There are quite a lot of stoves using different fuels - these are wood-burning, coal stoves, long-burning fireless stoves, and so-called “rocket” stoves. But all these types have a significant drawback - the high cost of fuel, especially if it is gasoline or kerosene. However, there is a type of stove for which the fuel costs nothing at all, or only a penny. And the Firststroy.ru will talk about the waste oil furnace, talk about the pros and cons, and discuss efficiency.

Types of homemade stoves in development

Engine oil contaminated with impurities will not ignite itself. Therefore, the operating principle of any oil stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, the waste must be heated, evaporated and burned in the furnace firebox, supplying air in excess. There are 3 types of devices where this principle is implemented in different ways:

- The simplest and most popular direct combustion design with afterburning of oil vapors in an open perforated pipe (the so-called miracle stove).

- Drip furnace using waste oil with a closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating potbelly stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on the indicators of factory heat generators with an efficiency of 85% (to get acquainted with the full picture and compare oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Take this fact into account when starting to manufacture a furnace for testing.

Design and disadvantages of an open-type potbelly stove

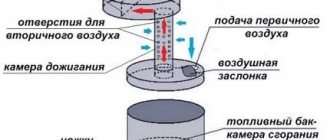

The pyrolysis stove shown in the photo is a cylindrical or square container, one-quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is an afterburning chamber with a partition for collecting heat from combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of the waste and its primary combustion will begin, causing pyrolysis. Combustible gases entering the perforated pipe flare up upon contact with the oxygen flow and are completely burned. The intensity of the flame in the firebox is controlled by an air damper.

This stove has only two advantages during testing: simplicity and low cost and independence from electricity. The rest is all downsides:

- stable natural draft is required for operation; without it, the unit begins to smoke into the room and die out;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, causing fiery drops to splash from the afterburner in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l/hour with low heat transfer (the lion's share of the energy flies into the chimney);

- The one-piece housing is difficult to clean from soot.

Although the potbelly stoves look different, they operate on the same principle; in the right photo, fuel vapors burn out inside the wood stove

Some of these shortcomings can be leveled out with the help of successful technical solutions, which will be discussed below. During operation, you should adhere to fire safety rules and prepare used oil - settle and filter.

Pros and cons of IV drips

The cardinal difference of this furnace is the following:

- a perforated pipe is placed inside a steel casing made from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of drops falling to the bottom of a bowl located under the afterburner;

- To increase efficiency, the unit is equipped with air pressurization using a fan, as shown in the diagram.

Diagram of a dropper with bottom supply of fuel from the fuel tank by gravity

The real drawback of the drip stove is the difficulty of execution for a beginner. The fact is that you cannot rely entirely on other people’s drawings and calculations; the heater must be manufactured and configured to suit your operating conditions and the fuel supply must be properly organized. That is, repeated improvements will be required.

The flame heats the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place in the body, which is why the latter will burn out quite quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe to use because the combustion zone is completely enclosed by an iron casing.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and convert the exhaust furnace into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Boiler with pressurized air, burning waste engine oil and diesel fuel

Advantages and disadvantages

As you can see, there is really nothing complicated in the design of a furnace operating in mining.

- Simplicity of design - having a set of tools, a welding machine and the ability to work with your hands, the stove can be easily assembled with your own hands;

- Versatility - the equipment can be used for heating rooms and garages, as well as for cooking;

- Cheap to operate - due to the low cost of heating oil, the operation of such stoves will not lead to large expenses (in some cases, fuel can be obtained absolutely free or cheap);

- Ability to work on any type of oil - from transmission to regular vegetable oil (sunflower oil, if you don’t mind burning this product);

- Minimum amount of harmful emissions - it all depends on reaching the operating mode and combustion temperature.

It is necessary to regularly clean the chimney so that it does not become completely clogged.

- Exhaust furnaces must be operated in ventilated areas. Otherwise, there is a risk of poisoning by fuel decomposition products and combustion products;

- Increased requirements for chimneys - to operate the furnace during mining, you need a good chimney with a height of about 5 meters. It must withstand high temperatures. Moreover, the use of an excessively high chimney is unacceptable - otherwise it will be difficult for the device to reach operating mode;

- When used oil burns, soot is formed - the equipment needs regular cleaning. In addition, the fuel does not burn completely, so its remains will need to be removed.

