Few people know, but it turns out that the speed of water flow in a home water supply can be controlled from a distance. To do this, instead of a conventional valve, a magnetic valve is installed. Let's figure out where such a useful device can be used, how it works, and what types of it exist. Read to the end and learn how to independently and competently purchase the necessary part.

Magnetic valve with control sensors Source aquacenter.es

Radiator Bottom Connection Kits

For piping heating devices, kits for bottom connection of radiators are used. They are designed for two-pipe heating systems and allow you to hide pipes in the floor, load-bearing walls or special boxes.

Advantages and design features

The side connection of radiators does not violate the style of the interior of the premises, but is more expensive than the side connection due to the increase in the number of consumables and the amount of work. The strapping unit includes the following devices:

- thermostatic element;

- shut-off valves.

The valve bodies are made of corrosion-resistant steel, resistant to mechanical damage and high temperatures. Seals made of synthetic rubber ensure tightness, chrome or nickel plating additionally protects against corrosion and gives the products an attractive appearance. Installation is carried out using a coupling connection with external and internal threads.

The Santekhkomplekt online store offers a large selection of corner and straight kits for connecting radiators produced by DANFOSS and HEATON. From us you can buy models with a diameter of 15 mm with a liquid and gas-condensate sensitive element.

The catalog also presents components and fittings for the installation and maintenance of water supply and heat supply networks. The range includes adapters and other connecting fittings, valves, drain taps, special brackets for fixing batteries on the wall, manual and automatic air vent devices. The Internet allows you to place an order without wasting time visiting stores and shopping centers. We provide guarantees for equipment and organize transportation of goods to any region of Russia.

Types of air vents in the heating system

Based on the principle of operation, they distinguish between ball and needle automatic devices, and according to design - straight, angular and radiator. Despite the different areas of use, the operating principle of all air vents is the same.

Special float devices are very popular. This is an automatic air vent that provides side air release. The device operates at an operating pressure of 10 bar, with a maximum permissible temperature of 110 degrees. The device can work not only with water, but also with various glycol solutions in concentrations up to 25%, and the connection thread is 1/2.

All modern automatic air vents are divided into several types, differing in general design. There are three main types of such devices:

- Angular;

- Straight;

- Radiator.

Direct air vent

The most common is the first type with a straight pipe. It is indispensable at the highest points of the system, where, according to all the laws of physics, the maximum amount of gases accumulates, and manual air release in such places is often difficult.

The closed system, which is constantly under pressure, is ensured by the boiler safety group. It is usually located on the supply pipe that exits the heat generator. In addition to the pressure gauge and safety valve, this kit also includes an automatic air vent for heating, which bleeds air when the tank is filled with liquid. If the unit is installed correctly, it can be separated from the system at any time and released for maintenance using a gas vent. For boilers operating on solid fuels, a safety group is required.

You can also find an air bleeder in circulator pumps. Its task is to create conditions for them to have an uninterrupted supply of water. The problem is that the pumping unit can only work with an incompressible medium. The penetration of air onto the pump impeller threatens to stop it completely. The active circulation of liquid is controlled by the gas vent.

Corner air vent

If the location is too inaccessible to install a simple valve (for example, the pipe is horizontal), use an angle version of the valve. Its pipe, rotated 90?, can be connected to the horizontal part. It is worth noting that the corner modification with external thread, except for the deployed pipe, is practically no different from its analogues, so these types are completely interchangeable.

Radiator automatic air vent

Sometimes, instead of the traditional Mayevsky tap, an automatic angle valve is installed on radiators. It is only slightly larger than its counterpart, a little more expensive (about $2), but does not require daily human intervention. This choice is justified if gases accumulate in the battery regularly due to the chemical reaction of the aluminum alloy from which the section is made and hot water.

Although for such cases they produce a special automatic device with a diameter like a radiator plug (see photo). The device is designed specifically for aluminum and partially bimetallic radiators and has a suitable connection type.

For cast iron batteries and old-type systems, the Mayevsky tap and drain pipe are more suitable.

