An ordinary fireplace heats a room well, but is not able to heat the entire house for a long time due to its low heat capacity.

For this purpose, a fireplace stove with a water circuit is suitable, to which you can connect radiators in all rooms of the home.

Thus, heating of a large number of rooms is carried out from one place.

The coolant heated inside the water circuit will evenly distribute the heat and help maintain a comfortable air temperature in the house.

| Place | Name | Price |

| TOP 5 best fireplace stoves with a water heating circuit | ||

| 1 | META Angara Aqua | Find out the price |

| 2 | La Nordica Termo Isotta | Find out the price |

| 3 | EdilKamin Aqua | Find out the price |

| 4 | Vesuvius PK-01(270) BEIGE | Find out the price |

| 5 | Vesuvius PK-01(270) RED | Find out the price |

| TOP 5 best long-burning fireplace stoves with a water circuit | ||

| 1 | MBS Thermo Vesta plus | Find out the price |

| 2 | MBS VULKAN | Find out the price |

| 3 | Romotop GRANADA | Find out the price |

| 4 | META Pechora Aqua | Find out the price |

| 5 | EdilKamin Warm CS | Find out the price |

What do we usually expect from a fireplace?

When we - you, me or anyone else - sitting in front of a computer screen, drawing our project or just thinking about the topic of heating a house, think about a fireplace and heating a house (especially if we think about the first and second at the same time), we often forget the primary expectations from the fireplace itself. Firstly, we forget the difference between an open fireplace and a fireplace with a door. And it is significant if the door is ordinary. The fact is that fireboxes come in “grate” and “hearth” types. I recently wrote a separate article about this, “Modern fireplace door with fireproof glass - important features!”

Many people know very well what the beauty of open fireplaces is. But it's unlikely that many people can distinguish between the important features of a fireplace insert (or any fireplace with a door) and an open fireplace. And even more so, fewer people will be able to choose a door behind the glass of which the fireplace will burn with the effect of an open fireplace - a good hearth door. The vast majority of steel fireplaces and any fireplaces with doors are grate. This is required for heating efficiency. The combustion in them is completely different; the aesthetics of burning wood in them will never compare with an open fireplace or a fireplace with a good hearth door.

Secondly, here is my personal experience and the experience of my colleagues. In order not to constantly put off starting the fireplace and generally be able to enjoy the view of the flame, the fireplace should be located in the most visible place in the living room. Also, he should not occupy a key place - so as not to get in the way. This is, of course, obvious, but when the question of the water circuit arises, we begin to scroll through the many placement options for profitable home heating. Often, we forget about the above-mentioned obviousness for the sake of heating efficiency.

Preparation and construction of the structure

To make a water fireplace stove with your own hands you will need:

- A cement mortar containing: clay, sifted sand, cement grade M300 (not lower). Before use, clean (sieve) the sand from dust and excess debris - rinse thoroughly Advice! For an incompetent stove maker, it is better to use Cambrian clay because it is very easy to work with. Ordinary can be safely used by those who have knowledge and experience working with it, in particular in preparing solutions.

- By the way, a half-brick should be considered as a whole one, and approximately 5% of the total quantity will certainly go to waste

- Smoke damper made of metal, reinforcing rods

Pouring the foundation

The principle of laying the foundation

- The base of the fireplace is not connected to the foundation of the house. Moreover, there must be a gap between the base of the fireplace and the surface of the wall. The gap between the base of the fireplace and the house is filled with sand. The width of the base, in contrast to the width of the base, increases by about 10cm

- To lay the foundation, a hole is dug 60 cm deep. A layer of crushed stone is placed at the bottom and compacted tightly. Before pouring concrete, formwork is built (must be at least 15 cm above the floor surface) and lined with roofing felt (for waterproofing). Only after this the foundation is filled with concrete mortar mixed in the proportions: 3 parts sand and 1 part cement.

- Pour the solution gradually in several stages, carefully smoothing each layer. The top one should be approximately 7 cm below the floor surface. After which it is left alone for 7 days to dry.

The truth about iron fireplaces with a water circuit or - 5 reasons not to do it

It must be said that the calculation of the power of cast iron fireboxes is very unique. To say that such calculations are slightly overestimated is to say nothing. Moreover, when such a firebox with a water circuit is taken into account. Let me make a reservation right away that I am not taking into account real direct or long-burning boilers designed for heating a house. I wrote about them in a separate article (the link will open in a new tab).

- Firstly, when calculating the power of a cast-iron fireplace insert, they simply can (most often do) not take into account the efficiency!

- Secondly, they can write the calculated power not as the average daily one (for “so-and-so” furnaces for “so-and-so” time). Since I and the vast majority of stove-makers calculate the power of our heating products - but the instantaneous one. This, in general, is the reverse medal of unaccounted efficiency. Relatively speaking, we can say that the power is, for example, 14 kW, but this is with continuous combustion. So, for example, they calculate water electric boilers, but they calculate electricity consumption per hour, and this is a completely different parameter.

