Popular gas equipment - heaters, water heaters, gas stoves and boilers - have been produced in St. Petersburg for more than 50 years. After the creation of the Baltic Gas Company concern, the enterprise became part of it, maintaining its production capacity and specialization. Current name. It is rapidly developing and produces high-tech boilers equipped with modern automation. For example, a popular and sought-after series is Neva Lux gas boilers, which is presented in two categories.

Specifications

Wall-mounted gas double-circuit boilers Neva Lux

Various modifications of Neva Lux gas boilers are suitable for heating homes, industrial and administrative buildings. Their modifications heat rooms of varying sizes. High reliability and “smart” automation have brought these boilers to a leading position among Russian manufacturers.

Specifications:

- Thanks to the powerful gas supply pump, they can work in low pressure systems. The pump itself will create the necessary conditions, depending on the settings.

- Copper heat exchangers have higher efficiency than cast iron and steel models.

- All the most important mechanisms are made in Italy. Localization of production is limited to the manufacture of the body and unimportant parts. Cooperation with foreign partners and the use of European technologies have a beneficial effect on the quality and cost-effectiveness of the product.

- Foreign technologies provide a 100% level of security.

- Easily adapt to specific operating conditions.

- The efficiency reaches up to 98%.

Thanks to the interaction of European manufacturers, the consumer is provided with a technologically advanced and reliable device of high quality.

Structural components

From a technical point of view, the Neva wall-mounted gas boiler is impeccable. It implements all the technical advances in heating engineering, as well as developments in the field of electronic control of heating circuits.

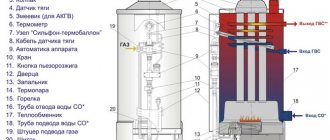

Structurally, the Neva double-circuit gas boiler consists of the following interconnected systems:

- a control system consisting of an electronic unit that controls the operation of the boiler and ensures safety, and an electrical harness that connects sensors, an electronic board and other devices into a single system;

- hydraulic system, including a pump for forced circulation, an automatic valve for removing air, a heat exchanger for heating the coolant, a secondary heat exchanger for the hot water system;

- the gas system includes a burner unit, which ensures uniform and complete combustion of the gas-air mixture in the combustion chamber, and an ignition transformer to create a spark on the spark plug, which automatically ignites the gas mixture;

- smoke removal system, which includes a fan for forced removal of combustion products and a chimney;

- a setup and adjustment system consisting of a gas supply regulator to the burner block, a heating circuit temperature sensor, a DHW temperature sensor, and a DHW circuit flow sensor.

Advertising on the Internet and on television encourages you to buy a Neva Lux double-circuit wall-mounted gas boiler as the most economical, cheapest, most convenient, etc. Can you trust this advertising and reviews on the web pages of online stores?

Main types of Neva Lux boilers

Models and technical characteristics of boilers

There are 2 basic modifications in the model range - Turbo and Lux. Turbo boilers are energy dependent. For their uninterrupted operation, an uninterruptible power supply, a 220 V network, and an electric generator are required.

The Neva Lux boiler is controlled by a thermostat. The automation operates completely autonomously and reduces fuel consumption. As a result of automatic regulation, the control unit independently adjusts the temperature regime depending on the degree of heating of the room.

Double-circuit gas boiler

Traditionally, the company produces models for main gas. But for those who only have liquefied liquid in stock, several models are available.

Double-circuit gas boilers are designed for heating and hot water supply. Owners of apartment buildings can refuse utility services and provide hot water themselves. It will be cheaper. The water temperature can be adjusted.

Single-circuit gas boiler

Models with one thermal circuit are smaller in size than dual-circuit ones. Their operation is much simpler. They only maintain the temperature of the coolant in the heating system. The most important of the current off-season maintenance is cleaning the working chamber and chimney from carbon deposits. Annual maintenance will prevent the occurrence of significant problems during operation.

Boiler Neva Turbo

Users left various reviews about the quality and ease of use: positive and negative. Over time, all the necessary adjustments resulted in the production of a separate series of heating devices. Neva Turbo units are, by and large, a modified version of the already familiar Lux series.