Radiator valves

Thermostatic fittings are a type of device that allows you to automatically regulate the volume of coolant passing through the radiator depending on the level of air temperature in the room. The thermostatic valves are controlled using an electronic display with buttons or a mechanical dial. A shut-off valve is installed at the inlet to the control radiator, which is programmed to maintain the previously set temperature in the room. Subsequently, it regulates the supply of coolant (hot water), reducing or increasing its quantity.

Thermostatic fittings include thermal heads for radiators and thermostatic valves. The thermal head has a scale of set temperatures, and after the desired temperature is indicated on it, it will itself react to changes in surrounding indicators and, accordingly, influence the thermal valve (shut-off and control valve), which will already increase or decrease the flow of coolant entering the heating device.

A thermal valve is a thermostatic element similar to a regular radiator valve. It can be controlled manually and independently regulate the heating of the heating device. The thermal valve becomes automatic only after attaching a thermal head to it.

In order for thermostatic fittings to work properly, you need to install it correctly, exclude extraneous heat sources in the room, and prevent direct sunlight from entering the sensor and preventing it from being curtained or blocked.

Leroy Merlin stores offer their customers a wide selection of thermostatic fittings from the world's leading manufacturers at an affordable price. Highly qualified staff of the network will help you answer any questions about the product and make your choice.

Leroy Merlin offers a wide selection of goods at low prices for residents of Moscow, as well as the cities of the Moscow region: Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye , Dolgoprudny, Zhukovsky, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Klin, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky and Solnechnogorsk. You can order the necessary goods online with delivery to all these cities or visit one of our retail stores in Moscow and Moscow Region.

Nuances of selection and installation

When purchasing the type of electromagnetic shut-off valve, you need to pay attention to two points. Initially, you need to study the parameters of the pipeline. So that the inlet and outlet openings of the valve completely coincide with the diameter of the line. Otherwise, the water flow may slow down. And this is fraught with an increase in pressure and temperature in the system.

It is equally important to study the specification. The manufacturer must indicate for which systems its products are intended. The description gives the minimum and maximum permissible values for the internal temperature, as well as pressure and flow rate.

It is always necessary to take into account the conditions and chemical composition of the product that will move through the pipeline. For example, acid will corrode the brass body of the device. And too hot water can destroy the plastic shell.

Installation of a magnetic valve in a heating system Source master-vodoved.ru

Radiator valves

Thermostatic fittings are a type of device that allows you to automatically regulate the volume of coolant passing through the radiator depending on the level of air temperature in the room. The thermostatic valves are controlled using an electronic display with buttons or a mechanical dial. A shut-off valve is installed at the inlet to the control radiator, which is programmed to maintain the previously set temperature in the room. Subsequently, it regulates the supply of coolant (hot water), reducing or increasing its quantity.

Thermostatic fittings include thermal heads for radiators and thermostatic valves. The thermal head has a scale of set temperatures, and after the desired temperature is indicated on it, it will itself react to changes in surrounding indicators and, accordingly, influence the thermal valve (shut-off and control valve), which will already increase or decrease the flow of coolant entering the heating device.

A thermal valve is a thermostatic element similar to a regular radiator valve. It can be controlled manually and independently regulate the heating of the heating device. The thermal valve becomes automatic only after attaching a thermal head to it.

In order for thermostatic fittings to work properly, you need to install it correctly, exclude extraneous heat sources in the room, and prevent direct sunlight from entering the sensor and preventing it from being curtained or blocked.

Leroy Merlin stores offer their customers a wide selection of thermostatic fittings from the world's leading manufacturers at an affordable price. Highly qualified staff of the network will help you answer any questions about the product and make your choice.

Leroy Merlin offers a wide selection of goods at low prices for residents of Moscow, as well as the cities of the Moscow region: Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye , Dolgoprudny, Zhukovsky, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Klin, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky and Solnechnogorsk. You can order the necessary goods online with delivery to all these cities or visit one of our retail stores in Moscow and Moscow Region.

