Methods for connecting a heating radiator and pipes

There are the following methods for connecting a heating radiator:

- lateral

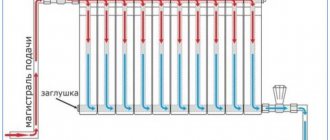

- this option for connecting the battery to the heating system is used most often in practice. With this type of connection, the pipe through which the hot coolant is supplied is led to the upper branch pipe, and the pipe with cooled water to the lower one. As a result, both pipes are located on the same side of the device. This method of connecting batteries into a single structure is considered the most efficient in terms of heat transfer, with minimal heat loss, but provided that the number of sections does not exceed 15 pieces; - diagonal

- it is used for long radiators. In this case, the hot water pipe is connected to the upper pipe on one side, and the return pipe to the lower pipe on the opposite side. As a result, the coolant is distributed evenly throughout the heating device. If, with a diagonal connection, hot water is supplied through the lower pipe and discharged through the upper, then the heat transfer of the system will decrease by almost 10% (read: “How to properly connect a heating radiator - choosing a battery connection diagram”); - lower option

- used when it is necessary to hide pipes in the floor. In this case, the efficiency of the radiator will decrease by about 15%.

How are corrugated pipes made from stainless steel?

The technical conditions for the manufacture of corrugated pipes regulate the use of AISI 304 stainless steel.

It is produced using the following technology:

- the stainless steel sheet enters the forming machine, where it takes on a cylindrical shape;

- the edges of the cylinder are welded together by laser, plasma or induction current;

- the strength of the weld is checked by eddy currents;

- then the workpiece undergoes calibration, during which the product acquires a characteristic wavy structure;

- When leaving the calibrating machine, cutting to the required length is carried out.

Such a pipe can already be used for installation, but it is less durable and ductile. To increase these indicators, products are subjected to heat treatment (firing) at a temperature of +600ºС, followed by a period of forced cooling (tempering).

Visually, the products are no different, but after firing they become stronger and more flexible, which means that when bent, creases will not form on them, as on unmolded corrugation.

Types of radiators for piping

Before you start creating a heating system and before connecting the radiators, you need to determine what types of radiators you want to use. Today there are a huge number of types of batteries. They may differ in:

- material;

- the principle of how to connect a heating battery;

- wall mounting method.

Today the most common types of radiators are:

steel panel batteries - are a relatively thin panel of flat steel plates. How to properly connect a heating radiator of this type? Radiators of this type are connected from the side or bottom.

Steel panel batteries

sectional radiators. Lightweight sectional model made of aluminum (there are also bimetallic radiators of this type). How to properly connect the heating batteries in this case? Such batteries can be connected in several sections or one at a time. For such radiators, it is best to use polypropylene pipes, the connection type is lateral.

Sectional aluminum radiators

About connecting bimetal in the article: Connecting bimetallic heating radiators.

It is noteworthy that recently, in apartments with central heating, bimetallic batteries are increasingly being installed, abandoning cast iron ones. The reason for this change is due to a number of reasons. First of all, cast iron radiators are heavier and bulkier. In addition, due to poor-quality water used as a coolant in the heating system, sediment, sand and rust appear in such radiators quite quickly - and these factors significantly contribute to a decrease in the heat transfer of radiators. Such problems do not arise with bimetallic radiators.

The main thing is to comply with all rules during installation.

It is important to remember that if you have a copper pipeline, then you can connect both steel and aluminum radiators to it. And if the pipeline is made of ordinary pipes, only aluminum batteries are allowed to be installed

Why is it better to seek help from specialists?

Only the gas supply organization has the right to install gas equipment. It will be better if the technician inspects the entire heating system and identifies shortcomings immediately, rather than this leading to problems in the future.

Gas heating is a dangerous equipment, so consultation with a qualified specialist is a must. Negligence in matters related to gas can lead to tragedy!

