated room;

- Incorrectly set burner power;

- Poor quality burner.

Additionally, it should be noted that any boiler is designed for a certain pressure. If the indicator is higher than permissible, the device will overheat, which will lead to its expansion and leakage.

The pressure in the heating system must be constantly monitored, since excessively exceeding the permissible level can cause an explosion.

Corrosion

Metal corrosion is the real scourge of any plumbing equipment. The heating boiler is no exception. Constant interaction with water is favorable conditions for the development of corrosion processes.

Of course, this does not mean that your boiler will rust very quickly. It all depends on what material its “filling” is made of. Ideally, it should be copper or stainless steel. These materials do not rust or accumulate scale, so they are excellent for the production of such devices.

But the problem is that all their excellent qualities are accompanied by a high cost. Therefore, when choosing water heating equipment, the decision is usually made in favor of boilers whose internal elements are made of ordinary steel or cast iron.

Cast iron does not rust, but it is not often chosen. Firstly, its weight makes it difficult to transport and install equipment. Secondly, cast iron does not tolerate temperature changes well - it can crack, which, by the way, will also lead to a leak. Therefore, this material is not very suitable for heating heating equipment.

As for ordinary steel, it has excellent characteristics necessary specifically for a heating boiler, and it is inexpensive. But there are always problems with rust. Many manufacturers add an anti-corrosion coating to it, but, as practice shows, it does not guarantee 100% protection.

Corrosion is not just a red coating on the walls of the boiler. It gradually destroys the metal. Sooner or later this will definitely lead to the formation of a hole.

A separate factor should be considered the quality of the water used in the heating system. The content of a large amount of air and various impurities in it leads to high corrosive activity. Therefore, it is strictly not recommended to use ordinary water for these purposes - for example, river or well. It is necessary to purchase distilled. This is a bit of a hassle, but believe me, constant repairs of heating system elements will cause much more difficulties.

Recharging equipment

Many users do not pay attention to this factor, but it has already been proven that it really affects the durability of the device. This is water quality. It is believed that “dead water” should be used in the heating system. It does not contain oxygen, additives, or microorganisms. Therefore, it does not react with metals. If you do add tap water, do so rarely. Oxygen contributes to damage to the internal walls of parts.

Welding seams

Manufacturers must pay increased attention to the quality of seams, because the device operates under pressure. Abroad, automation has long been involved in the assembly of equipment, but in our country, seams are made using X-rays. A small mistake will lead to a leak. This often happens after the warranty expires, when it is already difficult to prove a manufacturing defect.

You can repair the crack or weld the seam, but, according to user reviews, such repairs will not help for long.

We recommend: How to heat a room evenly using a heat exchanger

Increased pressure in the system

Each boiler is designed for certain operating parameters of the system - in particular, pressure. To monitor this indicator, pressure gauges are installed. If you see that the pressure is too high, this may indicate some problems at work.

Burnt walls

Although the combustion chamber is made of thick metal, improper operation leads to burnout of steel and cast iron.

- The boiler operates at maximum temperature constantly. A high flame bursts out. This happens due to poor insulation of the home or due to an incorrectly selected model - without taking into account the area.

- Incorrect burner power adjustment.

- The combustion chamber is set too low.

When choosing equipment, study reviews from users and the manufacturer. Consider the volume of the room and install a boiler of suitable power, with flame adjustment.

Warning

If your heating system has regulators, for example, thermostats, or coolant flow distributors (used to equalize flow resistance in different heating circuits), then the sealant can clog the passage gap in them. It's not a problem. From time to time you will have to open them slightly and then return these regulators to their original position. But if blockages continue to occur, then after the leak has been reliably eliminated, the coolant and sealant should be drained, the system flushed, and a new coolant pumped in.

I had one valve clogged, but it was easily cleaned by opening and closing it. There were no more blockages, so I didn’t drain the sealant.

Attention!! Engine cooling system sealant can cause serious eye damage if it gets in your eyes. Please wear safety glasses

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared. Subscribe to the news to stay informed.

Hello! I have a system of metal-plastic pipes connected with metal strands, open type, with an expansion tank. After the second winter, I discovered that there was a leak in the system. About 5 (possibly a little more) liters are consumed per day. Since the pipes are hidden under a screed, I cannot determine how serious the leak is. Following your example, I filled the system with liquid he Read the answer.

Good afternoon Please tell me how to add sealant to the coolant? I have a gas boiler + heated floors, and now the pressure began to drop on one of the circuits (hallway). Thank you! Read the answer.