Boiler Neva TURBO 24

All shortcomings were taken into account here. The technical characteristics of the models are as follows:

- closed combustion chamber - here there is a forced air supply through a fan.

Smoke removal is carried out using a special device through a coaxial chimney; What are gas boiler fans needed for and what types they are, you can find out in this article - automation - wall-mounted gas double-circuit boiler - Neva Turbo is fully adapted for operation. A multi-level system of sensors and valves is responsible for the safety of equipment operation and heating regulation. The package includes an autodiagnostic system, which automatically carries out a test, the results of which are displayed on the liquid crystal display;

- control is on regular buttons. Using a conventional regulator, you can set the desired temperature mode, provided that the programmer is installed, you can select operating conditions for several days or a week. The additional kit includes a room thermostat. The sensor issues a signal to turn off the heating when the room is heated to the desired temperature.

Turbo boilers are energy-dependent units. Electrical power to the boiler is achieved by connecting to a regular voltage network of 220 V.

Installation and connection

Installation and piping of the Neva Lux floor-standing boiler

Neva Lux boilers are installed as follows:

- The equipment is hung on the wall with special strips.

- Ball valves are installed at the inlet and outlet of the boiler to facilitate operation and repair.

- Filters are placed using squeegees.

- The hot water supply and heating system is supplied, or the boiler is connected to the existing water supply.

The boiler must be connected and configured by certified employees of the gas company. Neva Lux is usually located in the kitchen or utility room with a ventilation system. When choosing an installation location, you should take into account the locations of water and gas pipes.

A little about the Neva company

The company has existed for more than half a century, and initially it was a state-owned enterprise called Gazapparat. This enterprise specialized, as the name suggests, in the production of household gas equipment: water heaters, various heaters, and also produced heating boilers.

At the end of the 90s, the enterprise became the property of the Baltic Gas Company concern, while maintaining production facilities in the city of St. Petersburg. It was under the management of this giant that the company, one might say, received a second life and began to develop rapidly.

New types of Neva gas boilers, equipped with modern automation, saw the light. Errors and shortcomings of the first models were taken into account, and the equipment was seriously improved. As a result, today the domestic consumer has the opportunity to purchase a reliable single-circuit or double-circuit luxury series boiler at an affordable price. And the company is seriously thinking about entering the global sales market.

Typical faults

Boiler error codes can be found in the operating instructions.

Any complex equipment breaks down after prolonged use. The main indicator of reliability is quick commissioning through repairs with the elimination of typical faults. A warranty card is issued for any heating equipment and installation work. Therefore, calling a technician during the warranty period will be free - the manufacturer’s warranty will cover equipment malfunctions, and the installer company will eliminate installation defects.

A list of major equipment errors can be found on a special display.

Error 01

In the Neva Lux boiler, this type of error means that the device cannot be ignited.

- Check valve opening and gas supply. If necessary, call the gas service.

- The gap between the spark plug and the burner should be 5 mm. Adjust.

- Isolate the breakdown site when the candle is broken.

- Clean the dirty spark plug.

- Ring the ignition transformer circuit.

Error 03

An uninsulated chimney contributes to the accumulation of condensate, which interferes with operation.

The accumulation of condensate in the pipes causes error type 03.

- The chimney is clogged or its structure is damaged.

- Depressurization of the pressure switch tube or disruption of its electrical network.

- Fan failure.

Error 04

Error 4 indicates insufficient pressure in the heating circuit. This interferes with the functioning of the components and contributes to overheating of the boiler.

- Increase the pressure in the circuit.

- Remove the air lock using the air bleed valve.

- Check the pressure sensor.

- Clean the pump and inspect the connections.

A complete list of errors is given in the operating instructions. Some troubles in the form of replacing parts are carried out by a technician on site. The reasons for failure are related to improper maintenance or insufficient conditions for the functioning of the nodes. After repairing the components, the unit works like new.

User manual

If the instructions are lost, they can be downloaded from the company's official website.

The instructions are included with the equipment. It can also be downloaded from the official website of the manufacturer - NEVA (Russia) in PDF format.

