Today we have to consider in detail the issue of arranging a heating system in a garage. Of course, maintaining the desired temperature level there is very important. Then you can work effectively. Some garage workers even organize real professional workshops. Of course, for their uninterrupted operation, regardless of the weather and time of year, you will need to install a boiler in the garage.

Let's find out what heating systems are available, what types of fuel are more economical to use, and what kind of boiler is best to install in the garage. Let's find out what car enthusiasts think about this, who have already assessed the pros and cons of different options personally.

Comparison of heating sources with each other

In winter, the air temperature drops below zero, so it is unpleasant to be inside a garage building without a boiler room.

Heating devices today are manufactured in a wide variety. They differ in their cost, size, and power source, which largely determines the operational parameters of such equipment. Let's talk further about how to add warmth to a garage building. Heating a garage with a boiler is an excellent solution if the room is used all year round. But which equipment option should you prefer?

Today we will consider the following boiler models that are worth choosing:

- gas unit;

- electric boiler for the garage;

- on solid fuel: firewood, coal, construction waste, etc. heaters;

- garage heater that consumes alternative fuel: used engine oil, pallets, biofuel, etc.

Gas is cheap and efficient

Gas is the most economical fuel, provided that the main pipe is close. Otherwise, you will have to use gas cylinders, which is not always convenient, cheap, or practical. The installation of such equipment does not have to be supplemented by the installation of a water heating system for wall surfaces and floors.

Let us describe the main advantages of gas boiler equipment:

- significant savings on the purchase of energy resources;

- availability of gas provided that the main gas pipeline is located nearby;

- autonomy of work processes, no need to constantly monitor the device;

- high energy efficiency indicators;

- long service life, rare breakdowns;

- the ability to use liquefied gas cylinders or connect to the main gas pipeline;

The disadvantages of gas heating equipment are the following:

- installation of a gas boiler is carried out only with permission from the supervisory authorities;

- when installing equipment, you will need to allocate a separate room, carry out a series of actions, the purpose of which is to increase the fire resistance of wall and floor surfaces: this will eliminate cases of fire;

- the need for material costs to equip a high-quality ventilation system.

Electric heating

It is advisable to purchase an electric boiler for heating a motorhome if there is no main gas supply. It is very convenient to use, but installation inside a small building will be quite expensive. If the climate is mild, it is better to prefer an electric convector or fan heater, additionally equipped with a thermostat.

We will describe the advantages of electric boilers for heating a garage below:

- absence of noise when operating a garage electric boiler;

- It is not difficult to arrange heating for a garage with your own hands using electrical equipment;

- full automation of work processes: when a certain air temperature is reached, the unit turns off briefly and then independently begins to function in the same mode;

- high safety indicators: if the unit overheats, the fuses will stop the system;

- a homemade electric boiler operates without combustion products, it is economical: installation will cost less, since there is no need to buy chimney pipes;

- The equipment is compact in size, making it easy to plan for a small motorhome.

A heating element electric boiler has the following disadvantages:

- Although electricity consumption is quite low, it itself is highly expensive today;

- The functioning of the heating system is entirely dependent on the availability of electricity: if there is a power outage, the garage may become cold;

- Installation of the unit must be accompanied by the installation of additional wiring: if the equipment has high power, a three-phase network will be required.

Heating with solid fuel

The fuel of electric boilers for heating a garage can be solid materials: firewood, coal, peat, straw, construction waste. They are tucked inside the equipment at intervals of 2 to 14 days, which is quite convenient.

It is optimal to heat a garage with a solid fuel heating boiler when it is not possible to connect to the main gas pipeline and there is no desire to use gas cylinders. Similar models are also selected if installation of an electric boiler is not possible for certain reasons.

Let us describe the main advantages of boilers using wood, coal and other solid materials:

- high efficiency;

- wide choice of fuel types, its low cost;

The following points are considered to be the disadvantages of solid fuel equipment:

- the garage owner must monitor it almost all the time the heating system is operating so that there are no interruptions in operation or complete combustion of fuel;

- installation of a solid fuel boiler must be accompanied by the installation of a high-quality ventilation system and chimney.

Processing: alternative fuel

A garage heating system can be powered by alternative fuels. One of the advanced technologies is the use of used machine oil. No less relevant in rural areas today are models powered by biofuel, pallets made by farmers.

Let us give a brief description of alternative fuels for the garage heating system.

| Type of alternative fuel | Advantages | Flaws |

| used machine oil | Is affordable | Fire hazard, releases soot when burned |

| biofuel | Low price, ability to make it yourself, environmentally friendly | The need for searching and procurement work; when burned, it emits an unpleasant odor |

| pallets | Low cost, environmentally friendly, high efficiency | The pallet manufacturing process requires certain equipment |

Installation stages

To ensure safe operation of the boiler room in the garage, it is important to install a high-quality ventilation system that can remove all harmful gases from the room. To do this, you need to correctly assess the required fan performance. Its power can be calculated using the following formula: M = (SxHx12) + 30%, where M is the hood power; S is the area of the room; H is the height of the garage. In this case, the formula takes into account that complete renewal of the air volume must be ensured in 12 hours, and the minimum power reserve of the installation is estimated at 30%.

The design of the heating boiler can be single-circuit or double-circuit. In the first case, the coolant heated in the boiler is intended only for heating the room, and therefore circulates through a closed system with radiators. In the double-circuit version, an additional network is provided for obtaining hot water or removing coolant for heating another room, a house.

If the owner wishes, the boiler room in the garage can easily be installed with his own hands, but using standard equipment. When installing a gas boiler, the project must be agreed upon with the relevant authorities. The arrangement of the system must be carried out taking into account technical and fire safety requirements. After completing all these stages, you can use the installed equipment for many years and enjoy the unconditional comfort that it will give.

The best heating boilers

If you decide to choose a high-quality boiler for your garage, you should study the manufacturers’ proposals and understand which models are more popular than others. Then you can be confident in the quality of the chosen model. How to choose which criteria to take into account?

Criteria for optimal selection of a heating system:

- price;

- productivity;

- safety;

- installation features.