Why does concrete crumble, crack, or deteriorate in the foundation, walkway, . The path and foundation were poured in the summer. After the winter, serious damage is visible, observing.

Make a septic tank, drain, autonomous sewer with your own hands, yourself. I made the septic tank myself. I'm sharing. Little known but very important facts. Construction, c.

Pipe heating system to prevent winter water supply from freezing. With your own hand. DIY plumbing. External, non-freezing. Laying water pipes h.

We will install a backup, spare, emergency heating boiler. Orifice diagram For reliable heating you need a backup boiler. How to select it, install it, present it.

Electric heater, heater, boiler. Heating, electric heating Electric heaters. Heating by electricity. Comparison of electrical appliances. Review.

Causes of heating boiler leaks and their elimination.

It should be noted that regardless of the manufacturer, a boiler of any brand (for example Baxi, Ariston, Proterm, Beretta, Buderus, Vissmann, Vailant, Wolf, AOGV, etc.) may be susceptible to this breakdown due to improper operating conditions.

The causes of failure may differ for different equipment. In this article we will analyze several types of equipment and the reasons for their leakage.

Copper/brass wall-mounted gas boilers.

Main causes of leakage:

- Connection faults

- Faulty heat exchanger,

- Corrosion,

- Manufacturing defects.

If you have water leaking from a wall-mounted gas boiler, then most likely you should look for the cause in the heat exchanger. In this case, it is possible to eliminate the cause of the boiler leak only by replacing the heat exchanger with a new one.

Steel electric wall-mounted boilers.

Main causes of leakage:

- Connection faults

- Poor soldering in copper connections,

- Vaporization ruptures the heat exchanger,

- an increase in fluid flow (a large pump installed on a low-power boiler increases the flow rate of the coolant, which leads to thinning of the walls and their microcracks),

- Faulty heat exchanger,

- Corrosion,

- Tena scale fouling,

- Manufacturing defects.

Wall-mounted electric boilers are simpler in design and operation, but they can also experience coolant leaks. For its reasons, the breakdown of boilers of this type is similar to gas boilers, excluding only those options that are caused by an incorrectly configured burner of gas boilers.

Steel floor boilers

Main causes of leakage:

- Sudden changes in temperature from hot to cold lead to cracks,

- Corrosion of the steel body of the boiler,

- Clogged boiler filters,

- Manufacturing defects.

Cast iron floor boilers

Main causes of leakage:

- Poor sealing of sections (cast iron boiler),

- Sudden changes in temperature from hot to cold lead to cracks,

- Fogging of cast iron,

- Clogged boiler filters,

- Faulty heat exchanger,

- Manufacturing defects.

Cast iron boilers are quite reliable and durable, but at the same time they require proper installation. In order to minimize the risk of a burst boiler section, manufacturers recommend installing a three-way valve with a servo drive and a mixing pump at the inlet.

Cast iron can crack due to sudden large temperature changes. This happens under several conditions:

- Large temperature difference between supply and return lines.

- Failure to comply with the technology for recharging the heating system (when changing temperatures with a difference of 40 degrees or more. For example, the boiler is heated to + 80 ° C, and the temperature of the liquid during replenishment is + 40 ° C).

- Heating an empty boiler. The lack of coolant in the system and boiler during operation leads to overheating of the latter.

How to eliminate a leak in a cast iron floor boiler? Only by replacing the section with a new one. Our company’s specialists will carry out a qualified overhaul of the boiler, selecting and replacing the cracked section with a new one. You can read the prices and description of the work in the “Boiler overhaul”

.

Aluminum condensing boilers

Main causes of leakage:

- Clogged heat exchanger,

- Water hammer due to improper operation of the boiler,

- Fogging of cast iron,

- Vaporization ruptures the heat exchanger,

- Faulty heat exchanger,

- Manufacturing defects.

If you find a boiler leak, we advise you to call a professional to diagnose the breakdown and fix it.

What should a technician do to fix a broken wall-mounted boiler?

1. Determine the cause of the leak.

2. Turn off the boiler.

3. Drain the coolant from the system.

4. Wait until the equipment cools down completely.

5. Eliminate the cause: replace the heat exchanger, or solder it (if possible) and reinstall it; tighten or replace connections, etc.

6. Start the system into normal operation.

7. Give recommendations on the use of boiler equipment.

Damage to the heat exchanger and pipes

If the heat exchanger of a gas boiler is leaking, the wall may have burned out, a crack or a fistula has formed. Based on the material used, heat exchangers are divided into copper, steel, and cast iron.

Cracks in metal are formed under the influence of thermal stress and hydraulic pressure. Corrosive processes lead to the formation of fistulas. Repairs are carried out by soldering.

