Among the many models of stove equipment, the two-bell heating and cooking stove can be called perhaps the most popular unit among the population. It is capable of performing two important functions: heating the home and providing the ability to cook food. The design of this model also includes a hob and oven.

The niche above the stove is equipped with a shelf on which it is convenient to dry shoes. This is especially true during the rainy season and when the snow melts.

Do-it-yourself Kuznetsov stove: arrangement drawings and description of the stove laying

Since 1962, I.V. Kuznetsov has been designing, manufacturing and improving furnaces.

During this time, more than 150 different designs were invented, each of which strived for an absolute efficiency indicator - 95% efficiency. In this article we will tell you how to make a Kuznetsov stove with your own hands. Photo 1 Kuznetsov stove

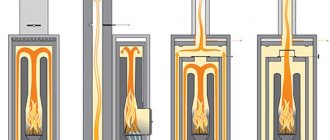

The fundamental feature of the development is the system for separating gases into cold and hot flows. Due to the unique bell-shaped structure of the stove, hot air is retained inside, and cold air is discharged through a separate channel into the chimney pipe. Considering that a higher combustion temperature is maintained in the bell, and the heat is distributed evenly throughout the body, the efficiency reaches its peak. For comparison, the efficiency of conventional stoves is 30-35%, solid fuel boilers - 80%, pyrolysis boilers - 85%.

The low performance of most solid fuel units is explained by the fact that warm air exits along with combustion products into the chimney. In addition to the fact that the remaining volume is not always enough for full heating, quickly escaping flue gases further reduce the thermal threshold. In some designs, they try to solve this problem by increasing (lengthening) the chimney pipe, but then there is a risk of reducing draft and, as a consequence, reducing efficiency. The creation of such a unit that would provide full traction and increase heat transfer became the main goal of designer Kuznetsov.

Video 1 Construction of a heating furnace using the Kuznetsov system

What explains the high efficiency of furnaces?

The reasons why bell furnaces are so efficient compared to traditional units are:

- Correct distribution of flue gases over heating temperature outside the combustion chamber.

- A large number of caps helps retain hot gas and more efficiently accumulate heat inside the device.

- Correct placement of the hood helps contain heated gases and maintain high temperatures. This leads to the collection of fuel combustion products in one place and a reduction in the level of soot formation in the chimney. For this reason, “blacksmiths” do not require frequent cleaning of soot.

- The heat exchanger is located in the hood, so it does not retain the heat produced by the furnace and does not reduce the level of efficiency.

Building a Kuznetsov stove with your own hands is not so easy, but all that is required from the master is to follow clear step-by-step instructions.

Construction of a Kuznetsov furnace with your own hands

The sequence of actions is as follows:

First, they study the floor plan of the room where the heating device is planned to be installed. In the case when the house is not built, it is necessary to ensure uniform heating of all rooms. It is not advisable to install a heating unit into a finished building, but if necessary, you can

But at the same time, you should take into account the location of the supporting structures and beams when arranging the chimney. Then the foundation for the heating device is prepared. It is made of concrete, and the width should be 10 centimeters greater than the size of the device

It is advisable to design the foundation for the stove at the house planning stage.

What will be needed for construction

Let us immediately note that it is better not to use used bricks to build a furnace. Constant temperature changes are not the most suitable conditions for its operation, and if you take a material with fatigue stresses, it is possible that after a couple of years the walls of the furnace will simply begin to crumble into dust. So, what will you need to prepare to implement our project:

- solid red clay brick M 150 in the amount of 754 pcs. – for laying the body of the heating device and chimney;

- sand, 150 kg;

- fine clay, 130 kg;

- refractory brick - 63 pcs., which will be needed to equip the core of the furnace; Fireclay bricks of the Sh-5 and ShB-8 brands are most often found on sale. In our case, it is better to take the latter, since its dimensions fully correspond to the dimensions of the red brick.

- blower door, 1 pc.;

- combustion door, 1 piece;

- doors for cleaning channels, 6 pcs.;

- grate, 1 piece (minimum size 250x375 mm, which can be assembled from separate grates);

- steel wire for tying rows;

- metal corner;

- chimney damper, 1 piece;

- asbestos cord or basalt sealant - for sealing the installation sites of cast iron castings.

If you have ever done brickwork, you should know what you will need:

- trowel (trowel);

- container for preparing the solution;

- building level;

- plumb line and cord;

- bushhammer;

- mixer for mixing the mixture (you can use an attachment for an electric drill or prepare the solution manually);

- roulette;

- pencil.