Despite the rather serious disadvantages and limited scope of application, waste furnaces continue to be quite popular equipment.

What is Babington's famous invention?

Every invention has its own author, even if his name is undeservedly forgotten by his descendants. For example, in 1969, British inventor Robert Babington received a patent for a stove running on diesel fuel, which was reminiscent of lighting kerosene gas operating on kerosene vapor. Robert Babington's design was originally designed for kerosene, then it was adapted for diesel fuel. When the number of cars increased disproportionately, the used oil had to be disposed of somehow. Therefore, innovators were looking for devices suitable for these purposes.

First, based on the patented invention of R. Babington, a do-it-yourself diesel burner appeared, then it was adapted for burning oil and other types of fuel. The testing device appeared much later than the diesel design, but it surpassed its predecessor in popularity and safety.

After some time, a similar device was proposed again, since the first patent had expired, and the liquid fuel stove had not lost its relevance. Similar devices were repeated in different versions, and not only self-taught craftsmen, but also design bureaus of reputable enterprises tried to assemble the Babington burner with their own hands.

By design, the burner is a simple device, so it can be successfully manufactured at home. It is characterized by fairly high efficiency in terms of obtaining the heat necessary for heating:

Burner diagram based on the Babington principle, where 1 – heating sensor; 2 – casing; 3 – heat exchanger; 4 – fuel sprayer; 5 – glow plug; 6 – supercharger; 7 – fuel pump; 8 – friction clutch; 9 – electric motor; 10 – lever for switching operating modes; 11 – fan; 12 – skeleton; 13 – fuel pipe; 14 – combustion chamber.

- technological installations;

- small workshops;

- workshops;

- garages;

- warehouse and utility rooms.

On a note! You should not adapt a homemade burner with your own hands for heating your home, since burnt oil has a specific smell.

Making a pyrolysis furnace for mining

Now you know how to assemble a stove from a gas cylinder with your own hands. The unit running on exhaust or any oil will delight you with a lot of heat. For example, the exhaust furnace diagram presented above is designed to heat a room with an area of 70-80 square meters. m. Let's now look at the scheme for creating a pyrolysis unit - that is, a small potbelly stove.

Assembly diagram of a pyrolysis furnace operating on waste.

This oven will consist of three main parts:

- Oil container with lid and flap;

- Combustion/pyrolysis chamber;

- Afterburner chamber.

It all culminates with a chimney. Its recommended length is at least three meters, but chimneys with a height of 4-5 meters work best.

The oil container is made from a piece of pipe with a diameter of 344 mm, its height is 100 mm. We weld a sheet metal lid on the bottom. Our top cover is removable, it is made from a pipe with a diameter of 352 mm - sides with a height of 600 are welded to it. In the cover we make a central hole for the combustion chamber with a diameter of 100 mm. We make a hole nearby with a diameter of 60 mm - it will serve as a blower. This hole is closed with a simple rotating lid.

By adjusting the clearance of the blower, we can regulate the intensity of combustion, which will affect the air temperature in the room. If you completely close the vent while the stove is running, it may go out.

We make an afterburning chamber - we use a pipe with a diameter of 352 mm and a height of 100 mm. In the lower part we make a hole with a diameter of 100 mm into which the combustion chamber pipe is inserted. In the top cover we make a hole with a diameter of 100 mm for the chimney. Inside, closer to the chimney opening, we weld a small partition 330 mm wide and 70 mm high. Our do-it-yourself oven is almost ready.

It remains to modify the combustion chamber. Everything is simple here - take a drill and a 9 mm drill bit, drill 48 holes (6 rows of 8 holes each). With a total combustion chamber pipe height of 360 mm, the holes should be located in an area 20 mm from the bottom and 50 mm from the top.

After completing all the work, check the tightness of all welds - this will allow you to count on maximum efficiency of the stove.

Check the performance of the resulting unit outside. This will protect you from possible fire and other accidents.