Main stages of the process:

- dismantling the heat exchanger;

- cleaning and degreasing the area around the leak;

- soldering using flux and solder;

- trial;

- installation.

If there is a leak in an easily accessible place, complete dismantling of the heat exchanger for repair is not necessary. It is enough to remove the casing, turn off the gas and water, disconnect the electrical wires, and drain the remaining water.

For soldering, select a solder that corresponds to the material of manufacture, for example, copper-phosphorus solder containing silver is suitable for copper heat exchangers; the temperature regime at the soldering site must be observed

The soldering area is cleaned and degreased with a solvent. Soldering is performed using a soldering iron or gas torch. The heat exchanger is installed in place and communications are connected to it.

Tests are carried out by crimping. The circuit is filled with water, the pressure is increased to the test value and monitored using two pressure gauges for at least 5 minutes. If no pressure drop is detected and no leaks are noticed during a visual inspection, the repair can be considered complete.

In case of severe damage, repairing the heat exchanger is impractical. It is simply replaced with a new one. It is also impossible to solder many Chinese-made heat exchangers, since they are made of thin-sheet alloys that cannot withstand soldering.

Leak elimination methods

So, we figured out the reasons. Now let's talk about how and with what to seal the hole so that you don't have to buy a new heating boiler. Strictly speaking, welding is usually used to repair metal products. To do this you need to take a few simple steps.

- Disconnect the boiler from electricity or wait until the fuel burns out in it and the equipment cools down.

- Drain all coolant.

- Disconnect the heat exchanger.

- Weld or solder the hole.

Of course, for this you need to have at least some skills in working with a welding machine or a soldering iron. But you can do without welding. The first three steps are performed in exactly the same way: turn off and drain the boiler, disconnect the heat exchanger. And then apply “liquid welding” according to the instructions.

Perform all these actions only if you are at least relatively confident in the result. If in doubt, it’s better to call a specialist. This is especially important in the case of gas boilers, where any poor-quality work can lead to very negative consequences. Therefore, to repair them, it is necessary to hire specialists licensed for the relevant type of activity. Good luck!

We recommend: Peat briquettes, use of peat for heating rooms, its types, advantages and disadvantages

A set of ideas - repairs of any complexity

What are we ready to offer our clients?

- Call service throughout the Moscow region, including emergency calls.

- Guarantee for the range of work performed.

- Acceptable prices.

- Fast and high-quality repairs, regardless of its complexity.

The experience of the “Complex of Ideas” specialists is a guarantee that they will eliminate any breakdown. In addition to repairs, you can contact us for help if you need to carry out preventive maintenance on your heating system and in a number of other cases. Don't put off repairs for too long - call now!

To solve your problem, you can call a specialist. Fill out the form, briefly describe your problem and we will call you back for a consultation.

Fixing leaks yourself

Before repairing a leak in a heating boiler or heating pipe system, it is worth preparing a certain tool. This could be a welding machine or a thermal imager. To eliminate a leak, use the following instructions:

- It is best to “enlighten” a hidden leak with a thermal imager. Such diagnostics will allow you to accurately find the location of the breakdown and prevent minor fistulas that can become a problem. Elimination of the problem area is carried out by replacing the emergency section of the heating main or tightening the connecting element.

- If the integrity of the membrane in the expansion tank is damaged, repairs are not performed. In this case, you need to buy a new product in the store.

- A crack in the heat exchanger is one of the most difficult problems to diagnose. If you have welding experience, you can try to weld the fistula yourself. However, it is better to seek the help of a qualified specialist or take the heating equipment to a service center.

- A faucet that is not completely closed is the most harmless reason that people often forget to check. Eliminated by a complete revision of all shut-off valves. They are stretched and set to the required value.

Of course, it is possible to fix a heating boiler leak without welding. In this case, it is necessary to act depending on the location of the breakdown. The first thing to do is turn off the entire system and allow the coolant to cool. After this, you need to drain all the liquid from the system. If a leak is detected in an open section of the heating main, apply a plumbing clamp with a rubber gasket. The leak on the heat exchanger can be sealed with liquid welding.

Devices for detecting leaks in walls and floors

There are a few such devices:

- Thermal imager. Records a temperature rise of several degrees. But:

- the water may be lukewarm;

- the leak site may be hidden by a thick layer of concrete;

- the location may be inaccessible to the device.

- Surface moisture meter - allows you to measure the high humidity of the wall surface.

The method provides low accuracy and requires a lot of time. It is better to duplicate it with a thermal imager showing a large problem area, and then look for it with a moisture meter.