High pressure solenoid valves

High pressure electromagnetic valves are used in distribution systems and manifolds. Automation of work is ensured by an electric drive: the device is controlled remotely and is triggered when power is turned off or supplied. Can be used in assembling a complex network, since shutdown in case of emergency mode is performed automatically.

Materials of high pressure solenoid valves

Case material:

- Made of brass.

- Malleable cast iron.

- AISI 304 stainless steel.

Piston seals:

Seal

- TEFLON - resistant to acids and alkalis.

- FKM - used in pipelines with aggressive working media: gasoline, mineral acids, hydrocarbons, oils

- PTFE - chemical resistance superior to that of all elastomers and some thermoplastics. It has good swelling resistance in almost all working environments.

- PEEK is a polyetheretherketone with high chemical resistance for universal use.

- EPDM - is resistant to diluted alkalis and does not lose elasticity at low temperatures. Restriction: transportation of mineral and animal oils and fats.

Execution:

- normally closed - when voltage is applied, the shut-off device opens. If there is no voltage, the working medium is blocked;

- normally open - cuts off the flow when triggered. Used for remote control.

By connection method:

- high-pressure coupling solenoid valves are connected using threads;

- flanged - mounted on a mating flange with bolts or studs.

Operating principle:

- Direct acting high pressure solenoid valve. The main channel is closed directly by a piston controlled by a solenoid.

- Indirect action. The flow is blocked by an additional pilot valve channel.

How to install the valve:

How to install a high pressure hydraulic solenoid valve

The solenoid is installed in a horizontal position, with the coil facing up. The ends of the pipeline are cleaned of contaminants: sand, scale, etc. Before installation, it is important to determine the direction of movement of the working fluid. An arrow on the housing indicates the correct position of the device. The solenoid valve is fixed with flanges or threads using a suitable seal.

Bottom connection valve for sectional radiators

Watch a video about airing the saddle or bench heating branch.

Typically, sectional radiators with tube inlets are located on the sides are connected to a saddle circuit. So, a plug is twisted into the upper fittings on one side, a Mayevsky tap on the other side, and an inlet and an outlet at the bottom.

Such a saddle connection will air the battery until the coolant flow is raised upward using a special plug. To do this we need a lower radiator connection valve. Which will not only prevent the heating battery from airing, but will also increase heat transfer by 25%!

This is the bottom connection valve.

The issue of correct and at the same time aesthetic connection of a radiator is quite popular among those who are concerned about installing heating in an apartment. You may also find interesting the material on how to install a heat flow extender inside a radiator, useful for lateral connections.

Recommendations

There are standards for the interaxial distance at the bottom connection terminals of radiators with bottom connections. Although, perhaps not standard ones like the Rifar Monolit Ventl, which is wider than its standard counterparts, which are sold in a wide range on the market...

Polypropylene piping The cost of such work to install a heating radiator in an apartment on pipes with a jumper and shut-off valves comes out at a price of around 2 -2.5 tr. For taps and pipes, the cost of the entire piping will be…

Bottom connection of the radiator where is the supply and where is the return

Many users of our site are looking for information about how Kermi radiators are connected, and what kind of jumper or so-called bypass they have inside, which is a tube originating below the supply connection itself (as Kermi knows, it is from below). From this lower connection pipe, the tube inside the radiator rises and is adjacent to the tap, with the help of which the supply of coolant is regulated.

It is needed in order to use a gasket supported by a spring to plug the intersectional flow inside the battery between the first and second sections, then the heat flow will have to rise upward and this is the same as the tube for radiators with a bottom connection, or it’s the same as a diagonal connection when the inlet is at the top and the outlet from below on the opposite side. But let’s return to the Kermi radiators, their bottom connection and bypass connector.

This is a direct connector for laying pipes of the heating branch under the floor.

And this is a corner connector for laying a heating main inside the wall.

If there are special requirements for aesthetics and even if the pipes will be laid inside the walls, then it is recommended to install corner connectors.