If during the construction process it is necessary to trim bricks for the front side of the stove, then this work is best done using a grinder with an installed cutting disc for stone and concrete.

Date: September 25, 2022

Kinds

According to their purpose and design features, blacksmiths can be divided into several types:

- Heating. The devices are designed for efficient and safe heating of premises.

- Cooking. Used for cooking. This includes ovens for baking bread and bakery products.

- Bathhouses. The Kuznetsov bathhouse stove is designed for simultaneous heating of the main bathhouse premises. Such devices have high heat transfer with minimal fuel consumption.

- Street. A stove complex consisting of a grill or barbecue for outdoor cooking.

- Fireplace. The equipment is used as a decorative element of the interior or as an additional heating option. Some fireplace stoves are equipped with special loungers for a pleasant leisure time.

The most popular are complex devices that are distinguished by their multitasking. A striking example is the Kuznetsov heating and cooking stove, which is intended both for heating residential premises and for preparing food.

Despite their functional features, all stoves operate on the same principle - effective distribution of heated gases in the bell into separate streams.

It is noteworthy that stove hoods can be equipped with additional equipment - electric heaters, hot water tanks, steam generators, oven and stove.

A competently designed and constructed Kuznetsov sauna stove will provide reliable heating in all functional rooms: steam room, washing room, dressing room, rest room. In addition, it will allow you to quickly heat water, accumulate hot steam and purify the air.

Operating principle of Kuznetsov bell furnaces: ordering

The operating principle of Kuznetsov furnaces is not complicated. When building a furnace, it is necessary to carry out all work according to drawings, diagrams and, of course, use procedures.

All Kuznetsov bell furnaces operate on the principle of separating combustion products. This principle lies in the fact that the gas generated as a result of fuel combustion is divided into two streams: cold and hot. The movement of gases inside the furnace design is very well thought out. Hot air is retained in the oven and retains heat for a long time. Cold air quickly flies into the chimney through a specially made recess. A furnace operating on this principle is called a bell-type (dome) furnace. Inside such a furnace, the hearth is combined with its lower part and forms something like a hood. It then acts as a gas separator into two streams. The flow of hot air rises and is retained in the hood, thus concentrating heat.

Advantages of Kuznetsov stoves:

- Cost-effective;

- Long-term heat retention;

- Slight soot formation;

- No need for frequent cleaning;

- A choice of different shapes and designs is possible.

The high efficiency rate (95%) of Kuznetsov furnaces is the result of a fundamentally new development and design features. For comparison, a traditional Russian stove has an efficiency of 25-40%. If Kuznetsov stoves have disadvantages, then they are few, and they are lost against the background of their advantages.

Podgorodnikov’s stove and the Swede A. Batsulina

There are 2 types of Podgorodnikov’s two-bell OVP: IP-1 and IP-2 with an oven.

The IP-1 oven has a height of 210 cm, a depth of 77 cm and a width of 115 cm. It consists of 30 rows. Just like the Kuznetsov stove, this one has a valve for summer mode so that the gases go immediately into the pipe. In winter, this valve must be closed all the time. In Podgorodnikov ovens, the cooking chamber is equipped with doors so that the heat is retained inside even longer and does not allow the food to cool down. The holes for cleaning the channels are covered with bricks, without pushing them in completely.

Podgorodnikov stove

Podgorodnikov's stove IP-2 has the same dimensions as IP-1, but slightly narrower - width 102 cm. The oven is mounted under the hob. Even when the two-bell ORP is running in summer mode, the oven still heats up, since hot gases pass right past it.

Podgorodnikov furnaces have a built-in ventilation valve. When the stove is heating, it is closed or slightly open. If you open it completely, the traction will noticeably deteriorate. Podgorodnikov stoves can be heated with wood and coal.

The two-bell Swedish A. Batsulina works on the same principle, but has a slightly different masonry. Its design allows, in addition to the hob, to build in an oven, the temperature of which can be regulated by a summer slide. The oven is installed in the second hood, as a result it will be heated from all sides.

To prevent the pipe from condensing, a direct-flow valve is provided. Thanks to it, you can heat the pipe to a high temperature (+150°C) in a short time. As a result, the possibility of condensation is completely eliminated. Also, unlike Kuznetsov’s stoves, this one has a regular brick ceiling instead of an arch.