- An acoustic device, an analogue of a hospital phonendoscope. Allows you to hear the sounds of a “trickle” flowing in the wall and find a leak.

Our company can eliminate almost all problems associated with leaks in heating systems, both in private homes and in Moscow enterprises.

We provide the following types of services:

searching for leaks and localizing these places; we find the location of hidden water supply and heating pipelines; We diagnose the condition of pipelines; We inspect the premises and find places of heat loss using a thermal imager; we localize and completely eliminate leaks in hot and cold water pipes; We can find places where thermal insulation is damaged, and much more.

If problems arise, call our specialists at any time of the day. Departure of specialists within Moscow occurs free of charge and promptly on the day of application.

Water leakage is a phenomenon that sooner or later faces any homeowner whose home has a steam heating system. Finding it is quite simple if the pipes are not laid in the thickness of the walls or floor. But eliminating a leak in a heating system is a more difficult task and even critically dangerous if boiling water is gushing from a broken pipe. It is better not to lead to such a situation and take measures to eliminate coolant leaks at the first sign.

What to do to prevent boiler leaks

Leakage can be avoided by timely maintenance of your equipment.

To protect the boiler from corrosion, it should be periodically treated with anti-corrosion agents, which can be found in abundance in any specialized store.

To avoid repairs due to burnout, you should purchase the device only from a trusted manufacturer. Additionally, you should regularly monitor the operation of the boiler to ensure that it operates without overload and does not heat up to the maximum possible temperatures.

To prevent leaks due to high pressure in the equipment, the condition of the valve and pressure gauge should be constantly monitored. When even small faults are detected. They should be eliminated as quickly as possible. Additionally, the diaphragm valve must be checked at least once every six months.

Failure to follow these recommendations may result in equipment breakdown and costly repairs, and in the worst case, the purchase of a new boiler.

Prevention of fistula formation

When purchasing a heat generator, carefully examine the quality of the soldering of the connecting seams, both on the water and on the primary heat exchanger; there should be no sagging or unevenness.

Set up the burner according to the instructions in the instructions. To avoid the appearance of fistulas, it is necessary to take timely measures in the presence of high pressure and airiness in the system. Avoid frequent refilling of the system with water; find out the cause of the pressure drop in this case and eliminate it.

What to do with condensate?

A puddle of water under the boiler is not necessarily a sign of a leak. Perhaps this is condensate, that is, water formed when steam condenses.

When the boiler starts, air containing moisture enters its combustion chamber. When a gas-air mixture burns, this moisture turns into hot steam much faster than the coolant heats up. The vapors come into contact with the still cold surface of the heat exchanger and settle on it in the form of condensate.

When condensing, steam settles on cold surfaces in the form of water droplets, which contain a small percentage of acids that cause corrosion of metal surfaces

After the coolant warms up to 60-70 degrees, the condensate evaporates. To speed up this process, when starting the boiler, you can set the adjustment knob to the appropriate division, and then, if necessary, reduce the heating to 40-50 degrees.

The formation of condensation when the boiler has been operating for a long time with a coolant temperature above 60 degrees may indicate improper organization of the heating system. It is worth checking again to see if any mistakes were made during the design and installation of the harness.

The problem of condensation formation should not be underestimated, since prolonged exposure to an acidic environment on metal surfaces leads to their corrosion. Wet surfaces attract soot, which deteriorates the thermal conductivity and reduces the efficiency of the boiler.

Condensation also settles on the internal surfaces of uninsulated chimneys, which leads to accelerated contamination and wear. Insulating the chimney helps solve the problem.

Sensitivity is the key to rapid wear.

Of course, everyone likes a comfortable temperature. Modern systems offer fine-tuning of heat exchangers that are able to maintain a strictly specified temperature in the room.

With volumetric gas boilers, everything is clear - 100 or 200 liters of water will take an extremely long time to cool, even by one degree. However, the situation is completely different with wall-mounted appliances with a volume of up to 10-12 liters. There the count goes on in minutes, which causes clocking. The situation is especially typical during the off-season.

Near-zero temperatures outside the window are a difficult problem for boiler automation. Heat transfer to the environment is not strong enough for constant operation even at low powers, but still manifests itself in the absence of heating. A small range of 2-4 degrees causes constant starting and interruption of the cycle, which significantly wears out the boiler. The right decision would be to increase the spread to 10-12 degrees.

The problem is in the expansion tank

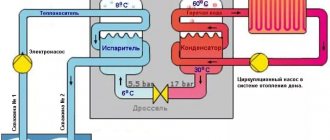

The volume of water filling the heating circuit varies depending on the heating level. As the temperature rises, the volume of water increases, which entails a change in the hydraulic pressure inside the closed heating system.