We start testing the furnace - we install it outside, pour the waste into an oil container, and add kerosene on top. Carefully set it on fire, leaving the ash pan open. After some time, the stove will return to operating mode - you can adjust the burning intensity using the blower. After this, the stove is moved indoors (it must be ventilated).

In order for heating to be as efficient as possible, install the furnace in a corner, and line the side walls with galvanized iron so that all the heat is reflected into the room.

Arrangement of doors

Making a chimney I made a smoke exhaust structure from a 10-centimeter pipe.

Nothing supernatural - I simply welded the pipe to the hole in the center of the top of the body. The chimney led to the street through the wall to the roof. A piece of metal sheet was attached to the wall for fire protection. It is better to pass the pipe itself through the wall in a special fireproof glass.

Here you can see how the pipe goes through the wall

The stove is almost ready. The finishing touches remain. I cut an opening in the door of the lower chamber through which air can freely flow to the pan and the stove burner.

I riveted the thrust plates and assembled a simple lock for the top door. During the heating process, the stove body “leads”. To ensure that the combustion chamber remains airtight, the top door must close as securely as possible. That's why I made the castle.

Simple castle

I screwed several pieces of metal corner to the wall.

I installed the stove on the screwed corner. This is both convenient (if necessary, it will be much easier to carry out an inspection) and functional (heat loss into the ground is reduced).

Installed the stove

What is mining and how to use it

Essentially, it is used motor oil, lubricating the engine and chassis. During the operation of equipment, oil, an initially fairly pure petroleum product, becomes saturated with slag - metal particles (the result of friction and mechanical damage to parts), soot, salts, and resinous compounds. As a result of such saturation, the oil is no longer suitable for lubrication, but it burns well - which allows the product to be used as fuel.

The composition of the waste burns approximately 85%, and during the combustion process it produces about 11 kW/hour of thermal energy per liter. Thus, the product’s fuel qualities are comparable to diesel fuel.

Important: if the oil is heavily clogged with solids, it is advisable to filter it before use.

At the same time, an oil furnace using filtered exhaust will work longer and better; it will have to be cleaned less often to remove carbon deposits.

Manufacturing instructions

A long-burning stove with a water circuit is made with your own hands in stages.

- The lower reservoir is assembled.

- A lid is made that fits tightly on it. Air leakage is extremely undesirable, since it can introduce water vapor into the container, so very precise fitting of the lid is necessary.

- A hole with a plug is made on the lid. Its diameter can be 30–60 mm, the plug is 5–10 mm larger.

- A hole is made for the combustion chamber. It must correspond to the internal diameter of the pipe used for this purpose (90 mm).

- The combustion chamber is marked, holes are drilled for air intake. Their number for a chamber length of 360 mm is 48 pcs. They are arranged in a checkerboard pattern with maximum uniformity to ensure a stable regime of oil vapor oxidation.

- The chamber is welded to the lid of the lower tank.

- The bottom with the walls of the upper tank with a hole for it is welded to the upper end of the chamber. The diameter of the hole is similar to that made in the lid of the lower container.

- The lid of the upper tank is made with a pipe for connecting the chimney.

- The entire structure is installed, assembled, connected to the chimney and tested for performance.

Furnace design for mining

Advantages and disadvantages of sauna stoves made of metal

Example of a metal pipe for a sauna stove

To build a sauna stove, they usually use metal or brick. Both options have their advantages.

What are the advantages of metal stoves?

- Resistance to high temperatures;

- Wear resistance and long service life

- The ability to quickly heat the bath. Even the simplest stoves made from a sauna pipe can warm up a room in 40-90 minutes, depending on the ambient temperature.

- Possibility of using different types of fuel.

- Availability of materials. For example, if you build a sauna stove from a pipe with your own hands, then the cost of purchasing materials will be insignificant. And if a piece of pipe is found on the farm, left over from repairs, then the stove will be built practically for nothing.

- Easy installation. If desired, the stove can be assembled by any person who knows at least a little how to handle the tool.

- Light weight. For a metal stove there is no need to build a massive pedestal, which is necessary for a heater.

We invite you to read: Finishing a steam room in a bathhouse - calculation of materials

Of course, metal stoves also have disadvantages. One of the main ones is that such a stove cools down quickly, so it has to be “heated” during the bathing procedures.