Based on these criteria, we will describe the main brands of electric boilers for the garage, which are in high demand in the domestic market and are worth the consumer’s attention:

- Baxi. An Italian brand known to customers all over the world, but it is most popular in European countries. Baxi models are distinguished by convenient adjustment, high efficiency, can operate in autonomous mode, and are capable of self-diagnosis. Baxi boilers are equipped with energy-efficient pumps that provide high efficiency. There are models that can be installed outdoors, but they are not cheap.

- Vaillant. The brand produces boilers with high performance and reliability thanks to the improved design of burners, the use of circulation pumps, and the creation of a casing made of high-quality steel alloys. Vaillant do not overheat and do not jam. But its large dimensions make it possible to place such a boiler only in a large garage.

- Protherm is a manufacturer that produces high-quality boilers of various capacities. Small-sized options are quiet, have an interesting design, and are often installed in motorhomes.

- It is also worth noting the products of the Ferroli and Bosch brands, which have also earned recognition from a large number of car owners.

A high-quality electric boiler for heating allows you to create optimal conditions inside the motorhome, turning it into a comfortable room for staying even in severe frosts outside.

Video: different heating options from experienced garage workers

It’s worth watching additional video materials to evaluate the advantages and disadvantages of different methods and to visualize everything clearly.

This video discusses the option of organizing a heating system in a garage on your own, with minimal investment.

The following video tells about the operation of the fireplace stove.

Of particular interest is a furnace that operates on waste oil. It is quite possible to make it with your own hands, and it works on already used oil. There are, of course, some nuances here. But in general, this method is quite rational and safe if it is possible to organize timely cleaning of the waste in a special installation. The arrangement and manufacture of a boiler for heating during mining is described in the following video.

A boiler in a garage will be an excellent solution for organizing a heating system. This will allow you to create comfortable conditions in the garage at any time of the year, work there with high efficiency, and carry out vehicle inspections and repairs.

Advantages and disadvantages of various systems

A garage heating system must be cheap, and this is the main requirement. The owner of a garage has to invest a lot of money in maintaining and repairing the car, and arranging the premises for it. This is costly, and it is worth taking every opportunity to reduce the cost of heating.

On the other hand, savings must be reasonable: without compromising the efficiency or safety of the system.

There are many different types of systems and devices that can be used to heat a garage. They are not perfect and have their own shortcomings. Each owner has to decide which selection criteria are most important to him.

Option No. 1 – classic water heating

To connect heating to the garage, it is not necessary to install a separate boiler, but an additional load is placed on the overall system. This must be taken into account when purchasing heating devices and take them with a power reserve.

Fuel consumption also increases, but the costs are still lower compared to installing a separate heating system for the garage.

The second option is to install a garage heating system with a separate boiler. This is a good solution if the building is located far from the house and the heat loss when moving heated water through pipelines is too great.

When installing a water system with a separate boiler, it is worth using antifreeze as a coolant to prevent possible defrosting.

The coolant is heated in the boiler and flows through the pipeline to the radiators. Cooling down, it returns to the heater again. The system can be one- or two-pipe. This determines whether the radiators will be connected to the boiler in parallel or in series.

The first type of connection guarantees equal heating of all radiators, but it requires two pipelines.

For a garage, a single-pipe system is best. This scheme allows you to arrange heating with minimal costs for materials, and installation is also simplified. If there are several radiators, they are connected in series.

It is worth considering: in each subsequent device the coolant temperature decreases.

Spacious garages, commercial auto repair shops, and service stations are equipped with a full-fledged dual-circuit heating system. You have to spend money on more materials and complex installation, but the heating of the room will be uniform and efficient.

Option No. 2 - heating with gas

Gas heating is the cheapest, but to connect to the main line you will have to obtain permission from the relevant services. In many cases, garage owners try to avoid a long approval procedure.

Another nuance: for unauthorized connection to the main pipeline or carrying out commissioning work, you can pay a serious fine.

Therefore, it is advisable to do everything according to the rules or use bottled gas mixtures.

If you connect to the mains, you can provide cheap and highly efficient heating. If you have to use liquefied gas, then you should choose a device that uses fuel economically. This could be a gas heat gun, an infrared heater or a convector.

Option No. 3 - electric heating

Electrical appliances are considered the safest. They are easy to use, compact, efficient and can instantly warm up rooms. Any buyer will find a model of the required power and with the necessary technical parameters.

The only drawback of electricity is the high cost, and this immediately negates all the advantages. Such electrical appliances should be chosen only for rooms where the owner spends little time. For constant heating of a garage, electric heaters are unprofitable.

A rational solution is to purchase a mobile infrared heater, convector, fan heater or heat gun. They are easy to carry and move from place to place. The most powerful and practical devices are heat guns.

An unsuccessful option is an oil heater. The device has its advantages, but is more suitable for long-term heating. In addition, it consumes a lot of energy resources and slowly warms the air.

However, there are exceptions. So, a homemade heater assembled from an old cast-iron radiator and heating element will cost literally pennies. The power of the heating element is chosen by the owner himself, and used oil can be used as a coolant.

If you add metal legs and attach a dryer to a homemade heater, you get a convenient multifunctional device. How to make it is described in the master class, which can be found in our selection of videos.

Option No. 4 - solid fuel devices

Solid fuel boilers and stoves are very profitable due to the low cost of coal and firewood. The disadvantages include the need to build a chimney, which leads to a slight increase in the cost of the system.

These costs are paid off due to the long service life, efficiency of the stoves, and low cost of fuel (you can use waste: sawdust, wood scraps, any combustible materials).

A solid fuel stove is cheap and does not require connection to centralized communication networks or obtaining permission for installation. However, it is worth mentioning the disadvantages: increased fire hazard, the need for constant combustion control, the smell of smoke in the room, the release of harmful substances into the air.

Option No. 5 – liquid fuel stoves and boilers

Heating appliances running on diesel fuel, diesel fuel, and waste fuel are popular. You don't have to buy them in the store. It is quite possible to assemble an oil-fuel boiler, a stove for a garage, and even a heat gun with your own hands. The housings of such devices are made from gas cylinders, old barrels, and heat-resistant steel sheets.

Homemade stoves are not as economical as industrially produced models, but they also allow you to save a lot on heating costs. The fuel consumption of a homemade miracle stove or a homemade heat gun is approximately 0.5-0.7 l/hour, depending on the power.