At this moment, the elements of the heating circuit would undergo increased load, fraught with their breakdown. But this does not happen, since the boiler design is complemented by a safety system, including an expansion tank, which receives the resulting excess water.

The design and principle of operation of an expansion tank divided by a membrane into two chambers, the location of the air valve and the pipe for connection to the water main

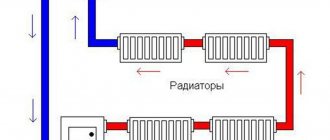

For installation on heating pipelines, open and closed expansion tanks are used. Open tanks are installed outside boiler rooms, for example, in attics, and are equipped with a whole system of pipes for connecting expansion, circulation, signal, and overflow pipes.

All models of wall-mounted, double- and single-circuit boilers are equipped with built-in expansion tanks. They are of the closed type, have only one pipe and two internal cavities separated by a membrane. To ensure the standard pressure in the expansion tank, its upper cavity contains air or an inert gas, for example, argon, and there is an air valve with a nipple.

Excess coolant flows through the pipe into the lower cavity. The membrane bends, the air is compressed in the upper cavity, and the coolant occupies part of the internal space of the expansion tank.

We recommend: How to make a chimney for a potbelly stove: installing a proper chimney with your own hands

The excess coolant produced during heating is discharged by the safety valve of the boiler or heating system itself. If necessary, the liquid is replenished through the boiler feed tap.

In open and closed expansion tanks, leaks occur at the threaded connections of the pipes and pipes. To eliminate them, tighten the union nuts or replace the gaskets, as discussed above.

The metal housings of expansion tanks are susceptible to corrosion due to the presence of oxygen bubbles in the water mass. Corrosion leads to the formation of fistulas (holes), which become the site of coolant leakage.

The more often you have to pump a new portion of water into the system, the higher the risk of damage to the expansion tank housing and other metal components. If there are fistulas, the tank is replaced with a new one.

Legislative solution to the issue of property

Are batteries a common property of the house or is it private property for which the owner is responsible?

The government approved Resolution No. 491 of 08/13/06, which provides a list of property common to residents of an apartment building. In this list:

- risers;

- shut-off and control valves;

- collective metering devices, heating elements.

According to this decree, radiator designs can officially be considered common property, common property.

But management companies and housing office companies servicing the house prefer to hide this information. And as a result, residents and apartment owners, when the battery leaks, try to repair it themselves.

Replace with a similar or more advanced, improved design. Management companies save on repair work by shifting their responsibilities to consumers.

Leaks through the safety valve

An important element of the safety system is the safety valve, which is necessary to “secure” the closed expansion tank. In boilers for individual heating systems, spring safety valves are usually installed.

Diagram of a spring type valve showing the main functional parts including pressure spring, poppet, seat

In the body of such a valve there is a metal spring that presses on the stem, and it, in turn, holds the support plate in a position where it is pressed tightly against the seat.

If, when the pressure in the heating system increases, the expansion tank for one reason or another does not cope with its functions, the coolant increases the pressure on the plate. At this moment, the spring compresses and lifts the plate above the saddle. Through the resulting hole, excess coolant flows into the drainage pipe and further into the sewer.

If the expansion tank is not selected correctly and its volume is not enough to accommodate all the incoming water, the membrane may rupture and water will fill the entire upper cavity. With a further increase in pressure, the safety valve is activated, through which the resulting excess coolant is removed.

The safety valve also operates if the membrane is torn due to wear, if air leaks through a faulty nipple, or if the automatic control system malfunctions

If the connection between the valve pipe and the drain pipe is not tight enough, the coolant will end up not in the sewer, but on the floor. To prevent this from happening, during a technical inspection, pay attention to this area and, if there is the slightest leak, perform sealing.

The safety valve installed outside the heating boiler has a similar design and can also leak, requiring urgent repairs

Be sure to determine the reason for the valve operation. If necessary, install a new expansion tank taking into account the volume of coolant in the system, change a worn membrane, faulty nipple or tank assembly, and solve problems with settings and control.

An emergency situation for a heating boiler is normal for the safety valve itself, because it is needed precisely in order to reduce damage from the consequences of an accident. But the valve itself may fail, causing a coolant leak.

Most often, the breakdown is associated with a spring, which is constantly under stress and eventually loses its elasticity, which leads to leaks even during normal operation of the system. The faulty valve is replaced with a new one.

