A fireplace in the classical view is perceived as a structure made of stone or brick, having a powerful base and actively participating in heating the house. Modern technologies have somewhat modified the fireplace, as models have appeared that can be installed in apartments; we are talking about electric options.

Any electric fireplace consists of a firebox and a frame; it is this frame that is often called a portal. Although we must pay tribute, the hearth of an electric fireplace can be built into a wall, furniture, or be a separate device, ready for use.

Beautiful natural stone finish

A portal is a housing that performs a load-bearing and insulating function. It may differ in appearance, depending on what type of fireplace is used according to the installation method. Wall models are framed in a portal in the form of a parallelepiped. Corner portals have the shape of a triangular or trapezoidal prism. In this article we will talk about how to independently build a portal for a fireplace from plasterboard.

Main stages of construction

In stores that sell fireplaces, any buyer will certainly be offered kits that already contain a firebox built into a ready-made portal. If you compare the price with the cost of one firebox, the difference will be simply colossal. That is why many are interested in the question of how to make a portal for a fireplace with your own hands from plasterboard?

Drywall as a material was not chosen by chance. This is the most optimal option for the material, since it is easy to process and cut, is resistant to moisture (of a certain type) and to temperature changes.

Not all fireplaces can be framed with plasterboard portals. Fireboxes for wood-burning and gas models are built into housings made of brick or metal. Those portals, which will be discussed below, are suitable only for electric fireplaces or biofireplaces. Therefore, when constructing with our own hands, we will not be burdened by safety restrictions.

The finish of the finished structure can vary greatly

All work should be divided into stages. By performing them consistently, you can get a high-quality portal, which in all respects is not inferior to an expensive factory product.

- Selecting a project. The project requires a drawing of the portal with all dimensions and a description of the materials used. The safety of fireplaces in operation will allow you to show your creativity and draw a diagram of the portal under the fireplace yourself in the form in which you see fit. But if there is no desire or time to create a diagram, then the finished drawing can be found in the archives of craftsmen who deal with this matter professionally.

- Construction of a frame from a profile. The metal profile ensures structural strength and allows convenient joining of drywall sheets. At this stage, the appearance of the fireplace portal is being formed, so once again carefully consider the installation location of the fireplace, its additional functions, and dimensions.

- Plasterboard cladding. Only by installing the sheets can you evaluate the general appearance of the design of the future masterpiece. There are certain requirements for fastening sheets, which we will discuss later. Otherwise, this type of work is the most favorite for beginners. This is because drywall is easy to handle.

- Finishing. At the final stage, the plasterboard frame for the fireplace should be finished with one of the proposed materials. It is this type of work that is responsible for the stylization of the entire fireplace as a whole.

Classic wall portal

What is needed to make a false fireplace?

To quickly and accurately carry out the tasks, you will need certain materials and tools:

- GKL slabs. For work, ordinary sheets with a thickness of 9.5 to 12.5 mm are used. If you plan to place an electrical device, then it is better to choose fire-resistant options that provide maximum protection.

- Metallic profile. Since the frame requires the presence of a large number of elements, the entire system can be made exclusively from UD (PNP) or CD (PP) profiles and their combinations.

- Set of self-tapping screws. You will need products for fixing galvanized parts and drywall directly.

- Elastic putty. For joints and further processing.

- Reinforcing tape and perforated corner.

To build an imitation fireplace, you can use ordinary drywall (gypsum plasterboard), but if you plan to insert an electric fireplace into a niche, then it is better to take fire-resistant sheets (gypsum plasterboard)

- Electric jigsaw or gypsum board saw.

- Metal scissors.

- Screwdriver and drill, set of drills and bits.

- Rack or laser level.

- Ruler, tape measure and corner.

Professionals use a lot of specialized tools, but for a home craftsman, a minimal set is enough to build a small fireplace box

Finishing materials are also being prepared. This can be artificial stone, brick, various types of overlays and stucco. Depending on the cladding product, appropriate tools and compounds for processing and fastening will be required.

The most affordable and fastest way to decorate a false fireplace is painting, followed by homemade gypsum board tiles, tiles will be the golden mean, and the most expensive, reliable and heat-resistant are clinker tiles

Let's start with the project

No type of work, even the most basic, should be carried out without a clearly defined purpose. When installing a portal, we set our goal in the form of a finished fireplace that will look great in a specific interior.

