When operating any mechanisms, technical oils are used. When used for their intended purpose, they do not burn and remain flammable. Instead of recycling, an alternative option for reusing them is a potbelly stove using waste oil, which you can make yourself.

Let's try to figure out how a potbelly stove works and what materials are needed to make it. We will also talk about popular models of homemade stoves and share the secrets of their successful operation.

Types of homemade stoves in development

Engine oil contaminated with impurities will not ignite itself. Therefore, the operating principle of any oil stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, the waste must be heated, evaporated and burned in the furnace firebox, supplying air in excess. There are 3 types of devices where this principle is implemented in different ways:

- The simplest and most popular direct combustion design with afterburning of oil vapors in an open perforated pipe (the so-called miracle stove).

- Drip furnace using waste oil with a closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating potbelly stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on the indicators of factory heat generators with an efficiency of 85% (to get acquainted with the full picture and compare oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Take this fact into account when starting to manufacture a furnace for testing.

Design and disadvantages of an open-type potbelly stove

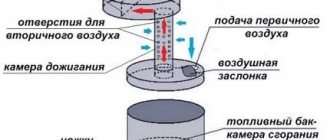

The pyrolysis stove shown in the photo is a cylindrical or square container, one-quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is an afterburning chamber with a partition for collecting heat from combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of the waste and its primary combustion will begin, causing pyrolysis. Combustible gases entering the perforated pipe flare up upon contact with the oxygen flow and are completely burned. The intensity of the flame in the firebox is controlled by an air damper.

This stove has only two advantages during testing: simplicity and low cost and independence from electricity. The rest is all downsides:

- stable natural draft is required for operation; without it, the unit begins to smoke into the room and die out;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, causing fiery drops to splash from the afterburner in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l/hour with low heat transfer (the lion's share of the energy flies into the chimney);

- The one-piece housing is difficult to clean from soot.

Although the potbelly stoves look different, they operate on the same principle; in the right photo, fuel vapors burn out inside the wood stove

Some of these shortcomings can be leveled out with the help of successful technical solutions, which will be discussed below. During operation, you should adhere to fire safety rules and prepare used oil - settle and filter.

Pros and cons of IV drips

The cardinal difference of this furnace is the following:

- a perforated pipe is placed inside a steel casing made from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of drops falling to the bottom of a bowl located under the afterburner;

- To increase efficiency, the unit is equipped with air pressurization using a fan, as shown in the diagram.

Diagram of a dropper with bottom supply of fuel from the fuel tank by gravity

The real drawback of the drip stove is the difficulty of execution for a beginner. The fact is that you cannot rely entirely on other people’s drawings and calculations; the heater must be manufactured and configured to suit your operating conditions and the fuel supply must be properly organized. That is, repeated improvements will be required.

The flame heats the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place in the body, which is why the latter will burn out quite quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe to use because the combustion zone is completely enclosed by an iron casing.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and convert the exhaust furnace into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Boiler with pressurized air, burning waste engine oil and diesel fuel

Making an economical wood stove

In order not to needlessly distract the reader’s attention with the well-known designs of simple wood-burning stoves, of which there are plenty on the Internet, we suggest familiarizing yourself with the drawings of a more serious heater. Its peculiarity is the presence of two smoke circulations (passes) organized inside the stove body for the best heat transfer. After all, what is the main disadvantage of an ordinary potbelly stove? That's right, low efficiency, since the lion's share of the generated heat immediately flies into the chimney.

In a do-it-yourself two-pass metal stove, hot combustion products pass through special channels in two directions before going up the chimney.

By making 2 revolutions through the channels of the stove, the combustion products will give off more heat to the air in the room.

Thanks to this design, a significant portion of the heat is successfully transferred to the room, which contributes to more efficient heating with wood and leads to savings. Although, to evaluate these savings, it is necessary to compare different furnaces in practice, which is not always possible. But rest assured that you will definitely get more heat from the two-pass garage stove shown in the diagram above.

To make a heat source you will need the following materials:

- Sheet metal with a thickness of at least 4 mm, optimally 5 mm. From it you will weld the body, smoke circuits and doors.

- For the roof of the firebox, which experiences the greatest thermal load, it is better to take a sheet 6 mm thick.