Briefly about the main thing

All you need to know about the magnetic valve is that it requires electricity and various control equipment to operate automatically. For example, a timer programmed for a certain time will send a signal to the induction coil. The latter drives the plunger on the valve, built into a regular water supply.

The raised rod will open a passage for water, and a strictly calculated portion of liquid will fall into the flower pot. And the amount of required moisture will be measured by a special meter. He will then send his signal to the same coil. And this time the electromagnetic field pushes the rod into place, blocking the flow of water.

Bottom connection of heating radiators: pros and cons of the circuit

Connecting pipes to the radiator from below is one of the best solutions in plumbing, providing a high level of aesthetics to heating devices. There are, however, a number of rules, the observance of which will ensure the correct operation of the entire hydraulic system and facilitate the connection process.

Which radiators are designed for bottom connection?

It is not without reason that the diagonal radiator connection scheme is considered the most effective. This is how maximum heat removal, uniform distribution of coolant and optimal temperature gradient are ensured, promoting intense convection. Even with a lower supply of pipes to the radiator, one of the mandatory requirements is to ensure water flow diagonally from the upper edge to the opposite lower edge. But not all radiators have a device that allows you to achieve such a distribution of coolant.

Design of a panel radiator with bottom connection

The most common type of heating devices, in which the required conditions are provided for by the design, are steel panel radiators. Another type can be called sectional radiators with a bottom connection, although only the first two sections have fundamental differences in their design, all the rest are the most common.

Both of the mentioned types of heaters have a pair of pipes located in the bottom part, that is, oriented towards the floor. In both cases, the specificity of the device is such that the supply pipe is connected directly to the channel through which the coolant is directed to the upper part of the labyrinth.

Sectional radiator with bottom connection

It is also possible to retrofit conventional sectional radiators in order to connect them with a lower side supply. For this purpose, special fittings are used, due to which the configuration of the circulation channels changes. The lower connection can be double-sided; in this case, on the supply side, instead of a fitting, a valve is screwed in, the end of which rests against the nipple of the first section and shuts it off, while the outlet is directed strictly upward.

Valve for lower radiator connection

A one-way connection is also possible, which requires the installation of a valve with a tubular probe designed for the outflow of cooled coolant.

Thermostatic unit for lower radiator connection

The described range of fittings can be used for most models of sectional bimetallic and aluminum radiators. The exceptions include such exotic representatives of the world of heating devices as Rifar Monolit, which do not have nipples, although their model range includes modifications for lower pipe supply. In plumbing practice, there are also examples of bottom connections of cast iron radiators, although the possibility of such installation is always determined individually depending on the model.

In which heating systems is bottom supply used?

It is obvious that the supply of coolant from the bottom up is unnatural, because it is directed against the action of gravity. For this reason, the lower supply of radiators cannot be performed in open heating systems with natural circulation. But this is far from the only limitation.

Even with a two-way bottom connection, where the return pipe is connected according to the standard scheme, a special valve is installed on the supply. Its throughput is lower than that of a conventional fitting with a screwed-in fitting, so the coefficient of local resistance of the radiator in this case will be at least twice as high as the nominal one. This forces the use of circulation pumps with more intense pressure and radically reconsider the hydraulic calculation procedure.

With a one-way bottom connection, even more difficulties arise. Firstly, the local hydrodynamic resistance of the radiator increases even more, because now two opposing channels with a fairly small nominal bore pass through one outlet. In addition, there are difficulties with installing shut-off and control valves. High-quality bottom connection units for radiators with a built-in thermostatic head are a rarity on the domestic market. Most of the range is represented by Chinese-made products that do not provide sufficient flexibility and accuracy of adjustment. Another nuance lies in the method of regulating coolant flow: instead of a rod that limits the throughput, most injection units have a built-in bypass, which radically changes the balancing method. At the same time, installing an injection unit with a separate throttle and thermostatic head is often unacceptable due to lack of free space, and if such a configuration is still possible, it will be extremely cumbersome and inconvenient to manage.

