Have you ever tried to detect a gas leak in the kitchen by smell? What if there is no smell or it is difficult to detect? Agree that those who understand the main differences between gas mixtures and know how to identify them feel more confident. It is important to know what liquefied gas is in cylinders and how it will behave if the integrity of the gas pipeline is violated. This is a security issue.

Each type of fuel has its own characteristics. Specific heat of combustion, color, smell, spontaneous combustion temperature - all these are signs by which we identify a substance. An important parameter is molar mass. The distribution of gas during a leak depends on this value: it will accumulate below, filling the basement, or, conversely, it will rise.

The ability to understand balloon mixtures is the key to proper operation and the absence of fatal errors during replacement and disposal. In addition, knowledge of the theory will help you make an informed choice when purchasing. And this is already half the battle.

Using bottled gas

At the dacha, liquefied gas can be connected to a stove, smokehouse, and, if necessary, to a gas heater. A comfortable stay at the dacha will be ensured - the process of cooking and heating water will speed up. All this is guaranteed only with professional connection, knowledge and compliance with the rules for the safe use and storage of gas cylinders.

Why in a cylinder?

If natural gas is not supplied to the dacha, liquefied propane - butane mixture is used instead. Its liquid state of aggregation is explained by the high pressure under which it is located in the cylinders. It is convenient to use, transport and store such gas.

Reasons for the prevalence of propane mixtures

Compositions of propane and butane are much more often used as raw materials for filling household gas cylinders.

The reasons are simple:

- Propane is easier to liquefy. To influence it, a pressure of 16 atmospheres is enough. Methane will only become liquid after exposure to 150 atmospheres.

- Inexpensive cost of producing liquefied gas in comparison with a methane mixture.

- Less durable cylinders, which has a positive effect on the price.

- Safety of use.

Using a container with an internal pressure of 16 atmospheres is much safer. And this is an important selection criterion.

What is required to connect

Before connecting, you should prepare a cabinet to store the container. Purchase a reducer, a gas pipe or flexible hose for stoves, and special gas tools.

Using a gearbox

The stoves are designed for the safe use of low pressure gas. Therefore, it is impossible to connect a high-pressure cylinder to the stove without a special device. A low pressure supply of 30 mbar will be provided by a reducer.

The reducer provides the required outlet pressure regardless of the inlet pressure.

To ensure that as little communications as possible are under high pressure, the device is installed directly on the cylinder. It should be taken into account that the threads on its clamping nut and on the cylinder are left-handed. That is, you need to screw it in the direction you usually unscrew it. For reliability, brass threaded connections and nuts are required.

Typically gearboxes are used:

- RDSG 1–1,2. For gas container with valve.

- RDSG 2–1.2. For a container with a valve (popularly called a “frog”).

Gas hose

To connect, you need a gas hose 1.5 meters longer than necessary. This is required so that during operation the hose is not strained and does not crack prematurely.

Adapters

The new plates are equipped with all the necessary adapters. If you need to connect the cylinder to a used stove, then for its safe operation you need to prepare new brass clamps and fittings.

Tools and additional materials

According to safety rules, you can use copper-plated or brass-plated tools in your work. In case of accidental breakdowns, they will not give a spark. You need to prepare a material for sealing - flax or fum tape. To check the tightness, use a soap solution.

Cylinders for summer cottages

Basically, a barrel-shaped red “country” cylinder is connected to the stove. It is usually metal, but there are gas containers made from more modern materials:

- Polymer-composite. Impact-resistant, explosion-proof and very easy to use containers made of fiberglass threads filled with epoxy resin.

- Metal-composite. This is something average between metal and composite cylinders.

The capacity of cylinders used in everyday life is from 5 liters to 50 liters. At the dacha they are connected not only to the stove. Liquefied gas is used as fuel for smokehouses, grills, barbecues, gas generators and heating boilers.

Manufacturers

The main countries producing liquefied gas are, according to 2009 data:

- Qatar - the volume reaches almost 50 billion m³;

- Malaysia and Indonesia - 29.5 and 25 billion cubic meters, respectively;

- Australia and Algeria – 24 and 21 billion m³.