When choosing a valve, its technical parameters are taken into account:

- nominal diameter of the pipe opening (DN);

- threaded connection size;

- response pressure.

The requirements for safety valves for heating systems are regulated by GOST 12.2.085-2002.

The traditional material for sealing threaded connections is plumbing flax (tow); to increase the reliability and durability of sealing, flax is impregnated with a special composition

But what to do if the gas boiler leaks due to a breakdown of a recently installed valve? This happens when a grain of debris gets between the plate and the seat, for example, rust from the expansion tank. In this case, the valve is removed, washed under running water and reinstalled.

The valve is installed so that the spring is vertical. There is an arrow on the body indicating the direction of coolant flow. To seal threaded connections, heat-resistant elastic gaskets or plumbing flax are used.

Prices

- ServicePrice

- Engineer visit during working hours from 8:00 to 22:00

- Within a small concrete ring 2000 rubles.

- Tariff for visiting a site outside the small concrete ring, per km. in both directions 30 rub.

- Departure on holidays ×1.5

- Departure after hours from 22:00 to 8:00 am ×2

- Diagnostics

- Fault diagnosis (up to 2 working hours) RUB 2,000.

- Fault diagnosis (more than 2 working hours) RUB 1,500. at one o'clock

- Replacement/installation of gas and fuel fittings and appliances

- Cleaning, replacing the electrode with setting the gaps 1000-2000 rubles.

- Cleaning, replacing the photocell 1000-2000 rubles.

- Replacement of the combustion control unit and combustion manager 1000-2000 rubles.

- Replacing a fan 1500-3000 rubles.

- Replacing the burner servo drive (without setting) RUB 3,000-5,000.

- Replacing the transformer 3000-4000 rubles.

- Injector replacement from RUB 3,000.

- Replacement of the fuel filter from 5,000 rubles.

- Replacement of a diesel burner fuel pump from RUB 5,000.

- Installing a fuel level sensor

- Bleeding the fuel line

- Replacement/installation of water fittings and devices

- Circulation pump from RUB 3,000.

- Pump group from 3000 rub.

- Top-up heating system with pump from RUB 1,500.

- Security groups from 3000 rub.

- Automatic air vent from 2000 rubles.

- Mixer servo drive RUB 3,000.

- Distribution comb from 5000 rub.

- Installation of a coarse filter from RUB 4,000.

- Cleaning the coarse filter from RUB 600.

- Repackaging of an engineering system for 1 point from RUB 3,500.

- Replacing a wall-mounted boiler pump from RUB 3,000.

- Replacement of the primary heat exchanger of a wall-mounted boiler from RUB 4,000.

- Replacement of the secondary heat exchanger of a wall-mounted boiler from RUB 4,000.

- General

- Repair, replacement, installation and commissioning of automation

- Replacement of electronic board 3000 rub.

- Replacement of the control panel from RUB 3,000.

- Replacing the thermostat 3000-5000 rubles.

- Replacement of thermocouple from 3000-5000 rubles.

- Replacing the thermostat 2000 RUR.

- Installation, commissioning of weather-independent automation from 7,500 rubles.

- Installation, commissioning of weather-compensated automation for up to 3 heating circuits from RUB 7,500.

- Installation, commissioning of weather-compensated automation for up to 5 heating circuits from RUB 8,500.

- Controller assembly from 6,000 rubles.

- Setting up weather-independent automation from RUB 5,000.

- Setting up weather-dependent automation from RUB 5,000.

- Connecting an additional boiler automation module from RUB 3,500.

- Installation of outside temperature sensor, room regulator (not including cable installation) RUB 2,000.

- Installation of a main temperature sensor RUB 1,000.

- Installation of a flue gas temperature sensor RUB 1,000.

- Installation of a traction rollover sensor from RUB 1,000.

- Installation of a boiler body temperature sensor from 1000 rubles.

- Installation of a boiler sensor from RUB 2,500.

- Installation and configuration of a servo drive from 2500 rubles.

- Installation and connection of a relay contactor from 2500 rubles.

- Installation of an additional automation module from RUB 3,500.

- Replacement of an additional automation module similar to the installed one from 2000 rubles.

- Replacement of an additional automation module that is not similar to the installed one from RUB 2,500.

Workmanship

The stability of the boiler depends on the quality of the welded joints made. If there are cavities or irregularities on the weld seam, someday this seam may leak. The void located in the middle of the seam is considered very dangerous. Ideally, the seams should be X-rayed, but not all manufacturers do this.

Although heating boilers are pressure vessels and high demands must be placed on them during the manufacturing process, defects often occur. And, basically, it drips from the heating boiler after the warranty expires. Brew the boiler

in the middle and stop

The leak doesn't always work out.