Two-pipe heating system with associated coolant movement

We can say that two-pipe systems with a parallel movement of the coolant or radial decouplings are best suited for the bottom connection of radiators. Due to the significant reduction in radiator capacity, there is no obvious reason to abandon thin PEX pipes with tension fittings, which look much sleeker than other power systems. It would not be a good idea to use a bottom connection for single-pipe circuits; in this case, it is quite difficult to balance the system and ensure its stable operation.

Pipe supply to the radiator

Of course, the use of cross-linked polyethylene in the heating junction is not at all necessary, although it is preferable for reasons of reliability and aesthetics. You should definitely stop using steel pipes. The reason for this is simple: traditionally, when connecting from below, the pipes go into the floor and run either under the covering or along the ceiling of the lower floor. If the heating pipeline passes through the ceiling, the passage needs to be lined, which does not have the best effect on the appearance of the floor covering. Otherwise, the choice of material for decoupling the system is quite free; polypropylene, the aforementioned PEX, and even copper can be used.

We should also touch upon the topic of using pipe insulation. There are three positions on this issue:

- Without insulation, pipes can perform the function of floor heating, provided that they are located in the passage area.

- The insulating casing effectively reduces parasitic heat leakage, which is important when laying pipes in the technical cavity of the ceiling of the lower floor.

- When pipes are in dense, incompressible environments, such as floor screed, the insulation acts as a damper, compensating for the thermal expansion of the plastic and allowing it to expand in both directions.

At the time of installation of the wiring, the installation position of the radiators must be known exactly. The height may vary, but horizontal movement is generally not acceptable. This is due to the fact that the rotary fitting is not located on the surface, that is, only a straight section protrudes above the coating and is connected to the radiator outlet. You can deviate from this rule only if lower side connection units are used; in this case, the pipe outlets are located at a distance of about 100–120 mm from the end of the radiator liner.

Fittings and consumables

The installation of radiators with bottom connections does not imply any particular complexity, but this requires preparing in advance all the necessary fittings, fittings and packaging. Depending on the type of radiator, the list may differ.

For radiators whose bottom connection is provided by the design, a set of adapters corresponding to the pipe material is required. As a rule, these are straight press fittings or sleeves for soldering; when using polypropylene, it is recommended to install threaded “American” ones. In such cases, control valves are extremely rarely installed directly under the radiator; its optimal location is on the distribution manifold. The situation is exactly the same when installing injection units.

With a lateral lower pipe supply, it is possible to install thermostatic and control valves on the radiator. In this case, all fittings are installed on the “metal” part, that is, they are packaged on threaded connections with fittings or threaded fittings of the lower connection valves. In any case, each radiator is equipped with two shut-off ball valves to allow the radiator to be removed without stopping the system. You will also need one or two radiator plugs and a Mayevsky tap. Sealing of threaded connections is traditionally done with tow and Unipak sealing paste.

Installation rules

Before connecting the radiator to the system, it is assembled in a lying state with the installation of all fittings. Ultimately, only two straight press fittings or union nut connections should remain: on the supply and return lines.

The lower connection valve replaces the radiator liner. Its sealing occurs in the standard way for this unit - using an o-ring seal. It is advisable to mark the position of the through hole on the shank on the valve nut so that after tightening it is positioned strictly vertically. To adjust the position, you can use seals of different thicknesses and adjust the degree of tightening.

The injection unit is connected in a similar way, but quite often it does not have a nut that replaces the fitting. With a one-way bottom connection, the outlet on the reverse side is plugged with a plug, like one of the top ones, and a Mayevsky tap is installed in the remaining one. The further assembly scheme is simple: all the necessary shut-off and control equipment is packed onto the threaded fittings of the valve, injection unit or lower outlets onto tow with sealing paste. Ultimately, the radiator is installed in place as an assembly and fixed using a wall or floor mounting method, then it is connected to the system.