Swede Batsulina stove

Recommendations for self-construction

If you decide to build a stove according to one of Kuznetsov’s plans with your own hands, get ready for careful and scrupulous work. On the diagrams you will find a graphic representation of each row, but before starting laying you need to become familiar with the features of the technique, in particular:

- selection and pre-processing of bricks;

- purchase of metal parts (plates, dampers, doors, valves);

- determining the most suitable location;

- preparation of the base and foundation;

- possibility of installing a chimney, etc.

Fireclay refractory brick (Sh-5, ShB-8) is recognized as the best material for the internal masonry of “smiths”, and ceramics (M-150) for external decoration. To strengthen brick walls, metal elements (rebar, wire) are used. In order for the stove to function with maximum heat output, experienced craftsmen hone not only their skills, but also every brick - literally. They polish every detail, which is why projects completed by professionals look flawless.

Fireclay brick masonry

Having the author's order in hand, we recommend not to experiment, but to follow the designated order. Deviations from the diagram do not guarantee complete heat transfer.

Materials and tools

To arrange a brick “blacksmith’s shop” for a house or bathhouse, first of all, you should prepare working drawings and procedures. The author himself has developed over a hundred different stoves with step-by-step instructions for their construction.

The order of the stove is a complete guide that clearly explains the correctness of laying each individual row in the prescribed sequence. Beginning craftsmen are advised to strictly follow the order of Kuznetsov furnaces, which will allow them to build a reliable and durable structure.

To carry out construction work, it is necessary to prepare basic materials and working tools:

- solid red fire-resistant brick;

- fireclay brick;

- fire-resistant clay of medium fraction;

- mountain sand (twice the volume of clay);

- steel wire;

- metal corner;

- structural elements: doors for the ash pit, fireboxes, grate for the grate, valve, stove for the hearth.

Attention! If desired, instead of clay and sand, you can purchase a ready-made mixture for masonry, which is sold in specialized stores. It contains all the necessary proportions of the main components.

When purchasing bricks, it is recommended to check the material for defects and mechanical damage.

Do-it-yourself Kuznetsov stoves have their own subtleties of construction, so before starting work, the layout of the device must be carefully studied.

What is the difference

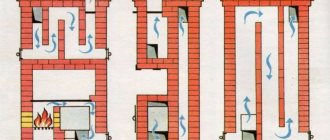

The main feature of the group of stoves invented by Kuznetsov is the absence of extended smoke channels with many turns and bends. To make the most of the heat from burning fuel, duct stoves have a system of passages through which hot smoke heats the bricks. In this case, the oven heats up unevenly at different levels, which can lead to cracking of the masonry. In addition, there is a need for regular cleaning of narrow places and corners.

Kuznetsov's stoves for home and bathhouses do not have this drawback. In them, hot gases from the firebox enter the so-called hood - an internal space limited at the top by the ceiling and having an outlet at the bottom. The heated smoke rises to the very top of the hood, where it lingers until it begins to cool. As they cool, they gradually fall down along the walls of the bell, and a new portion of smoke takes their place.

The cooled smoke exits through the channel into the chimney or into another hood, depending on the design and purpose of the stove. Gradually, as it passes through cascades of hoods, the flue gases cool to a temperature of 120-150 degrees. The temperature of the gases at one level of each cap is the same, which avoids uneven expansion of the brick.

Mechanical removal

How to remove super glue from laminate flooring mechanically? The most important thing is never try to pick super glue from the laminate; it is bound to the substrate at the molecular level. You will simply tear off a drop along with a piece of laminate, thereby irreversibly damaging the surface.

But there is a way, and with the help of a file, a needle file, a sharpening stone or just a nail file, you can achieve good results.

Due to the transparency of cyanoacrylate, you can gradually remove the top layers to the base, however, the main thing is not to overdo it. A thin layer of glue will remain on the floor, which will not be very noticeable, and if the stain is located where the inhabitants of the house constantly walk, it will be erased over time.

Let's summarize. The best and relatively safe way to remove glue from laminate flooring, and indeed from any other surface, is naturally specialized means - debonders, preferably using the same brand.

In any case, no matter what method you use, you need to clean the surface carefully and slowly. You should not make excessive efforts; in addition, you should scrub surfaces using cleaning agents or solvents without using abrasive materials.

Design and operating principle

Bell furnace design

The stove with a hood was developed by engineer Igor Kuznetsov in the early 60s of the last century. Subsequently, Russian metallurgist Leonid Kotlyar improved the design so that it retains heat for up to 19 hours. The peculiarity of the “blacksmith” is that the heated air does not leave the pipe, but is collected under a hood. Slowly it cools down and is forced out by rising hot streams. Saving heat is the advantageous difference between a bell-type stove used for heating a house and a channel stove, where hot air, under the influence of draft, freely escapes to the street.