You must make a drawing at your own discretion. The only significant parameters of the product are the dimensions of the niche where the hearth is inserted. But it is impossible to know these dimensions in advance. Therefore, before buying a fireplace, you can only make a schematic sketch of the future model.

At the same time, start calculating the costs of the material. Write down all the results on a separate sheet, which you will have to go to the store to see. The following materials are subject to recalculation:

- drywall (number of sheets);

- guide profile;

- self-tapping screws;

- putty;

- decorative material for finishing.

The simplest drawing

In some projects, there is advice according to which the load-bearing structures should be made of a PN profile, and the box should be reinforced with a PS profile. To facilitate calculations, it is possible to allow the entire frame to be manufactured with one type of profile, since it can be easily processed using special scissors.

Good to know: How to make a fireplace with a water heating circuit with your own hands

What materials do you need to have?

Drywall is widely used today to create a false fireplace for a country cottage, as in the photo. To perform this operation without the help of specialists, you need to have the following materials.

| Current materials | Purpose of application |

| plasterboard sheets | for cladding the frame of the product |

| metal profiles of various types | to create the frame of a future fireplace |

| hardware | for fastening gypsum boards to the frame |

| dowels | for fixing the profile on the wall |

| putty mixture | used to make slab joints invisible |

| decorative plasters | such finishing can decorate the product |

| glue | fixes decorative elements on the structure |

Frame assembly

Installation of the frame begins with drawing out the contours on the wall and floor. Firstly, the assembly will be carried out according to established guidelines, and secondly, vertical and horizontal lines will be immediately marked off, which will guide the future edges of the portal. By the way, level verification is one of the most important stages. Any violations will lead to gaps forming during the cladding, especially if the finish is in the form of tiles.

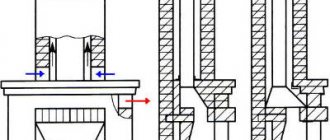

You can start with a horizontal base or a vertical frame. The frame is assembled to size from four prepared profiles. The profiles are fastened together with self-tapping screws. Immediately the frame must be secured to the wall. The portal itself, after the firebox is installed in it, will turn out to be quite unstable. When fastening, a hammer drill is used. Dowels are inserted into the holes and the frame is screwed to the wall.

Next, horizontal posts at the corners are attached to the frame. Their length should be several centimeters greater than the depth of the firebox. And even though you haven’t chosen the firebox yet, you should evaluate all the dimensions and make racks with a certain margin. Another frame is installed on the racks. The frame in the form of a parallelepiped is ready.

Assembling a metal frame

The remaining work will only strengthen the resulting frame from the profile. Prepare horizontal spacers and secure them along the portal plane. It is important that these spacers cut off the space for installing the firebox. To attach these elements, you will have to work with scissors. At the ends of the profile, the side parts are cut off so that they do not interfere with the tight joining of the horizontal and vertical posts. The completed composition must be screwed to the floor. Note that such a portal, together with the fireplace, could theoretically be placed in another place, but the remaining perforations will need to be sealed.

We return to the place where the fireplace was installed. In the simplest version, it is only necessary to make vertical inserts between the horizontal struts. An opening is formed where the firebox will be inserted. The support for the firebox is made from the same profile. It is mounted horizontally in the form of slats that go deep into the fireplace and attached to the wall. If you decide to make a fireplace opening in the form of an arch, then our favorite profile is used as the ceiling. You can bend it by making notches with scissors. The completed arch already makes a change in the entire design process.

Good to know: Fireplace complex, which includes a barbecue, grill, smokehouse, cauldron and oven

Portal shape and style

Before decorating a fireplace niche, determine its size and style. It is preferable to buy an electric fireplace in advance, and then design a portal for it. This will avoid unpleasant moments during the final assembly of the fireplace.

USEFUL INFORMATION: Plasterboard ceiling in the bedroom: design, 7 photos

Of course, most people want to install a purchased fireplace in their home as quickly as possible. This leads to the temptation to assemble the portal in advance by selecting the device you like from the catalog. But it’s one thing to see the design of a fireplace in a photo, and quite another to design a niche for it, based only on the indicated dimensions. To successfully fit the portal, you need to know many little things: the size and location of air exchangers, fastening elements, features of the electrical supply.