Did you like the article? Subscribe to the channel to stay up to date with the most interesting materials

Types of automatic air vents

There are three types of these devices in total - despite this, the operation of the automatic air vent, or rather its principle, remains unchanged. In all cases, the same needle valve and the same float are used to open and close it - the only difference is in the position of the body relative to the connecting pipe, i.e. threaded connection.

- Direct automatic air valve for heating. The most common device for automatic air removal. It is intended only for vertical installation - in the sense that if you suddenly decide to use it for a battery, you will additionally need a 90-degree angle. The optimal area of their application is pipelines, or rather their upper points, where, according to all the laws of physics, the air generated in the heating rushes. If it were not for such devices, it would be very inconvenient to vent air at the highest points of heating systems. In addition, some heating system equipment is also equipped with automatic vents with direct connecting pipes. For example, an automatic air valve is an integral part of the boiler safety group, which also includes a pressure gauge and an explosion valve. Indirect heating boilers and other equipment are also equipped with air vents, at the top of which there is a possibility of air accumulations.

- Corner air vent. In short, corner air machines are used where it is not possible to install its direct counterpart - it may either not fit in the right place, or the equipment may have a side outlet with a thread. In general, there are many different situations, and it makes no sense to list them all, especially since the essence and principle of operation remain unchanged - only the location of the threaded outlet connection pipe and, as a result, the appearance of the Mayevsky automatic crane changes. A very important condition for the proper functioning of the corner air vent machine is the strictly vertical installation of its body. Horizontally and even at a slight angle, the machine will not be able to operate adequately - the float will get stuck and, as a result, air removal will be untimely or will not be removed at all.

- Automatic air vent for radiators. In essence, this is a type of angular machine for removing air, although you can’t tell from the outside - all these nuances are hidden inside the case. The outer part of the battery vent is created based on aesthetic considerations. In addition, these devices also differ in the diameter of the connecting pipe - on modern radiators they are installed directly into the battery, without the use of foot nuts. On old batteries they are mounted through a fitting with a threaded hole through it, and for steel convectors special machines with a half-inch pipe are used.

These are all the varieties that an automatic air valve for heating systems can boast of. In principle, you don’t need more, since regardless of the different installation conditions, one of them will still work.

Connections for radiators

Connection units for radiators are designed for reliable piping of heating radiators. We offer to buy fittings for radiators from various manufacturers, with which you can connect different types of heating devices.

Such units allow you to control the movement of the coolant, as well as regulate the heating temperature of heating radiators. In addition, various types of fittings make it possible to shut off certain areas of the heating system in the event of accidents or emergency situations.

Using the parts for connecting radiators presented in our catalog, you can install heating devices with various types of connections.

Connection diagrams

One-way side connection. This type of connection (coolant inlet from the top, outlet from the bottom of the radiator, all on one side) ensures the maximum level of radiator efficiency. This connection is characterized by a high level of reliability and the ability to quickly replace the radiator. Devices up to 1.6 m long can be connected.

Diagonal side connection. Provides good heat transfer from the radiator. Strapping - entry from above on one side, exit from below on the other side.

Bottom side connection. Piping - coolant inlet at the bottom on one side, outlet at the bottom on the other side. With this type of connection, 90% of the power of the heating device is used.

Bottom connection. This type of connection is used in devices that provide such a wiring diagram. Maximum heat transfer of devices is ensured.

Depending on which radiator connection diagram was chosen, a certain set of parts is selected for tying and fastening the heating battery.

Standard set

A standard kit for connecting a heating device usually consists of the following parts:

Bottom supply valve 1″x¾” for radiator, right

Bottom supply valve 1″x¾” for radiator, right

Article: 011080102-02 Right 1″ x ¾” radiator valve - designed for supplying coolant to the radiator according to the “Leningradka” scheme, i.e. when the pipe runs along the floor and is connected to the lower manifold on both sides (without connecting to the upper manifold). 400 RUR / piece Select a gift When purchasing this product, you are entitled to one of the gifts presented below Questions and reviews Delivery and payment

Radiator valve 1″x3/4″ right - designed for supplying coolant to the radiator according to the “Leningradka” scheme, i.e. when the pipe runs along the floor and is connected to the lower manifold on both sides (without connecting to the upper manifold).