The main element in a flexible hose is a rubber hose. When made with high-quality connections, this hose is made from completely non-toxic rubber of a special brand EPDM, this is the so-called ethylene propylene rubber. This material, in case of contact with water, does not emit harmful substances, and it can be used for drinking water supply. It is also quite resistant to high temperatures; this property allows the use of liner when installing heating devices (up to +95 ° C).

The outer braid is the second most important element of the eyeliner. The flexible liner provides the product with sufficiently high strength in the event of external mechanical impacts and internal hydraulic shocks. That is why, externally, the hose is braided with stainless steel thread, thanks to which the flexible water supply will reliably serve for 10-12 years. A high-quality braid will allow the liner to withstand pressure up to 10 atmospheres. If, on the outside, the braid protection is made of aluminum thread, then both the service life and the strength of the product will naturally be less.

The braid is also made from galvanized steel wire; it does not withstand the action of condensation, and provided that it constantly forms, this liner will last no more than a year. Another element is the brass fitting. A fully braided rubber hose is attached to this fitting using a sleeve made of stainless steel. To install the liner, mounting elements are used, these are union nuts or a fitting.

Types of heating systems

Heating systems are installed in different ways. But the main component is the installation that produces heat. With its help, the temperature regime of the heat carrier is formed, which is transferred to heating devices by natural or forced circulation.

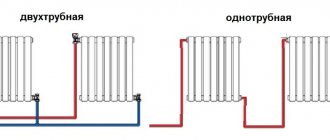

Conventionally, such a network is divided into two types, as it is assembled using a single-pipe or two-pipe interchange

The first option can be installed independently, but for the second type you will have to perform complex calculations, taking into account the mass of operating parameters of all technical components

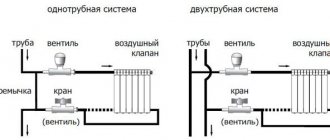

Single-pipe

This type of installation has been used for a long time. Significant savings are generated due to the absence of return risers for the transfer of coolant.

The operating principle is simple. The coolant is transmitted through one closed system, which includes a heating installation and appliances. The binding is made with one common contour. A hydraulic pump is used to ensure the transfer of coolant.

What does a one-pipe heating system look like?

Schematically, a single-pipe heating system is divided into:

- vertical – used in multi-storey buildings;

- horizontal - recommended for private houses.

Both types do not always give the desired effect in work. Radiators connected in series cannot always be adjusted so that all rooms are equally warm.

No more than a dozen batteries are connected along the vertical riser. Failure to comply with this rule leads to the fact that the lower floors in the house will not warm up well.

A serious disadvantage is the need to install a pump. It is this that is the source of leaks and forces you to periodically replenish the heating network with water.

For normal operation of such a network, you will have to install an expansion tank in the attic.

Despite the negative aspects, there are also positive aspects to such heating, which perfectly compensate for all the shortcomings:

- new technologies have made it possible to solve the issue of uneven heating of rooms;

- the use of balancing devices and high-quality valve equipment allows repair work to be carried out without shutting down the overall system;

- installation of a single-pipe system will cost much less.

Two-pipe

In such a network, the coolant moves up the riser and is supplied to each battery. After this, it goes back to the heating boiler.

With the help of such a system it is possible to organize uniform heating of all radiators. During the circulation of water, large pressure losses do not occur; the liquid moves by gravity. It is possible to repair the heating network without stopping the supply of heat to the facility.

Two-pipe heating system

If we compare systems, the two-pipe system will be much more effective. But it has a main drawback - assembly requires twice as many pipes and components, which affects the final cost.

Double-circuit boiler and indirect heating boiler

This combination began to appear among homeowners who were not satisfied with the performance of the DHW circuit of a gas heat generator. And it is not surprising, because a medium-power unit is capable of producing 10-13 liters of hot water per minute, which is not enough to simultaneously supply two consumers - a kitchen sink and a shower stall.

Another thing is that the purchased indirect heating boiler is connected to a double-circuit boiler in a perverse way, shown in the diagram. An imitation of the flow is created by an additional circulation pump, which is turned on and stopped by a signal from the thermostat.