The better to heat or the choice of energy carrier

In 99% of cases, garage buildings are not connected to centralized heating networks or main gas, so owners have to choose autonomous heating methods. To heat a garage, you can use 4 groups of energy carriers:

- various types of solid fuel - firewood, coal, briquettes, agricultural and other combustible waste;

- diesel fuel, waste oil;

- electricity;

- liquefied gas in cylinders.

Advice. When you start choosing an option for heating your garage in winter, keep in mind an important rule: the more expensive the energy source, the easier and cheaper it is to organize heating that is convenient to use. Conversely, cheap or free fuel in the form of waste and garbage will bring a lot of trouble - labor costs and initial financial investments.

Solid fuel combustion

Wood and various waste are the cheapest fuel for heating, and in some cases it is available completely free of charge. In the southern regions, which are not rich in forests, another type of fuel is widely used - small agro-industrial waste.

For reference. Agricultural waste consists of small particles sifted from grain crops. These are pieces of stems, weeds chopped by a combine, straw and other waste. The energy price is very attractive and starts from 20 USD. e. for 1 ton.

After cleaning grains, waste remains that is used for heating.

We recommend: How to evenly heat a room using a heat exchanger

If you decide to heat your garage with solid fuel in the winter, get ready to deal with the following issues:

- purchase or manufacture of a furnace (ideally a boiler);

- chimney installation;

- storage of firewood, coal or waste;

- labor costs for preparation, combustion and soot removal.

Storing firewood in the garage is not a very convenient solution

The gain is in money and excellent heating of a room of any size, the losing points are listed above. Add here the time for kindling and warming up (0.5-1 hour). Hence the conclusion: cheap heating with solid fuel is suitable for owners of garages and boxes who stay there for 4-6 hours or more every day.

Potbelly stove for heating a garage

Potbelly stoves are the most primitive stoves that began to be actively used at the beginning of the last century. Then their popularity sharply decreased due to the spread of centralized heating. However, potbelly stoves are still used, because they are practically the cheapest way to heat a garage.

The potbelly stove is made of metal. The largest part is occupied by the chamber into which the fuel is thrown. The room warms up due to the contact of the stove walls with the surrounding air. Not the least important role is played by the pipe, which also accumulates heat. To prevent heated combustion products from immediately flying out into the street, a pipe of a clearly defined diameter is used, due to which the warm gases make several revolutions in the vertical plane. This allows you to make maximum use of the heat of combustion of the fuel (efficiency reaches 60-80%) and effectively suck in the air necessary for the fuel to burn completely. The diameter of the pipe in mm should be 2.7 times greater than the volume of the stove in liters.

It is important that the chimney has a complex shape: first there is a vertical insulated part, then a horizontal or inclined part, the so-called. hog, which provides up to a quarter of the heat received, because the flue gases burn out here. Potbelly stoves are sold ready-made: there are both the simplest and most primitive options, as well as sophisticated designer ones. If you have the skills, you can assemble a potbelly stove yourself from a barrel or sheet metal.

Advantages:

- a potbelly stove can be heated with any solid fuel, but wood is usually used;

- low price and low cost of operation;

- relatively high efficiency;

- allows you to quickly warm up the room and dry the air in it;

- There are models that can also be used as a stove. They will come in handy for those who spend even too much time in the garage.

Minuses:

- the need for constant monitoring of work;

- high fire danger;

- Suitable for small spaces only;

- the air cools quickly;

- it will be impossible to get rid of the specific smell;

- the need for regular chimney cleaning.

Solid fuel boiler

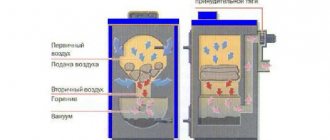

This is a more expensive, but at the same time, safer and more effective solution. The principle of operation is simple: fuel is burned in the firebox, a container with coolant is heated, which is supplied through pipes and radiators. improved types of boilers are increasingly used

- a pyrolysis boiler has two combustion chambers, in the first the firewood smolderes at a high temperature due to the fact that the amount of air is insufficient. The combustion product is pyrolysis gas, which is burned in the second chamber, releasing much more heat than just wood. The boiler efficiency increases to 90%, and one portion of firewood lasts for 10-13 hours;

- Pellet boilers are fired using pellets obtained from wood waste. They are placed in a bunker, from where they are fed into the firebox in doses. The boiler efficiency reaches 95%; fuel can be loaded once every few days.

The body of solid fuel boilers is made of cast iron or steel. Pyrolysis and pellet boilers are, of course, very convenient, but they are expensive. If funds allow, you can afford such a purchase - it will soon pay off

.

Brick oven

Building a brick oven in a garage is a long, expensive and painstaking task. The fuel for such a stove is usually wood, but coal can also be used. The principle of obtaining heat is still the same. The fuel burns, heats the walls of the stove, and they heat the air. A good option for small spaces. Brick takes longer to warm up than metal, but it also cools more slowly.

Stove Buleryan

The Buleryan stove is often confused with a potbelly stove and a regular wood-burning stove. She actually absorbed a little bit of both. The operating principle is based on convection. The design assumes the presence of pipes at the base of the furnace and in the upper part. Cold air enters through the bottom of the stove, receives heat from the chamber where the fuel is burned, and exits, already heated, through the top. The pipes are 2/3 soldered into the furnace body to ensure maximum heat transfer. The special design of the firebox and chimney allows you to extract maximum heat from fuel combustion. The presence of a chamber for pyrolysis combustion of fuel plays a significant role here. Combustion products are removed through the chimney.

Advantages:

- rapid heating of the room due to convection and heat transfer from the surface of the stove;

- compactness;

- there is no need to frequently add firewood;

- higher safety compared to a potbelly stove.

Minuses:

- price;

- complexity of chimney installation;

- the need for frequent cleaning of soot.

Use of mining and diesel fuel

Heating a box or garage with diesel fuel purchased at a gas station is expensive and extremely unprofitable. An exceptional option is to heat a small area of the room where work is being done using a portable heater, whose characteristics are described in a separate material.

Waste oil is a more financially economical energy carrier, although not the cheapest. This option can be seriously considered when used oils can be obtained at a reduced price. What are the features and pitfalls here:

- Homemade potbelly stoves are used to burn liquid fuel in various types of mines. The safest is a drip stove, which you can order from craftsmen or do it yourself.

- A chimney installation is required.

Drip-type exhaust boiler with forced air supply - Oil containers take up less space than firewood. They are usually placed in the basement.