A two-meter-high structure with a base of 1m*1m can reach a thermal power of 3.5–4.5 kW. Such a bell-type stove is enough to heat a house of 50 square meters in a temperate climate zone, if you heat it twice a day.

The inventor improved the design by adding another cap. In Kuznetsov’s two-bell heating stove, the first covering element is connected to the combustion compartment and separates the cold and heated flows. The second cap is located in the upper part of the stove, trapping hot air, which, before entering the chimney, gives off heat to the bricks for a long time.

A two-bell stove uses fuel more economically and is usually equipped with a hob. This allows you to cook delicious meals without consuming electricity or gas. The design of the stove already includes an exhaust hood - there is no need to install an additional ventilation system.

Manufacturing procedure

Required Tools

Double-bell heating stoves are very different from the traditional designs that were used by our ancestors. Without going into details, it should be noted that to design them you do not need to hire a qualified stove maker, whose services are very expensive.

All work can be done independently; it is enough to have only basic skills in handling bricks, mortar and a trowel.

Before you begin, you should prepare the following tools:

a trowel, which will be needed for laying bricks;

Materials used

The size of the stove depends on the area of your country house. As a rule, a small structure is enough to ensure an acceptable temperature in a room whose area does not exceed 50 square meters. meters. Otherwise, it is advisable to choose a more efficient heating system.

To build a stove, you need to stock up on enough bricks (about 300 pieces). It must be fireproof, otherwise it may crack from exposure to high temperatures.

Clay is also needed, which is used for laying stoves. In addition, make sure you have sand, without which it is impossible to prepare a high-quality mortar.

You should purchase the following structural elements in advance at a hardware store (they are impossible or very difficult to make yourself):

- corners and steel strips - they are useful for arranging floors at various levels of masonry;

- hot water and drying boxes - their sizes depend on the dimensions of the oven you choose;

- valves and doors are elements of the firebox and protect the room from fire;

- hob - its design can be chosen depending on personal preferences.

Furnace laying

Before describing the process of constructing a stove, it should be noted that when building a country house, it is necessary to provide in advance for the arrangement of the foundation for it. Otherwise the design will be unreliable. And casting the base after laying the finished floor will either be impossible or too expensive.

The work is carried out in the following sequence:

- The first and second rows are laid out. They will serve as a base, so it is not recommended to use broken stones. In extreme cases, they can fill up the middle. Moreover, broken bricks along the edges of the masonry will spoil the appearance of the structure.

Double bell oven

The most common option for high-quality heating of a private home is the Kuznetsov device with two hoods.

Its efficiency is significantly higher due to longer retention of hot air.

The heat-resistant brick hoods are located one above the other with a slight offset - the air displaced from the first hood immediately enters the second, from which it goes into the exhaust pipe.

The size of such a stove is directly dependent on the area of the house; it is even possible to build with an internal volume of up to 5 cubic meters. m. The firebox usually occupies the entire base area, this helps to increase the heating power of the air in the furnace.

d79996939d6d9526a6f20a7cb2b08264.jpe 18ae580d3f50fc0040ae71d956f18099.jpe

Reference. In the design of a two-bell furnace, special valves are often installed to insulate the second bell and reduce the heat transfer of the device. This is necessary in warmer times of the year, when high heating power is no longer required.

When using dampers, hot air from the first hood is directed directly into the chimney.

Advantages and disadvantages

The draft in the stove is carried out due to the voids inside.

The efficiency coefficient exceeds that of traditional stoves, for which it is in the range of 70 - 85%. In Kuznetsov’s designs, the soot burns out completely, so the period between two adjacent cleanings is calculated at 3–4 years.

Advantages of the inventor's models:

- traction is carried out due to the voids inside (caps), and not channels, so less brick is used;

- stoves operate on any fuel, not just wood;

- the use of a short smoke channel also saves money on arrangement;

- uniform heat transfer occurs throughout the day;

- it is possible to heat several levels of the house from one device;

- DHW and steam-water heating circuits are inserted into the design, and it is combined with a hob, a stove bench, an oven, and a fireplace.

Complex masonry is being carried out, which must be fully mastered before construction begins. Furnaces of this category have significant weight and are massive, so a solid foundation is needed.

Kuznetsov's fireplace stove: ordering

Kuznetsov's fireplace stove is a large heat storage device. A brick structure that looks like a fireplace and is as warm as a stove. Due to its mass, the fireplace stove heats the room in a unique way.

