Heating is an important issue that every home or cottage owner faces. In addition to choosing equipment, you need to decide on the heating fluid. More and more people are thinking about using oil rather than water for their home heating system. There are many opinions regarding this issue, which we will try to understand.

Operating principle of waste oil boilers

Appearance of used oil

It is possible to set up full-fledged air heating using waste oil only after familiarizing yourself with the specific design of boilers. This type of fuel is similar in technical characteristics to diesel, but has a larger number of additives. They arise due to the specific use of oil - in a car, industrial vehicle, etc.

Therefore, many factory heating boilers using waste oil are in fact diesel. Their principle of generating thermal energy is similar to a car engine. With the help of a pump, fuel is supplied to the nozzle while simultaneously pumping a large amount of air. This mixture ignites, producing large amounts of thermal energy.

An alternative option is to make your own waste oil heating boiler. In it, fuel burns as in conventional solid fuel. However, the efficiency of the system is much lower. Therefore, experts recommend installing factory models.

The principle of operation of a waste oil boiler

This is due to their advantages:

- Accurate calculation of fuel consumption and air supply to the injector;

- Reliability and safety of operation;

- Organization of a carbon monoxide removal system;

- Preheats fuel to improve combustion efficiency.

But at the same time, heating a house with waste oil using factory boilers is characterized by high initial costs. You can reduce them slightly by purchasing a burner that is installed in a solid fuel boiler.

The nozzle diameter for waste oil must be larger than for diesel fuel.

Properties

Transformer oil freezes at a temperature of -45 °C, which is of great importance when used in low-temperature climatic conditions. It also retains the ability to effectively remove heat at high temperatures: a mandatory condition is not lower than 90 °C, but there are oils with a temperature limit of 125, 135, 150 °C.

When the transformer operates, the oil heats up and oxidizes, aging. Accordingly, such an indicator as stability against oxidation decreases - the oil retains its original characteristics during further use. The higher the grade of oil, the longer the operating time without the need to replace it.

In our country, all types of transformer oil, which are used on industrial equipment, are necessarily inhibited by the additive ionol. This additive interacts with active radicals that arise during the oxidative reaction of hydrocarbons, which leads to a significant increase in the induction period. Thanks to the development of modern manufacturing technologies, modern oils are produced with high stability, which do not require the addition of inhibitors, with the exception of oil for very large heavy-duty transformers.

Transformer oil creates the conditions for the arc extinguishing environment. By lowering the temperature, insulation reduces copper consumption, noise and vibration. The normal color of fresh oil is light yellow. During use, under the influence of temperature and contamination by sediment and dirt, it darkens and becomes dark brown. Transformer oil is flammable, it decomposes without harm to the environment, is practically non-toxic, and does not harm the ozone layer.

Feasibility of installation

Heating scheme using waste oil

Is it really profitable to heat a country house using waste oil? This heat supply option can only be used if relatively cheap fuel is available. Otherwise, it will not be economically feasible to install complex and expensive equipment.

Heating a country house using waste oil, in addition to the boiler, must include a container for storing fuel. It has special requirements. The use of open barrels is strictly prohibited, as used oil gradually evaporates. This requires closed containers. In addition to them, pumping equipment will be required to supply fuel to the combustion chamber.

Summarizing all the above factors, we can identify the main requirements for the feasibility of heating with waste oil for a private home:

- Access to cheap fuel . For a house of 150 m² with 9 hours of heating, about 22.5 kg of oil will be required per day. During the heating season, this figure will be about 2200 kg;

- Special storage container . Its capacity must be at least 2 months' consumption, i.e. about 500 kg;

- It must be remembered that the amount of soot in a heating furnace using waste oil will be an order of magnitude greater than that of diesel or solid fuel. In this regard, the frequency of cleaning the combustion chamber and chimney will increase.

Also, do-it-yourself heating using waste oil involves installing a fan rather than a turbine. This reduces the air flow, which affects the composition of the combustible mixture. This technology leads to rapid clogging of the nozzle and frequent failure.

You can negotiate with the nearest car service center to purchase used oil. It is best to do this 4-5 months before the start of the heating season.

