Heating from a wood stove in Russia, rich in forests, was for a long time the only way to heat a home. More recently, alternatives have appeared - gas or electric heating, each with its own advantages, which, however, have begun to decline rapidly due to the continuous increase in energy tariffs. Today, many owners have begun to consider water heating in a private home from a wood-burning stove as a practical option for heating a country house, which has additional benefits.

Traditions combine perfectly with technology Source kelohouse.ru

Advantages and disadvantages of stove heating

Traditional stove heating is preferred by many rural residents because it has time-tested advantages:

- Autonomy . The house does not need to be connected to additional communications, which is always expensive and troublesome. The operation of the system is based on the principle of natural circulation.

- Savings during installation . Equipment for a furnace connected to water heating is cheaper than for other heating systems.

- Availability of fuel . Firewood is a natural, abundant and cheap fuel throughout much of the country. There are combined furnaces that allow the use of coal, peat briquettes, and coke.

- Savings during operation . Some stoves (long-burning designs) can significantly reduce wood consumption.

- Environmentally friendly . Burning natural fuels does not harm the environment.

- Aesthetics . Modern wood stoves can become a significant interior detail.

Autonomy of operation is an important feature of a wood-burning stove Source heaating.ru

Along with the undoubted advantages, stove heating also has some disadvantages:

- Relatively low efficiency . The efficiency (coefficient of performance) of the furnace will always be lower than the efficiency of a gas or diesel boiler. Significant losses of thermal energy occur through the chimney.

- Constant service . For the system to operate smoothly, constant human supervision is required; It is impossible to establish automatic operation; you need to monitor the fuel supply and waste disposal.

- Slow and uneven heating of rooms . The stove will only warm up the room where it is installed; in the far corners of a spacious house it will be noticeably colder

- Usage skills . Maintaining the combustion process in a firebox is more difficult than in a boiler.

- Place . It is necessary to allocate a place to store a supply of firewood.

- Fire hazard . Individual parts of the structure need careful insulation (which is especially important if the building is wooden). Another difficulty is that combustion cannot be stopped instantly.

You will have to find a place to store firewood Source pinterest.com

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

How to prepare the solution?

The durability, reliability of the structure, and the possibility of smoke in the premises depend on this material. If clay is used, it should not contain any inclusions of earth or other materials. River sand is used, sifted through a fine construction sieve:

- Pour clay and sand into the trough in a ratio of 1 to 2 and mix well.

- Pour in water and bring the consistency to the consistency of homemade sour cream.

- Mix the solution.

- Let it sit for 15-20 minutes and you can start working.

To save time and effort, you can buy a ready-made solution of red clay and sand and use it.

Additional Pros and Cons of a Water Loop System

The design of the water circuit makes it possible to distribute heat more evenly throughout the home. Stove heating, supplemented with a water circuit system, is characterized by improved parameters and additional advantages:

- Productivity . A system with a water circuit is capable of efficiently warming up large areas of housing. Due to its high specific heat capacity, water absorbs and releases significant amounts of energy, with little loss during transportation.

- Size . The water circuit has small dimensions, unlike, for example, the air ducts of an air-convection system, which often remain visible.

- Multitasking . A stove for heating a house with water heating can easily cope with several tasks: maintaining a comfortable air temperature in the rooms, heating water for domestic needs and cooking.

- Coolant quality . Water is a safe and affordable filler for the home circuit.

Visualization of a structure with a large firebox and a water circuit Source yandex.uz

The use of water has disadvantages due to its physical and chemical properties:

- High freezing point . If people live in a country cottage all year round, nothing threatens the water circuit. If your home sits empty during the winter, water can freeze, expand, and damage the system. A common solution is to drain the water (but then the corrosion of metal parts increases). An alternative option, the use of antifreeze, is not suitable for all systems and radiators and requires additional cash injections.

- Composition of water . If the water circulating through the system has a high salt content, scale forms on the internal parts and corrosion begins. Undesirable processes can be slowed down by adding special additives to the system. Arranging a closed system will also help extend the life of the water circuit.

The Dutch oven has high heat output and takes up little space. Source opalennia.com

Heating boiler assembly

In order not to look for any special materials to assemble a water tank, you should consider cast iron heating radiators as an alternative. They are the most reliable, as they can easily withstand high temperatures inside the oven. The unit must be disassembled into its component parts and washed with a solution of hydrochloric acid to remove scale and residual products of former water heating.

Then the sections are connected using asbestos cord, previously soaked in drying oil, as a seal. It is wound onto the joints and carefully knocked down the structure along with the cast iron nipples. Leave the holes free, on one side - the top and bottom. The supply and return pipes will be laid there. Thus, the heat exchanger for the furnace is ready.