The construction of fireplace stoves is a complex matter, but if you wish, you can do everything yourself. To begin such a complex process, you must have the procedures at hand. Kuznetsov's fireplace stove has a lot of advantages.

Advantages of fireplace stoves:

- The beauty and grace of stonework;

- Efficiency of brick heater;

- Low carbon monoxide and soot emissions;

- Long-term maintenance of a comfortable temperature in the house;

- Economical.

Some fireplace lovers make them look like works of art by decorating them with grates and decorative elements, using the services of a blacksmith. You can feel a pleasant feeling of radiant heat if you equip your country house or cottage with such a fireplace stove.

Temperature conditions for different types of poultry

Suitable temperature is one of the most important conditions for incubation, without which hatching of chicks is simply impossible.

For each type of bird, these indicators are purely individual, so when laying eggs from chickens, ducks, geese or turkeys, you should focus on the following values:

| Type of eggs | Required temperature in the first days of incubation, °C | Required temperature in the last days of incubation, °C |

| Chicken | 37,9 | 37,6 |

| Goose | 38,4 | 37,4 |

| Duck | 38,0 | 37,1 |

| Turkeys | 37,6 | 37,1 |

| Quail | 37,8 | 37,5 |

In general, a homemade incubator is a good solution both for those who are just trying their hand at poultry farming, and for experienced farmers who do not want to spend extra money on purchasing ready-made equipment. By equipping the structure with automatic egg turning, you can achieve 80–90% hatchability of chicks.

Building a foundation for a furnace: universal instructions

Regardless of the stove model, it needs a reliable and durable base. This foundation is suitable for both the Swede and the two-bell model.

The sequence of arranging the support is as follows.

We dig a pit about half a meter deep.

Foundation pit

Second step

We compact the bottom of the hole and fill it with a 15-20 cm layer of sand. Pour water over the sand and compact it thoroughly.

Fifth step

We prepare a solution from part cement, five parts crushed stone, three parts sifted river sand and water. Fill approximately half of the free horizontal space of the pit with this solution. Let the fill dry.

Sixth step

We prepare a solution from part cement and three parts sand. Fill the remaining space of the pit with the mixture. Carefully level the upper part of the fill using a rule.

Poured foundation for laying a brick stove

Types of designs with an oven

Kuznetsov furnace

It is installed in rooms with minimal space possibilities, while the design and decoration are selected individually. A special feature of this type of furnace system is its high efficiency, which for such devices is more than 80% along with a small amount of soot formed during operation. The design is suitable for placement in any area of the room; it is possible to place several similar stoves at once. Any type of solid fuel is suitable for the firebox.

Bykov's device

The thick-walled structure has a simple laying pattern and a rectangular shape. This type of stove provides for placing the device in 2 rooms at the same time. Nevertheless, the Bykov design has significant differences in its structure from bell-type structures. The lower region includes 2 gas channels: ascending and descending. The upper part has the shape of a sieve, the cap of which is divided by 5 channels.

Characteristics

Kuznetsov's bell-type stoves have a number of distinctive characteristics and advantages that set them apart from the main competitors in the market of heating equipment for home and bathhouses.

The operating principle of such a device is quite simple: the lower level (tier) and the firebox are a single structure - a cap, which is designed to effectively move gases formed during fuel combustion. In this case, the accumulation of light gases occurs at the top of the bell, and heavy gases at the bottom. Gases with an average heating temperature are concentrated in the middle.

“Kuznetsovka” made of brick provides for long-term retention of heated air inside the hood for effective accumulation of heat indoors, and then the rapid removal of combustion waste through the chimney.

A special feature of the furnace is maintaining the maximum combustion temperature. In addition, the Kuznetsov stove has a high efficiency, which is several times higher than that of a classic Russian stove.

The specific advantages of such furnaces are as follows:

- High efficiency – up to 94%.

- High temperature combustion of fuel material.

- Fast accumulation and long-term heat retention.

- Low level of soot deposition.

- Easy to care for and unpretentious.

- Low material consumption with high thermal output.

- Possibility of additional installation of a circuit for hot water supply.

- Increased draft with small chimney sizes.

- Attractive design and a wide choice of structural forms. An improved option is the Kuznetsov two-bell stove, which can be designed for any type of room.

- Fast distribution of thrust between channels in automatic mode.