- In addition, thirdly, the power of a water heating boiler from direct fire is calculated based on the area of the register located in the high temperature zone. There is a special formula for this. Looking at any metal firebox, you can easily calculate the power yourself, just knowing this formula.

- Based on all that has been said, fourthly, such a metal boiler, having no heat capacity (and metal has high thermal conductivity and, accordingly, low heat capacity), we will in fact only have momentary power. With, in any case, low efficiency - what is it in any fireplace, even with a water circuit.

- Fifthly, not every firebox, if you mercilessly heat it for the sake of warmth, can withstand the load of high temperatures. After all, each heating is for her a cycle of expansion and contraction. How many cycles is this firebox designed for? It's good if this is written in the instructions. And if we heat it twice a day, then we will accumulate about three hundred such cycles during the heating season.

Well, you probably haven’t analyzed your home heating capabilities enough. If, out of all the options for heating with wood, you decide to consider a fireplace, and even with a water circuit. Especially if it is not the main heating. Read more about this. By the way, here is a short video about a fireplace insert (in which you can build a heating register). My review of the firebox of our production “TKDp (Two-leaf hearth firebox) 800 Ogonyok”:

Selection of oven power

The most important parameter that must be taken into account before buying a specific model is the thermal power of the heating unit . It is measured in kilowatts, and it is generally accepted that 1 kW of furnace power can heat 10 m² of house area.

However, it is worth considering that the manufacturer tests the stove in conditions close to ideal, and if insufficiently dried firewood is used, its power may decrease by a third. Therefore, to use a stove with a heating circuit as the only heating source, it is better to buy a model with a small power reserve.

Steel or cast iron?

Heating stoves-fireplaces are made of steel and cast iron. Steel stoves are cheaper, lighter, but more susceptible to corrosion. Models made entirely of cast iron have increased durability and resistance to corrosion, but at the same time they are much heavier and are susceptible to sudden temperature changes, which can cause them to crack.

The best option is combined models, in which the body and slightly heated elements are made of steel, and the firebox elements, grate bars and doors, which are subject to severe overheating, are made of forged cast iron. They are not afraid of prolonged exposure to high temperatures and are suitable for constant use, and with periodic firing, the condensate formed in the pipes does not cause corrosion.

Connection to the heating system

Most industrial fireplace stoves can be operated either with or without a connected water circuit. However, their service life does not differ significantly.

If the fireplace stove is connected to a water circuit, under no circumstances should it be operated with the coolant drained! This will lead to failure of the heat exchanger and the system itself! Furnaces with a water circuit can be used in systems with both natural circulation (gravity) and forced circulation (using a pump). At the same time, the connection diagrams to the heating system do not differ from traditional ones.

Features of connecting a stove with your own hands to a gravity heating system:

- Immediately after leaving the heat exchanger, an accelerating manifold is installed, raising the coolant to the top point of the system.

- An open or membrane type expansion tank is installed at the top point.

- The main pipe requires a minimum diameter of 32 mm; with a smaller pipe cross-section, the hydraulic resistance of the system increases, which leads to worse circulation.

- The slope of the main pipe must be at least 5 cm/1 m, otherwise the movement of the coolant will slow down, the temperature in the system will be uneven, and heating will be ineffective.

- Pipe outlets to radiators should have a diameter of 16-20 mm. Radiators are installed parallel to the main line in a lower or diagonal pattern.

When using a forced system, the requirements for its installation are significantly less:

- The expansion tank can be installed in any convenient place; it is usually placed on the return pipe, after the circulation pump.

- The connection diagram for radiators can be any.

- It is not necessary to withstand a significant slope of the main pipe.

- Using automation, you can set the speed of movement of the coolant, as well as the return temperature, which will avoid the appearance of condensation in the furnace.

The choice of coolant is an equally important step, which depends on the operating mode of the furnace .

For homes with permanent residence, it is more convenient to use purified water - it is cheaper, practically does not cause corrosion in a closed heating system, and is easily topped up from the water supply if necessary. If the home is used occasionally, using water during the winter may cause the system to freeze. At the same time, the water expands and damages the elements of the system: pipes, radiators, fittings, which will subsequently lead to leaks.

In this case, you can use special antifreeze, or install an electric boiler parallel to the stove, operating in the mode of automatically maintaining a positive temperature at a level of 5-10ºC.

Fuel requirements

Any stove will not produce the efficiency indicated in the passport if it is heated with wet firewood or unsuitable wood. It is optimal to use naturally dried birch firewood in fireplace stoves with a heating circuit , which has lain in a covered woodshed or under a canopy for at least 18 months, or industrially produced briquettes with a humidity of no more than 20%.

