Bimetallic radiators are very popular among consumers today. These are highly efficient heating devices that have an elegant, laconic design that fits perfectly into modern interior style. What should you pay attention to so that, under the guise of such a battery, you do not purchase a device that is similar to it only in appearance?

Design of a bimetallic radiator

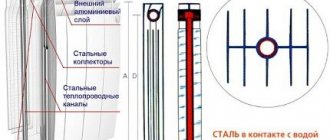

The essence of the design of bimetallic radiators is reflected in their very name. The products consist of two parts - internal pipes through which the coolant flows, and an external casing that ensures heat exchange with the outside environment. Pipes are made of stainless steel or copper. These materials fully meet the main requirement for heating pipes, namely, they are resistant to water hammer and excess pressure in the system, as well as chemical corrosion at high temperatures. The radiator body is made of aluminum: it heats up quickly and conducts heat well; its thermal conductivity coefficient is 230 W/(m‧⁰С). For reference: for cast iron this figure is approximately 60 W/(m²‧⁰С), for steel - 50 W/(m²‧⁰С).

Disadvantages of bimetal radiators

Like other types of radiators, bimetallic batteries have their disadvantages. Among the most significant we note the following:

- price is the main disadvantage of bimetal products. The costs of purchasing them are very high in comparison with cast iron heating appliances. But they have a more pleasant appearance. These heating devices can be easily integrated into a modern interior, and in terms of the duration of the operating period they are ahead of all other types of heating products;

- Another disadvantage of these products is the poor corrosion resistance of the core of these radiators, which is made of steel. This happens under the influence of water and air. Rust on bimetallic radiators can also appear under the influence of antifreeze, which is used as a coolant in autonomous heating systems by owners of private houses. If the choice was made in favor of such a coolant, then the best solution is aluminum batteries.

Preparatory work

Before expanding the battery, you should not only make calculations, but also purchase the necessary tools. This is especially important if you have to do all the work yourself. For quality work you will need:

- pipe wrench;

- radiator key;

- special nipples (must be included with the battery section);

- plugs with left and right threads;

- gaskets installed between sections;

- emery cloth;

- paronite gaskets.

When the tools are at hand, you can begin the preparatory work.

- First of all, the radiator is removed, to which the section will be built up. To do this, the coolant supply to the system is closed and the battery is disconnected from the pipe.

- The removed radiator must be thoroughly washed to remove dust and checked for contamination inside. Although stainless steel is not afraid of water acidity, the core is “not immune” from the deposition of debris and scale on its walls. They should be removed by flushing the radiator with a special product.

- Check the connections for integrity and thread quality. It happens that growths form at the joints, so you need to sand each threaded hole with sandpaper.

Even if no growths are found, it is worth going over the threads with an emery cloth. This will remove contaminants that may prevent the gasket from creating a good seal.

- After the old battery has been cleaned, it must be placed on a previously prepared, flat surface. This is important, since bimetallic radiators need to be connected to each other without distortions, even the slightest ones. Unnoticeable at first, they can lead to a serious accident in the future.

Only after preparation has been completed can you begin to build up new sections.

Determining the number of aluminum battery sections

It is not easy to recalculate the parameters of a heating device for specific conditions. The thermal power formula and calculation algorithm used by design engineers are too complex for ordinary homeowners who are ignorant of heating engineering.

We suggest calculating the number of sections of heating radiators using a more accessible method that gives a minimum error:

- Collect the initial data listed in the first section of this publication - find out the amount of heat required for heating, the temperature of the air and coolant.

- Calculate the actual temperature difference DT using the above formula.

- When choosing a specific type of battery, open the technical data sheet and find the heat transfer rate of 1 section at DT = 70 degrees.

- Below is a table of ready-made conversion factors for the heating power of radiator sections. Find the indicator corresponding to the real DT and multiply it by the value of the rated heat transfer - get the power of 1 fin under your operating conditions.