It depends on how the heat exchanger is designed. In models where a bithermal heat exchanger is installed (the secondary and primary ones are located in the same housing, heat exchange occurs due to the 2-in-one design), this is problematic. However, even if you have done this, as practice says, it will not help you for long.

The circulation pump is leaking(?) ⇐ Electrolux

Posted by Sandroe » Mar 18, 2022 11:58 pm

Post by Guest » March 19, 2022, 00:00

Posted by Fulcrum » Mar 19, 2022 3:52 pm

Posted by Guest » Mar 19, 2022, 04:43 pm

Posted by Fulcrum » Mar 19, 2022 4:44 pm

I’ll tell you a little later, right now I’m just at work, the main thing is to find the oil seal, it’s spring-loaded and universal

Posted 56 minutes 42 seconds later:

https://zipm.ru/catalog/salniki-prokladki-pm/ First, you disassemble the pump (unscrews counterclockwise), remove your seal, it is ceramic and match it. It may also be that everything is fine with him, he just needs to be tightened up. Here's a video I found

Can you tell me where this can be done? I asked a couple of stores and they said that they were only assembled.

Post by Guest » Mar 20, 2022, 10:33 am

Posted by Fulcrum » Mar 20, 2022 6:12 pm

Posted by Sandroe » 03 Apr 2022, 19:29

Finally got around to it. Everything is as in the video: all gaskets are intact. I washed it and screwed it back on. Not leaking yet. Thanks for the help!

I didn’t remove the tachometer, so I unscrewed the impeller.

Post by Guest » 04 Apr 2022, 00:24

The pump no longer leaks. However, by the middle of the wash, water still flowed into the tray (but not too much, the sensor did not work). I felt the pipes, looked with a flashlight to see where the leak was coming from, and saw nothing. The machine washed the dishes completely, but no water was added to the tray.

Ideally, the pan should be completely dry, or does something still drain there by default?

Post by Fulcrum » 04 Apr 2022, 19:17

Hi all. Machine LSI 48A (Ariston). When starting, it drains and fills with water, but the recirculation pump does not start, it hums. I took off the side walls and took a look. The winding (as far as I could see) is intact, there is no stink. Could the reason for the non-start be in something other than the motor itself, for example in the capacitor? How to check it (conder)? Thanks in advance.

Added after 8 hours 42 minutes 57.

Water stopped flowing from the rocker arm at 5002.

I suspect the circulation pump. I bought the impeller.

Does anyone have a Service manual? I can't find it on the net.

Source of the article: https://posudomojki.ru/viewtopic.php?t=667

How does the sealing effect manifest itself?

You should not expect the leak to be eliminated immediately, but only on the 3rd or 4th day. During this time, the sealant for heating pipes will compact and close the cracks in problem areas from the inside. Eliminating the problem of coolant leakage will manifest itself in the fact that the sound of falling drops of liquid will no longer be heard in the house, moistened areas on the floor will dry out, and the pressure in the system will no longer decrease.

At the same time, one of the negative effects may be a slight blockage of passages in devices for distributing coolant flow, as well as in thermostats. But this problem can be easily solved by periodically opening and then adjusting these types of regulators to the desired position to prevent them from further sticking.

The video lesson will help you understand how to fix a leak in your heating system yourself using liquid sealant.

Based on all that has been said, you can be sure that liquid sealant is undoubtedly worth using to eliminate leaks in the heating system. Even though its price is steep. However, it should be understood that hidden installation of heating pipes is not only a convenience, but also a certain risk, for which you sometimes have to pay.

What to do with a small leak in the heating system? (10+)

Repair of leaks in the heating system, heating boiler, underfloor heating

Sometimes coolant leaks may occur in the autonomous heating system. There may be several reasons. Firstly

, antifreeze was poured into the system after it was running on water.

In this case, the rubber gaskets and sealing winding first swollen from water, and then slightly shrunk. Secondly

, heating boilers usually consist of cast iron or steel structures connected by threaded connections sealed with sealant.

With use, the tightness may become compromised. Thirdly

, overheating, freezing or excess pressure (an expansion tank that is too small) in the heating system can lead to cracks in pipes, radiators and the heating boiler.

In the latter case, nothing can be done. It is necessary to replace damaged equipment and pipelines. In other cases, you can try to restore the tightness without expensive repairs.

System errors

When a malfunction occurs in the Baksi double-circuit wall-mounted gas boiler, an error code is displayed on its electronic display, which can mean one of two things: either blocking the operation of the heating device or turning on the standby mode.