In addition, the heat from metal stoves is distributed unevenly. However, if the bathhouse is small, then this drawback is almost invisible.

Factory furnaces, their characteristics and features

The photo shows the factory furnace Teplamos NT-612, running on waste oil.

Before we tell you how to make a furnace for working with your own hands, we will look at several models of factory-assembled furnaces. A typical example is the Teplamos NT-612 oven. This is a typical drip fanless heater, intended for use in garages, workshops, hangars and other non-residential and technical premises. The power of the device varies from 5 to 15 kW, fuel consumption - from 0.5 to 1.5 l/hour.

Teplamos NT-612 is a closed type oven. It contains a chimney and a pipe for air supply. Combustion of fuel occurs in the inner chamber. In order for the stove to reach operating mode, it must be heated with a small amount of diesel fuel poured into a special bowl. After the fuel burns, we get a stove ready for refueling and further work - we open the waste supply and set it on fire.

The design of this unit has a built-in tank that can hold up to 8 liters of fuel.

A mini-furnace of the “potbelly stove” type is as simple as a matchbox. It is made of sheet iron and is characterized by versatility - it heats non-residential premises and allows you to cook food (small pots, pans and kettles are placed on the surface of the afterburning chamber). The power of such units varies widely. The equipment operates on the basis of pyrolysis.

Zhar MS-25 can operate on both waste oil and diesel fuel.

Let's consider a more solid stove - this is the heat generator Zhar MS-25. The unit can operate on both waste oil and diesel fuel. For its operation, electricity is required to power the built-in fan. The thermal power of the device is 25-50 kW, which allows it to heat an area of up to 500 square meters. m. In this case, the maximum flow rate is up to 4.5 l/hour. The stove is quite large, it weighs 130 kg and requires a good chimney. The temperature of the air entering the heated rooms is +50-70 degrees.

Principle of operation

The equipment operates using pyrolysis technology. The design consists of a combustion chamber and a special tank, which are located at different levels. Fuel (waste oil) is loaded into the lower compartment. During the process, a gas is formed in the fuel tank, which combines with oxygen.

The resulting mixture enters the chamber. In the upper compartment, volatile substances mixed with air are burned. If the temperature in the tank is maintained at an average temperature, then at the top it rises to 700-800 C. In a properly designed factory model, the efficiency reaches 90%, in a homemade one - 70-80%. Due to the intense heat, a small structure can quickly heat up a medium sized garage.

What to assemble the stove from?

To assemble such a stove, I prepared the following:

- 50 liter gas cylinder;

- steel pipe. It is best to use a pipe with a diameter of 10 cm. Two meters of the product was enough for the body, burner and chimney;

- steel corner. In total, it took me a little more than a meter of 5 cm corner. From it I made a stand for the stove, various internal parts of the heat exchanger and door handles;

- sheet of steel. About 50 cm2 of 4 mm sheet was used for the plugs and the bottom of the upper chamber;

- brake disk. I used a cast iron disk from a machine. The main thing is that it fits freely into the cylinder;

- empty freon bottle. A standard bottle will do. The main thing is that the needle valve works. I used it to make a fuel tank;

- a piece of fuel supply hose;

- a pair of clamps;

- a piece of half-inch pipe. Oil will be supplied to the stove through it;

- half-inch valve;

- loops.

Ensuring oil supply

I'll insert a tube into the hole

Waste will drip through the tube

The tube was caught by welding

I cut the pipe

Next I worked on the oil supply system. To do this, I took a piece of pipe and welded it to the pallet through a previously prepared hole. I cut the pipe in advance so that the waste stream could pass normally through the opening in the pan.

This is an emergency valve and a tube that leads to the tank

I ran the tube to the tank and installed the valve.

Types of garage stoves

You can find gas and electric appliances on sale; they are effective, but expensive and require regular refueling and careful handling. The most popular options use the energy of combustion of wood, diesel fuel or waste oil.

From a gas cylinder or pipe

The option is attractive due to its ease of manufacture. Located vertically, these ovens are very compact. A gas cylinder can be found at a landfill or metal collection point, after which it can easily be converted into a stove.