Water heating device

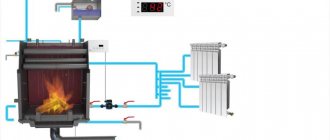

Water heating systems installed in modern buildings can be implemented in two ways. In the most common radiator system, rooms are heated thanks to all kinds of radiators (batteries). A less common type is a heated floor system. Here, the role of heating elements is performed by pipes located in the floor screed. The elements of any heating system with a water circuit include:

- Heat generator . A stove or fireplace with a heat exchanger that produces heat to heat the coolant.

- Heating circuit . A system of pipes through which water circulates. In a heated floor system, the pipes are also a heating element.

- Heating elements . The main heating of the rooms is carried out thanks to radiators; their design promotes maximum heat transfer.

- Expansion tank (open or membrane). It helps avoid damage to the system when pressure increases.

A stove with a water circuit in a house with an attic Source otopleniehouse.ru

- Circulation pump . Maintains water movement in the system at the proper level.

- Additional elements . Depending on the type of system, various control devices and security sensors are built into it. A variety of shut-off and control valves may also be present.

Useful additions

A home-made long-burning boiler assembled at home must be equipped with monitoring devices - a pressure gauge and a thermometer. If you decide to install an automation kit and a blower fan on your unit, then you will need to make a seat for it. The fan is placed in the top cover of the housing; it is better to make the electronic control unit remote by mounting it on the nearest wall inside the furnace room. Temperature and pressure sensors are embedded in the water jacket body. In this case, conventional indicating devices should not be ignored, because they will be able to operate when the power is turned off. Therefore, it is also better to install them, since not every electronic display displays coolant pressure.

After assembly, wood heating boilers must be checked for permeability of welds. Using a compressor, this is easy to do: fill the jacket of the device with water and create an excess pressure of 3 bar in it. Before testing, the seams must be cleaned of slag. Sinks and uncooked areas will make themselves known by leaking. When there is no compressor on the premises, the heating installation will need to be ignited and heated outside until a critical pressure of 3 bar is created in the jacket. Water pressure and temperature can be monitored using a thermometer and pressure gauge.

It is recommended to cover the casing of the water jacket and the inside of all doors of a home-made unit with heat-insulating material. As the latter, asbestos sheets and basalt wool are used, which are not afraid of high temperatures. For external cladding of insulation, you can use thin metal 0.3-0.5 mm with a polymer coating of the desired color.

Operating principle of a water heating system

Such a system can work in two ways:

- Based on natural (gravitational) circulation of water . Natural circulation of water becomes possible due to the fact that the specific gravity of cold water is greater (it is heavier) than hot water. Such a significant difference allows cold water, which has given up heat and flows through the pipes to the heat exchanger, to displace hot water into the heating circuit. The main condition for organizing such a system: the entry point of cold water into the heat exchanger is designed below the exit points from the radiators. In order for the condition to be met, they try to place the heat exchanger as low as possible, often in the basement.

Diagram of a closed heating system with a storage boiler Source petrenco.com

- Based on forced water circulation . In private buildings with an area of more than 80-100 m2, the natural circulation system becomes ineffective - it takes a long time to warm up and is poorly regulated. The problem is solved by installing a circulation pump in front of the heat exchanger. It ensures constant movement of water along the circuit, allows you to flexibly regulate pressure and quickly increase or decrease the heating temperature. Depending on the model, the pump may have different dimensions, be integrated into the circuit differently and produce noise of varying degrees.

About the features of furnaces with a water circuit (PVC)

Wood-burning stoves for water heating at home can have different appearance, power characteristics and additional functionality. If they are installed not in a technical room (basement, boiler room), but in a residential area (kitchen, living room), its appearance also becomes important. A modern wood-burning stove can fit into any interior and become a decoration of the living room. Based on the material used, stoves are divided into three types:

- Brick.

- Metal (steel or cast iron is used).

- Combined (as a rule, a metal combustion chamber is framed by a brick body).

Calculation of basic parameters

In order to correctly build a Kuznetsov furnace, it is necessary to strictly follow the diagram developed by specialists. Craftsmen who have extensive experience in the construction of such furnaces recommend that before starting major masonry, practice laying it “dry” if you are doing this for the first time.

If the stove is being built during the construction of the house itself, then it is necessary to draw up the project in such a way that it can heat several rooms at once.

The foundation for the stove must be of high quality and must have a waterproofing layer. It is also necessary to take into account that the foundation of the house should not go into the base for the stove. This structure must have its own foundation, which shrinks on its own.