This scheme does not work correctly and here's why:

- The heating unit produces water from the DHW circuit with a maximum temperature of 60 °C. Passing through the boiler coil, it will never be able to heat its contents (which is 150-200 liters) to the same temperature.

- From the boiler heat exchanger, hot water of 50-55 °C flows into the second circuit of the boiler instead of cold. It is instantly heated by the burner, which is switched off by a signal from the temperature sensor. But due to the flow, the switching on occurs again after a few seconds - “clocking” occurs (start-stop mode), which reduces the resource of the heat generator.

- The boiler heats up much longer than expected - from 40 minutes to 2 hours, depending on the power. During this period, the heating is turned off - the unit is occupied by the DHW circuit (this is discussed above in the video). The house is cooling down.

- A harmful bacterium that lives in warm water, Legionella, multiplies in the storage tank. It can be removed by heating the boiler weekly to maximum temperature, which is impossible to achieve.

Correct wiring diagram for an indirect boiler with a heat source

In order for the indirect heating boiler to load in 20-25 minutes, connect it according to the correct diagram to the main heating circuit of the gas boiler. Simply plug the DHW pipes - this will not affect the life of the heat generator in any way. The expert will give more information on the topic in his video:

What does it take for batteries to work efficiently?

An efficient heating system can save money on fuel costs. Therefore, when designing it, you should make informed decisions. After all, sometimes the advice of a neighbor in the country or a friend who recommends a system like his is not at all suitable.

It happens that there is no time to deal with these issues yourself. In this case, it is better to turn to professionals who have been working in this field for at least 5 years and have grateful reviews.

Image gallery Photo from Step 1: Regardless of the type of heating device, its installation includes a number of similar steps. First, mark the wall and install brackets for the radiator. Step 2: Before attaching the radiator, you need to check that it is installed correctly using a building level. If necessary, it is better to move the bracket before connecting Step 3: If there are no complaints about the location of the heating device, its branch pipe is connected to the supply pipe Step 4: Then a connection is made to the pipe that removes the cooled coolant from the radiator to the heating boiler Marking the wall and installing brackets Checking the location before mounting Connection radiator to the supply pipeConnecting the radiator to the return pipe

When deciding to install new batteries or replace heating radiators yourself, you need to take into account that their efficiency is directly affected by the following indicators:

size and thermal power of heating devices; their location in the room; connection method.

The choice of heating devices amazes the imagination of the inexperienced consumer. Among the offers are wall-mounted radiators made of various materials, floor and baseboard convectors. They all have different shapes, sizes, heat transfer levels, and connection types. These characteristics must be taken into account when installing heating devices into the system.

For each room, the number of radiators and their size will be different. It all depends on the area of the room, the level of insulation of the external walls of the building, the connection diagram, the thermal power indicated by the manufacturer in the product passport.

The location of the batteries is under the window, between windows located at a fairly long distance from each other, along a blank wall or in the corner of the room, in the hallway, pantry, bathroom, in the entrances of apartment buildings.

It is recommended to install a heat-reflecting screen between the wall and the heating device. You can make it yourself using one of the heat-reflecting materials - penofol, isospan or another foil analogue.

You should also adhere to the following basic rules for installing a battery under a window:

all radiators in one room are located on the same level; convector fins in a vertical position; the center of the heating equipment coincides with the center of the window or is 2 cm to the right (to the left); the length of the battery is at least 75% of the length of the window itself; the distance to the window sill is at least 5 cm, to the floor - no less than 6 cm. The optimal distance is 10-12 cm.

The level of heat transfer from devices and heat loss depends on the correct connection of radiators to the heating system in the house.

It happens that the owner of a home is guided by the advice of a friend, but the result is not at all as expected. Everything is done like his, but the batteries don’t want to heat up.

This means that the selected connection diagram was not suitable specifically for this house, the area of the premises, the thermal power of the heating devices were not taken into account, or annoying mistakes were made during installation.