Knowing the real heat flow, it is not difficult to find out the number of battery fins required to heat the room. Divide the required amount of heat by the output of 1 section. For clarity, here is an example calculation:

- Let's take a corner room with two translucent structures (windows) with an area of 15.75 m², ceiling height - 280 cm (shown in a fragment of the drawing). Specific heat consumption for heating is 130 W/m², the total requirement will be 130 x 15.75 = 2048 W.

- We found out the magnitude of the thermal pressure in the previous section, DT = 43 °C.

- We select low aluminum radiators GLOBAL VOX 350 (center distance - 350 mm). According to the product documentation, the heat output of 1 fin is 145 W (DT = 70 °C).

- We find in the table the coefficient corresponding to DT = 43 °C, K = 0.53.

- We multiply the nameplate power by the coefficient and find the real output of 1 section: 0.53 x 145 = 76.85 W.

- We calculate the number of aluminum fins per room: 2048 / 76.85 ≈ 26.65, round up and get 27 pieces.

All that remains is to distribute the sections throughout the room. If the window sizes are the same, we divide 28 in half and place a radiator with 14 fins under each opening. Otherwise, the number of battery sections is selected in proportion to the width of the windows (approximately possible). The heat transfer of bimetallic and cast iron radiators is recalculated in a similar way.

Battery placement diagram - it is better to place devices under windows or near a cold outer wall

Many well-known companies, including GLOBAL, indicate in the documentation the heat transfer of their devices for different temperature conditions (DT = 60 °C, DT = 50 °C), an example is shown in the table. If your real ΔT = 50 degrees, feel free to use the specified characteristics without any recalculation.

Manufacturers

Currently, on the heating equipment market you can find a large number of different models of bimetallic radiators produced by both Russian and foreign manufacturers. Let's look at the main characteristics of the most popular models.

| Model | Distance between axles, mm | Section size: width*height*depth (mm) | Maximum working pressure, Bar | Thermal power of the section, W |

| Rifar (Russia) | ||||

| Rifar Forza 350 | 350 | 415*90*80 | 20 | 136 |

| Rifar Forza 500 | 500 | 570*100*80 | 20 | 202 |

| Rifar MONOLIT 350 | 350 | 415*100*80 | 100 | 136 |

| Rifar MONOLIT 500 | 500 | 577*100*80 | 100 | 194 |

| Global Radiatori (Italy) | ||||

| Style 350 | 350 | 425*80*80 | 35 | 125 |

| Style 500 | 500 | 575*80*80 | 35 | 168 |

| Style Plus 350 | 350 | 425*80*95 | 35 | 140 |

| Style Plus 500 | 500 | 575*80*95 | 35 | 185 |

| Royal Thermo (Italy) | ||||

| BiLiner Inox 500 | 500 | 574*80*87 | 20 | 171 |

| BiLiner 500 | 500 | 574*80*87 | 20 | 171 |

| Tenrad (Germany) | ||||

| Tenrad 350 | 350 | 400*80*77 | 24 | 120 |

| Tenrad 500 | 500 | 550*80*77 | 24 | 161 |

| Gordi (China) | ||||

| Gordi 350 | 350 | 412*80*80 | 30 | 460 |

| Gordi 500 | 500 | 572*80*80 | 30 | 181 |

| Sira Industrie (Italy) | ||||

| Gladiator 200 | 200 | 275*80*80 | 30 | 90 |

| Gladiator 350 | 350 | 275*80*80 | 30 | 140 |

| Gladiator 500 | 500 | 423*80*80 | 30 | 185 |

| LLC Litiz (Ukraine) | ||||

| Altermo LRB | 500 | 575*82*80 | 18 | 169 |

| Altermo RIO 500 | 500 | 570*82*80 | 18 | 166 |

| Grandini (Italy) | ||||

| Grandini 350 | 350 | 430*80*82 | 16 | 130 |

| Grandini 500 | 500 | 580*80*80 | 16 | 167 |

Thus, high-quality bimetallic heating radiators are able to operate effectively for a long period of time.