The design of the furnace can be vertical or horizontal. The first option is more compact, in the second case it is more convenient to stack long firewood. The wall thickness is at least 3 mm, preferably 5–6 mm.

The chimney should also not be too thin. Such a stove will serve for a very long time, and it can be heated with wood waste, chipboard, sawdust, pellets, and coal.

You can use a system of two barrels located one inside the other, the gap between them is filled with pebbles or sand. The structure takes longer to heat up, but it emits even heat and does not cool down for a long time. In general, there is no standard for making a conventional wood stove.

The main thing is to follow simple rules: use a thick steel wall, a firebox and ash pan, grates to improve combustion and an exhaust pipe with a diameter of at least 10 centimeters.

Advantages of wood stoves:

- ease of operation;

- low cost of the device itself and fuel for it;

- installed without a foundation in any suitable place;

- high efficiency and very fast heating of the garage;

- can be used for cooking.

Wood burning design

In order not to frequently throw firewood into the firebox, stoves with limited access of air to the combustion zone were invented; such devices can operate for up to 12 hours on one refill. The same gas cylinder is used as the body.

Photo 1. A homemade wood-burning stove in the garage, which is convenient for heating dishes, such as a kettle.

Combustion occurs from top to bottom under the influence of the load, resulting in the combustion of the firewood itself and the pyrolysis gases formed during heating. The efficiency of such a stove is high, and the wood in it burns with virtually no residue.

Oil burner and diesel heaters

The idea of using old motor oil led to the development of a device capable of burning it, releasing a large amount of heat.

The lower container of the device serves as a reservoir for fuel, and the main combustion process occurs in the upper half, so its wall thickness should be higher. The heating temperature can reach 850–900 °C.

Photo 2. Oil stove in the garage. The device is small in size, with good heat transfer properties and no soot.

Advantages of using mining:

- fuel availability;

- absence of smoke and soot during the combustion process;

- safety and environmental friendliness, only oil vapors burn;

- compactness;

- good heat dissipation.

Important! The chimney must be up to 4 meters high to ensure good draft and stable operation. The design of a diesel fuel furnace is similar to a unit operating in mining. The design of the diesel fuel furnace is similar to the unit operating in mining

The design of a diesel fuel furnace is similar to a unit operating in mining.

To increase efficiency, simple nozzles at the bottom of the burner can be used.

Such furnaces are used:

- diesel or heating oil;

- fuel oil;

- kerosene;

- transformer, machine oil.

Safety precautions

- Don't experiment with fuel. The furnace was made for mining work, and only it needs to be used!

- Do not leave the oven unattended for long periods of time or under the supervision of children or other inexperienced users.

- The stove must not be mounted on walls or placed on high stands. Only on the floor!

- The floor and walls in contact with the stove must be made of non-combustible materials.

- Make sure that there are no objects above the stove that could fall on it (do not place the stove under shelves).

- You cannot place the stove where there are strong drafts. At the same time, the room must have ventilation.

- Do not keep flammable objects or combustible substances near the stove.

- Do not allow water to get into the oil! It will foam, splash out, and may cause a fire!

- If a boiler catches fire during production, it is extinguished with a fire extinguisher and covered with dense material or sand.

Under no circumstances should you add oil to a burning stove! A portion of the oil must burn out, the oven must cool down, and only then can it be refilled.

Even if you have a small country house in which you live only in the summer, it is advisable to install a stove in it, because in spring and autumn, during sowing and harvesting, the weather can be unpredictable. Do-it-yourself brick stove for a summer residence: which one to choose? Basic masonry of the “baby Swedish” stove, construction of the foundation.

You will find a detailed example of calculating the power of a heating boiler in this topic.

Types of garage stoves

Before you start considering a long-burning stove, it is worth familiarizing yourself with what kind of heating devices are generally used in garages. Here you can install units that run on different fuels - gas and electricity, liquid or solid. It is only necessary that the furnace has a sufficiently high efficiency and consumes as little fuel as possible.

Long burning stove

Potbelly stove

One of the most popular options, probably familiar to everyone. The potbelly stove is compact, simple, heats up quickly and is not picky in terms of the fuel used (you can use almost anything that burns).