It is not advisable to use firewood from coniferous trees - they emit a lot of resins, clog the chimney and smoke the glass in the firebox. The use of coal in fireplace stoves is generally not allowed.

Firewood can be ignited using birch bark, wood chips, paper or a special liquid. When igniting, the damper must be completely open, and access to fresh air through the ash pan must be ensured.

Specifications

European manufacturers of fireboxes with a water circuit manufacture them according to the German DIN+ standard. In Russia, it is necessary to take into account not only these standards, which determine the technical characteristics of stoves, but also heating standards. It is better to understand the features of fireplace production and their capabilities using the example of Spartherm Varia 1V H2OXL. The dimensions of the stove are exactly the same as they would be if it did not have a heat exchanger: width - 75 cm, height - 123 cm, depth - 55 cm.

To calculate the compliance of the technical characteristics of the stove with heating needs, a house with a total area of 160 square meters was selected as an example. meters. According to Russian heating standards, at a temperature outside the window of -27 degrees Celsius, spend 1 square meter on heating. meters you need no more than 50 W every hour. The rated power of this firebox is 14 kW, of which 10 kW is provided by the heat exchanger, 4 kW by thermal radiation. There are two glasses in the firebox door: the inner one has a film that reflects heat, so as not to overheat the building and not burn the skin when touched; the outer one is decorative.

The calculation period is 5 days, during which the stove will heat the house all day. In 12 hours, the fireplace produces 14 kW hourly, of which 8 kW is spent on the heating needs of the house (radiators, etc.). 1 kW is spent on heating water for domestic use. The boiler accumulates the remaining 5 kW every hour. On average, throughout the day it can accumulate about 60 kW, which will be used to heat the house at night. To accumulate such an amount of heat, the storage boiler must have a volume of at least 700 liters.

How it works - video guide

Device Features

A fireplace stove with a built-in water circuit is a steel chamber with varying wall thicknesses . In a closed system the indicator will be 6 millimeters, in an open system - 4 millimeters.

Heat exchanger tubes are mounted between the walls to circulate the coolant liquid. To be able to control the temperature in the oven, temperature sensors are installed.

The air flow into the combustion chamber is usually adjusted manually.

PLEASE NOTE! Exterior decoration can be made using various materials in order to fully comply with the overall style of the interior.

In summer, such equipment can only be used for water heating.

Types of fireplaces by material of manufacture

To construct aqua fireplaces, brick, natural stone, ceramics, cast iron, steel sheet, basalt fiber insulation, and heat-resistant glass are used.

Brick

The fireplace stove can be custom-designed to almost any configuration. Finishing with tiles will emphasize the individuality of the interior. As a rule, high-quality working bricks (refractory) are used in such fireplaces.

Requires careful adherence to technology and high-quality installation. Installed on a separate foundation. The high starting cost is justified by the increased comfort.

Metal

The most profitable due to the optimal price/quality ratio. Light weight, affordable price, simple installation, and varied designs contribute to their widespread distribution.

Combined

They combine the comfort of infrared fireplace heating, the heat capacity of a massive stove, and the functionality of a water heating system. They have the highest possible efficiency. They release accumulated heat for a long time after the fire goes out.

A combustion chamber with a heat exchanger is built in during the construction of a brick or stone fireplace facade. Since access for repairs will be difficult later, the cast iron option is optimal. A separate foundation is required, so it is recommended to use a durable ceramic chimney.

How to choose and what to pay attention to?

What qualities must a heating equipment have to become a reliable source of heat?:

- Power . Varies with the size of the firebox and the dimensions of the stove. On average, a room of 10 m² requires 1 kW of power.

- Dimensions . Must fit into the installation room.

- Coolant volume . It consists of the volume of pipes and radiators, depending on the total length of the system and the number of batteries. Another 10% is added to the resulting value.

- Chimney cross section . The indicator is important for selecting suitable structural elements.

- Additional options . Cooking and heating food, easy glass cleaning, non-heating handles and other easy-to-use little things.

Delivery to regions

We can deliver your order to any region and city in Russia. The cost of delivery depends on the distance between cities, weight, volume of the goods and is calculated when ordering the goods. On the page of each product in the delivery section, you can specify the city and find out the cost and delivery time of the product. You can write to the delivery service at the address, indicating the product you are interested in, the exact delivery address (pickup warehouse or your address) and the delivery service will calculate the cost of shipping the goods. You can also get advice by phone: 8 (495) 926-26-22. Payment for goods in case of delivery to the region is made by bank transfer with 100% prepayment or by card through the website, or can be paid by your representative in Moscow in cash. All necessary documents are transferred along with the goods or to your representative.

The delivery time depends on the distance and the product and ranges from 2 days to the nearest regions and up to 2 weeks to the most remote corners of the country.