Manufacturers and what to look for when purchasing

The bulk of stainless steel corrugations are produced in South Korea by the following companies:

- Lavita is a manufacturer of corrugated stainless steel pipes for heating in the mid-market price segment. There are complaints about the strength characteristics of the walls: when installing fittings, there is a danger of damaging the stainless steel, which subsequently causes leaks. However, this drawback is most likely the result of illiterate installation.

- Corrugated stainless steel pipes for heating from this company are considered the best among similar products. It’s true that their price is several times higher than the cost of corrugations from the previous manufacturer. These models are connected with fittings equipped with thicker O-rings, which provides a more reliable connection.

- Hydrost products are comparable in price to pipes from Lavito, but these products often have factory defects. Leaks at fitting installation sites occur on average in 7% of systems assembled from these pipes.

- Quite high-quality products, but their cost is considered unreasonably high.

When purchasing a corrugated product, you should visually inspect its surface for damage, creases and deformations. The distance between the ridges should be the same size along the entire length of the pipe.

It is also necessary to familiarize yourself with the certificate of conformity, which will confirm the quality and allow you to avoid buying handicraft fakes.

Additional selection criteria depend on the type of corrugation:

- numbered length. The pipe must have a complete set of fittings;

- arbitrary length. It is necessary to check the quality of the cutting line. The edges should be smooth and free of burrs.

Heating system options

The following disadvantages should be mentioned:

- there is no way to regulate the degree of heating of the devices, and, accordingly, the temperature in the room;

- on the lower floors the batteries will be less hot than on the upper floors, since the coolant cools down when moving through the pipes;

- if it is necessary to make repairs or eliminate a leak, you must completely disconnect the entire riser from the heat supply (for more details: “The heating battery is leaking, what to do, how to eliminate the leak in a short time”);

- If you want to install autonomous heating, it is impossible to disconnect from the centralized heating system.

connecting heating radiators The advantage of two-pipe heating systems is undeniable:

- the temperature of the coolant in all batteries will always be the same, regardless of the distance of the device from the heating boiler;

- Of great importance is the ability to adjust the degree of heating of each radiator separately (for more details: “Adjustment taps for heating radiators, valve installation”).

When radiator connection options such as a two-pipe system are used, the design consists of the following elements:

- a heating device having a valve at the top and a plug at the bottom;

- valve with heating temperature regulator for radiator;

- radiator plugs;

- bypass;

- stopcock;

- metal or polypropylene heating pipes;

- couplings and locknuts;

- shank.

thermostat for heating radiator

Warm floor

Heat-resistant hoses for heated floors differ from water hoses in that they can also be designed for other liquids. In some cases, antifreeze is poured into these systems. When choosing flexible communications for a heated floor, you need to take into account how much insulation is required. This depends on the climate of the area and how high the temperature will have to be maintained. Metal-plastic elements are mainly used because they last a long time, make almost no noise, and are resistant to strong heat and mechanical stress.

Possible radiator connection diagrams

The most efficient connection of batteries is quite easy to carry out - both in terms of the number of nodes and in terms of installation technology.

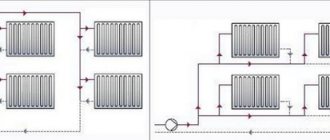

Two-pipe classic wiring

Classic two-pipe heating system wiring diagram.

In the classical scheme, the direction of movement of the coolant in the supply pipeline is opposite to the movement in the return pipeline. This scheme is most common in modern heating systems, both in multi-storey buildings and in private individual ones. The two-pipe circuit allows you to evenly distribute the coolant between radiators without loss of temperature and effectively regulate heat transfer in each room, including automatically through the use of thermostatic valves with installed thermal heads.

Such a device has a two-pipe heating system in a multi-story building.

Associated scheme or “Tichelman loop”

Associated heating wiring diagram.

The associated scheme is a variation of the classical scheme with the difference that the direction of movement of the coolant in the supply and return is the same. This scheme is used in heating systems with long and remote branches. Using a passing circuit allows you to reduce the hydraulic resistance of the branch and distribute the coolant evenly across all radiators.