Photo of a potbelly stove with dimensions

Previously, such stoves were used to heat residential premises, but after the advent of central heating they became irrelevant. Therefore, today they can only be found in garages and utility rooms.

As a rule, to make potbelly stoves yourself, you use old gas cylinders or large metal pipes with thick walls.

Be that as it may, it is important that the thickness of the material is at least 2 mm, but 5 mm is still better. The body must have a cross-section of at least 30 cm

We also note that a potbelly stove lasts for several years on average.

A potbelly stove, if you make it yourself and do not buy it ready-made, must be made from high-quality, durable materials

Table No. 1. What types of stoves are there?

Another feature of a potbelly stove is that it gets very hot during operation (sometimes even hot), so it is not easy to be near it. Because of this, designs with two walls appeared. The simplest option is to take barrels of different diameters, insert the smaller one into the larger one, and fill the voids between them with sand or pebbles. The result is a thick-walled unit that is more convenient to use and retains heat longer. On the other hand, a double-walled potbelly stove takes longer to warm up.

Homemade potbelly stove made from a barrel

Brick oven

Brick is a heat-intensive material, and therefore a stove made from it will store and release heat into the room for a long time. You just need to warm it up thoroughly. The best option for car owners who spend a long time in the garage every day.

Construction of a brick oven in a garage

Brick stoves are less common than potbelly stoves, but they are still not as fire hazardous and more convenient. We also note that such a stove must be placed on a reliable foundation, since it weighs a lot.

Waste oil furnace

Such stoves are characterized by efficiency and economy; they do not require additional fuel purchases. A properly equipped furnace will not smoke or release heavy metals into the air (the latter may be present in used engine oil).

Furnace in production

In essence, such an oven is a pair of containers connected using a perforated tube. The weight of the unit can reach 30 kg, and it can hold about 12 liters of used oil. Average consumption is 1 liter of fuel per hour of operation. If you decide to make a choice in favor of a furnace for testing, then first think about where you will get the fuel - there certainly won’t be enough oil from one car, provided that the heating unit is constantly used. You can ask the owners of other garages in the neighborhood - maybe they will agree to give you the oil.

Waste oil furnace

The disadvantages of this design include the large length of the chimney (minimum 4 m), which must be positioned strictly vertically and not have any bends. In addition, regular cleaning of the waste container will be required, which can hardly be considered a pleasant task.

Long burning stove

Let's get straight to the topic of our article today. Let's start with the fact that such a stove (and you can also make it yourself from a cylinder) operates on the principle of converter combustion. Long-burning units are more complex than the potbelly stoves described above, but still nothing is impossible. You can use coal, wood, pellets, etc. as fuel, but only solid fuel is used.

Diagram of a long-burning furnace

Let's get acquainted with the key features of long-burning units.

- Fuel burns longer. Firewood in a conventional firebox will burn quickly, while in such a stove it smolders and gives off heat for 6 to 10 hours; therefore, the garage will take longer to warm up.

- Firewood must be pressed before laying - this way it will not flare up too much, and the smoldering time will increase.

- Fuel combustion starts from the top (in traditional stoves - from the bottom), and therefore such structures are usually vertical.

Wood-burning garage stove

Table No. 2. What types of long-burning stoves are there?

Long-burning gas cylinder stove

No. 1. Water heating system

The water heating system is organized in the garage by analogy with residential premises. The coolant is heated in the boiler, and then it passes through pipes and radiators, uniformly heating the entire garage room. After the heat supply stops, the pipes remain heated for another couple of hours. This is the main advantage of this system.

The main disadvantage is the complexity of the organization. In addition, the water in the heating circuit may freeze, so if the system will not be used in the coming days, it is better to drain the water. On the other hand, frequent water changes lead to rapid corrosion of pipes and radiators. To avoid this problem, it is better to use metal-plastic equipment. It is better not to use ordinary water in the heating system - it is replaced with antifreeze, a non-freezing coolant.

The complexity of the arrangement results in another drawback - the high price. The most economical way to heat a garage is to connect its circuit to a home boiler. The cost of general heating will increase, but it will still be cheaper than organizing an independent heating system.

