Attaching heating radiators to the wall surface is not a labor-intensive process, but it has its own characteristics and subtleties. Installation of heating radiators to the walls is one of the important stages of work on organizing a heating system. The rules for fixing radiators primarily depend on the material from which they are made. To do this reliably, you should know about the types of these elements of the heating system, fastening options and take into account other subtleties of the work process. Then attaching radiators to the wall will not cause you any difficulties.

Types and features of batteries

- Cast iron radiators are characterized by thick walls and resistance to corrosion. They retain heat for a long time and have a long service life. However, it is the large weight of these products that makes it necessary to make the most durable fastenings and supporting stands for them.

- Steel batteries are light in weight, which makes their installation not difficult at all. But they are short-lived and quickly lose heat.

- Aluminum products for the heating system are attractive in appearance, the installation of which is also simple due to their light weight.

- Bimetallic radiators are considered the most universal, combining the properties of steel and aluminum structures. Their installation is also not labor-intensive.

Advantages of a country house

The main trump card of an individual private house is a heating system that is not tied to the thermal power station or other enterprises that decide when to turn on the heat and when to turn it off.

Also, the happy owners of their homes are not familiar with the eternal problem with pressure in the system. Replacing heating batteries in a private house is done only on an individual basis, and only the owner has the right to decide when to start a replacement and which radiators to install.

In cases where there is no candidate for “crazy hands”, it is worth contacting local authorities and applying for replacement of heating batteries through the housing office during the hot summer months.

This is due to the fact that in the fall the likelihood of getting into the queue will decrease significantly, and during the heating season, budget spending on repair work will naturally increase significantly.

Mounts for different types of batteries

To attach heavy heating appliances to the wall, you should choose massive holders that can easily hold a lot of weight for many years. For such products, thicker, more solid metal is used, most often marked as “reinforced”. For this purpose, brackets and hooks are available for sale, supplied with dowels. After drilling a hole in the wall, just insert the dowel and screw the hook into it.

Often, cast iron batteries are equipped with legs that can be adjusted in height. In order to hang them on a wall made of concrete or brick, you can use standard dowels, but in the case of plasterboard or wooden walls, it will be necessary to provide an additional floor base. In this case, the legs will come in handy.

To attach bimetallic, aluminum and steel radiators to the wall, similar brackets are used, only made of thinner metal. Convenient in this case are corner fasteners, which are considered universal and equipped with recesses for the collector. Such parts can be fixed on both the right and left. However, for heating radiators of these types, there are also special racks that allow them to be installed on the floor.

Incorrect calculation of the number of sections

Using a tap, you can lower the heating temperature if it suddenly turns out to be too high for the room, but you cannot raise it above that achieved with the tap fully open. In apartment buildings with centralized heating, the coolant temperature varies. If for some reason it turns out to be low (this often happens), it will be impossible to raise the air temperature inside the apartment. Now, if only there were a little more sections in the radiator...

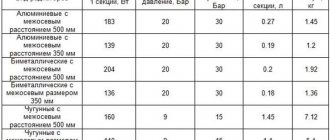

Calculation of radiator sections when replacing is made based on the basic coefficient, which is equal to 1.4 per sq. m. It can be done with the help of store consultants when purchasing a radiator. But here the following error awaits buyers: the calculation is carried out based on the average heating temperature of the coolant, and there are situations, as already mentioned, when the temperature of the water inside the batteries drops below. In order not to experience discomfort, the number of sections should be slightly larger than calculated by the average coefficient.

Basic subtleties of work

The type of heating system plays an important role in the entire operation. With single-pipe heating, a bypass will be necessary, allowing, if necessary, to turn off individual sections of the heating system. To work on mounting radiators, you will need to prepare all the necessary tools and materials:

- plugs and stoppers;

- dowels;

- taps and brackets;

- construction level and hammer drill.

When attaching radiators to the wall, you should follow some rules to do the job as efficiently as possible. First of all, the following dimensions must be observed:

- Be sure to take into account the distance of the structure from adjacent surfaces. So, the space from the floor to the radiator should remain at least ten centimeters. Approximately the same distance should be maintained from the batteries to the windowsill for uniform air distribution.

- The distance from radiators to walls must be maintained within three centimeters.

In addition, you should take into account other nuances that allow you to correctly fasten the elements of the heating system:

- Square footage of the room. The number of sections of the heating device depends on this parameter, which plays an important role when mounting.

- The number of brackets must be chosen with reserve. It is advisable to use at least three brackets: two on top and one on the bottom. But it is best to use four, two at the bottom and two at the top. If the battery size exceeds 10 sections, it is recommended to increase the number of brackets to six.

About methods of connecting radiators

The connection diagram must be thought out in advance; the position of the heating device on the wall depends on this. Example: installing batteries with a bottom connection involves installing a headset with taps that takes up up to 10 cm of space under the heater. Imagine that 2 lines of a two-pipe system are laid above the baseboard, then with a low window sill the radiator simply will not fit into the niche.

Example two: you decide to make a replacement yourself - remove the old cast-iron “accordion” in your apartment and install a modern device. Iron distribution pipes will not allow for bottom connection - only side connection. To place the radiator in the middle of the window, you will have to build up pipes made of polypropylene or metal-plastic.