- The workings need to be settled and filtered.

- The inevitable companions of liquid fuel heating are smell and dirt, although this is not critical for a garage.

- Homemade waste oil stoves are considered a fire hazard.

Note. Due to their cheapness and simplicity, the oil miracle stoves shown in the photo have become especially popular. They tend to shoot flames when the fuel contains a small amount of water or antifreeze, causing a fire.

The advantages of using mining are high heat transfer, quick ignition and warming up of the garage box, ease of use (it’s easier to add oil than to chop and carry wood). The conclusion is this: if fuel is inexpensive, or you spend a little time in the garage, then liquid fuel is a suitable option. The initial investment is comparable to wood heating.

When using diesel fuel, it is worth considering the option of a factory-made diesel air heater of the “Planar” type, shown in the photo. With a fuel consumption of 250 ml in 1 hour, the unit develops heat transfer of up to 2 kW. There are also more powerful heaters - 3 and 4 kW with diesel consumption of 0.37 and 0.5 l/h, respectively. Price – within 330 USD. e.

Autonomous diesel-powered air heaters designed for cars

Electrical heating

Heating with electricity is the most comfortable and cheapest option in terms of initial investment. But during operation you will have to pay the full tariff - it makes no sense to install a two-zone meter, you are not going to work in the garage at night.

Let's list all the advantages of electric heating:

- Heating with electricity is convenient and safe. There is no dust, dirt or odors, no need to carry firewood or barrels of fuel.

- There is a wide selection of different air-type electric heaters on sale: convectors, oil radiators, infrared panels and heat guns.

- You can make a water heating system with an electric boiler (if the power limit allows).

- Heating of the garage begins immediately after turning on the heater; a comfortable temperature for work is reached in just half an hour (again, when there is enough power).

An inexpensive portable fan heater can heat only part of the room where work is being done

There are only two disadvantages, but they are critical: the price of electricity and the limitation of the power consumption limit, which does not allow installing an effective heat source. For example, if the contract with the management company specifies a figure of 3 kW, then a convector with only 2 kW is installed, which is not capable of properly heating the garage in the winter.

For reference. Sometimes car enthusiasts use homemade “goats” and fan heaters in the pits, despite the restrictions. Why you can’t do this: there is a danger of the wiring catching fire, the neighbors’ voltage drops, and if employees check the electrical networks, you will face a large fine or shutdown.

Electric heating is an option for short stays in the garage. They came, turned on the heater, completed the intended work in 1-2 hours, turned off the heating and left. If you turned the room into a workshop where you spend your working hours, you will have to pay significant amounts for energy consumption.

A standard wall convector heats the air in the room much slower than a fan heater

Gas heating

This method of heating a vehicle storage space is acceptable for residents of the Russian Federation, where the retail price of liquefied gas is quite low. It will be too expensive for Ukrainians to heat their garages with propane.

Autonomous heating from gas cylinders is as safe and comfortable as electric heating. Moreover, in the Russian Federation the cost of energy is lower. But there are a number of pitfalls here:

- you need to place the propane tank somewhere so it doesn’t interfere with your work;

- you will have to periodically take the tank to refuel;

During operation, the tank freezes over, causing the gas supply to deteriorate. - To burn propane, you need factory-made equipment; making gas burners yourself is strictly not recommended;

- you will need a chimney pipe to the street.

If you add up the financial costs, the problems of organizing such heating and refueling cylinders, then the negative aspects will cover up some of the positive aspects of ease of use.

Watch this video on YouTube

A comparison of the cost of 1 kW of heat obtained from various energy sources in Russia and Ukraine is published on this page.

What type of heating is most profitable?

It all depends on the specific operating conditions and preferences of the garage owner. The cheapest system is a single-pipe water system powered by a gas boiler.

You will have to invest a lot of money in its arrangement, but it is so economical that the costs will be recouped in 1-2 heating seasons. However, this solution is not suitable for everyone.

You can economically heat your garage using gas cylinders or solid fuel. These options are not suitable if it is not possible to control the operation of the devices, but they are good for heating while the owner is in the garage.

The versatility of a solid fuel boiler

Solid fuel boilers and systems based on them are attractive primarily for their autonomy. They allow you to provide uninterrupted heating, which will not depend on the electrical network or gas mains. The simplest stove can be loaded with firewood, sawdust, and coals. Such fuel does not require significant costs.

At the same time, almost every car enthusiast, if desired, will be able to quickly and easily make a stove like a “stove stove” with his own hands. Few materials are required either. It is not necessary to have a large budget to make a stove with a chimney or organize an exhaust system.

Remember that fire safety techniques will always occupy a central place. This is especially important in a garage. In addition, stoves and chimneys, solid fuel boilers must be cleaned regularly.

How to reduce heat loss and not go broke?

No heating system will be profitable and efficient if care is not taken to reduce heat loss. Heaters will waste a huge amount of energy resources. This is expensive and impractical, so you will have to insulate the gates, walls, floor and roof.

You can use expanded clay, polystyrene concrete, foil insulation, but the cheapest and most versatile option is polystyrene foam. It is suitable for insulating all structural elements.

It can also be used for thermal insulation of the floor, provided that a floating screed is made: polystyrene foam does not tolerate mechanical stress well, so it is filled with cement.

The ceiling, walls and garage doors are covered with polystyrene foam. There are two options - external or external wall decoration. Both are equally effective and allow for excellent thermal insulation of the building. The choice should be based on the convenience of the garage owner himself.

Step-by-step instructions for making a stove

Step 1. In our example, we use a simple 250-liter barrel with thick walls - ideal for making a stove. Cut off the top of the barrel, but do not throw it away.

The top of the barrel has been cut off

Step 2. Make a kind of lid from the top - a “pancake” for oxygen supply. Adjust it to the size of the barrel - as a result, when installed, there should be 2 mm between it and the walls around the entire circumference. Weld the neck of the lid. In its center, make a hole to install a pipe through which air will be supplied. Also weld 4 channels, as in the photo below.

“Pancake” for air supply

Another photo of the item

Step 3. Stepping back a little from the top edge, cut another hole in the barrel wall for installing a chimney. In our example, the chimney will be a pipe with a diameter of 140 mm.