Choosing the right style is not easy: in addition to personal preferences, you will have to focus on the overall design of the room and the features of the purchased device. It may already contain some decorative elements that determine the style of the entire portal. There are many options here, so just a few recommendations are worth mentioning:

- At the base of the fireplace, it is necessary to arrange a small elevation - a pedestal. It should be 30 centimeters wider than the portal and have a minimum of 20 cm from the floor level.

- Corner portals are ideal for small spaces to save space.

- The functionality of the design can be increased by placing additional shelves for storing various small items. They are decorated in a variety of ways, for example, by decorating them as firewood.

- A good solution is to combine a decorative fireplace and a TV shelf.

Installing gypsum boards

There is no need to list all the advantages of drywall, but it should be emphasized that in different designs certain qualities can be most clearly highlighted. We are interested in heat-resistant drywall, since an electric fireplace has a heating function, which means that heat will certainly be transferred to the walls of the portal. Any drywall is already fire-resistant, the only difference is the paper.

The more jumpers you make on the frame, the easier it is to cover the frame with plasterboard. After all, you can cut the sheet into small pieces, but you shouldn’t get too carried away with this matter. It is desirable that the casing be solid. Solid sheets give the portal additional stability.

If experience does not allow you to cut the material so precisely, as an exception, it is allowed to divide it into parts, because all the joints will be sealed with high quality. The main thing is to make sure that the place where the sheet is attached is not empty, otherwise you will simply ruin the material.

Working with drywall

The drywall is attached to the profile using self-tapping screws. They need to be tightened with such force that the caps fit inside the sheet, but do not damage the cardboard layer. The joints of the sheets and the holes from the screw heads are puttied with a metal spatula.

Seam processing has a certain technology. Using a stationery knife, the joint is deepened and a chamfer is removed from the sheet. It turns out to be a kind of channel for putty. Thanks to this channel, the mastic will stick to the sheets better. Putty is also applied to the screw holes. After it dries, the excess should be removed with sandpaper. The resulting perfectly smooth surface is ready for finishing.

Let's make a mess

Now that the box is out, covering it with plasterboard sheets will be quite easy

Particular attention should be paid here to the portal, which must be sheathed very carefully, since it will be the “face” of your fireplace. You can make the correct plating of the portal according to the following scheme:

- First we sheathe the inner part with the material, and then the outer part;

- try to ensure that the sheets of drywall match in the corners. To make them even, use a special metal perforated corner;

- The sheet is fastened with self-tapping screws. The step for installing them can be chosen arbitrarily or stopped at 10-15 cm;

- avoid coinciding places for screwing in screws on adjacent sheets;

- The fastening elements are embedded by 1 mm. The heads of the screws must not be allowed to protrude above the surface of the sheet.

Portal skin

After this, all you have to do is putty the surface of the portal until it is even and smooth. Do not forget that before you finally decorate the fireplace, its entire structure should be primed. This increases adhesion between the surface and the finishing material.

Finishing

The appearance of the fireplace is dictated by the texture of the finishing material that you decide to use. You can familiarize yourself with the entire range and choose the material you like. Wooden lining, MDF panels, ceramic tiles and artificial stone tiles are especially popular when carrying out such work. All these materials are quite processable. The use of MDF is somewhat limited by the temperature and power of the fireplace, so they are trying to avoid this type of finishing.

Good to know: Why is the draft in the fireplace greater in winter than in summer, the reasons for the appearance of reverse draft

It is advisable to use fire-resistant adhesive for installing tiles. It's not that this zone experiences high temperatures. This glue, even when frozen, is elastic. It is needed to avoid destruction of tile surfaces due to thermal expansion. The technology of laying tiles is that each element in a row is glued and aligned with the previous one, which is why it was necessary to maintain the levels of the frame.

To imitate the presence of a real fireplace in the room, many construct a chimney from plasterboard. Its installation steps are the same as for the portal. This type of work is often performed by novice craftsmen and is considered the most accessible and easiest.

Main element

The fireplace has several functional components, the correct assembly of which determines the overall success of the business. The fireplace consists of the following elements:

- base;

- portal;

- top shelf;

- a device that makes it possible to simulate the fire of a real fireplace.

The portal for the fireplace, made of plasterboard, is the main component. It represents the external design of the structure. Also, the portal means the “front entrance” of the fireplace. Those. the portal is the external part of the structure, having the appearance of a combustion recess.