The concrete base should be approximately 10 centimeters larger than the size of the stove on all sides. The degree of its depth will depend on the height of the structure and the soil composition where the furnace will be built. Typically the depth of the pit is from 40 to 60 centimeters. A sand cushion is placed at the bottom for waterproofing and a layer of crushed stone to strengthen the building. To form the side walls, formwork from boards is installed.

Layout diagram of the bell-type furnace OVIK-9

- The oven (OVIK-9) has a cooking chamber with 2 burners and steel lockable doors.

- It is equipped with a separate exhaust duct, which allows you to regulate the temperature inside the locked niche.

- It can be used as an oven, so metal runners for baking sheets are built into the walls.

- The two-bell stove can be used in “summer” and “winter” mode.

Therefore, in the summer you can only cook with it. Heating and cooking stove Kuznetsov OVIK-9

The depth of the firebox is 450x470 mm with a dry seam to expand the brick by 2–3 cm. If the firebox needs a large size of 510x530 mm, then the back wall is laid out not in ½ brick, as shown in the order, but in ¼ brick.

Video description

About the visualization of the stove project with a water circuit in the following video:

Wood stoves built into a water circuit can also be divided according to the method of burning fuel:

- Stoves with traditional firebox . Such stoves have a volumetric combustion chamber where a large amount of firewood is placed.

- Pyrolysis or gas generating units . These stoves have a special design, thanks to which the wood burns slowly. During combustion, flammable gas accumulates, which is then burned in a separate chamber.

A special feature of any PVC is a heat exchanger, which can be made in the form of a coil, radiator or boiler. The size and type of device is affected by the volume of the firebox; At the same time, the design of the heat exchanger determines the efficiency of the furnace. Based on the organization of the heat exchanger, furnaces are divided into three groups:

- The heat exchanger is built into the firebox and is a simple chamber (water boiler) made of sheet steel or a pipe system. This method reduces the capacity of the firebox; There is also a risk of damage (leakage or explosion if overheated).

The pyrolysis furnace is characterized by high efficiency and economy Source pechivdom.ru

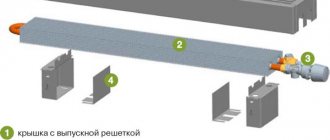

- The heat exchanger is placed around the perimeter of the combustion chamber or in the chimney duct (then called a tubular flat register), which increases the efficiency of the system. Such PVCs are more technologically advanced, more expensive and are not suitable for use in gravity systems. If power outages are possible, the circulation pump will require autonomous power.

- Pyrolysis furnaces , where the heat exchanger is located next to chambers filled with hot gas. The furnace equipment is characterized by a complex structure and the highest efficiency; energy is effectively absorbed by the coolant (water), and the smoke from the furnace comes out barely warm. For the full operation of pyrolysis structures, the quality of workmanship and the steel used are important.

Trial fire

After drying, we pull out the brick halves left to clear the areas of construction waste from the grooves, scoop it out and take it out of the room. We cover all the gaps between the walls and doors with a solution of fireclay clay or fill them with heat-resistant sealant.

We dilute a small amount of masonry mortar and place the halves in the grooves. We fill the voids in the seams with mortar; the seams must be completely sealed.

We lay a full stack of dry, small firewood from deciduous wood, but not alder. We open all the spaces to ventilate the firebox. We make a torch out of paper or a large splinter, light it and hold it in the cleaning window located under the cooking compartment for up to 8 minutes.

We close this channel and set fire to the wood. The stove should not smoke. If the wood immediately begins to burn poorly, check the draft level again, there may be debris left.

A test run of the unit is necessary to eliminate possible malfunctions and construction defects. After burning through the firewood stack, the ash and remains of firewood are cleaned out of the firebox and ash pan. The oven is left to cool completely. After this, the oven is ready for use.

Important! You can determine the quality of draft by the color of the flame in the firebox. Light color of smoke - the wood is burned completely, the chimney system is working properly. But if the color of the fire is dark red, burgundy flowers, then it’s time to clean the chimney due to incomplete combustion of wood and insufficient draft.

Brick PVC - operating features

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick stove as a source of thermal energy. By properly expanding the capabilities of a brick oven using a water circuit, you can efficiently heat not only the nearest living rooms, but also the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement . To build a high-quality stove and then install water heating, you will need highly qualified craftsmen.

- Size . A large traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller sizes, but full functionality.

Heat exchanger installation diagram Source ogon.guru

- Improved efficiency . The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) disappears irretrievably in the pipe. The design of a full-fledged water heating system allows you to increase this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia . Unlike electric boilers, it will take some time to heat up a system connected to a brick oven.