Hole for chimney installation

Step 4. Start making the lid. Make it from sheet metal 4 mm thick, and weld a sealing ring at the bottom corresponding to the diameter of the barrel. In the center of the lid, make a hole for the pipe that was welded to the “pancake”.

Oven cover

In the middle of the lid there is a hole for the air duct from the “pancake”

Step 5. Make simple legs at the bottom of the barrel to make the structure stable. The legs must be metal, as well as all other elements.

Making legs for the stove

Legs must be metal

Step 6. Install the stove in the desired location and begin creating the chimney. In our example, it is of a prefabricated type. First of all, make a clamp with which the chimney will be attached to the body.

A clamp that will allow you to attach the chimney to the stove

Step 7. Make guides in the chimney, thanks to which it can be easily fixed to the body.

Guides in the chimney

Step 8. Join the barrel with the pipe, making sure to lay all the joints with asbestos fabric. Place a clamp over the fabric and tighten it.

Asbestos fabric

Tightening the clamp over the fabric

Finished joint between pipe and barrel

Step 9. That's it, the structure is assembled, you can check its functionality. Load sawdust or firewood inside.

The stove is loaded with fuel

Step 10: Add used oil to the fuel, then install the cap. As for the “pancake”, don’t use it yet. After the fuel ignites, remove the lid and place the “pancake”. To fully warm up such a structure, it takes about 10 minutes; in the future, the firewood will burn for a long time. Although exactly how long the combustion will last largely depends on the quality of the fuel.

Photo of the finished stove for the garage

Calculator for calculating solid fuel consumption for a furnace

Go to calculations

Video - Making a bubafoni stove

Video - Homemade potbelly stove for the garage

If you wish, you can modify the design described above, although it will already cope with its functions perfectly. For example, to increase efficiency, you can increase the surface area and thereby improve heat transfer. For this purpose, weld metal plates on the sides of the body.

In addition, you can make a grate with an ash pan: cut a circle from a sheet of metal along the inner diameter of the body, drill holes with a diameter of 60-80 cm and install from below. After this, the ash will be poured down through the holes - to where the ash pan is equipped. It is believed that this will cause the fuel to burn faster, remember this point and make sure that the ash pan is sealed as much as possible.

Conclusions and useful video on the topic

We offer a selection of videos that will help you better understand the issues of heating and insulation of the garage.

Instructions for assembling a super-economical water heating system:

Mini-review of an economical gas stove that consumes 0.5 liters of gas per hour:

Tips for self-assembling an oil heater from a used cast iron radiator:

Video instructions for rational organization of heating in the garage:

Recommendations for reducing heat loss in the garage:

The issue of heating a garage is not difficult to solve. It is enough to understand the main advantages of each heating system and possible limitations in its use. You should choose based on your own needs.

The main thing is not to forget about fire safety rules. No amount of savings is worth putting your car and your own health at risk.

Perhaps you have personal experience in arranging heating for a garage? Please share your own opinion with our readers, tell us which heating system you prefer and why. Leave your comments and ask questions in the block below.

Most car enthusiasts use the garage not only for its intended purpose, but also as a room where they can take a break from household chores, do hobbies or do some household chores. To ensure that your stay in the garage remains comfortable in winter, the room must be heated somehow.

In order for heating to be economical, you need to know the features of existing heating methods, since you can choose the optimal one for yourself only taking into account the specific situation and a number of factors: the dimensions of the room, its distance from housing, the availability of fuel consumed, the budget for providing the garage with heat, etc. d.

Western European experience

If you type the phrase “garage heating” in the search and look at pictures on English-language sites, you will not find any wood-burning or oil-fired stoves in Western European garages. How do local motorists warm themselves:

- electric portable heaters;

- infrared hanging heaters;

- air heating units (heaters).

The suspended air heating unit does not take up useful space in the garage

We have already discussed the first 2 options above. The third method is also far from new: water heated in the boiler passes through a radiator, blown by a powerful axial fan. Ideally, the unit is suspended from the ceiling and distributes hot air throughout the room.

The advantages of this option are compactness, heating speed and the possibility of air conditioning in the summer (cooled water is sent to the radiator instead of heated water).

Heater made from a car radiator

There is one downside - increased costs for equipment, because the coolant must be heated in the boiler and supplied through pipes to the heater. But if the garage is attached to a private house, then the problem is easily solved by connecting the radiator to the building’s water heating system.

Reference. Many garage craftsmen already use such heating, installing a homemade analogue of a heater made from a car radiator and any suitable fan. How this is implemented, look at the video:

Watch this video on YouTube

Convector

Models of electric convectors for use in garages and other technical premises

A reliable and efficient device, the operating principle of which is based on air convection initiated by heating elements - cold air enters the device from below and, heating up upon contact with the heating element, rises warm to the top.

Convectors are available in floor-mounted, wall-mounted or universal versions - on support legs, with brackets for mounting to the wall, or equipped with both mounting options. The latter version is especially convenient, as it allows you to compactly place the heater on the wall with the possibility of quick dismantling and installation next to the car - at the place of repair.

Advantages of an electric convector:

- quick heating to working condition;

- heating in automatic mode - a certain temperature value is manually set, upon reaching which the device turns off and resumes heating the room only when the air cools by 1 degree;

- safety of operation and ease of routine maintenance;

- durability;

- Possibility of use in rooms with high humidity and pollution, since the operating elements of the device are covered with a protective housing.

- higher cost compared to some other types of electric heaters (quartz);

- the effect of operating a convector in a garage is achieved after at least half an hour;

- increased electricity consumption.

How to make everything perfect

In order for the garage boiler room not to cause criticism from regulatory authorities, the following basic principles must be taken into account during its installation:

- The room must be equipped with effective and reliable forced ventilation. The combustion products must be removed through an air duct, the outlet of which is located on the roof (at a standardized height).

- All fire safety regulations must be strictly followed. In this case, the number of boilers in the room should not exceed 4 units. with a total power of up to 190-210 kW.

- The boiler must be at least 100 cm away from the garage wall.

- The minimum size of a garage in which installation of boilers is allowed is 6.5 sq.m. with a height of at least 2 m.

- A heat-resistant, solid base (foundation) must be built on the floor under the boiler. Combustible materials must not be placed around the boiler.

- Connection of communications must be done professionally, taking into account all standards.