Japan ranks first among LNG importers. Gas is also purchased by: Spain, USA, France, India.

There are also 2 operating factories in Russia. One of them is the Sakhalin-2 project launched in 2009. The controlling stake is owned by Gazprom. The co-owners are: 27.5% Shell, 12.5 Mitsui, 10% Mitsubishi. At the end of 2015, annual production reached 10.8 million tons, which is 1.2 million tons more than the designed capacity. Unfortunately, due to falling prices on the world market, exports have decreased noticeably in recent years.

Another significant player in Russia is Novatek (Yamal-LNG).

The Americans did not stand aside either: they commissioned 5 LNG export terminals, the total capacity of which is 57.8 billion tons/year. It is clear why there has been a fierce confrontation between these countries for many years.

Connection

If the stove is installed, the cylinder for it should be placed at a distance of one meter or, even better, in an adjacent room.

- First we connect the hose. We screw its fitting onto the corresponding inlet pipe of the plate. Compaction is carried out with special gaskets or fum tape.

- The reducer is connected directly to the gas cylinder, also sealing the connection to prevent gas leakage.

- The last thing we connect is the hose to the reducer.

After making all connections, they must be checked for gas leaks. Carefully apply a thick soap solution to the joints and carefully open the valve:

- a hissing sound appears - the gearbox is working and gas is flowing;

- Soap bubbles are blown at the joints - the joint needs to be tightened;

- There are no visible flaws - the stove can be turned on.

It is strictly forbidden to check for gas leaks using an open flame. If you are not sure about the correct connection of the stove, consult a specialist.

During connection, carefully inspect all parts:

- The reducer, cylinder and threaded connections must be clean.

- The hose must be of the required length, not twisted, without visible narrowing or cracks.

During operation, you should monitor the condition of the clamps; if rust appears, they should be replaced with specialized clamps with anti-corrosion treatment.

How to refill a cylinder

When the stove is not in use, the cylinder valve must be kept closed. If you need to turn off the tank for refilling, the valve must also be closed. When refueling at the station, be aware that the tank is filled with less than the indicated capacity. There is always free space in the cylinder. Therefore, when filling a 50-liter cylinder, you pay about 40 liters.

Users should also be aware that non-volatile impurities - condensation - accumulate in the container. So that it does not take up space, they get rid of it. Condensate can be flammable, so it is better to pour it out at specialized stations.

Gas stoves using liquefied gas have long been used in dachas. If you have certain knowledge and experience, you can connect bottled gas yourself. But it is better to contact specialists who can professionally perform this work, ensuring the safety of further use.

Ecological fuel

Liquefied gas has a fairly high octane number and is distinguished by high energy indicators, which allows it to be used for refueling cars. Without harming the environment, the use of this fuel reduces oil consumption and engine wear. Its price is lower than the cost of gasoline. In addition, liquefied gases are safe, and refueling is carried out at specialized gas stations. This explains why it is considered a more economical fuel than gasoline.

Construction of a summer house in SNT. Part 31 – Introducing bottled gas into the house

Last time I wrote about how a metal box for bottled gas was installed on the street. Now I’ll tell you about how I introduced this same gas into the house before the Darina gas stove. You can read about replacing jets in a stove here. Initially I planned to introduce gas like this:

– we take a metal pipe 1/2 – we cut it into the required lengths – using tow and gas paste we pack it in turns (in total it was necessary to make three turns at the corners. In this case, the pipe would go up the facade of the house, through the sleeve in the wall of the house inside the house, in the house it would go down to a distance of about 50 cm, after which you would install a tap, a dielectric gasket and then connect it to the stove with a flexible hose.

For these purposes, a 6-meter black VGP pipe was purchased (two sections of 3 meters each). At first I thought of bending this pipe with a lever right on the spot:

- cut threads on the edges, pour water in there, plug the ends with plugs and bend them on the mandrel as needed.

Safety requirements when working with gas equipment

When operating gas equipment, knowledge of the norms and rules of connection is required, which makes operation safe for the user. If the gas stove is correctly connected to the cylinder, accidents during its operation are rare and are associated with careless operation and ignoring safety rules.