Rating of the best coolants for heating systems

| Nomination | place | Name of product | rating |

| Rating of the best coolants | 1 | DIXIS-65 | 4.9 |

| 2 | Warm House Eco | 4.8 | |

| 3 | THERMAGENT-65 | 4.8 | |

| 4 | RODA | 4.7 | |

| 5 | AMT-300 | 4.7 | |

| 6 | Hot Stream | 4.7 | |

| 7 | Teplokom | 4.6 | |

| 8 | WARME BASIC-65 | 4.5 | |

| 9 | Thermagent Eco 30 | 4.5 | |

| 10 | FTX-30 | 4.5 | |

| 11 | PRIMOCLIMA ANTIFROST | 4.4 |

Security measures

Homemade installation using waste oil

The most important question for the consumer remains: is steam heating using waste oil safe? All complaints about an unpleasant odor and fuel combustion are related to non-compliance with safety rules.

It is important to choose the correct composition of used oil. It should not contain waste gasoline, acetone and other flammable substances. You should also pay attention to third-party impurities typical of automotive waste. They are the cause of premature contamination of the burner.

For air heating using waste oil, the following safety measures must be provided:

- Chimney with a diameter of at least 100 mm. It is best to use a sandwich chimney, since the least soot forms on its surface;

- It is not allowed to store fuel containers in the immediate vicinity of the boiler;

- Tanks with used oil must be sealed. If water gets into them, fuel will splash during combustion. This may cause a fire;

- The temperature impact on a heating boiler using waste oil is much higher than that of solid fuel. Therefore, the wall thickness of the heat exchanger and combustion chamber cannot be less than 2 mm;

- To avoid smoke in the boiler room, a forced circulation system is installed in it. The recommended air exchange should be 180 m³/hour per 1 m³ of area.

Only after meeting these requirements can we talk about a safe heating system for a country house using waste oil.

The operation of a fan or turbine can draw a large volume of air from the boiler room. Therefore, the power of the room’s ventilation system should be 1.2 times higher.

How to choose a coolant

The rating of coolants for open and closed heating systems contains products that prevent pipes from defrosting, as well as prevent scale formation, bacterial growth and corrosion of metal joints. But when choosing antifreeze for the boiler and radiators, it is important to pay attention to some parameters of the substance:

- The basis.

The packaging always indicates which product is the main one in the composition. The most antifreeze is ethylene glycol. It has increased fluidity, so sealing joints must be especially careful. But there are never any problems with it in terms of circulation. But this coolant is also the most toxic. A medium-priced and relatively new type is glycerin, which is more gentle and harmless, but requires replacing conventional gaskets with Teflon ones. The most expensive is propylene glycol, which is chemically neutral and resistant to overheating. A separate substance is oil, which has low antifreeze properties, but allows it to be heated to higher temperatures. - Crystallization point

. This is the number of degrees below zero, after which the fluidity of the product is lost. The indicator varies from -15 to -65 degrees, which is important to consider when choosing a coolant for use in heating systems in various regions with cold and temperate climates. - Boiling point.

Indicates when antifreeze begins to foam. For some, this occurs after 70 degrees. The maximum indicator is 115º C. The later the liquid boils during overheating, the longer it will retain its fluidity, the effectiveness of additives and will continue to perform its main functions - transfer heat. - Possibility of dilution with water

. Some substances for heating systems can only be used in their pure form, while others can be diluted with ordinary water according to the parts ratio table, depending on the winter temperature in the region. The second option is more economically beneficial, since it allows you to fill the volume of the system with less antifreeze, and add the rest with free water. - Life time

. Each coolant indicates a safe service life guaranteed by the manufacturer. During this period, the product will be gentle on seals and metal, and will also meet the specified crystallization and boiling characteristics. Some fluids last 4-5 years, others up to 10, which affects heating maintenance costs.

Overview of heating boiler manufacturers undergoing testing

Factory waste oil burner

Reliable heating using waste oil, reviews of which are mostly positive, is impossible without a factory burner. The safety and efficiency of the heating system at home will depend on it. Currently, the market is dominated by foreign manufacturers of this type of equipment. This is due to the labor intensity of production and the relatively low demand among Russian consumers for heating boilers during testing. Most models are designed for heating large rooms, and their power exceeds 60 kW. But despite this, it is possible to organize heating using waste oil in a private home using less efficient burners.