Increased requirements are imposed when using gas. When a gas boiler is installed in a garage, approval is required already at the design stage. Permission to divert the gas main must be obtained and standards for gas consumption must be established. Installation of gas boilers must be carried out in strict accordance with regulatory documents: SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000.

Fan heater

Operating principle: a heat exchanger (heating elements or coil) is heated by electricity, air from the room is pumped into the heater by a fan, passed between the heating elements and returned hot to the garage.

- environmental friendliness - the absence of any emissions into the surrounding space during operation;

- ease of adjusting the heating intensity - there are switches for heating modes (turning off some heating elements) and fan rotation speeds;

- small dimensions and mobility - can be installed anywhere in the garage;

- the possibility of focused heating of zones or objects;

- quick heating of the room;

- equipped with automatic shutdown devices in case of overheating or overturning;

- the possibility of additional independent configuration with an electromechanical thermostat to automatically maintain the set temperature in the room;

- low cost of electrical appliances of low and medium power;

- ease of operation and maintenance.

Like any unit, the fan heater also has disadvantages that must be taken into account:

- accompanying heating, a decrease in air humidity in the room;

- the presence of dust accumulation on heating elements, fraught with fire or, at least, an unpleasant odor in the garage;

- noise caused by the operation of the fan;

- increased electricity consumption.

Despite these disadvantages, the use of a fan heater is the most popular heating option for a garage.

Setting up a boiler room in the garage

Next, we suggest finding out how to organize a boiler room in a garage.

Layout of accommodation

It is better to install a gas boiler in a separate building, the area of which is at least four square meters. There is also a requirement for ceilings - they must be more than two meters. As for the width of the door, its size should be 80 centimeters and above. In addition, the room should be ventilated and have a window that would provide natural light in the room during the day.

It is recommended to build a boiler room at a relative distance from a residential building for several reasons. Firstly, so that the noise from work does not disturb the household. Secondly, the boiler room is a fire hazardous facility.

Preparatory work

First of all, the walls in the garage need to be finished with heat-resistant material. If it is necessary to install a chimney, the pipe is installed above the level of the garage roof, approximately one meter. In addition, it is worth considering how many bends are present on the pipe. So, the lower this figure, the better, since otherwise the substances that are released during combustion will settle on the sections. As a rule, to equip a chimney, a pipe with a diameter of 130 millimeters is taken.

The area of the roof where the connection to the chimney occurs must be protected with fire-resistant material. Take something like galvanized steel.

Ventilation arrangement

To ensure the safe operation of a boiler room in a garage on your own site, you will need to ensure there is a good ventilation system that can cope with the removal of harmful gases from the room.

Fan power is calculated using the following formula:

- M – fan power;

- S – building area;

- H – building height.

This formula includes the fact that the air in the room is renewed on average in 12 hours, and the minimum power reserve of the equipment is estimated at 30%.

Installation of a heating boiler in a garage

For garages, wall-mounted or floor-mounted boilers are often purchased. The equipment is installed on a brick (concrete) stand.

The boiler is fixed horizontally and vertically. Walls and other objects in the room should be 30-50 centimeters away from the device.

Connecting the device to gas and water

After the installation work is completed, the boiler is connected to gas and water supply. Water is supplied to equipment standing on the floor from above or to the side. In the version with a wall-mounted boiler, communications are connected to the transverse side.

Also, the remaining components of the device must be installed. In that situation, if there is no need to purchase an electric pump for the room, the pipes are laid with an inclination of five millimeters (per meter of length). Otherwise, there will be difficulties with circulation in the heating.

System startup and testing

After completing the manipulations to connect the device to the water supply system, the boiler is started in order to check the tightness of the connections. If the test run is successful, the boiler is connected to the gas pipeline.

Heat gun

A compact and easy-to-use device that provides quick and effective heating of the garage. It differs from a fan heater in the significantly higher power of heating elements. The device is based on electric heaters and a high-performance fan, which provides intensive air flow to the heating elements, causing rapid distribution of heat in the room.

Connecting high-power heat guns requires a three-phase power supply with a voltage of 380 V; less powerful units are designed for 220 V.

In small garages, the use of heat guns creates dust in the air, so they can be used effectively only if the room is constantly kept clean, including through high-quality finishing of the enclosing structures.

The essence of the problem

At its core, any garage is a utility room (usually detached) of a warehouse type, but containing a car and substances belonging to the flammable category. These circumstances give rise to increased requirements for fire safety. Naturally, the question arises: is it even possible to place a boiler room in a garage?

When solving this issue, you should understand what a boiler room is and why it is installed. It is possible to set several tasks. Most often, the concept of a garage boiler room means a boiler for heating only the room itself, but sometimes a boiler room in a garage functions as a source of coolant for heating a private home. If in the first case a small standard boiler of various types is used, then in the second case fairly large areas and special permission are needed.

In any case, a garage with a boiler room is not prohibited by regulatory documents. At the same time, it must meet all technical and fire safety requirements. The need to draw up a project and coordinate it with the relevant organizations depends on the type and power of the equipment, the type of fuel consumed and the connection to centralized highways.

Infrared heater

The operation of the device is based on the emission of infrared rays, which, upon reaching the surface of objects along the propagation path, heat them, and they, in turn, give off heat to the room. Such devices are sometimes called UFO heaters, but UFO, the common Cyrillic abbreviation of the same name in everyday life, has nothing to do with ultraviolet irradiation.

UFO heaters are available in various sizes and power; they can be on a leg or designed to be attached to a vertical or horizontal base (wall, ceiling). Provided the housing is waterproof or placed under a canopy, infrared heaters can also be used in front of the garage on the street.

- economical electricity consumption;

- ease of operation and installation;

- reliability, safety and environmental friendliness.

The disadvantage of infrared heaters when used in a confined garage space is the effect of infrared rays on a small area, which causes less heat transfer from objects into the air. But when focusing radiation in the direction of the actual zone, these heaters are quite effective.

The best brands of garage electric boilers

Energy-saving electric boilers for heating a car garage are produced by Russian and Western manufacturers.

In order to limit the boundaries of the search, settings are systematized into categories based on the operating principle used:

- New electric heating boilers: Elvin EVP-6 EU, EVP-9 Teplotechn, E.V.P.M LLC "Resurs-ElectroTerm", E.V.A.N EPO 2.5 kW, "Stanless" E.V.P- 6M, Novel-Evos 2/4/6-220.