You can calculate the cost of delivery to your region on the product page in the delivery section. We will deliver the goods to the shopping center for free when ordering a chimney kit or order amount over 100,000 (except for promotional items). The cost of delivery to shopping center for orders from 60,000 to 100,000 and promotional goods from 100,000 is 1990 rubles. For orders up to 60,000 - 2990 rub.

Close

Rating of TOP 10 best models

In this rating, we have collected for you the best models in terms of price, quality and reliability.

La Nordica Termo Isotta

The Isotta cast iron stove is equipped with a water circuit and is designed to heat several living

spaces at the same time .

Its double walls allow you to effectively manage air flow. A hob is built into the surface. It has a protective cover that protects the walls from contamination during the cooking process.

The firebox door is decorated with panoramic ceramic self-cleaning glass . There is a separate door at the bottom for easy use of the ash drawer.

Characteristics:

- power: 15-19 kW;

- Efficiency: 78.4%;

- location: wall;

- chimney: 150mm, front/rear;

- material: cast iron;

- glass type: panoramic;

- dimensions: 77.5*76*52cm;

- weight: 212kg.

Advantages:

- long burning;

- convenient door;

- self-cleaning glass;

- moderate fuel consumption.

Flaws:

- No.

META Angara Aqua

The total power of the model is 16 kW, of which 7 kW is the power of the water circuit . Heat exchanger holds 10 liters

liquid and is made of 5 mm steel. The firebox has a significant volume and is easy to clean from combustion products.

Firewood can burn in a prolonged mode, which is especially convenient at night.

The body is decorated with ceramic inserts, and the glass door provides excellent visibility..

Design solutions made it possible to reduce the volume of soot entering the chimney.

Characteristics:

- power: 16 kW;

- location: corner/wall;

- chimney: 150mm, front/rear;

- material: steel;

- heated area - up to 160m2;

- glass type: prismatic;

- dimensions: 104*70*54.5cm;

- weight: 205kg.

Advantages:

- attractive external design;

- presence of panoramic glass.

Flaws:

- high fuel consumption;

- insufficient heat transfer to the coolant;

- soot on the glass.

EdilKamin Aqua

The combustion chamber of this furnace has double walls . This allows you to reduce the temperature impact on the case and extend the service life.

stove-fireplace services.

The inside of the firebox is lined with fireclay, resistant to combustion products and high flame temperatures.

The door is decorated with glass, which can withstand heat up to 750 degrees, but is not resistant to pinpoint impacts . The water circuit will allow you to create a full-fledged heating system in the house, heating the neighboring rooms.

For safety, there is a built-in sensor against system overheating . The oven can be used in the kitchen; the cooking surface has a heating temperature of up to 200 degrees.

Characteristics:

- power: 6.5 kW;

- hob;

- location: wall;

- chimney: 150mm, ;

- material: steel, ceramic tiles, fireclay;

- glass type: straight;

- dimensions: 95*52*52cm;

- weight:186kg.

Advantages:

- high quality materials;

- excellent assembly;

- overheat protection.

Flaws:

- No.

Vesuvius PK-01(270) BEIGE

The stove is made of a combination of cast iron and steel . The door is cast iron with heat-resistant glass. The grate is cast iron. Firebox

trimmed with chamotte.

The ends are decorated with beige ceramic inserts, which help the stove retain heat longer. It is possible to heat rooms with a total area of up to 200 m2.

Burning time on one stack of wood is up to 5 hours.

High-quality components guarantee a service life of at least 10 years. The furnace firebox is 100% airtight.

The parts are fixed using a bolted connection to guarantee reliability . In the economical operating mode, the firewood only smolders; in the intensive mode, quick kindling is carried out.

Characteristics:

- power: 9 kW;

- hob - no;

- location: wall;

- heating area - up to 200m2;

- chimney: 150mm, ;

- material: steel, cast iron, ceramic tiles, fireclay;

- glass type: straight;

- dimensions: 82*46*43cm;

- weight:141kg.

Advantages:

- design;

- ergonomics;

- holds temperature for a long time.

Flaws:

- No.

Vesuvius PK-01(270) RED

The fireplace stove is made from high quality induction steel . The firebox door is made of cast iron and equipped with glass

insert, the blower door allows you to control the intensity of combustion.

The firebox is finished with high-quality fireclay, which can be easily replaced if necessary. Decorative inserts on the sides are ceramic, red.

The power is 9 kW, which will allow you to warm up a room with a volume of up to 150 m3.

One stack of firewood will provide heat for up to 5 hours. You can connect an electric fan to quickly heat the room. The minimum service life of the product is 10 years.

Characteristics:

- power: 9 kW;

- hob - no;

- location: wall;

- heating area - up to 200m2;

- chimney: 150mm, ;

- material: steel, cast iron, ceramic tiles, fireclay;

- glass type: straight;

- dimensions: 82*46*43cm;

- weight:141kg.