Clean Burn boilers

The American company specializes in the production of powerful waste oil boilers. Its products are in demand in boiler houses for heating 2-3 apartment buildings. The minimum boiler power is 200 kW. A special feature is the unique shape of the heat exchanger, providing 95% efficiency.

Kroll burners

The German manufacturer specializes in the production of burners operating on waste oil. It is important that the company’s engineers took into account the specifics of heating a house using waste oil - the burner can be installed on almost any type of solid fuel boiler. In addition, it has a unique fuel heating system so that its viscosity is close to ideal.

A special feature is the mandatory presence of compressed air, which can be generated using a compressor. This is a prerequisite for organizing heating using waste oil with your own hands.

Boilers Heat

This Russian manufacturer is one of the few who were able to make truly unique heating equipment using waste oil. Their heating boiler "Zhar-20" with a nominal power of 30 kW can be installed in a private home. It does not take up much space, and all safety measures for waste oil steam heating are taken into account.

The price of equipment from the above-described manufacturers depends on the power of the boiler (burner) and its design features.

| Model | price, rub. |

| Kroll KG/UB, 75 kW/hour | 270000 |

| Clean Burn SV-2000, 200 kW | 580000 |

| Zhar-20 | 170000 |

Before purchasing a specific boiler model, it is recommended to read reviews on heating using waste oil. They will help you form an objective point of view on the performance of specific equipment.

Flaws

Despite the obvious advantages of this type of coolant, there are still a number of disadvantages:

- The need for filtration before injecting into the system. The fact is that usually the oil is a mixture of many oils of different brands and viscosity. In addition, it contains third-party components in the form of dirt and metal. The process of cleaning a considerable volume can cost a large sum.

- Availability of the required quantity. At the moment, there are no companies that are engaged in the targeted collection and purification of oil for future infusion into heating systems. Therefore, finding a sufficient amount of the desired consistency will be problematic.

- High fire hazard. In the event of a leak, there is a risk of fire. True, for this the liquid must come into direct contact with an open source of fire.

- It is not permissible to use a boiler with direct heating.

- Replacing all rubber gaskets and connectors with oil-resistant ones, which will be more difficult to find, since conventional heating systems are not equipped with them. In addition, their purchase can cost a large sum.

Homemade waste oil boiler

Homemade waste oil stove

A heating stove using waste oil is not always necessary to supply heat to a home. In some cases, it is made for heating the garage and utility rooms. Then it is almost impossible to select a factory model of a burner with a power of up to 10 kW. The only way out is to do it yourself.

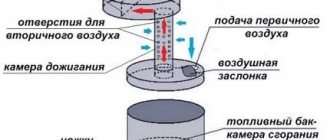

The operating principle of this device is based on burning a mixture of oxygen and oil. During the combustion of this composition, the water tank located in the upper part of the structure is heated. To make such a heating boiler using waste oil with your own hands, you will need to select the right starting materials. The temperature in the combustion zone can reach +700°C, so it is best to use heat-resistant steel grades.

Scheme for making a homemade boiler

To supply air you will need a small power compressor. The hose from it is installed in a pipe located next to the waste oil reservoir. For ignition, a piezoelectric element or a similar device is installed.

Unlike factory burners, steam heating using waste oil has its own specific operation. It lies in the principle of obtaining thermal energy. Let's look at the stages of heating using waste oil using a homemade boiler:

- The oil heats up to +40°C, resulting in the formation of vapors that enter the upper chamber;

- In the combustion zone, air is mixed with the fuel mixture, resulting in the release of a large amount of heat;

- The resulting energy can be directed to heating water in the upper heat exchanger or supplied directly to the room through the walls of the combustion chamber.

For this homemade waste oil boiler, it is important to make the chimney system correctly. It must freely remove combustion products outside the room. The high oxygen consumption during fuel combustion should also be taken into account. Therefore, to heat a country cottage using waste oil, an autonomous air supply system is made.

To regulate the boiler power, a tap is installed on the air supply hose. With its help, you can reduce (increase) the flow of oxygen and the composition of the combustible mixture.