- Induction boilers: SAV-PROF 2.5, Spec-SAV-20.0.

- Modifications of the Galan electrode type: Hearth 3(N), Vulcan (25 kW).

For heating garage workshops, a domestically produced electric heating apparatus has the best balance between cost and production quality.

It is possible to buy a Russian-made heating element device within the range of 10,000-14,000 rubles. Replacing the electric heating element, which will be needed after about 5 years of use, will cost only up to 2000 rubles.

Water heating of a large capital garage

The most familiar to consumers is a water heating system, the use of which in spacious garages is justified by many factors, including the possibility of do-it-yourself installation. If the cost of purchasing a heating boiler, radiators and other components does not bother the garage owner, then water heating is the best way to heat a large permanent garage.

The operation of a garage water heating system requires compliance with the following rules:

- equip the enclosing structures, including gates, with insulation - this will provide up to 40% energy savings;

- use non-freezing liquid as a coolant - this will eliminate the need to drain water during the owner’s long absence;

- To avoid damage, use heating radiators of industrial use, anti-vandal design.

If the garage is no more than 20 m from the house, you can connect it to the home heating system (in the case of autonomous heating, if the heating boiler has sufficient power). But heating a large garage will require significant additional coolant consumption, that is, the installation of a common high-power boiler, the operation of which in the summer will not be economically justified. Therefore, in a spacious garage it is more advisable to arrange an autonomous heating system and install an individual boiler. After making such a decision, it is necessary to decide on the optimal fuel for specific conditions, for which the heating boiler will be purchased.

In terms of the cost of energy (natural gas), this is the most economical way to heat a garage, but it is accompanied by hidden costs:

- preparation of design and permitting documentation;

- payment for the work of licensed gas equipment installation specialists;

- costs for ventilation and removal of combustion products;

- costs for routine maintenance of the boiler;

- possibly the necessary construction and subsequent maintenance of the chimney.

Alternatively, to heat the garage you can use infrared gas heaters, heating panels, convectors that consume liquefied propane and butane in cylinders - this eliminates the need to go through the authorities, but adds the problem of providing fuel.

- advantages - high level of automation of the heating system, when using natural gas - constant availability of energy in the main line, cost-effectiveness and high efficiency of gas equipment;

- disadvantages - the presence of a danger factor of explosion, fire or carbon monoxide poisoning.

When using gas heating, the building owner must especially strictly observe safety requirements in his garage.

A good option for a garage is an automatic steam-drip condensing unit, which is up to 15% more economical than other models, as it can operate efficiently at low gas pressure. In the heat exchanger of such a boiler, water from heating with a gas burner turns into steam, and then condenses again into a liquid state, which is accompanied by the release of heat. Such boilers are produced in floor-mounted and wall-mounted versions. For a garage, the second option is preferable, eliminating the possibility of tipping over when performing some work.

Water heating system

You need to understand that installing water heating makes sense when you are in the garage all the time. Otherwise, the costs will not justify themselves, because in addition to a source of heat and fuel, you will need to buy:

- cast iron or steel batteries (as an option, weld registers from pipes);

- circulation pump;

- expansion tank;

- pipes on the main line;

- non-freezing coolant - antifreeze.

For reference. The garage space is heated periodically, so the system cannot be filled with plain water.

Knowing the need for the amount of heat to heat the room (calculated in the previous section), select the power of the radiators or determine the length of the pipes of the homemade register using the table:

In the table, t1 means the coolant temperature, t2 means the air in the room

The calculation method is as follows. We take a steel pipe DN 80 (Ø89 mm) and find out from the table that 1 m of length is enough to heat an area of 1.37 m². We take the square footage of the garage, for example, 20 m² and divide by this figure: 20 / 1.37 = 14.6 m - the total length of the heating part. We distribute it among 2-3 heating devices and cook the registers according to the drawing.

Use the circulation pump with the lowest pressure (4 m of water column), and the expansion tank with the minimum volume. Pipes - polypropylene, steel or metal-plastic size DN 15. Then install radiators on 2 opposite walls and assemble a simple two-pipe closed-type heating system connected to a heat source according to the following diagram:

Instead of a wood-burning stove with a water circuit, an electric boiler or other heat source is installed in the circuit

The following can be used as a water heating installation:

- a wood-burning or exhaust stove with a water circuit, shown in the diagram above;

- heat exchanger – samovar-type economizer installed on the chimney;

- an electric heating element mounted in a vertical steel pipe, as shown in the diagram;

- a full-fledged electric boiler or solid fuel unit.

The simplest electric boiler with a water register

Advice. Do not forget to add a filter to the circuit - a mud trap and ball valves to cut off the heat source and drain water from the system. At the top point, install an automatic air vent, and on the batteries - Mayevsky valves for bleeding air.

Why don’t we recommend making an open-type system in the garage, as it is simpler and cheaper? The reason is antifreeze, which will evaporate from an open tank, which is unsafe for health (ethylene glycol is poisonous), not to mention the price of the coolant.

Electricity

Heating with an electric boiler is a rather expensive solution to the heating problem for a garage. If there is no alternative type of fuel, then it is better to use electrical appliances (convectors, fans, heat guns, UFO heaters - described in detail above).

When using electric heating equipment indoors with open heating elements (coils, heating elements), it is necessary to remove flammable and combustible materials (fuels, lubricants, solvents, paints, tow, etc.) from the garage.

Choosing the right gas boiler

You can purchase a suitable gas boiler yourself

It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if there is one), as well as the ignition system

In addition, you need to find out which gas connection option is available.

The most popular devices are boilers made of cast iron and steel. If you choose between the two, preference should be given to the latter, since cast iron is considered a rather heavy metal. A convenient boiler is one that has an electric igniter installed.

Particular attention should be paid to the chimney. Since combustion products are aggressive, this part must be made of durable material

Alloy steel is considered the ideal option. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Solid fuel

Today, solid fuel boilers are in demand among homeowners and industrial buildings on a par with gas equipment. The fuel is coal, sawdust, and firewood. This is a fairly economical heating system that provides the room with heat well.

Disadvantages of heating a garage with a solid fuel boiler:

- need for smoke removal;

- the need to allocate a significant area for arranging a fuel storage area, which is not always possible in a garage;

- the danger of having anything in the garage that could ignite from a spark when the firebox door is opened;

- the need to regularly clean the firebox from ash and the pipes from soot.