How to calculate the number of radiator sections

There is a simplified way to do this quickly. To do this, we will need the standard power required to heat one square meter of room. Let's give three options.

- If the ceilings in the room are of normal height (from 2.5 to 2.7 meters), there is one wall facing outwards, and one window. Standard power is 100 watts.

- If the ceilings are the same, there are two walls outwards, and one window. Standard power is 120 watts.

- If the ceilings are the same height, there are two walls outward, and there are two windows. Standard power is 130 watts.

Now let’s multiply two values – the standard power for our option and the area of the room. If you have higher ceilings or a larger window (for example, if it has a bay window), we will additionally multiply by a correction factor of 1.1. As a result, we get the radiator power (total).

The radiator's passport indicates the thermal power for one section. The resulting total power must be divided by it. We round fractional numbers upward.

Climatic factors

Adjustments can be made depending on average winter temperatures:

- 10ºC and above - 0.7;

- 15ºC - 0.9;

- 20ºC - 1.1;

- 25ºC - 1.3;

- 30ºC - 1.5 .

Taking into account all the required adjustments, you will receive a more accurate number of radiators required to heat the room, taking into account the parameters of the premises. But these are not all the criteria that influence the power of thermal radiation. There are also technical subtleties, which we will discuss below.

Heat transfer from heating batteries: what is it, its calculation according to the product data sheet

The amount of heat that is transferred per unit time to a certain volume per unit time is the heat transfer of the heating battery. Heat output is sometimes called thermal power because it is measured in watts.

Sometimes heat transfer is called heat flow power, and therefore you can find the unit of measurement of heat transfer cal/hour in the product passport. There is a relationship between Watts and calories per hour: 1 W = 859.85 cal/hour.

The manufacturer indicates the nominal heat transfer parameter in the radiator passport. Based on this parameter, you can calculate the required number of elements for each individual room or room. If the passport indicates the power of one section is 150 W, then a section of 7 elements will produce more than 1 kW of heat.

Calculation of real heat transfer in kW

To do this, you need to decide on the number of external walls and windows. With one external wall and one window for every 10 m² of room area, 1 kW of heat will be required.

If there are two external walls, then for every 10 m² 1.3 kW of thermal energy will be required.

More precisely, you can calculate the required power using the formula Sxhx41:

- S is the area of the room;

- h is the height of the room;

- 41 is an indicator of the minimum power per 1 cubic meter of room volume.

The resulting thermal power will be the required full power of the heating battery. Now all that remains is to divide by the power of one radiator and determine their number.

Formulas for accurate calculations

KT=1000 W/m²*P*K1*K2*K4…*K7.

The CT indicator is the amount of heat for an individual room.

P - Total area of the room.

K1 is the coefficient for taking into account window openings. If there is a double window, then K1 = 1.27.

- Double glazing - 1.0,

- Triple glazing - 0.85.

K2 - coefficient of thermal insulation of walls:

- Thermal insulation is very low - 1.27;

- Laying walls with 2 bricks and insulation - 1.0;

- High-quality thermal insulation - 0.85.

K3 - ratio of window area to floor area in the room:

- 50% — 1,2;

- 40% — 1,1;

- 30% — 1,0;

- 20% — 0,9;

- 10% — 0,8.

K4 - average air temperature in the room during the coldest period:

- 35 °C - 1.5;

- 25 °C - 1.3;

- 20 °C - 1.1;

- 15 °C - 0.9;

- 10 °C - 0.7.

K5 - accounting for external walls:

- 1 wall - 1.1;

- 2 walls - 1.2;

- 3 walls - 1.3;

- 4 walls - 1.4.

K6 - type of room above the room:

- Cold attic (uninsulated) - 1.0;

- Attic with heating - 0.9;

- Heated room - 0.8.

K7 - taking into account ceiling heights:

- 2.5 m - 1.0;

- 3.0 m - 1.05;

- 3.5 m - 1.1;

- 4.0 m - 1.15;

- 4.5 m - 1.2.