Advantages:

- heating rate;

- nice design in a classic style;

- high legs.

Flaws:

- soot on glass.

Product lines

The Angara series of fireplace stoves is presented on the Russian market in several versions: standard, with a heat exchanger and/or stove, as well as with increased dimensions.

1. Angara fireplace stove standard.

Specifications:

- A 9 kW oven heats rooms up to 90 sq.m.

- Dimensions – 1020×560×490 mm.

- Weight – 140 kg.

- Location – corner/front.

The basic model does not require a reinforced foundation. Small dimensions and wall placement allow homeowners to maintain enough free space in the room. Parts of the side surfaces of the furnace body are lined with ceramic tiles. The combustion chamber is lined with fireclay tiles on the inside. This protects the steel walls from burning out and increases the service life of the furnace. There are also cast iron grates inside, through which ash and ashes fall into the drawer. Below the firebox there is an open chamber for storing firewood. One stack of fireplace stoves consumes 3-4 kg of fuel. The burning time is about 4 hours. The strength of the flame is regulated using slide valves.

2. MetaFire Angara 12 series fireplace stove with stove.

Specifications:

- Heating area – 100-120 sq.m.

- Thermal power – 12 kW.

- Dimensions – 950×700×545 mm.

- Weight – 195 kg.

- Location – frontal.

The new stove features a larger combustion chamber volume and an improved heat exchanger. The extended functions of the model are manifested in the presence of a plate. The ability to simultaneously use a fireplace stove to heat the house and cook food brought Angara 12 into the ranks of top products.

3. Stove-fireplace with water circuit Angara Aqua.

Specifications:

- Heated area – up to 210-230 sq.m.

- The total thermal power is 18 kW.

- The water circuit capacity is 9 kW.

- The volume of the heat exchanger is 4 liters.

- Dimensions – 1020×550×490 mm.

- Weight – 150 kg.

A stove with a water circuit, Angara Aqua, heats the house using radiators. It is used in open/closed heating structures with forced/hydraulic coolant circulation. The original device and front placement provide accelerated heating. Softened water or antifreeze liquid can be used as a coolant. The fireplace is equipped with a door with heat-resistant glass “Neoceram NO” and a “clean glass” system.

For uninterrupted operation of the furnace, it is necessary to use coarse filters, safety structures and air vents. It is advisable to install thermostats on radiators. The Angara Aqua fireplace can be heated independently, without connecting to the water circuit. The system must be full. The heat exchanger operates stably under such conditions, but its service life is significantly reduced.

4. Meta Angara 12 Aqua fireplace stove with water heat exchanger.

Specifications:

- Heated area – 140-160 sq.m.

- Productivity – 16 kW.

- Dimensions – 1040×700×535 mm.

- Weight – 205 kg.

- Heat exchanger volume – 10 liters.

- Location – wall.

The water loop furnace is a new heating device with improved characteristics. The heat exchanger system ensures high combustion efficiency and reduced soot volume in the chimney. The large dimensions of the fireplace allow the use of large firewood. Decorative ceramic elements are used in the design of the stove lining. The combustion doors have a prismatic shape and are made of heat-resistant glass ceramics.

Pros and cons of fireplaces with a water circuit

Among the advantages of fireplaces with a water circuit it is worth noting:

- System price. A ready-made stove model or custom-assembled brick fireplace will not cost that much.

- Cost of operation. The system is completely energy independent, the price of solid fuel is low, which means its use will not ruin the family budget.

- Multitasking. Such a system will decorate the interior; a separate boiler room is not required.

- A fireplace with a water circuit can be a replacement for a traditional heating system.

The disadvantages of such systems include:

- Not very high efficiency, especially when it comes to fireplaces with an open firebox. The power of such equipment may not be enough to heat the house in frosty winters.

- Lack of automation systems. It is impossible to quickly adjust the coolant temperature. You will have to add firewood or briquettes and clean the firebox manually.

Additional positive aspects

In addition to the above main advantages, there are several additional advantages of water furnaces. For example, if the owner of such a design expresses a desire, the fireplace can be equipped with a grill and other additional devices on which you can cook delicious dishes, and not just enjoy the live fire.

Equipped with glass side inserts and transparent spherical screens. In addition to conventional structures, combined fireplaces can be erected. They use the heat of the chimney, warming the atmosphere of the room. An air-heated fireplace will save approximately 20% of fuel energy compared to conventional fireplaces.

Construction of fireplaces with a water circuit

All work can be divided into two stages:

- Construction of the body of the heat source, that is, the fireplace itself;

- Installation of heat exchanger.

Construction of the fireplace body

The construction of the fireplace body should begin with the search for a formal masonry scheme. When choosing materials, give preference to those that allow you to build a fireplace with a water jacket. To ensure tightness, steel sheets are usually used.