Second thermal load

Nothing works on bare principles. In order for a theoretically absolutely correct stove to heat, dry and cook well, it must also be made correctly in the material. In relation to bell-type furnaces (and especially double-bell furnaces), this means that the thermal load on the material must be high. Making a bell furnace massive, with thick walls, is like lighting a fire in a cave. To feel the warmth, you need to sit next to the fire, and there will be soot...

c309b8141378ec4433e1fa6a65105e41.jpe

eb9a96611664c70a0b926656370364e4.jpe

Take a look at fig. On it are drawings and orders of some Kuznetsov stoves: a bathhouse. heating and cooking. a double-circuit hot water boiler and an improved Russian stove with a stove bench. Not being an experienced stove maker, it is clear that the material per unit of output power (500 W * sq. m of outer surface) in the Kuznetsov stove uses one and a half to two times less than in traditional ones. In general, any bell-type oven is “emptier” inside than a channel oven of equal power.

Orders of some Kuznetsov furnaces

On the one hand, this is good; bricks and mortar cost money. But on the other hand, it requires careful development and adherence to construction technology (see below). The heat load, which would not cause a pile of cobblestones to move, would destroy a thin brick wall even during the accelerating fire.

Structural mechanics are also important for Kuznetsov furnaces. The strength of the wall with clay mortar decreases much faster when its thickness decreases than with cement-sand mortar. Therefore, the foundation for these furnaces must be done especially carefully in strict accordance with the author’s recommendations. They must be strictly followed during construction.

Note: I.V. Kuznetsov allows freely copying his materials for himself, for construction, but objects to republications. However, the pictures in Fig. small. An amateur cannot build anything using them, but a master knows where to get full-fledged drawings. Therefore, we hope that Igor Viktorovich will forgive us this small borrowing for the benefit of the cause.

How to make Kuznetsov brick stoves with your own hands

IN AND. Kuznetsov developed a large number of furnace designs. Some types of stoves can be made with your own hands. To do this, you will need the order of the furnaces and their drawings.

Many, knowing about the positive reviews about Kuznetsov’s stoves, and also in order to save money, begin to build them themselves. Everything will work out, of course, but for this you need to use the appropriate materials and strictly follow the procedures.

Materials used for the construction of the Kuznetsov furnace:

- Fireclay brick;

- Clay brick brand M150;

- Good quality clay;

- Cleaned sand;

- Metal fittings.

For the construction of internal masonry, fireclay bricks are used. According to the order, you can calculate its quantity. For the construction of external masonry, clay bricks are used, preferably grade M 150. Its quantity is also calculated using the same order. It is recommended to use only good quality clay for mortar. Purified sand for masonry is used twice as much as clay. You can use commercially available clay-sand mixtures. For 500 bricks you will need about 0.2 cubic meters. m of clay-sand mixture. In addition, you will need grate bars, two doors (blower and furnace), two steel corners and five meters of wire. Kuznetsov’s book “Building stoves and fireplaces: a practical guide” will help you build the structure you need. It presents all types and designs of stoves and fireplaces.

Basic rules for creating a heating stove

- To make Kuznetsov stoves, the ordering (masonry diagrams) should be printed in advance.

- The refractory shell located inside the furnace must be free on all sides, since the brick expands during the heating process.

- Internal refractory masonry when using fireclay bricks is always done on edge. If the bricks are made of clay, on the inner walls and on the posts, they are laid at the discretion of the stove-maker.

- To strengthen the bond, a wire is laid every two brick rows.

- When a Kuznetsov stove is created, the ordering of brick stoves for a home provides that various elements (for example, doors) are installed in such a way that there is room for expansion. A special gasket is placed between the brick and the metal element.

- After completing the construction of a brick structure, it should be treated with a fire-resistant compound.

- The first kindling begins at a minimum temperature and is then gradually increased.

Kuznetsov furnaces design and principles of operation, advantages, variations, drawings

Kuznetsov's stoves are well known not only to stove makers - they heat many homes in Russia and abroad. I.V. Kuznetsov has been working on improving furnaces since 1962 and has gathered around him a strong team of like-minded people. The team has more than one and a half hundred developments to its credit, covering almost the entire range of household stoves, see fig.

Some of the furnaces of I.V. Kuznetsov

Many would like to build one of Kuznetsov’s stoves with their own hands, and this article will help them. But we are not going to reveal some hidden secrets of the “blacksmiths” - they simply do not exist. On Igor Viktorovich’s website stove.ru, those interested will find a huge array of stove information for free: from information on the design and construction of stoves to detailed drawings and recommendations for installing a stove in a house and constructing a blind area around a building with stove heating. We also do not intend to criticize or correct anything in this home-stove encyclopedia: we are, to put it mildly, far from I.V. Kuznetsov in the oven business.