- A piece of pipe with a diameter of 100 mm for the chimney pipe.

- Periodic profile fittings with a diameter of 16-18 mm for the manufacture of grates.

- Angle No. 4, pipe 40 x 40 mm or other rolled metal for the legs.

- Finished door handles.

Note. To weld a garage stove with your own hands, you need to use low-carbon steel grade St10 or St20. High-carbon or alloy steel is hardened by high temperatures, and the body may crack at the welds. How to roughly determine the grade of steel is described in the instructions for making a sauna stove.

Solar ovens for the garage

In order to make an inexpensive stove for heating a garage with high efficiency, we will need:

- Fuel tank with a capacity of 7-15 liters;

- Seamless cylinder with thin metal walls (15 cm or less);

- Pipes with a diameter of 10 cm and a wall thickness of up to 2 mm. Their length must be at least 4 meters;

- Copper pipes for the burner.

As for the tools, diesel stoves for the garage are made using an angle grinder, a drill and files, drills, and a level. You will also need to find a tape measure, steel angles (20 cm) and electrodes. Once all this is in your hands, you can start assembling the diesel stove with your own hands. This process consists of the following steps - wizard:

- Drains the condensate from the cylinder and rinses it with water several times (removing any remaining odorant);

- Fills the container with water and buries it in the ground (to give it stability);

- Makes an incision on the container, waits for the water to completely flow out, after which it finally separates the upper part of the container from the lower part;

- Welds the legs from the corners to the bottom.

The next step is to reproduce the above diagram of the garage furnace. You can perform actions in any order

It is only important to accurately reproduce this drawing, everything else is secondary

Stages of making a homemade potbelly stove

The construction of this heating equipment consists of several stages. You need to think about its size and determine what it will be made of. Next, a drawing of a potbelly stove for the garage is drawn up. It indicates not only the parameters of the entire structure, but also the amount of material used for its construction.

It’s quite easy to make a “potbelly stove” for the garage with your own hands. Drawings of this equipment are drawn up independently. You can also seek the help of specialists.

Then the structure is welded and refined.

How does a waste oil furnace work?

Having looked at the drawings of a potbelly stove for a garage, few people will immediately understand what exactly the “work” of this unit is. In fact, physics is at the forefront here; there are no moving parts or complex design solutions in the design of the potbelly stove. This is both a plus and a minus. Assembling it with your own hands is quite simple, but making any drastic changes is extremely difficult.

In fact, everything is extremely simple. There are two tanks that are connected by a pipe. It has many holes (quite large), which are located at a distance of 2-3 cm from each other. The bottom element contains “working off”. Oil is poured there and then heated (you can see the details in the video). Firstly, heat is being generated already at this stage, but the next one is much more important. Vapors of heated oil rise through the connecting pipe, where they begin to burn, but this process occurs especially actively in the upper reservoir.

The stove itself is quite compact - moving it from one place to another with your own hands will not be difficult, but the chimney must be very long. Everyone advises making it at least 4 meters in length. Such requirements are due to the following: the longer the pipe, the stronger the thrust. This means that the vapors will burn more actively, releasing a lot of heat.

A small potbelly stove can heat a room with an area of at least 50 meters, but if you do everything correctly and assemble a larger stove with your own hands, you can easily hope to heat a fairly large area (up to 100 “squares”). The only requirement is that the room must be free of partitions, for example a garage, warehouse, workshop.

Cost and sources of oil

As we said earlier, the main reason why potbelly stoves are used is cheap fuel. Some believe that you can use oil that has just been drained from the car. In fact, this is dangerous - such fuel contains many foreign impurities that, at best, will make the stove less efficient. At worst, it can explode, splashing burning oil all around. Sometimes you get lucky and the explosion turns out to be weak - the structure simply “disassembles”, and the oil goes out.

We recommend purchasing quality fuel from suppliers who refine the processed oil and sell it further. In this form, it is inexpensive - only 10-20 rubles per liter. The price varies greatly depending on the region where you purchase fuel, as well as the season. In winter, people buy it much more actively, just for heating workshops, workshops and garages.