In the first case, you need to manually restart the boiler. The device can be blocked when problems are detected affecting the main parts of the system, which can cause harm not only to the equipment, but also to the health of its owner. Such errors include excessive heating of the boiler, insufficient or reverse draft, as well as its absence. If gas does not flow into the storage tank, the equipment also becomes blocked. Sometimes this problem resolves itself, and then the device turns on automatic startup mode.

Code E01 - burner sensor

Code E01 appears on the display when the sensor monitoring the burner operation reacts. This error can be caused by a number of reasons:

- gas stopped supplying to the burner;

- there is no correspondence between zero and phase;

- sensor is disabled;

- the sensor needs cleaning or repair;

- malfunction in the ignition device;

- the gas supply valve has failed;

- the electronic board does not work;

- there is not enough air to maintain the flame;

- There is not enough gas pressure for combustion.

Having seen such a signal on the display, you first need to check whether the flame sensor is working correctly. Then see if gas is supplied to the device. If there are no problems, you should press the R button or switch the toggle switch to neutral mode, which is also indicated by this letter.

If the sensor is triggered involuntarily, the boiler will continue to operate as usual. If the error repeats, it is better to ask for advice from a gas equipment repair specialist. This fault code indicates problems in the chips, and trying to fix the problem yourself may lead to undesirable results.

E10 - water cycle indicator

Code E10 relates to sensors that monitor the operation of pumps and regulate the water cycle in the system. Such a cipher can diagnose the presence of the following problems:

- pressure decreased;

- the conductivity between the relay and the board is broken;

- the pressure switch does not function properly;

- malfunction of the pump sensor;

- the pump itself needs repairing;

- the heat exchanger is dirty.

Having noticed the E10 code, there is no need to rush to deal with the problems yourself. You can replace the pump yourself; it is not very difficult. It is also easy to clean clogged filters yourself. Other faults are best left in the hands of a qualified worker.

E96−98 - electronic board problems

The remaining Codes E96, E97, E98 indicate problems in the operation of the electronic board. If they appear on the display, the owner should not take any action and immediately call a repairman, because only an experienced specialist can deal with them without outside help.

Fixing problems with household appliances is a kind of treatment . There are simple diseases that a person can get rid of on their own, but for complex diagnoses it is better to consult a doctor. But both can be prevented with timely prevention. This also works in the case of preventing malfunctions of the Baksi wall-mounted double-circuit gas boiler.

Replacing a faucet without shutting off the riser

Is it possible to replace the shut-off valve without shutting off the water?

Do not practice on upper floors! Don't do this with hot water and heating!

One of the site’s readers under the nickname stefano asked a similar question:

Tell me what to do. The house has a riser and water drains from polypropylene pipes. The crane on one of the branches fell down. Is there any way to replace it without shutting off the water in the entire house? And what is better to put? We turn off the water every day before leaving for work.

The first thing to do is to secure the pipes on which the meters hang. Meters should not hang on pipes. To replace the faucets you will have to turn off the riser. You can, of course, install a backup one if this one also overlaps, but this is only as a last resort.

In your case, it is better to turn off the riser. If this is possible, then after disconnecting you will have to re-solder something here, namely: if you look at the photo, then after the meters you have two 90-degree bends installed, which take the pipe closer to the wall. With the same two outlets, take the faucet and meters to the wall immediately after the riser. Next, the meters need to be mounted on clamps so that they do not hang on the pipes.

For example, use these clamps:

They fit very well into the girth of the counters. After installation they are almost invisible.

As for shut-off valves, install reinforced valves from Valtek, or for example Bugatti.

There is material about shut-off valves here and here.

Cold welding

The leak area should be thoroughly dried and cleaned. After this, quickly knead part of the plastic mass with your hands and apply it to the hole so that the diameter of the patch is 2-3 cm larger than the diameter of the through hole. Let it dry for a day, then install the water heater in the boiler and run the system at minimum temperatures

Advantages:

- quick and easy hole repair

- you can solder several perforations at once, including seams

- relatively cheap repair method

Temperature sensor malfunction

The boiler determines the actual hot water temperature based on the readings of the temperature sensor. Therefore, if for some reason it receives incorrect readings, the boiler may not operate correctly in the hot water preparation mode. The temperature sensor is a thermistor with resistance depending on temperature. Testing such a sensor consists of measuring its resistance at a known temperature. Baxi boilers are equipped with NTC sensors with an inverse dependence of resistance on temperature. At room temperature, the sensor resistance should be approximately 10 kOhm, at a temperature of 45 degrees 4.3 kOhm.