A heating register is an integral part of the heating system, a device consisting of several parallel horizontal smooth pipes. This type of heating device has not gained much popularity among private homeowners, and there are objective reasons for this. A register-based heating system has a large volume of coolant, which requires much more energy to heat than with conventional radiators.

A mobile heating register with a built-in heating element allows you to move the device to another location in a short time in case of an emergency.

Application area

Currently, water heating registers are mostly used in industries (workshops, workshops, warehouses, hangars and other buildings with large areas). The large volume of coolant and large dimensions allow the registers to efficiently heat such rooms.

The use of heating registers in industrial buildings ensures the most optimal efficiency of the heating system. Compared to cast iron or steel batteries, registers are characterized by better hydraulics and heat dissipation. The relatively low cost of their manufacture reduces the cost of installing the entire factory heating system. In addition, they are not expensive to operate.

Registers are also recommended for use in premises with high sanitary safety requirements (medical institutions, kindergartens, etc.). The devices are easily washed from dirt and dust.

Despite this, the concept of efficiency does not apply to this type of heating device. As noted above, heating a large volume of coolant requires a lot of energy.

Heating registers at one of the food industry production facilities in the Moscow region.

Heating registers made of steel electric-welded pipes can be used in both single-pipe and two-pipe heating systems with forced or gravity circulation of the coolant (based on water or steam).

Note! Due to the large volume of coolant, which requires a lot of fuel to heat, only enterprises can afford to use heating registers, but not the owners of private houses, for whom the efficiency of the heating system is important.

Adviсe

Before you start making registers, you should take care of purchasing the appropriate materials. You will need pipes of one diameter or another and some length. Exact numbers are not given here, since the device of the type in question can be assembled from any pipes without focusing on their diameter and thickness. More important is to ensure optimal heat transfer, which involves carrying out calculations regarding the required surface area of the register.

To do this, you will need to determine the outer area of the entire system. The resulting value is then multiplied by 330 W. The use of this method is based on the statement that 1 m2 gives off 330 W of heat if the temperature of the medium is 60 °C and the air inside the heated room is 18 °C.

Advice! You don’t have to do manual calculations, but use a simple program in EXCEL and then correctly weld the register according to the exact parameters. You can download the program in one click from the link: https://al-vo.ru/wp-content/uploads/2014/02/teplootdacha-registra-otopleniya.xls.

For people skilled in welding, assembling the structure will not be difficult. It will be necessary to prepare pipes and cut them into sections, and also take care of the plugs, for the manufacture of which a steel sheet will be required. Register assembly does not imply the presence of a strictly defined order of actions. Upon completion of welding work, it is necessary to ensure the tightness of the created structure. Otherwise, the following advice can be given:

- you should select pipes with an optimal wall thickness, since too thin ones cool quickly enough, and thick ones take a long time to warm up;

- the upper section must be supplemented with a Mayevsky valve, with the help of which air is released;

- assembly of the register in the form of a coil involves the use of a pipe bender; if this is not possible, the rotary sections can be assembled from ready-made elbows;

- the coolant inlet must be equipped with a tap, and the outlet with a valve;

- The installation of the register should be carried out with a slight slope in the direction where the supply pipe is located, which ensures that the Mayevsky crane occupies the highest position.

Advantages

- The large length of the devices (up to 6 m) allows you to heat the entire area of the room evenly and in the shortest possible time.

- High hydraulic characteristics.

- Relatively low price. The cost of a mobile 3-pipe device (designed for heating a room with an area of up to 200 m²) with steel pipes with a diameter of 108 mm, a wall thickness of 3.8 mm and a length of 3 m, with a built-in heating element with a power of 2.5 kW is about 13,000 rubles.

- Easy to use. The devices can be easily and quickly cleaned from accumulated dust and other contaminants.

Mayevsky tap at the top of the register.

Flaws

- The large volume of coolant does not allow efficient use of registers in private homes. Home boilers simply will not be able to heat such an amount of water, or the heating will be insufficient.

Advice! To increase the power of the entire heating system of a private house, in addition to the boiler, a tubular electric heater can be installed. The heating element is mounted in the lower pipe of the register and is an additional source of heat. In the coldest weather, when the boiler cannot cope with heating the house, you can turn on the heating element.

Self-installation

Split bolt mounting

Two mounting methods:

- detachable bolted connection;

- non-detachable welding connection.