List of basic requirements:

- The need to undergo training at the gas management organization on the safe use of devices.

- Monitoring by the consumer of the correct operation of appliances, chimneys and ventilation.

- Check the chimney draft before using gas appliances. Before using a gasified oven, check the “open” position of the gate to the maximum. Clean chimney bends regularly.

- After finishing using bottled gas, you need to close the tap on the gas appliance and in front of it, and when placing the cylinder indoors, additionally close the valve on the cylinder.

- If the equipment malfunctions, inform the specialists of the company serving the consumer.

- If the gas supply suddenly stops, you should quickly turn off the burner valves of the gas appliance and call the emergency service by phone 04.

- If you smell gas in the apartment, you should immediately stop using the appliances, turn off the valves on them and the supply pipelines, open the doors and windows to ventilate the room, and call the emergency service by calling 04 (from another room). It is prohibited to light a fire, smoke, or use electric lighting or electrical appliances.

Capacity 480 l

from 9,900 ₽

Order installation

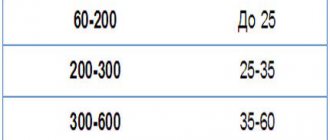

When placing cylinders outdoors, their operation is safer, however, at low ambient temperatures, their evaporation capacity decreases sharply, and when a certain temperature minimum is reached, it is completely absent. In this case, the amount of unevaporated gas residues in the cylinder can be very significant and, under certain conditions, reach 85%. When installing cylinders in cabinets outdoors, this circumstance significantly complicates the work of gas filling stations (increasing the volume of work to drain unevaporated residues from the cylinders). Due to the presence of a large amount of unevaporated residues, gas accounting at the gas pumping station and the work of filling cylinders are complicated, especially when automating these processes.

Features of connecting the stove to a gas cylinder

Connecting a gas stove to a cylinder should begin with choosing a place to store the container with fuel and organizing its supply through a pipe or flexible hose to the point of consumption. You need to determine in advance what kind of gas is supposed to be used - bottled or natural.

To perform the connection work, you do not need to have special skills in handling tools. You just need to carefully study the rules for the safe operation of gas equipment.

Selecting a location

Connecting a gas cylinder to a stove in a dacha is permitted both inside and outside a residential building. But, according to fire safety standards, it is recommended to choose a place to store gas outside, and not in the kitchen or utility room. When placed outdoors, it is necessary to attach a long pipe or hose, but this significantly reduces the likelihood of a fire; in the event of a leak, gas will not be able to accumulate in the basement to a dangerous concentration.

How long does a gas cylinder last?

Not everyone is lucky enough to have mains gas in their country house. An acceptable alternative for a summer cottage is gas from cylinders. Before embarking on the practical implementation of such improvement, of course, I would like to understand how long a gas cylinder will last ? This is certainly an important question. For many decades, the most common gas cylinder for the avid summer resident is a metal 50-liter gas cylinder with a propane-butane mixture.

Metal 50-liter cylinder with a mixture of propane-butane.

For him, we will try to estimate how long the gas will last. We look at the cylinder passport - a metal “skirt” under the valve, on which a lot of useful information is stamped.

Gas cylinder passport

The passport states: – “empty weight 22 kg; total weight 43 kg.” This means that a full 50-liter cylinder should contain 21 kg of liquefied propane-butane gas. If a housewife cooks on a fire for an hour, then a normally working stove will have to “eat” approximately 0.62-0.65 kg of propane-butane from the cylinder.

By simply dividing 21 by 0.65 we get something like 32 hours. This, of course, is the ideal model; in real life, for a number of reasons, the number of hours of work turns out to be somewhat smaller .

Smaller, but not so catastrophically small as to abandon the option of using a gas cylinder in the country, and even look for such avid summer residents, where the housewife stands at the stove every day, and even for a whole hour.