The purpose of this article is to provide a kind of introduction to Kuznetsov’s body of information, allowing one to more freely navigate the source material. Let us explain with an example why this is necessary.

Let's say I'm a generalist auto mechanic with extensive experience and want to pass it on to others who are interested. A car is a complicated thing. If I begin to get distracted along the way, explaining in detail that how running and caster (let’s assume that readers are not exactly dummies, now everyone drives) affect the handling and directional stability of the car, and the valve timing diagram affects fuel consumption depending on road conditions. conditions, and so on, I will eventually become confused to the point that I myself will no longer understand how the car I drive works. Willy-nilly, I will have to present the material, albeit “on the fingers,” but in a professional, fluent manner.

189e53d9f8ccba456843c21464a99fef.jpeHowever, it will be a little difficult to read even for specialists like me, but for an amateur it will make his head spin. Therefore, I will need someone to help me, who can be called a “half-teapot”. In fact, he is not a kettle at all; he can adjust the suspension and set the valve lifters himself. But in this case, his task is to describe how the entire filling of the car is assembled into one whole, controlled according to the principle: “steer with the steering wheel, gas with the gas, brake with the brake.”

In the automotive industry of the USSR, a similar situation arose in the late 50s and early 60s, when the industry began producing cars for wide sale to the public. Then the super bestseller of that time, “How a Car Works,” was published. Edited by none other than the most important designer of the legendary “Victory”, A. A. Lipgart.

Information “from the recipient” will not yet allow you to start working: it does not provide deep knowledge that will allow you to at least intuitively estimate the required values of numerical parameters along the way. But it is essentially fundamental: mastering it, a professional text can be read with understanding and faster. And, if somewhere in it something is still unclear, it no longer causes loss and wandering, but simply a mark in the mind: this is what you need to find out in more detail.

The government has not yet adopted any landmark resolutions on stoves and stove heating. But their role in household heat and power engineering in times of energy shortage is undeniable: already a heating stove with an efficiency of 70%, when used on a large scale, will provide fuel savings on a national scale, because The designs of new heating plants include heat losses in the mains of 35%, and it is not yet possible to reduce them. So, with the popularization of stove knowledge, you have to figure it out yourself, without being either Lipgart or Kuznetsov. Well, let's try.

More about round ones

Round stoves theoretically have a lot of advantages, but they are not very convenient in the house. However, there is also a significant demand for compact mobile ovens, and here the extremely high efficiency of round multi-caps can be a decisive factor, because when the size of the oven decreases, its efficiency drops sharply due to the square-cube law.

Such furnaces, of course, would have to be made of metal. This solves the problem of cleaning; the stove can be made collapsible. But the choice of metals suitable for the ratio of heat capacity and thermal conductivity is extremely limited. The only inexpensive ones are cast iron, but it is heavy and fragile.

However, there is a lighter and stronger metal material with similar properties. These are products of powder metallurgy. In relation to scissor knives, “powdered crap” is quite justified, but for a stove in which nothing works for shear, powdered parts can be a godsend.

The second problem, which has already been mentioned, is the heat-resistant lining on the arch of the first cap. If it can be solved, then perhaps the works and efforts of Igor Viktorovich Kuznetsov will bear fruit that is more extensive and significant than it now seems.

Duct or bell-type?

Duct or bell-type?

Which is better: a time-tested average or a new promising upper limit? This dilemma has been going on for over 45 years among stove makers across the country! How to choose between a pie in the sky and a bird in the hand, who can tell you which is better and how not to end up with nothing? If we turn the conversation to the topic of brick kilns, then all these questions can be reduced to one thing - which type of brick kiln is better, channel or bell-type?

From all the variety of options for brick stoves, several varieties can be distinguished, differing from each other in their functionality; there are stoves only for heating, only for cooking, there are combined and highly specialized ones. However, according to their technical data, all of them are divided into two types of hot gas removal, and, accordingly, into their heating method. These two methods of removing gases have long been known to everyone - the channel system and the bell-type method. Debates about which method is better and which type of furnace gives the greatest return have been going on since the middle of the last century, because it was then that a model of a brick furnace was first created, in which the bell-type method of heating and removing combustion products was used.

Operating principle of ovens with two hoods

The secret to the efficiency of this stove lies in its original design, which allows it to accumulate and save heat for a long time. To understand the operating principle of a two-bell furnace, let’s consider its design diagram.