The construction of a fireplace begins with the installation of the foundation. To fill it you will need:

- Boards for installation of formwork;

- Ruberoid;

- Crushed stone;

- Sand;

- Cement.

The size of the base should be slightly larger than the dimensions of the future fireplace. To ensure waterproofing of the finished foundation, roofing material is laid on it. After this you can start laying. Fire-resistant bricks are used for the construction of the building; the firebox is assembled from a heat-resistant fireclay grade. A special clay mixture is used as a solution. It is not recommended to make it yourself. Experts use ready-made dosage formulations.

The masonry should be assembled from horizontal main rows. At this stage, it is important to ensure accurate positioning in the horizontal plane. After this, the ash pan is assembled, then the craftsmen lay out the fireplace firebox. The final part of the installation differs significantly from the construction of a classic fireplace. At this stage, installation of the heat exchanger is required.

Heat exchanger organization

The simplest type of heat exchanger is a small tank with two flanges for connecting pipes. Cold water enters through the first pipe, heated water is discharged through the second. Due to the harmful effects of open flames, temperature changes, and the negative effects of combustion products, it will not last long. The material for the heat exchanger must be sheet steel with a thickness of at least 4 mm.

The exact dimensions of the tank are determined by the design of the fireplace. To increase efficiency, it is recommended to use coil-type heat exchangers. Such designs consist of sections and registers, assembled in the form of a labyrinth.

After the heat exchanger is manufactured, it is built into the body of the fireplace. After this, special stands are formed on which the tank will rest. Installation is carried out in such a way that the heat exchanger flows are outside the fireplace. This allows for repairs in the event of a breakdown.

After installing the heat exchanger, the assembly of the fireplace fuel chamber is completed. It is covered with masonry with the obligatory organization of a smoke hole. Finally, a chimney is erected.

After the masonry has completely dried, which will take at least 10 days, the system can be filled with water for the first time. During initial start-up, it is necessary to check for leaks. In an open system, leaks lead to a decrease in the volume of water, but in a closed system they will cause a lack of circulation.

If the fireplace will be used as a backup heat source, a system must be provided for turning on and off the circuits from it. Using a bypass valve allows you to stop the water supply.

How to choose a fireplace?

The main parameter that you should pay attention to when choosing a fireplace is the power rating of the fireplace insert. This indicator directly depends on the size of the combustion chamber, since the more fuel a cast iron firebox can hold, the higher the power.

Photo 3. Water fireplace

The technical data sheet of a fireplace insert usually indicates three values: maximum, nominal and minimum power parameters. The most acceptable of them is nominal, which can be determined experimentally after a short period of time.

To heat ten square meters of an ordinary living space with ceilings of two and a half meters, a power of one kW is sufficient. Keeping this parameter in mind, it will not be difficult to calculate the required furnace power for your home.

However, you need to keep in mind that using the fireplace too intensively can significantly reduce its service life. For this reason, it is necessary to buy a fireplace that has a power reserve of ten to fifteen percent of the nominal value.

If you plan to install a fireplace system in your home, then it is wiser to design fireplaces, water heating systems and boilers before construction begins. This will allow for a more rational distribution of hot water and heat in the future and will provide the most organic interior possible.

Heating distribution systems

When organizing a heating distribution system, it is worth considering that they come in two varieties: open and closed.

In the first case, water circulation occurs due to the inclination of the pipeline. Heated water is supplied to the highest point. After this, it passes through the entire pipeline by gravity. The level gradually decreases. Water returns to the boiler through a pipe called return. An expansion tank is installed in the attic to allow for expansion as temperatures increase. The heated water is forced into the expansion tank; with gradual cooling, the reverse process is observed.

The main advantage of an open system is its simplicity. Installation can be done independently. However, it is not suitable for heating a large area.

Chimney

The pipe that will be connected to the firebox can be made of the following materials:

- rough steel with a thickness of at least 2 mm;

- enamelled steel with a minimum thickness of 1 mm;

- high-alloy chromium-nickel steel 0.6 mm thick;

- titanium-containing steel 0.6 mm thick.

Standards for installing a chimney to a fireplace stove

In places where the chimney passes through the ceilings, additional thermal insulation must be installed.

To do this, use basalt cardboard, after which you need to install a special adapter.

Passage units in the ceiling must be sealed with basalt, and then closed with a special lid.

Treat all joints of the structural elements of the chimney with heat-resistant sealant.

When connecting an elbow at a right angle, provide an inspection hole for cleaning the system.

Advantages of fireplace stoves

Among the main advantages of using such equipment, several points stand out.

- Creating a pleasant indoor environment.

- High heating rate.

- Possibility to combine with existing heating systems.

- Arrangement almost anywhere, the main thing is to comply with fire safety rules.