Often, the summer season at the dacha means weekly visits to the dacha from late Friday evening (if you are lucky enough to get through traffic jams) until Sunday evening. In this situation, one 50-liter cylinder is just enough for a summer resident from the long weekend in May until the last mushrooms in September. The conclusion is simple. Yes, a gas cylinder at the dacha makes sense . Need to do.

Where to install the gas cylinder

You can, of course, place the cylinder in the room where the stove is located. However, in order to sleep more peacefully, I advise summer residents to choose the option of installing it in a metal box outside . It is convenient to have a box that can accommodate not one, but two cylinders at once. If two cylinders are used, then the housewife will never be left without a working stove in the kitchen.

As soon as the gas in the first cylinder runs out, you move the second full cylinder in its place and there is quite a sufficient period of time to refill the empty first one without fuss and unnecessary haste.

According to the rules, there must be at least 0.5 meters from the building window to the nearest wall of the gas box and at least 0.5 meters from the window to the gas inlet into the room .

Gas cylinder in a metal box, on the street.

The best place to install a metal box with a gas cylinder will be a shady place near the northern wall of the building in which the kitchen is located. So that the summer sun's rays do not heat the cylinder. Do not forget that it is always better to close the tap on the gas cylinder after you have finished cooking on the stove.

In addition, keep in mind that in order to change empty cylinders for new ones, you will have to take care of a convenient approach to the metal box, especially considering the considerable weight of a fully filled cylinder - 43 kg.

After choosing a place for the gas box. a neat non-combustible foundation for the cabinet Having reliably checked the horizontal and vertical lines, we install the cabinet and fasten it in place (the cylinder inside the cabinet should not stand at an angle).

Below, at the bottom of the gas cabinet, holes are needed for ventilation. Install a lock on the cabinet doors - for country life there is no way without locks.

Areas of application

In addition to the fact that liquefied gas (grade PBA, used at air temperatures not lower than -20 degrees, and PA) is used in the automotive sector as a fuel that is more economical, safe, cheap and environmentally friendly, it is used in heating systems and in industry (as a source of heat and cold in metalworking, ceramics and glass processing), for household and utility needs (BT, PBT, PT brands).

The main players in the fuel segment are butane, methane and propane, which combine the following indicators:

- no smell. On the contrary, such fuel is given an aromatic marker to quickly detect leaks;

- safety, i.e. resistance to possible fire, which occurs at temperatures of plus 429 degrees (butane), at 466 (butane) and at 537 (methane). For comparison, diesel fuel and gasoline ignite when they reach 250-300 degrees;

- combustion is complete, thereby minimizing harm from emissions into the environment;

- minimal carbon deposits, allowing to extend the service life of piston cylinders, spark plugs and the engine combustion chamber;

- high octane number: 110 for methane and 100 for a propane-butane mixture. It should be noted that the mixtures can be used in different climatic zones, but taking into account the fact that in a liquefied state they are not frost-resistant, but are immune to zones with a hot climate: these components in the mixture complement each other and form a fairly stable substance. Unlike them, propane reacts to high temperatures, which leads to an increase in pressure in the cylinders where it is stored.

Important: Gas stations sell different mixtures for different seasons, which differ in the percentage composition of gas mixtures: in summer, for example, butane should be 60%, in winter - 40.

The requirements regarding liquefied hydrocarbon gases can be found in GOST 27578-2018.

How to connect a gas cylinder to a stove

After the gas box is installed, install the gas stove against the wall of the kitchen room. It is necessary to leave at least 15 cm between the wall and the back wall of the stove, and attach a protective non-combustible screen to the wall itself behind the stove (a metal sheet is also possible). Above the stove, in the outer wall of the building, you will have to make a through hole for laying a gas pipe.

You can’t just push a gas (usually a half-inch metal) pipe into a wall hole! First you need to install the so-called wall hole in the hole. sleeve - a small (as long as the thickness of the wall) piece of metal pipe, the internal diameter of which is slightly larger than the external diameter of the gas pipe. The space around the gas pipe inside the sleeve must be filled with non-flammable plastic material.