After kindling in winter, hot flue gases rise under the arch of the lower hood, transferring heat to the surrounding walls and hob. But new air enters the combustion chamber, the combustion process continues and the release of hot combustion products continues, displacing cooled gases under the top of the bell. Those, in turn, descend and fall into a vertical channel leading to the upper bell, where the two-bell design of the furnace provides for the repetition of the previous process with the release of gases out through the chimney.

The temperature of the exhaust flue gases is lower than any other stove with a stove, since they intensively transfer their heat to the walls of the stove. For this reason, chimneys of heat sources of this design must be protected from the destructive effects of condensation. After heating is completed, the heat remains for a long time at the top of both hoods, even if the main valve remains open. Cold air entering through the ashpit cannot rise under the hood arch and passes into the chimney along the path indicated in the diagram by blue arrows.

A two-bell cooking stove with a stove allows you to cook food in the summer thanks to an additional valve, the opening of which allows gases to pass directly into the chimney pipe. If the valve is not opened completely, then the flow of combustion products will be divided into two, going along different paths. In this way, in the autumn-spring period, you can regulate the intensity of heating of the hoods, that is, the thermal power of the stove.

Features of the Kuznetsov furnace

Since the main goal of Kuznetsov’s developments was efficiency and productivity (he worked to increase the efficiency value), this required a fundamentally new and improved approach.

From the above, the conclusion follows: the system of free movement of gases created by this master is more natural, it optimizes the operation of the device and uniform heating. In addition, soot formation is minimized.

In addition to these advantages, Kuznetsov furnaces have other positive aspects:

- combustion occurs without soot and smoke;

- heating is more uniform;

- better heat transfer;

- the need for cleaning is ten times less;

- efficiency;

- there is more space to place the steel heating element;

- low level of heat loss;

- resistance to cracks;

- the ability to change the shape and design of the structure.

Construction of the Kuznetsov furnace

In most models that were invented earlier, hot gases always moved through channels. During their movement, the structure heated up and then cooled down. This movement of gases was created by draft. At the same time, the body was heated unevenly, which ultimately led to cracks. The heat exchanger was placed in the firebox because there was no more room for it. There it came into direct contact with fire and its service life quickly expired.

d929e2742175cf2fa25982de10eadaee.jpe

Kuznetsov used a completely different principle of gas movement for his model. The stove has hoods turned upside down. The caps can be mounted on top of each other and tied together with a dry seam, as a result of which gas begins to pass through them from one cap to another. It is because of this principle of operation that the Kuznetsov furnace is also called a bell furnace.

Improve your designs I.V. Kuznetsov started in 1962, and a large number of like-minded people gathered around him. Many summer residents also want to create a Kuznetsov stove with their own hands. Let’s say right away that you can build a Kuznetsov bell furnace with your own hands, but like-minded masters did not reveal many of the hidden secrets, or maybe they simply don’t exist.

It is worth noting that, thanks to the operating principle of the Kuznetsov stove, it is possible not only to create separate heating in the house, but also to obtain a supply of hot water. To do this, the rear side of the hood must be equipped with a steel heat exchanger.

Advantages of the Kuznetsov bell furnace:

- Smoke gases are stratified throughout the entire structure equally after the combustion chamber.

- One building may have not one, but several hoods. They will help achieve more warmth.

- The hood is located near the firebox and all carbon monoxides enter it. Therefore, ash, carbon monoxide and volatile hydrocarbons, which in other furnaces exit through the chimney, in this case burn out under the hood. This will increase heat transfer and minimize soot production.

- With the help of their convection, all products formed as a result of combustion cannot escape from the oven, so they give up their heat to it.

- The heat exchanger in this building is located in the hood or outside the combustion chamber, so it does not affect the temperature of the fire and cannot reduce efficiency.

Performance indicators of the bell-type method

The stove needs to be heated twice a day.

The stoves need to be heated twice a day to create a comfortable microclimate in the room. The average consumption of logs for heating 100 square meters of area is 16 - 17 kg per day. Skeptics claim that holding smoke for a long time leads to a weakening of the draft in the chimney, but this is not so:

- The smoke rarefaction in the hood cavity shows a value of 0.18 hPa, which is considered normal in relation to atmospheric pressure and creates conditions for natural convection.

- The open door of the blower chamber helps to compress the air, which replaces the rarefied flows in the hood.

- The smoke exhaust pipe is a pipeline for exhaust gases; thanks to its adjusted length, it ensures high speed of movement.

The hood is placed behind the combustion chamber, because of this the heated smoke immediately moves into it, without cooling during the short transition.