- Easy to use with heat exchangers, absolute autonomy.

- Work from an accessible and inexpensive type of fuel.

- Multifunctionality. This is both a heating device and equipment for cooking.

Preparing a fireplace project

It is very important to place it in the right place and determine the dimensions. As a rule, it is placed closer to the outer wall of the room or in a corner since the back side of the structure gets very hot during the fire. If it is placed opposite doors or windows, then the formation of drafts is inevitable.

Important Calculations

- As for the dimensions, here you also need to correctly calculate the value. It should be 1/70 of the entire area of the room. For example, with a room size of 80 square meters, the firebox opening will be about 36 by 52 cm. Important parameters are the size of the chimney and the depth of the firebox. For example, with a firebox opening area of 0.4 square meters, the depth is about 35 cm. Important! If the depth of the firebox is shallow, smoke will pour into the room. If it is too large, heat will be lost.

- The chimney meter is no less than 4 meters, its area is an order of magnitude (this is 10 times) smaller. In our case, this is 0.04 square meters.

- The main construction material is standard brick. In certain places, you can also use silicate double grade M150. It is strong and economical, giving a beautiful appearance and neat design. It is also important to calculate how much it will actually be needed, taking into account defects, quarters and halves.

- There is an order for calculation - this is a detailed diagram of the laying of each row separately. You will need to lay brick over the firebox, gradually narrowing the smoke chamber. A pass is made between them - a ledge that prevents sparks from escaping into the chimney and smoke itself into the room.

- The back wall of the fireplace must be insulated in accordance with fire safety requirements. You can use a regular sheet of metal for this.

Principle of operation

The unit is a hybrid of a conventional stove, boiler and fireplace. The circuit for heating water can be made of separate register pipes located in the firebox or along the walls. Another alternative is that the coolant circulates inside two partitions in the housing; this design is called a “jacket”.

Less often, a water heating tank is placed in the upper part; this is a less effective solution.

Each element is directly connected to the overall space heating system. Due to thermal conductivity, you can warm several rooms at once.

Such devices operate according to the same algorithm, since they are aimed not only at providing housing with heat, but also with hot water supply.

- The boiler heats the liquid, which flows through pipes using electric pumps.

- The cooled coolant is returned for further heating.

Review of popular models

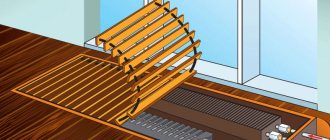

The easiest to install and connect are considered to be free-standing devices made of steel and cast iron with a built-in heat exchanger. They can be located in a double housing, creating a water jacket around the camera, or located in the upper part of it. The pipes brought outside are simply connected to the heating circuit. For the heating device itself, it is enough to find a convenient place in any area of the room where the chimney can be removed. The main thing is not to forget to cover the floor with a metal screen over a non-flammable coating (minerite sheet, for example).

Stove-fireplace AQUA

They are made of steel in the form of 5 mm plates. The transverse edge and chambers are covered with heat-resistant tiles, which can be replaced if damaged.

The product includes a tempered glass door for viewing. There is a niche for firewood at the bottom.

Specifications:

- energy supply ranges from 13 to 16 kW;

- the circuit gives a power indicator of 5-7 kilowatts;

- steel heat exchanger;

- designed for wall installation;

- the lining of the side walls is made of ceramics;

- the front panel has panoramic heat-resistant glass;

- chimney diameter – 150 mm.

Even if there is no connection to the heating system, the ability to warm up the space is not lost. Only this method increases wear. It is imperative to fill the circuit with water when turning it on, otherwise the elements will be damaged and they will fail.

Bavaria fireplace stove

Manufactured from steel sheets, complemented by a cast iron grate to separate the firebox and ash pan. Experts note good technical characteristics:

- compact size - the device is suitable even for small spaces:

- mobility – the fireplace stove can be moved from one place to another at the owner’s discretion;

- the units are easy to install and use;

- strong heat-resistant glass ensures safety by reducing the risk of flame entering the room;

- warm-up speed is very high;

- fairly high productivity (efficiency - 80%);

- environmental friendliness - carbon dioxide emissions are reduced and barely reach 0.20%;

- if you purchase a model that has a built-in hob and oven, you can cook food over an open fire by first removing the cast iron rings from the burners;

- Externally the devices are very attractive.

Devices with a water circuit are connected to pipes in all rooms of the house. On top of the chamber or in the partitions of the stove there is a heat exchanger with a coil through which the liquid coming from the distribution tank moves. On both sides, pipes diverge along the edges to supply cold and hot water, which have the property of removing boiling water that gets into the heating system. To determine whether the stove will perform its functions fully, you need to evaluate the power factor.