The choice should be based on the weight and size of the device, and also take into account the characteristics of the heating system.

You can take the rules for installing heating radiators as a basis; there is no fundamental difference. Slope indicator - it is important to take into account, when connecting to a gravity system, the slope along the flow of the coolant.

In systems where pumping equipment is not used and where the driving force is the difference in its partial pressure, there are no such problems.

Installation rules:

- The recommended distance, in accordance with the technological process, from the wall and windows is at least 20 cm.

- Detachable installation requires the use of only paranite pads or flax used in plumbing work;

- All steel heating registers must be painted to avoid rusting.

- It is better not to carry out installation during the heating season.

A comparative analysis of the calculated and actual power of the register can be carried out at the end of the test launch of the system, and if necessary, design changes can be made.

Technical characteristics of heating registers

- Working pressure: 10 atmospheres

- Working medium (coolant): water, steam.

- Connection type: threaded or welded.

- Heat dissipation: 500-600 W/meter

Types of registers.

There are 3 main types of registers:

- sectional U-shaped;

- S-shaped coils;

- “mixed” (U-shaped coil).

The main elements of heating registers are steel pipes (or pipes made of stainless steel grade 304) with a diameter of 25 to 200 mm. Registers with a diameter of 25 to 100 mm are used for heating factory premises for administrative or utility purposes, devices with a diameter of 100 to 200 mm are used in production shops or large sports complexes (swimming pools, volleyball, basketball halls).

As for private households, the use of registers is one of the most ineffective ways to heat a private home.

2-pipe register.

The number of sections of the device can be unlimited and depends only on the area of the room and the required heat transfer.

Advice! If you use too many pipes (more than 4), it will still not be possible to significantly increase the power of the entire device, because The rising warm air heated by the lower pipes will be less able to accept thermal energy from the upper pipes.

Features of Cast Iron Finned Economizer Tube

The heating pipe for industrial economizers can be rectangular in shape and with round fins. The dimensions of the products are standard: the internal diameter is 70 mm, and the external diameter is 175 mm. Due to the differences between the outer and inner diameters, the effect of a low pipe surface temperature with a sufficiently hot coolant is achieved.

Economizer pipes are produced in the same lengths: 2 m and 3 m. Cast iron finned pipes go on sale equipped with two plugs with holes and two blind plugs. Plugs with holes are left-handed and right-handed, with left-handed ones marked with the designation “L”.

There are certain operating conditions under which a cast iron pipe with a ribbed surface will function as efficiently as possible:

- the highest temperature allowed for cast iron economizer pipes is 95 degrees. In emergency cases, a short-term rise in temperature to 150 degrees is allowed;

- constant operating pressure – 0.6-1 MPa (10 atmospheres). However, cast iron finned tubes are compatible with steam boilers whose pressure is maximum 2.4 MPa;

- the outer surface of the economizer is coated with a special primer;

- When installing finned pipes, the mandatory distance from the floor to the middle axis of the economizer is taken into account, which is at least 200 mm. From the surface of the side wall, the distance to the pipe axis is taken into account from 130 mm;

- if economizers are arranged in two rows, the distance between the axes of the radiators is maintained at 250 mm. The rows of economizers are connected to each other by a special arc.

All economizer pipes are equipped with plugs - blind and with holes

The main disadvantages of economizer pipes include their rather heavy weight, which makes transportation difficult, and low resistance to mechanical damage.

Manufacturing of heating registers

For the production of heating registers, steel pipes of various diameters (25-200 mm) are used, which are welded together at a distance of 50 mm from each other (reducing the distance between the pipes can lead to a decrease in heat transfer). This distance allows you to achieve maximum heat transfer and minimize mutual radiation.

The register includes supply and return, as well as an air vent with a ball valve installed in the upper part of the device. The supply and return pipes can be made in two versions:

- Threaded connection;

- Welded connection.

When ordering registers individually at the manufacturer, registers can be supplied either ready-made, assembled, or disassembled, which allows you to save money on logistics.

How to make a heating register with your own hands?

Unlike other heating devices, the production of which requires complex, expensive equipment, water heating registers can be made with your own hands. The main thing you will need for manufacturing is smooth steel pipes and the ability to use a welding machine. If you weld it yourself, you will get the cheapest option, but if you have to invite a third-party welder to carry out welding work, such a register may be more expensive than the factory one. In this case, you should think about whether it’s worth doing this yourself or whether it’s easier to buy a factory device.