The document stipulates: technical characteristics of devices, safety parameters, requirements for installation and installation of the boiler. Also given are diagrams of the device and control panel, recommendations for igniting the boiler and methods for connecting it. Methods for seasonal inspections, maintenance, and care of the unit are described. The table provides lists of errors and methods for eliminating them. At the end there are marks about the acceptance of the device, warranty statements, and a list of service centers.

When working with equipment, the instructions should be at hand. If you cannot fix the error yourself, you should call the service center and call a technician.

Maintenance and operation

Regardless of which model you prefer, installation of a wall-mounted boiler is carried out in the shortest possible time without any additional costs.

The manufacturer places the main emphasis on ease of installation and subsequent operation of the unit. That is why the heating devices of the Neva Lux company are a completely ready-to-use station. All you need to do is connect the equipment to the heating system and power supply and start heating the room. As practice shows, all work takes 3-4 hours. After installation has been completed, there is no need to worry about the safe operation of the station. Consistent operation of the automation reduces to zero the risk of gas leaks and emergency situations, even in the event of an unplanned power outage.

Overview of the boiler line

Model 8224 Turbo is suitable for heating an apartment up to 250 sq. m.

m The Lux model line has been updated with a new Turbo modification. This is a separate series of equipment. It was made taking into account the advantages and disadvantages of the previous modification.

Widely used models:

- For heating an apartment or house, a single-circuit wall-mounted boiler is suitable. Instead of a water circuit, you can install an indirect heating boiler. The modulation burner allows you to effectively save fuel. The 8618 boiler is attractive due to its simplicity of design and low cost. It does not contain volatile, complex electronics. Compact dimensions allow installation in small spaces. The circulation pump in the boiler makes it possible to connect to existing heating systems. It is possible to connect an indirect heating boiler, a forced smoke removal fan, or a room thermostat.

- The 7218 and 8224 Lux series are very popular among dual-circuit models. Modern automation monitors the temperature in the hot water supply and at the same time energizes the heated floor outlets. To reduce heating costs, a separate thermostat is installed to monitor the room temperature - it turns on the boiler only when the set temperature drops. Neva Lux 7218 is suitable for heating an area of 180 sq.m. The bithermic heat exchanger reduces equipment costs while maintaining user-specific features. The efficiency is 90%. The device can be converted to liquefied gas. It has a closed combustion chamber. The coolant temperature is 30-85 degrees. An electronic safety unit with permanent flame monitoring constantly checks the burner.

- Neva Lux 8224 heats 250 sq. m. of residential premises. Water cooling of the combustion chamber doubles the operating life. The microprocessor maintains the temperature level of the working environment with an accuracy of 1 degree. A copper heat exchanger is used for the heating circuit; a stainless steel one is used for the hot water supply. The ability to connect a computer has been added to the control to simplify diagnostics and equipment configuration. The digital display displays self-diagnosis information with parameters and errors.

The operation of the boiler is based on the “set it and forget it” principle. Once you set the parameters, you don't have to worry even when you turn off the power. During a long business trip or trip, the equipment is set to minimum mode and saves gas. When the gas supply stops, the boiler switches to circulation mode and circulates water around the circuit, preventing it from freezing.

Advantages and disadvantages

Gas boilers have a number of important advantages.

- Modern design. These heating boilers have a beautiful and neat appearance, as evidenced by many consumer reviews.

- Low price. According to most experts, this heating equipment will be affordable for almost anyone.

- Good performance. Such units can operate stably even when the gas and water pressure is too low.

- Safety. This equipment is equipped with a multi-level security system.

- Ease of control. To set the desired mode, you just need to use the remote control to select the temperature you need on the monitor.

- Possibility of heating on two wings. Neva gas boilers can be used to heat a house with two branches.

Despite this list of positive qualities, Neva gas boilers also have some disadvantages.

- Presence of noise. Often, during operation, such a device makes extraneous sounds.

- Possibility of breaking screen buttons. Some users noted that a short time after purchase, these units experienced a breakdown of the button that is responsible for switching the temperature mode. After that, it had to be purchased additionally and installed at a separate price.