Diagonal connection options: on the left is a diagram with a ball valve, on the right – with a thermal head

Battery connection methods:

- Lateral scalene (diagonal). The coolant is supplied through the upper hole and comes out of the lower one on the opposite side, flowing evenly through the internal channels. Heat transfer is maximum, the radiator works efficiently.

- Lateral – both eyeliners are connected from 1 side. Approximately 10% of the thermal power is lost, since the far part of the battery warms up worse.

- The lower versatile scheme is used in horizontal single-pipe systems of the “Leningradka” type. The efficiency of the device decreases by 10-20% depending on the pressure created by the circulation pump.

- A purely bottom coolant supply is not inferior to a diagonal one due to its design feature - through the first vertical channel, water rises to the upper zone of the radiator, and then diverges along the remaining ducts and collects below.

Schemes with lateral connections are more often implemented in traditional systems - two-pipe or single-pipe (except for Leningrad), which are mounted openly. Bottom supply is a more modern option; pipes from the boiler are laid in the floor, exiting directly under the battery.

Scheme of one-way connection of a radiator to a two-pipe and one-pipe system of an apartment building. Instead of the top tap, you can install a thermostat with a head, and instead of the bottom tap, you can install a balancing valve

4 types of radiator fittings

When starting water heating, the system must be balanced, and radiators must be repaired and flushed during operation. To solve these problems, the following shut-off and control valves are used:

- balancing valve;

- ball valve;

- thermostatic valve with thermal head;

- fitting for lower pipe supply.

Important point. When installing radiators, always use American-style taps - straight and angled. The connection with the union nut will allow you to remove the heater at any time without emptying the pipeline network.

On the left is a diagram of a one-way connection of a battery with a balance valve, on the right is a lower multi-sided one (used when installing single-pipe horizontal distributions)

How to correctly install radiator fittings:

- When connecting a heating device to centralized heating, install 2 ball valves; a balancing valve is not needed. Option two: a valve with a thermal head can be provided on the supply line to automatically regulate the air temperature in the room.

- Radiators in a private house are connected as follows: at the input there is a ball valve, at the output there is a balancing valve. If you want to regulate the flow automatically, install a thermal head instead of an inlet valve.

- For bottom connection, use a special headset with a built-in balance valve from Danfoss, Herz Armaturen, Oventrop. There are models for installing a thermostat.

When replacing the battery in an apartment, do not forget to provide a bypass for direct flow of water through the riser. Equip the last radiator of the individual heating network of a country house with 2 shut-off valves; you will not have to balance it.

With a lower connection, the coolant flow is directed to the upper horizontal channel of the radiator

Battery location and height

Radiators should be installed in areas of greatest heat loss:

- traditional location - under the window, in the middle of the light opening (when viewed vertically);

- in the corridor near the front door;

- on staircase landings;

- near the cold walls of living rooms without window openings.

The drawing shows the minimum distances to the nearest structures. For efficient battery operation, it is better to increase them: the top and bottom margins are up to 10 cm, the rear ones are up to 50 mm

Explanation. When the battery is installed in a window sill, the rising convection flow mixes with cooled air from the window. If instead of an outer wall the room has stained glass windows, it is better to install water or electric convectors in the floor.

If heating radiators are installed under windows, maintain the following minimum clearances:

- from the outer wall – 2.5 cm;

- from the window sill – 50 mm;

- from the floor - 60...200 mm, depending on the type of heating device and the method of its connection.

Unlike aluminum and bimetallic batteries, the depth of steel panel radiators varies in a wide range - from 6 cm (type 10) to 160 mm (type 33). The thicker the battery, the more air it can pass and heat. This means that it is necessary to provide air supply from below and removal of warm flow from above the heater. Installation diagrams of different types of steel panels are shown in the drawing.

The installation height of panel radiators depends on the specific type

Recommendation. We do not recommend completely sewing up the radiator after installation, making 2 convective openings with grilles. You will lose all the infrared heat flow, which is at least 20% of the battery power. But the air under the casing will heat up to 30-40 °C, and due to the temperature difference between the street and the niche, heat loss will increase.

Procedure for attaching batteries to the wall

- After carrying out all the necessary calculations and purchasing materials, you can begin fixing the heating devices. Before mounting, the wall surface should be prepared by plastering or wallpapering.

- The space for hooks or brackets is marked. Using a building level and a ruler, all measurements are carefully taken, and only then drilling is carried out.

- Dowels are inserted into the holes made and fasteners are screwed in.

- After hanging the battery, you need to check that it is fixed correctly and make sure that there is no play. After trying on the batteries, it will be clear whether the work was done correctly. If the radiator is seated tightly, immobilized and its weight is distributed among the fasteners, then we can conclude that everything was done technologically correctly. A horizontal level and gaskets of the required thickness, which are installed where they come into contact with the brackets, will help eliminate the possibility of radiator distortions.

- Only after this should you begin connecting radiators to other elements of the heating system.