The most advanced, and therefore economical, type of solid fuel boiler is a pyrolysis type unit, where the fuel, under the influence of high temperatures, decomposes into two components - pyrolysis gas and ash, each of which is burned practically without residue in a separate chamber.

Most models of pyrolysis boilers use only wood, pellets and waste (not bulk) from the woodworking industry as fuel. However, universal units are also produced that are also designed for the use of coal and peat briquettes. The only common conditions for all models is that in order for the boiler to enter the pyrolysis mode, the fuel humidity should not exceed 20%, otherwise it will work like a conventional solid fuel heater.

However, pyrolysis-type boilers are expensive equipment, and therefore not every consumer can afford to use them to heat a garage - heating a garage with your own hands is truly economical only when all components of the process do not require significant costs.

For a clearer idea of how to equip a garage with a stove, you can watch this video:

It’s not difficult to build a stove by watching the corresponding video.

Solid fuel system

A good solution is to make a heating system with a boiler that will run on solid fuel: coal, wood. Simply put, it will be a stove. For example, the well-known “potbelly stove”. You can purchase it ready-made or make it yourself. For this purpose, metal profiles and pipes are used.

There is a more modern option - install a stove with convectors, long-burning. Now the Buleryan solid fuel boiler is growing in popularity. It is interesting that the heating system itself will be air, but the boiler will be solid fuel. Thermal energy is transferred due to the movement of heated air currents. Inertia remains low.

The big advantage of such a stove is that it quickly warms up the garage space. True, when the fuel is used up, the garage will soon cool down. The problem is low inertia.

If the goal is to achieve higher inertia of the heating system, it is worth making water heating based on a wood stove. Heating units must be installed around the entire perimeter of the room. The expansion tank is mounted inside, at the highest point of the heating system.

Garage workers use special volumetric tanks with a layer of thermal insulation. Such hydraulic accumulators significantly increase heat reserves. There is one more significant point: such heating systems must be filled not with plain water, but with antifreeze. This will prevent the liquid from freezing.

Some car enthusiasts install water heating systems on their own. It's economical and effective. You can stably maintain a comfortable temperature in the garage if it is well insulated.

Air heating system for garage

Air heating is not as popular among garage owners as water heating, but with its help you can not only heat, but also ventilate the room.

The method consists of equipping the garage with an air duct with deflectors through which air is supplied, pumped by the fan of a heat gun or fan heater and additionally passed through an air filter.

The main advantage of air heating for a garage is the rapid simultaneous drying of the entire volume, which prevents the aggressive effects of moisture on the car and other furnishings.

What to look for when choosing

The decisive factors when choosing a gas boiler are:

- the material from which its body is made;

- ignition system;

- the presence or absence of the need to install a chimney;

- features of indoor installation;

- method of connection to gas and water supply.

Material

The most common models on the gas equipment market are cast iron and steel models. Cast iron is a high-strength and durable material, but its disadvantage is its heavy weight. Therefore, it is preferable to use steel heaters.

Manual or electric igniter?

Boilers with an electric ignition are much more convenient to use. When installing them, the following conditions must be met:

- uninterrupted power supply;

- separate connection to the power supply network;

- grounding

The solution to the first problem is to install an electrical stabilizer that suppresses voltage surges.

Types of boiler equipment

The chimney stove has an inlet temperature of about 120°C. The gas combustion process produces substances such as carbon monoxide, hot steam, sulfur dioxide, etc. All of them are removed from the garage using a chimney. At low ambient temperatures, vapors condense on the walls of the chimney and flow down.

Combustion products are quite caustic substances, so increased demands are placed on the chimney material. For the construction of a chimney, it is recommended to use alloy steel pipes, as well as carefully insulate them.

The garage can also be heated by boilers that do not require a chimney. They have built-in fans. Condensing boilers with a pulsed gas combustion mechanism are also becoming very popular.

Advice

To reduce heating costs, the owner is recommended to insulate the outside walls and ceiling of the garage, having previously sealed all the cracks and holes. For thermal insulation of walls, you can use foam sheets, and expanded clay for the ceiling and floor. The use of mineral wool slabs will require subsequent waterproofing

A properly selected garage heating system will not only ensure a comfortable temperature in the room, protect the enclosing structures from dampness, but also prevent the development of corrosion on the metal parts of the car, which is detrimental to equipment.

Location of a gas boiler room in a private house, distances

The main condition is to maintain the thickness of the wall connecting the garage and the boiler room, everything else is optional

It is also important to maintain a time period, not immediately after the foundation, start building walls, but wait a year until the foundation settles. This is necessary so that there are no cracks in the walls

Today, construction projects are often rushed, but in vain! - fraught with consequences

Since gas heating is one of the cheapest, the best option for heating a garage is to install just such a system.

Before installing a gas heating system, the following points must be considered:

Since the gas has explosive and flammable properties, it must be handled with great care. This means choosing high-quality gas appliances and having them installed by professionals; Gas heating is best used if the garage is attached to the house, has a gas pipeline nearby, or if it is necessary to provide heat to several garages at once.

What is important to consider?

Any of the designs can be made independently, if only you have the desire and some skills in working with tools and materials. So, in any case, metal is used as the basis for a long-burning furnace. The thickness must be at least 4 mm, otherwise the stove will quickly burn out. As for the chimney, it is recommended to make it composite, that is, from several parts - this will simplify its cleaning in the future. The metal for it must also be thick enough, otherwise it will not last long.

Advice! If a person plans to work in the garage often and for a long time, then saving on materials is not worth it.

Making stoves with your own hands will not be very difficult for a person who has the necessary skills

The body for the furnace can be welded from separate pieces of metal, or you can also use an old 200 liter barrel or a pipe with a large cross-section. Gas cylinders are also suitable. A chimney will be mounted in the upper part of the stove, and a small hole will also have to be made, which will provide the flow of air necessary for burning wood. The diameter of the chimney should be about 15 cm, and the holes for air access should be about 10 cm. By the way, the chimney outlet can be made from the side.

It is also important to think about the weight that will put pressure on the fuel. A heavy metal circle is suitable as a press, the dimensional parameters of which should be smaller than the diameter of the structure, but not by much - a few millimeters are enough. The press also makes a small air duct for oxygen access.