- Care . Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned frequently and thoroughly.

- Security requirements . Improper operation of a brick stove for a home with water heating poses a threat not only to fire, but also to carbon monoxide poisoning.

Varieties for different purposes

Igor Kuznetsov and his team have created a large number of universal and specialized models. Some are intended only for heating rooms, others are supplemented with elements for cooking or heating water. Fireplaces are a separate area.

Drawings of options tested in practice are collected on the inventor's website. For convenience, the structures are assigned alphanumeric designations.

Heating

Kuznetsov’s heating stove for a two-story house allows you to save on fuel

Various configuration options for domes make it possible to construct structures for heating one- and two-story houses.

Heating models are abbreviated as OIK (heating models by I. Kuznetsov). You can find options with a firebox located inside the room or in the utility room.

For variety and to give the desired qualities, there are stoves supplemented with warm beds (OIK -6 bed. AND OIK 19 bed.) and seats (OIK-7s).

Some products have built-in ovens. In this case, the letter D is added to the code designation, for example, OIK-5D.

Heating stoves also include stoves with a built-in fireplace.

Models RTIC (Russian heated heater by I. Kuznetsov) are needed for heating large rooms. They are massive and need a strong foundation.

Options with fireplace

Model with fireplace

Fireplaces, in addition to their heating function, serve as interior decoration. In this case, the firebox is open, the fire can be observed visually. The stoves are equipped with a firebox for conventional heating, which can be located on the facade, on the right, left side, or behind.

For construction, they choose an option in which it is convenient to service the stove from a utility room or hallway - you do not have to carry firewood into the living room. Working with waste (ash) also does not imply inevitable dirt in the room when cleaning the ash pan and the vent from the hallway.

Options for OIK-K have been developed with couches, built-in ovens and a corner fireplace.

Boilers

To organize a water heating circuit, options have been developed with the designation KIK (I. Kuznetsov boiler). A steel heat exchanger is built into the second dome. Water circulates through the system due to an electric pump.

Models are designed for power of 16, 17, 34 and 64 kW. The first option (16 kW) is equipped with a hob.

Heating and cooking

Heating and cooking model - a structure that completely exhausts the fuel resource

Universal heating and cooking stoves are designed for homes with year-round occupancy. The model has built-in hobs and ovens, shelves for heating food and water.

The firebox can be located on the front or side, which allows you to choose an option for any interior design.

Installation of a bed is available as an option. For large rooms, elongated fireboxes are made, which allows the use of large-caliber firewood. They burn longer and you will have to add fuel less often.

For the bath

I. Kuznetsov singled out sauna stoves as a separate area. There are three varieties: BIC, BIC BC and BIC PC. The abbreviation BIC corresponds to the purpose, and additional symbols indicate that the structure is equipped with a fireplace.

For different layouts, models are chosen that differ in the location of the firebox and fireplace - in the steam room, relaxation room or in the dressing room.

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (wood-burning), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, so for installation a specialist stove specialist is hired who can professionally perform all the work:

- Make a heat exchanger and double check its quality - before and after installation.

- Install the heat exchanger at the required stage (after completing the foundation), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use exclusively heat-resistant seals .

Steel pipes for the manufacture of a heat exchanger Source 36doors.ru

Requirements

When equipping your heating installation with a water jacket yourself, you need to know some simple rules:

- To create a coil, you can use steel pipes or sheet steel with a thickness of at least 5 mm. Thinner metal can quickly burn out due to high temperatures in the firebox.

- The internal diameter of the pipe (or sheet steel structure) should not be less than 40 mm, otherwise the water in the coil will boil almost instantly, which can lead to mechanical damage not only to the water jacket, but also to the masonry.

- A gap of 1.5 - 2 cm is required between the coil and the masonry for thermal expansion of the steel. Failure to comply with this rule will certainly lead to the destruction of the masonry.

It should be understood that the shape of the heat exchanger also matters.

Recommendations for placing heating system elements

Elements of the heating system can hardly be called decoration of a modern interior. Only pipes that look organic in some industrial interiors can fit this definition. In general, building codes and architectural principles recommend placing parts in areas that are hidden but accessible for repair and maintenance. When placing, they are guided by the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (with a power of up to 30 kW) can be installed in the kitchen, hallway, basement or warm heated extension. Stoves intended for residential premises are installed taking into account fire safety rules.

- The place for an open type expansion tank is in the attic ; supply and collection pipelines tend to be located along the main wall structures.

Compliance with operating rules helps the smooth operation of the system Source yandex.ru

- The main riser runs openly in the corners of the living quarters ; in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings . They participate in room circulation, heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.