In this case, the supply is carried out from the left side, and the return leaves from the right.

Using a valve allows you to increase the heat transfer of the battery by 20% due to the forced redirection of flow up the section. The diagram of water movement is shown in the figure next to it (in the figure the valve is located on the left, in our case it should be on the right).

The valve can be used for all models of radiators that have a width of each section of 80 millimeters and a nipple thread of 1″.

The valve provides a ¾" pipe connection.

Questions and feedback

- Questions and feedback

Loading comments. Shipping and payment

Payment Methods

- Delivery by our own courier service – cash payment.

- Regions of the Russian Federation – non-cash payment (details are sent to the buyer’s email).

- For legal entities - the same as for clients from regions of the Russian Federation (see above).

Delivery by our own courier service:

- delivery in Moscow (within the Moscow Ring Road) – 750 rubles;

- delivery in the Moscow region – 750 rubles + 30 rubles/km beyond the Moscow Ring Road using Yandex cards;

- delivery to the transport company terminal in Moscow (inside the Moscow Ring Road) – 750 rubles (you calculate the remaining amount for delivery with the selected transport company).

Delivery is carried out to the entrance! If carrying/lifting is required, this will be discussed separately with the operator.

Pickup

The operation of the pick-up point is temporarily suspended.

Thank you for understanding. —> Pickup is available from Monday to Friday - from 9:00 to 18:00. Pickup is free of charge at the address: Moscow, st. Verkhnelihoboskaya 8с2.

When picking up, always place your order in advance and check the product's availability for pickup. You risk not receiving the goods if you arrive without a pre-order, since the goods may be in a distant warehouse and not available at the pick-up point.

Bottom connection unit for radiator with side connection

Bottom connection unit for radiator with side connection

Article: me877+me866+M331-15-60

This unit makes it possible to connect a regular radiator with a side connection to pipes prepared for radiators with a bottom connection.

It consists of 3 components: an upper unit, a lower unit and a tube, which is cut to fit the center-to-center size of the radiator.

RUB 1,236.11 / piece Select a gift When purchasing this product, you will receive one of the gifts presented below Questions and reviews Delivery and payment

This kit makes it possible to connect a regular radiator with a side connection to pipes prepared for radiators with a bottom connection.

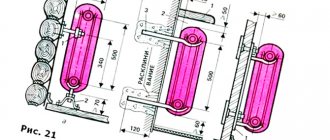

It consists of 3 components: an upper unit (me866), a lower unit (me877) and a tube with a diameter of 15 mm (M331-15-60), which is cut to fit the center-to-center size of the radiator.

The use of this set is permitted at pressures up to 10 bar.

Design

Top component

It is a thermostatic angle valve installed to supply coolant to the radiator. The kit includes manual adjustment by rotating the lid, which can be replaced with a thermostatic head size M30*1.5.

- Diameter to the battery - G1/2″;

- Connection of the external tube, collet - 15mm;

- Thermal head size M30*1.5;

- Air vent included.

Bottom component

Provides connection to pipes coming from the floor. Organizes the transfer of liquid to the upper component from the supply pipe and the return of the coolant through the radiator back to the pipe, but in the return direction. It also provides the possibility of use in both a two-pipe system and a single-pipe system. In the first case, the entire coolant flow passes through the radiator, and in the second case, part of the liquid (up to 50%) is discharged directly to the return line, bypassing the radiator.

- Diameter to the battery - G1/2″;

- Connection of the external tube, collet - 15mm;

- Connection to the highway - 3/4 HP (under the Eurocone);

- Ability to configure one- and two-pipe systems;

- The distance between the outlets of the main pipes is 5 cm.

Outer tube 15mm

A stainless steel tube connects the two components mentioned above into a single structure.

This component can be 80mm long depending on stock availability.