Fireplace portal

To decorate this part of the structure, you can use a wide variety of finishing materials, especially if the fireplace itself was covered with plasterboard sheets. Drywall is an excellent base for any type of finishing. It is thanks to this quality that false fireplaces look very similar to real ones and you can make them with your own hands.

Where can I buy

If you really want to, you can always build a portal for an electric fireplace yourself; this will require minimal construction skills. However, a simpler and more practical solution would be to buy a finished product in a store.

In construction and specialty stores there is a wide range of various devices and additional accessories for an electric fireplace. You can find here ready-made frames made of plaster, polyurethane, stone, marble, brick, wood, MDF, metal and even plastic. Choose a structure suitable in size for your built-in electrical appliance, evaluate its strength, stability and appearance.

Modern electric analogues of fireplaces look so believable that they take your breath away. In this case, the portal plays an important role in the design of the hearth. Therefore, try to choose a product that matches your interior and the general atmosphere in the house.

DIY corner fireplace made of plasterboard

There are several types of homemade corner decorative fireplaces, each of which has its own advantages:

- symbolic. It is made in the form of a picture imitating a fireplace portal. This is the simplest option, which has few similar details to the real one;

- conditional. In this solution, in addition to the decorative image of the fire and firebox, a portal is installed, which can be made from old furniture, a cardboard box, or drywall. Instead of a decorative image, you can install an electric fireplace, provided that all fire safety rules are followed;

- floor biofireplaces. This is a modern high-tech solution where a device with an LCD TV capable of simulating the burning of a real flame is mounted in a portal that is installed against a wall in an apartment or country house.

For realism, firewood and stones can be laid out in the firebox, and an iron damper can be placed outside, just like in real fireplaces.

The cost of organizing a fireplace at home will directly depend on the choice of design type.

Creating a fireplace, like any other engineering structure, should begin with choosing a location. After this, measurements are taken on all planes, after which a drawing of a corner fireplace made of plasterboard with dimensions is drawn.

Important! To make the fireplace as similar as possible to the real one, you should maintain the proportions in the ratio 2:3 (width x height). The depth of the firebox relative to the height should be set in a ratio of 1:2.. Another condition that will help create a beautiful and realistic fireplace is the thickness of the drywall (optimally if the sheet thickness is from 9 to 12.5 mm), for which you need to select the appropriate metal profile and screws to connect elements into a single structure

Another condition that will help create a beautiful and realistic fireplace is the thickness of the plasterboard (optimal if the sheet thickness is from 9 to 12.5 mm), for which you need to select the appropriate metal profile and self-tapping screws to connect the elements into a single structure.

Photo: dimensions of the false fireplace

Gallery of ready-made solutions - for inspiration

The portal appears flat, while the hearth is built into a tall plasterboard box

Using additional elements, an elegant composition is created

Making such a portal will not take much time

An unusual solution for a corner fireplace

Sockets above the mantel can be easily hidden behind a clock or photo frame

Strict design and noble ivory color

Creating a portal for an electric fireplace yourself allows you to save part of the repair budget. Although it is easier to buy a ready-made kit, the cost of decorative structures from all manufacturers is comparable to the prices of electric fireboxes built into them. You won’t need any expensive materials for your work, so you can pay half as much for an island of comfort in your home. And this is a great incentive to work with your own hands.

Interior or electric?

Now let's look at: what solutions and designs are applicable inside the enclosure box? Why not install an electric fireplace, and also use a variety of techniques to give the portal greater expressiveness and originality?

For these purposes, you can choose ceramic tiles you like, stones made from artificial material, or real small cobblestones brought from the river coast. Take, for example, brick or marble material, as well as wood traditionally used in the interior.

When choosing a cladding for the appearance of the fireplace, remember that the product consists of plasterboard, so you shouldn’t load it too much. When decorating a fireplace, do not forget about blacksmithed metal elements created using the artistic forging technique.

If you decide to add a highlight to the appearance of the fireplace using stone or tiles, then a special glue designed for fixing ceramic tiles or liquid nails, which can also effectively cope with this task, will help you here.

Electric fireplace

Let's look at how to install an electric fireplace in a false fireplace you created from plasterboard. The wall where the electric fireplace will be located must be sheathed with heat-resistant materials.

On the floor, install a special podium for an imitation fireplace and a metal frame, the base of which should be reliable enough to withstand the load that an electric fireplace will give it. For this reason, attach profiles to the base every 200 millimeters.