We connect the metal gas pipe to the gas inlet of the stove, securely fasten it to the kitchen wall, laying the pipe from the gas inlet of the stove, up to the shut-off valve and from it to the sleeve. We pass the gas pipe through the sleeve and, attaching it to the outside of the wall, lower it to the gas box and insert it inside it.

Inside the box, from the gas pipe to the cylinder there will be a flexible gas hose, the length of which should not exceed 1 meter.

Attention! Before touching the tap on the gas cylinder, be sure to install a reducer on it ! Only with a reducer can you open the gas cylinder to supply gas. The cylinder valve has a side fitting with an “unusual” reverse thread, i.e. you need to screw the union nut of the reducer onto the cylinder fitting counterclockwise, and when the time comes to disconnect the empty cylinder, then the union nut of the reducer will need to be turned clockwise. With this left-handed thread there are often very unpleasant and even dangerous cases, which I will discuss below.

Attention! We must not forget, every time when replacing a cylinder and unscrewing a conventional cylinder reducer, change the special paronite gasket to a completely new one . You will always have to have a sufficient set of paronite gaskets “in reserve”.

We place the reducer on the gas cylinder, put a gas flexible hose on the reducer fitting (it must be clamped onto the fitting with a clamp), and connect its other end inside the gas cabinet with a gas pipe. We stretch all the connections.

Advantages

- Convenience of energy storage (due to the high density of liquefied gas), delivery and consumption. The cryogenic non-toxic liquid is stored at minus 162 degrees Celsius. For large volumes, above-ground containers are used, where it is under atmospheric pressure;

- Intercontinental transportation, for which gas tankers, tank trucks or railway tanks are used;

- Opens up the possibility of gasification of objects located at considerable distances from gas mains. There is no need to build expensive pipelines.

Checking for gas leaks

All is ready. No, not so that the housewife starts cooking on a gas stove. Everything is ready to finally make sure that there are no dangerous gas leaks in the assembled system. Check using soap foam. We open the tap on the gas cylinder and carefully coat each joint with ordinary soap foam. We carefully examine the newly coated area. If no soap bubbles are inflated anywhere (even very small ones), then everything is fine, we move on to checking the next joint. If somewhere foam is inflated into a bubble, it is necessary to eliminate the gas leak in the system. To do this, tighten the nuts, sometimes you have to change the gaskets, tighten the clamps. This soap foam test should always be carried out after replacing the cylinder. At the slightest suspicion of a gas leak, be sure to check with soap foam.

This is where the time has come to remember about dangerous mistakes with the left-hand thread of the gearbox. The owner suspected something was wrong with a gas leak from under the gearbox nut, and he “tightened it”, but only, out of habit, he tightened it as usual, like a right-hand thread, but in fact he made it even worse - his gas leak became even worse.

Well, if you weren’t too lazy to wash it and check it, then it’s half the trouble. And if you “pulled it up” in a hurry and closed the doors of the gas cabinet, that’s a disaster. In no case should you use gas in a hurry or “at random”. All connections were washed, tightened, washed again, and carefully checked that there were no gas leaks anywhere. Now the gas stove at the dacha is correctly connected to the gas cylinder.

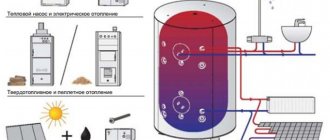

Necessary equipment for heating with liquefied gas

If you decide to heat your house with liquefied bottled gas, then in addition to the basic equipment described below, you will need the following parts:

Comb or tee - necessary for combining several cylinders;

Fittings – threaded or quick-release;

Pressure gauges for pressure control;

High pressure taps and hoses;

Heating of cylinders and reducer;

Switches between groups of cylinders;

Valves – check and relief valves, emergency shut-off valves.

Heating boiler

When using LPG, the heating boiler is a conventional one designed for burning gas (gas heating boiler). It can be a wall-mounted gas boiler or one mounted on the floor. The only thing when purchasing is to choose the most economical option, for example, a condenser boiler, this will reduce the consumption of such expensive fuel.

However, a standard gas boiler needs a little modification to accommodate operating conditions from bottled gas. This applies to burners - they are replaced with special ones, and as a rule, they come complete with the heating boiler.