Fan (radial)

A fan or radial scheme is used in multi-storey construction for apartment heating with the possibility of installing a heat meter (heat meter) in each apartment and in private housing construction in systems with floor-to-floor piping. With a fan-shaped scheme in a multi-storey building, a collector is installed on each floor with exits to all apartments of a separate pipeline and an installed heat meter. This allows each apartment owner to account for and pay only for the heat they consume.

Fan or radiant heating system.

In a private house, a fan diagram is used for floor-to-floor distribution of pipelines and for radial connection of each radiator to a common collector, i.e., each radiator has a separate supply and return pipe from the collector. This connection method allows you to distribute the coolant as evenly as possible across the radiators and reduce hydraulic losses of all elements of the heating system.

Connection methods

To connect stainless steel corrugated pipes, a brass compression fitting with a silicone or rubber O-ring is used. The end of the pipe is inserted into it until it stops and tightened with a ring.

When switching from a smooth steel pipe to a corrugated one, the fitting is first attached to the smooth pipe, and then a stainless corrugated pipe is inserted into it.

Flexible radiator connection

A manual rolling machine is used to make flexible hoses for radiators and heaters.

First, a piece of pipe of the required length is cut with a pipe cutter or grinder, and the cut line is carefully cleaned. The pipe is then inserted into the protruding flaring machine onto two corrugated rings to allow the protruding edge to be flared using a hammer. Next, a union nut with a rubber gasket is put on this end of the pipe. Attaching the union nut to the other end is done in the same way.

Warm floor

For laying corrugated pipes in a “warm floor” system, it is recommended to use plastic clips as fastening elements.

Holes for dowels for attaching clamps must be drilled through the insulation layer into the concrete screed.

Installation should begin from the distribution cabinet, connecting one end to the manifold outlet. Next, the pipe is rolled out of the coil and placed between the clips in coils, the distance between which should be 30 cm and at least 20 cm from the walls. After the pipe is evenly distributed throughout the room, its second end is connected to the outlet of the return collector.

Installation subtleties

Bending of the water and steam line is undesirable. If possible, bend it without mechanical stress. We must not forget that the hose must sag. Nuts and other fasteners are partially tightened. Only after checking that everything is in order, tighten it with a key.

The joints must be perfectly clean. Avoid contact with sharp parts. Of all welding methods, plasma welding is the most effective. Not everyone can do this kind of work, so it’s better to turn to specialists. The connection using flanges is made without threads; it is needed where regular inspections and prevention are needed.

To learn how to choose a flexible eyeliner, see the following video.

Recommendations for selection

When selecting food hoses for hot water and steam, primary attention must be paid to their strength, throughput, and thermal parameters. But chemical properties are no less important. They also check the method of fastening and the length of the structure. A high-temperature steam hose is most often reinforced with wire. Only with minimal steam pressure is it permissible to use lines reinforced with fabric.

According to experts, the highest operating pressure should be 10 times lower than the burst pressure. Most steam generator hoses are made with a cross-section of 2.5 or 3.2 cm. You should definitely check what substances they are made of. If the mixture settles near the fittings, steam leakage is inevitable. Hoses rated for 100 degrees are impractical; it is best if they can withstand temperatures up to 220 degrees.

Insulated hoses are more correctly called pipes. A heating cable can be used as a heating means. Occasionally, shell coating made of polyurethane foam or polystyrene foam is used. Typically, a protective layer is used for underground routes. Surface pipelines are made mainly with cables.

For heated towel rails, flexible hoses are not used at all. It is better to adjust the location of the pins. Coils for moonshine stills are mainly made of silicone. We must carefully check that PVC is not sold under the guise of silicone. Many sellers themselves do not understand the difference.

For heat removal of air, only hoses that meet sanitary standards are selected. The frequency of air exchange and the intensity of ventilation are taken into account. Calculate the optimal thermal regime. It is necessary to compensate 100% of heat loss.