Run electricity inside the structure so it can power your electric fireplace. Make several holes on the body of the plasterboard structure, which will become a kind of hood.

Cover the portal body with plasterboard sheets and strengthen it with special construction corners. Apply putty to the resulting item and decorate the fireplace as you see fit. At the final stage, place an electric fireplace in the finished structure.

Tips for creating a drawing

As mentioned above, before starting all the work, it is necessary to measure the area where the fireplace is planned to be placed. Then you need to make a drawing. When creating a drawing, it is recommended to adhere to the following principles:

- the fireplace support should be slightly longer than its top shelf (for example, the length of the lower part can be 160 cm, and the upper part - 150 cm);

- the height of the lower pedestal should measure from 15 to 20 cm;

- the total height of the structure should be up to one and a half meters (so that the fireplace does not look too bulky);

- the height of the side panels, which can be reserved for “columns”, should be 60-80 cm;

- the fireplace portal should look like a rectangle, but the lengths of the sides should differ slightly (maximum 15 cm);

- between the top of the fireplace portal and the top of the entire structure there should be something like another pedestal (its height should be 20-25 cm);

- The thickness of the top shelf of the fireplace should be small (up to 10 cm).

Selecting a design

The dimensions of the portal will be determined by an electric fireplace, which should be purchased before building a “frame” for it. But the style will be determined by the design of the room. Some foci have a clearly defined affiliation with a particular direction, others are simple and universal. What to rely on:

- Country style (rustic). Natural materials are used - wood and stone (and their imitations). Wood will look good in a small room. Stone is only for large spacious living rooms! The use of plaster is allowed.

- Classic style is unthinkable without monograms, columns, pilasters, stucco moldings and other delights. On sale you can find many ready-made elements made of gypsum or polyurethane foam. In case of an acute shortage of funds, you can simply depict columns, and for some elements use the papier-mâché technique. Colors – white, light shades of any color, gilding.

- The Victorian portal is somewhat similar to the classic one, but looks more massive. Dark colors, carved wood, marble and other stone, arched metal vaults, and forging are used.

- Urban, High-tech, Modern. Modern styles. The fireplace in such a room has a regular geometric shape, is devoid of frills, and is compact. Glass, stone, plain painting and plaster can be used.

Fireplace decoration

Location

In any house or apartment there is unused space that we would like to fill as efficiently as possible and it is desirable to provide multifunctional use.

If you have made the right decision, watch the video on the Internet “how to make a fireplace from plasterboard” - choose an option that is interesting to you.Don't try to copy, you'll waste your time, just take the idea and do the rest yourself. Only the frame is identical, but finishing the fireplace with plasterboard allows you to show your imagination 100%.

First, decide on the location. It is better to do this with the whole family, as it is necessary to take into account some nuances: do not arrange it under the window, do not block the doorways.

It is advisable to position the fireplace so that it is immediately noticeable and does not create difficulties in movement.

The role of the fireplace in our lives: the process of operating the device

Today, traditional bulky fireplaces, consisting of a firebox and a chimney, are a thing of the past, and their construction is extremely rare and requires significant costs. And not all premises are suitable for their construction, which also contributed to their partial oblivion. However, such difficulties do not mean that the fireplace should not be used at all.

Constant progress in the technical field and the field of electronics has led to the emergence of products that are a complete imitation of a fireplace, capable of replacing it.

Electric fireplaces are a unique example of modern technology that has made it possible to enclose the energy of a fireplace in a small box and harness it.

A modern version of an electric fireplace. The portal cladding is made of wood

In itself, a similar product is absolutely safe, since it does not heat up at all during operation, takes up little space and makes it possible to admire a full-fledged fireplace. However, the main advantage of the product is the absence of combustion products, which allows it to be placed in any room, despite its size and stylistic orientation. At the same time, the appearance of the electric analogue resembles a small rectangular box, which, when turned off, does not at all resemble a traditional fireplace. The construction of a portal, which is a distinctive feature of any fireplace system or even its calling card, will help give it a classic appearance.

Portals for electric fireplaces are purely decorative structures designed to structurally highlight the hearth against the background of the entire interior, separating it and visually delimiting the room. They can be made from absolutely any materials without fear of fire or damage, since the body of the product practically does not heat up during operation, projecting the image only on the screen. Based on this, we can conclude that portals are used only to create an accent on the fireplace and should not violate the integrity of the existing design.