Ignition of the oil furnace

Unfortunately, the design does not have automatic ignition using piezo or electricity. The manipulations are complex and require experience:

- The condition of the unit is checked every time it is necessary to put it into operation. If necessary, the chimney and other channels are cleaned.

- Attention should be paid to the fuel tank to ensure that no water has entered it. What this entails is written above. In addition, it is important that there is a sufficient supply of fuel in the tank each time - 2-3 liters.

- Light the stove using a wick. They make it themselves, and the whole process is reminiscent of lighting a kerosene lamp. The oven does not set immediately, within 5 minutes. When stable combustion is ensured, the draft and other parameters for a productive process should be adjusted.

You can regulate the heat supply using devices on the unit itself. For this purpose there are dampers, valves, etc.

Reviews about heating using waste oil

How can you determine the relevance of installing a waste oil heating furnace? There are many criteria - calculated efficiency indicator, operating comfort. However, the most effective way to find out about possible problems is to read reviews about heating using waste oil:

- We decided to install air heating in our car service during testing. Fortunately, there is always plenty of fuel. We installed a homemade boiler and conducted “field tests”. The first problem is the mandatory cleaning of the oil before filling. Even a small amount of antifreeze (which happens often) significantly increases the volume of soot. After updating the system, everything functions normally;

- We have heard a lot about heating a private house using waste oil - efficiently and at low cost. My husband works in electrical networks and managed to negotiate the sale of transformer oil at a good price. We installed a German burner on an old boiler and made a proper fuel supply. The system works like a clock. The only drawback is the high consumption - in winter up to 25 kg per day;

- I made a homemade boiler for the garage during testing. It works fine - I installed a good chimney in advance. The walls of the boiler become red hot and therefore you have to blow them with a fan. He also noted that the firebox needs to be cleaned frequently.

From operating experience, it will take from 1 to 3 years to compensate for the initial costs of installing equipment using waste oil. This only applies to boilers with a power of 60 kW and above.

The video shows an example of how a homemade boiler works:

Timing for oil changes

During operation of the transformer, an oil oxidation reaction occurs, dirt accumulates and the viscosity of the oil increases, which reduces its ability to cool the operating transformer. If the oil is not changed on time, the service life of the equipment is significantly reduced.

The average time to replace transformer oil is 1 year. And no more than after 5 years it is necessary to carry out drying and regeneration work. To extend the life of oil and equipment, you need to follow some rules:

- install an expander with a filter to absorb water and oxygen to prevent oil from contacting air;

- try not to bring the oil to maximum and long heating;

- carry out cleaning and drying in a timely manner;

- Perform continuous filtration of lubricants.

Heat exchanger assembly

I made the stove to heat the garage. I don’t have hot water heaters in my garage, so I decided it would be better to have it immediately heated and circulate the air. If you have water batteries, then you can abandon the air heat exchanger and simply run 4-5 water coils through the upper chamber, connecting them in parallel. In this case, the design must be supplemented with a circulation pump and fan. Such equipment will allow you to heat the entire house with a stove; you just need to allocate a room for installing the stove.

Heat exchanger assembly

Let's go back to my heat exchanger. I installed it between the smoke exhaust pipe and the stove burner - this is where the heat is greatest. I welded an iron plate to the heat exchanger. Thanks to it, the flame will be held better. It will also help distribute the fire inside the stove body.

An air swirler was installed inside the heat exchanger. There are no engineering delights in such a swirler, but it copes with its task one hundred percent. When operating at maximum power, the metal of the case heats up to a scarlet color, and the heated outgoing air even penetrates the glove. You can see the swirler itself in the photo.

I'm making a swirl

I'm making a swirl

I'm making a swirl

Installed a swirler

Next, I took a duct fan and placed it on one side of the heat exchanger. By the way, you can connect a thermal relay to the fan for automation. This will allow you to set the temperature yourself and save resources. For example, I decided to use a thermal relay from Autonics - I just had it lying around idle. But you can also take some budget model, for example, Vemer KLIMA. I tried it too, it works great.

Supercharged

This is what happens

Heat is concentrated in the firebox compartment.