Heating system connection options

In addition to choosing the radiator itself, during installation you will also need to decide how to connect it to the centralized network. There are several different options available to you, each of which has its own scope of use:

Diagonal connection. This scheme is the best choice for long multi-section heating batteries. It is distinguished by the fact that the water supply pipe is attached to the pipe from above on one edge of the radiator, and the outlet pipe is attached to the lower pipe on the other side. Among the disadvantages of such a system are difficult repairs in case of problems: the scheme does not imply removing the battery without completely turning off the heating.

Radiator connection options

Important! When supplying water from below, you will lose about 10% of the possible heat

Bottom connection

This wiring diagram looks the most inconspicuous. It is used if pipes are located inside the floor or hidden under baseboards. The supply and outlet pipes are directed perpendicular to the floor surface. The main disadvantage is that this system involves the greatest possible amount of heat loss. Lateral one-way connection. It is the most common and effective. Maximum heat transfer is ensured by connecting the inlet pipe from above, and the outlet pipe from below on the same side of the battery. When inverted, the heating power is significantly reduced, so it is not recommended to swap pipes.

- Bottom connection. This wiring diagram looks the most inconspicuous. It is used if pipes are located inside the floor or hidden under baseboards. The supply and outlet pipes are directed perpendicular to the floor surface. The main disadvantage is that this system involves the greatest possible amount of heat loss.

- Lateral one-way connection. It is the most common and effective. Maximum heat transfer is ensured by connecting the inlet pipe from above, and the outlet pipe from below on the same side of the battery. When inverted, the heating power is significantly reduced, so it is not recommended to swap pipes.

Important! If the distant sections of the battery are not warmed up enough, a water flow extension is used. Parallel connection

It occurs through a heat pipe built into the heating system. The withdrawal is implemented in the same way. This system allows you to replace batteries without turning off the central heating, but the main disadvantage is that if there is insufficient pressure in the system, the batteries do not warm up well

Parallel connection. It occurs through a heat pipe built into the heating system. The withdrawal is implemented in the same way. This system allows you to replace batteries without turning off the central heating, but the main disadvantage is that if there is insufficient pressure in the system, the batteries do not warm up well.

Important! Connecting a heating radiator with your own hands in this way is quite difficult; it would be better to entrust this work to experienced installers. Serial connection

In this case, heat transfer through the system occurs due to air pressure in it. Excess air is drained using a Mayevsky tap. The main disadvantage of such a system is also the impossibility of repairs without shutting down the entire heating system

Serial connection. In this case, heat transfer through the system occurs due to air pressure in it. Excess air is drained using a Mayevsky tap. The main disadvantage of such a system is also the impossibility of repairs without shutting down the entire heating system.

Problems of insufficient fastening of batteries to the wall

Correct and reliable fastening of heating devices to the wall is a guarantee of peace and well-being of apartment residents. Insufficient fixation of batteries, especially in combination with the following factors, can lead to deformation of the product or depressurization of seams, which will cause leaks. That is why it is very important to install them correctly and reliably.

So, the factors that aggravate the improper fastening of batteries:

- mechanical damage to devices during their operational life;

- distortions of heating radiators when filling them with water.

Replacement of heating devices through the housing office

So, replacement of heating devices is carried out through the housing office only in situations where the established service life of the radiators has been exceeded, they are in disrepair and cannot be repaired. In other cases, when batteries leak, minor repairs are performed.

According to current standards, the service life of a cast iron radiator is 15-30 years when used in an open system and 30-40 years when used in a closed system. But, even if we are talking about an apartment building where the batteries were installed more than 40 years ago, the operating company is often limited to only repairing the radiator, since replacement is included in the list of major repairs, the timing of which may not yet be determined.

Replacing the battery using gas welding

To replace emergency batteries free of charge, residents must contact the Housing Office with a corresponding application. It is recommended to prepare two copies of the application and mark both as having been accepted by the responsible person at the housing office. The application and its copy are marked with the number, date and legible signature of the responsible person.

Duplicating the document will help if problems arise in the future related to the reluctance of the management company to change emergency batteries at the expense of the capital repair budget. But residents must defend their rights, since they paid for the replacement of old radiators through monthly payments for housing, maintenance and major repairs of the common property of the house.

Step-by-step instructions for installing cast iron batteries in an apartment

A standard cast iron radiator has 10 sections. Before installation, you need to screw the nuts with winding into the holes. Often the sharp edges of the nut damage the sealing material. Grinding the edge with a rasp helps to avoid this.

Wind the winder onto the threads of the nut in the direction opposite to the thread.

You need to wind it tightly so that the material does not slip while screwing the nut. Lubricate the winding with silicone sealant.

Tighten the nut with an adjustable wrench.

Perform the same operation with the other nut. Prepare the taps in a similar way - wrap a linen thread and lubricate them with sealant.

Screw the tap into the previously installed nut.

Tighten using a large screwdriver or a homemade wrench.

In order to connect the polypropylene pipe from which the line is made to the tap, wrap it with thread and lubricate the coupling with silicone. Twist the coupling and tap. Assemble the supply and return units.

A Mayevsky tap will be installed to remove air. Hang the cast iron radiator on hooks fixed in the wall. Now it is ready to connect.