Additional devices and elements

Modern operation of heating devices requires strict control of the temperature of the coolant, so the presence of thermometers is necessary. But you can regulate the temperature itself quite simply:

- First, increase the amount of fuel burned.

- Secondly, use the blower damper, which helps increase or decrease the flow of air into the firebox.

There is another device that must be used if the fireplace insert is located at the same level or slightly above the radiators. This is a circulation pump. Why is it needed in such conditions? It's all about physics. It's no secret that heated water rises and cold water goes down. This property of water is used in heating systems with natural circulation. And if the coil is located above the batteries, then the circulation is immediately disrupted, the water inside the system will not move, the coil will simply boil.

For these purposes, a pump is installed, which significantly increases the efficiency of the fireplace. Usually the pump itself is mounted either in the basement or outside the house in a utility room to avoid noise.

Water circuit connection

You can connect the fireplace to the existing heating system in the house. Pipes for water supply and drainage, as well as a chimney pipe, are connected to the fireplace. If it is necessary to heat the floor for a private house, additional pipes for water circulation are installed in the boiler.

When connecting the water circuit, the following important points must be observed:

When connecting the water circuit, the following important points must be observed:

- installation on a flat surface. If it is not possible to level the floor on which the fireplace will stand, you can use adjustable legs. Uneven installation entails operating hazards and a significant reduction in the efficiency of the fireplace;

- mandatory check for leaks after filling the system with water. First, you should check all pipe joints without applying pressure. Then, turning on the circulation pump, once again eliminate leaks and leaks in pipes and joints. It is also necessary to ensure the tightness of the chimney by covering the joints with heat-resistant sealant;

- checking the operation of the fireplace and water heating. Do not be alarmed by the smell from the fireplace when you first light it - it will disappear within a short time. It is necessary to check the correct operation of the automation: how accurate is the regulation of the water temperature in the radiators, is it possible to regulate the speed of its supply.

Installation and installation

You should entrust the installation work to specialists and not take risks by installing it yourself.

- After a thorough inspection of the fireplace, you should ensure the integrity of the parts and the strength of the connections.

- The device is installed on a 30-40 cm foundation.

- The device should be leveled and connected to the chimney ducts and water system. According to consumer reviews, this procedure is not difficult.

- The next step is the installation of the components, according to the instructions for each individual model, which can be seen in the video.

The standard connection model for most fireplaces with a water jacket is approximately the same:

- install the fireplace itself in the basement or living room;

- a hydraulic accumulator is installed in the utility room,

- Radiators are installed along the internal perimeter of the house to heat the room.

The placement of the expansion tank changes the type of system, which, depending on its location, can be closed or open:

- An open system is characterized by placing the expansion tank at the highest point of the room; the heat exchanger, located in the free part of the firebox, is located in the coil and is filled with water under the influence of gravity. Such a system is simple, you can easily install it yourself, but due to the large energy loss of water and the high hydraulic pressure of the pipes, it is ineffective.

- With a closed system, the heat exchanger is located in the closed part of the fireplace, and a pump is used to circulate water in the system. Water boils when circulation stops, causing an emergency shutdown of the equipment. Such a system is much more difficult to assemble yourself

To prevent this phenomenon, an additional coil is installed in the rear of the device, which is filled with cold water if necessary. A water temperature sensor is built into the water jacket of such fireplaces, and if it overheats, the system automatically turns off.

Types of water furnaces

- installations running on traditional wood. Let us make a reservation that such fireplaces should not be too productive, since failure of the fireplace is inevitable earlier than necessary.

- The Buleryan stove is different in that it does not require the installation of a special register for heating the coolant. In Buleryan, water or antifreeze is heated in the furnace itself, and to increase the productivity of the device, an additional compartment is provided where wood gas is supplied.

- Heat stoves made of durable cast iron are devices based on a cast iron body where heat is produced. Very good stoves, in simple terms, they are bought “for centuries”, since cast iron is one of those materials that have high durability and reliability of their use. Only the water body in the device is made of thermal steel, everything else is cast iron.

- the simplest: by reducing or increasing the portion of fuel, they affect the decrease or lowering of the temperature mark.

- To transform temperature conditions, a special damper-regulator is used.

- The use of a circulation pump affects the rhythmic heating of the house.

Sources

- https://domspechkoy.ru/pech-kamin-s-vodyanym-konturom/

- https://gidpopechkam.ru/kaminy/pech-kamin-s-vodyanim-konturom.html

- https://expert-dacha.pro/otoplenie/pechi/pechi-kaminy/s-vodyanym-konturom-otopleniya.html

- https://zapodlico.ru/kak_organizovat_kamin_s_vodyanym_konturom_otopleniya_plyusy_i_minusy

- https://feflues.ru/blog/kaminy/pech-kamin-s-vodyanym-konturom-dlya-otopleniya-doma/

- https://www.tproekt.com/kamin-s-vodanym-konturom/