If it is not possible to connect to your home system, you will have to install a separate boiler. It can run on different fuels. The following types of boilers are used in the garage heating system:

- An electric boiler is the easiest to install, extremely safe, but expensive to operate. Even if you are not worried about electricity bills, you should not use such boilers in areas with frequent power outages, power surges, or in regions with severe windy winters, because the wires may break, which will ultimately lead to freezing of the water in the system. If you do not manage to drain the water in time, the pipes may burst;

- gas boilers are used extremely rarely in garages, since not everywhere there is access to a gas pipeline. If the gas pipeline runs nearby, then you are very lucky - gas heating is inexpensive, and such systems are quite simple in terms of operation. The main thing is to follow safety precautions;

- boilers for liquid and solid fuel. You can choose a stove that runs on wood, coal, diesel or waste oil - it all depends on which resource is more accessible in your case. Solid fuel boilers require constant monitoring and frequent loading of fuel. Pyrolysis and pellet units are more convenient in this regard, but they are not cheap; the most economical option is a potbelly stove, which can also be used in a water heating system.

For all boilers, except electric ones, you will have to organize a chimney. In addition to the boiler, radiators, heating pipes and chimney pipes, you will need a circulation pump and an expansion tank. All this costs money, so using a hydronic heating system only makes sense in large garages. Often such heating is done at service stations and commercial auto repair shops. If the garage is small, then there is no point in organizing such a complex water heating system - this is an option for more or less spacious rooms where constant heating is required.

The operating principle of a water heating system is quite simple. The coolant heats up, passes through the pipes, gives off heat and returns to the boiler. The system can be one- or two-pipe. A single-pipe system is much easier to organize and cheaper; it is best suited for a small private garage. In this case, the heated coolant sequentially enters the radiators, i.e. in the first radiator the temperature will be higher than in the last, where the antifreeze reaches it already cooled down. The two-pipe system allows for more uniform heating, but much more materials will be needed.

Even if the garage is not attached to the house, but is located nearby, you can try to connect it to the home heating system, but there are limitations. The distance from the garage to the house should not be more than 20 m, and the pipes must be properly insulated.

If antifreeze is used as a coolant (a liquid that does not freeze even at -45C), then you must work with it carefully, because it is a toxic substance that becomes even more dangerous when heated. Antifreeze is not recommended for use in two-pipe systems

The coolant is replaced every 5 years.

Pros and cons of IV drips

Unlike the previous heater, the drip-type furnace is safe to use because the fuel is supplied in small portions into the bowl, and the pipe with holes is hidden in a steel casing. The strengths of the stove look like this:

- economical fuel consumption - from 0.5 to 1.5 l/hour;

- the possibility of burning oils mixed with water or antifreeze;

- efficient combustion of fuel, which is confirmed by smokeless exhaust to the street;

- a forced air furnace is undemanding in terms of chimney height;

- the unit does not smoke into the room.

This is how combustion occurs in a dropper

If desired, the dripper can be improved by equipping it with automatic safety, or by turning it into a boiler by installing a water jacket. To supply heat to 2-3 registers, it is enough to weld a furnace with a water circuit in the form of a coil installed in the upper part of the housing.

The negative point is that the oil lines become clogged when operating the heater. To avoid this, the used lubricant must be filtered and settled. For the same purpose, in a separate fuel tank, the oil line fitting is cut 5-10 cm above the bottom of the tank, where debris settles.

Ventilation.

Ventilation holes for exhausting the atmosphere should not be blocked by anything. Or there will be an increase in carbon monoxide in the room, which can cause poisoning. Stoves burn in the absence of soot and smoke, there is no aroma, and are in many ways more efficient than a wooden stove. The heat of the oven is up to 900 degrees - rapid heating. Acceptable auxiliary equipment is a fan, automatic oil supply, water tank, boiler, heater. The bent chimney increases the warm air supply. Operating rules Any oil, artificial or mineral, is suitable for using the stove. It is possible to pour no more than half of its size into the tank, because there must be room for the formation of vapors. When you have poured the oil, you need to take time for the vapors to become enriched with oxygen, after which they are ignited using long matches. As soon as the vapors ignite, the damper must be closed halfway; after heating the furnace, place the damper in this position so that the gases burn moderately in the central chamber.