This calculation takes into account the maximum number of features of the room for heating.

Attention! The result must be divided by the heat transfer of one radiator and the result rounded up

Calculation by volume

If you make such calculations, you will need to refer to the standards established in SNiP. They take into account not only the performance of the radiator, but also what material the building is built from.

For example, for a brick house the norm for 1 m2 will be 34 W, and for panel buildings - 41 W. To calculate the number of battery sections based on the volume of the room, you should: multiply the volume of the room by the heat consumption standards and divide by the heat output of 1 section.

For example:

- To calculate the volume of a room with an area of 16 m2, you need to multiply this figure by the height of the ceilings, for example, 3 m (16x3 = 43 m3).

- Heat standard for a brick building = 34 W, to find out how much is required for a given room, 48 m3 x 34 W (for a 41 W panel house) = 1632 W.

- We determine how many sections are required with a radiator power, for example, 140 W. For this, 1632 W/ 140 W = 11.66.

Rounding this figure, we get the result that a room with a volume of 48 m3 requires an aluminum radiator of 12 sections.

Design of bimetallic heaters

The body of these radiators is figured-ribbed, made of aluminum alloy, which is distinguished by excellent heat transfer. Under the housing there is a heating circuit made of pipes (copper or steel).

This “filling” helps the battery adequately withstand the attack of chemical and mechanical impurities present in hot water for heating.

The steel from which the core tubes are made is very strong. Therefore, the radiator will withstand even under high pressure. This can be 20, or even 40 atmospheres (some models up to 100 atmospheres). And the temperature of the coolant can rise to 110 or 130 degrees. If you need more specific numbers, you need to look at the passport of a specific radiator. Aluminum not only increases heat transfer, but also significantly makes the device lighter. In addition, the complex shaped housing has a very attractive design, giving the radiators an excellent appearance.

According to their characteristics, these radiators are quite suitable both for apartments in buildings of various heights, and for individual cottages with autonomous heating systems.

But don’t rush to the store right away - first we’ll tell you how to intelligently approach the issue of choosing them. Date: September 25, 2022

Permissible temperature of the working medium and maximum pressure in the system

When choosing, you need to take into account the characteristics of bimetallic radiators in terms of the maximum permissible coolant temperature and pressure in the system. The presence of steel inserts in the design of such devices allows them to withstand:

- Constant pressure from 16 to 40 Atm (equivalent to 1.6 - 4.0 MPa) . In practice, radiators are capable of briefly withstanding greater pressure that occurs during testing of the heating network (about 1.5-2 times higher than standard), as well as water hammer. In a centralized heating system, the standard operating pressure does not exceed 14 Atm, and in an autonomous one it is no more than 10 Atm.

- The temperature of the thermal environment is up to 100-110 degrees Celsius . This value is close to the temperature of the coolant that enters the facility from a centralized network. For obvious reasons, the coolant loses some of its energy by the time it “hits” the radiator, so real indicators usually do not exceed 90-95 degrees Celsius.

Would you like to learn more about the characteristics of bimetallic radiators that you need to pay attention to when choosing a model? Then contact a SANTEKHPROM representative by phone. Our specialist will provide competent recommendations and help determine the optimal characteristics of a bimetallic radiator for your apartment, home or office.

Dependence of battery power on connection and location

In addition to all the parameters described above, the heat transfer of the radiator varies depending on the type of connection. A diagonal connection with a supply from above is considered optimal; in this case, there is no loss of thermal power. The largest losses are observed with lateral connections - 22%. All others are average in efficiency. Approximate percentage losses are shown in the figure.

The actual power of the radiator also decreases in the presence of obstructing elements. For example, if a window sill hangs from above, the heat transfer drops by 7-8%; if it does not completely block the radiator, then the loss is 3-5%. When installing a mesh screen that does not reach the floor, the losses are approximately the same as in the case of an overhanging window sill: 7-8%. But if the screen completely covers the entire heating device, its heat transfer is reduced by 20-25%.