Connection diagram for heating registers.

So, if registers are made for use in a private home, you will need the following tools and materials:

- Steel pipes with a diameter of 25 to 100 mm, or profile pipes of a similar size;

- Jumpers made of steel pipe with a diameter of 25-32 mm;

- Pipe plugs;

- Inlet and outlet pipes for welding or threaded connection;

- Branch pipe for air vent with ball valve;

- Fastening elements (brackets for fastening to the wall, or floor stands);

- Welding machine;

- Electrodes;

- Welder personal protective equipment (mask, gloves).

- Gas key;

- Angle grinder;

- Centimeter;

- Building level;

Important! If a heating register made of steel pipes acts as an autonomous heating system for a separate room, when the heat source is a heating element built into the device, then in this case it is necessary to install an expansion tank.

Portable heating register with expansion tank and heating element.

After completing the welding work and connecting the components (air vent valve Mayevsky, etc.), the register is pressurized under pressure. If no leak is detected, the device is painted. If a leak is detected, the coolant is drained and the problem area is welded again.

Selecting a heating device configuration

Homemade radiator designs are mainly made on the basis of metal pipes with a diameter of 80 - 150 mm.

Design features are limited to two versions:

- Lattice.

- Snake.

The lattice design of the heating battery differs from the “snake” in a slightly different circuit design, and, depending on the variations in such batteries, the distribution of the coolant may be different.

Options for circuit design of heating registers for their own production: 1 – one jumper and one-sided power supply; 2 – two jumpers and one-sided power supply; 3 – two-way power supply and 2 jumpers; 4 – two-way power supply and 4 jumpers; 5, 6 - multi-pipe

Coil structures actually have a monotonous design, implying strictly sequential movement of the coolant.

Lattice registers are constructed according to different schematics:

- with one or two jumpers and one-way power supply;

- with one or two jumpers and versatile power supply;

- parallel connection of pipes;

- sequential connection of pipes.

The number of pipes in one assembly can range from two to four or more. Rarely, there is also the practice of making single-pipe registers.

A coil assembly usually contains at least two pipes connected on one side by a blind jumper and on the other by a through jumper, which are made from two pipe bends (2x45º). It should be noted that the design of heating registers in the form of a coil is used much less frequently than “grid” designs.

Options for the possible manufacture of “snake” type registers. For coil-type register battery designs, the choice of manufacturing options is limited compared to lattice-type designs.

Both manufacturing options - lattice and coil - can be made not only on the basis of classic round pipes, but also on the basis of profile pipes.

Profile pipes seem to be a somewhat specific material, since they require a slightly different approach when assembling heating radiators. However, registers made from a profile pipe are more compact and take up less usable space, and this factor is also important.

How to improve register efficiency?

Registers have a relatively small heat-transfer surface and to increase it, metal plates can be used, which are welded vertically to the pipes. The result is a kind of finned tube.

4-pipe register with profile convector pipes.

In addition, the registers can be improved in such a way that they will “produce” convector heating. To do this, instead of metal plates, round or profile pipes are welded vertically onto the front of the device, which will create a convection effect. Convection is based on the fact that hot air always rises. Cool air located in the floor area is drawn in through the bottom of the pipe and, when heated, rises. As the air passes through the pipe, it heats up and exits, already heated, through the top of the pipe.

Operating rules

There are no special requirements for the operation of registers compared to radiators:

They must be securely mounted on legs or strong brackets.

Any heating devices with water should not freeze.

If corrosion occurs, the damaged areas should be cleaned, covered with an anti-corrosion primer and painted in several layers.

Registers must not serve as a support for any loads.

It is necessary to ensure that the heating system does not become airy - this impairs its performance.

Calculation of heating registers made of smooth pipes

The calculation is made using the following formula:

Q = 3.14*D*L*K* (Tr – To), where

- Q – pipe heat transfer

- D – pipe diameter (measured in meters)

- L – pipe length (m)

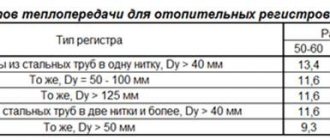

- K – heat transfer coefficient

- To – room air temperature

- Tr – coolant temperature

Thus, by substituting the values of each specific room, the heat transfer of the lower pipe is calculated. The top pipes have approximately 10% less heat transfer than the bottom pipe.

Note! On average, 1 m² of room requires 1 m of pipe with a diameter of 60 mm.