Disadvantages and advantages of using a potbelly stove

This homemade garage stove has only three drawbacks:

- Heating devices are made of steel, so they quickly give off heat and cannot accumulate it, unlike cast iron stoves. But solving this “trouble” is quite simple - to do this, you can simply cover it with refractory or “fireclay” bricks from open-hearth furnaces. For lining, you can use simple building bricks.

- To ensure sufficient air extraction, you will need to provide the stove with a hood, the height of which is at least 4 m. But this is also a dubious drawback. For better heating of rooms, experienced stove makers advise stretching exhaust pipes across the entire box. The gas will give off heat throughout the entire box - this will save fuel.

- An undeniable drawback is the need for constant cleaning of the chimney, especially if it is made of a thin pipe and the possibility of condensation formation.

The advantages of a homemade stove for heating a garage are many times greater:

- ability to quickly heat a room. Garage stoves, made in accordance with all the rules, can raise the temperature to a comfortable level in just 10 minutes. But if the heater is covered with bricks, this period of time will increase;

- the ability to ensure uniform heating of the entire room with ventilation pipes stretched throughout the garage;

- A potbelly stove for a garage can be made to operate on different types of fuel. This could be a wood-burning garage stove. Used oil and coal will do. Even wood shavings and sawdust can be used as fuel;

- the simplicity of the design allows the use of different schemes for production. You can make a wood-burning stove for a garage with your own hands from an old gas cylinder, a piece of pipe, or just old sheet metal;

- such a home-made design does not require large expenses for the purchase of materials and time for its production. If you make a garage oven with your own hands, running on used engine oil, it can save significant money. Electric convectors or infrared heaters increase the figures for paying for electricity;

- By adding minor changes to the plans, you have the ability to quickly reheat or cook hot food in the garage.

Let's take a closer look at the process of making a stove for a garage with our own hands.

Connecting the structure in the bath

The stove design includes a part of the chimney with many holes (usually up to 50). This part of the unit is called the burner. In such a burner, oil vapors are mixed with oxygen entering the smoke exhaust pipe under the influence of draft. As a result of their mixing, the combustion process begins to be much cleaner and more intense, releasing a huge amount of heat.

The tray was made from a cast iron automobile brake disc. Cast iron has good heat resistance, so I decided to use it.

I will make a pallet from this disk

I welded the bottom underneath.

The steel circle is the bottom

I welded the lid on top. In it you can see the counterpart of the burner and the opening. Air enters the stove through the opening. I made it wide - it's better that way. With a narrow opening, the air draft may not be strong enough, which is why the oil will not be able to get into the pan.

Next I made a coupling. In my stove it connects the pan and the burner. With a coupling it will be much easier to maintain the stove. If necessary, I can take out the tray and clean the burner from below.

Next I made a coupling

The coupling was made from a 10-centimeter pipe, simply cutting it along the longitudinal edge. I did not weld the opening in the coupling - there is no need for this.

The ancestor of such stoves was kerogas, known to the older generation. It differed significantly from other designs in its safety and efficiency. Since the fuel vapors were burned in a special chamber, the entire volume did not heat up and did not create a danger of ignition and fire.

The operating principle of a waste oil furnace is approximately the same. It consists of two containers located one above the other, between which there is a combustion chamber with holes for air intake. The waste is poured into the lower container, the vapors of which actively burn in the middle chamber, and combustion products, smoke and other substances enter the upper chamber connected to the chimney, from where they are removed naturally.

The hot water boiler is located at the top of the stove. It is non-removable and has taps for drawing water into the bathhouse and for starting the heating circuit. The steam room is heated from a brick wall facing inside. To maximize its effect, it is necessary to make the distance from the stove to the brick box quite small to reduce heat loss, but also sufficient for air penetration.

There is another option for making a structure using mining, combined with a brick kiln. Only the lower reservoir is manufactured. The combustion chamber has the shape of an elbow, smoothly bent at 90°. A vertical plate is welded to the end, which communicates with the internal (furnace) part of a conventional brick oven. The hot gases generated during the combustion of waste enter the brick stove and heat it.

The further design is no different from the usual one: a water boiler is installed, a heating circuit with natural or forced circulation, shut-off valves, and so on are connected. This compact option is optimal for those who already have a ready-made furnace and only want to adapt it for burning waste.

The best option: creating a closed heating circuit with a hot water mixing unit. The coolant is heated in a heat exchanger installed inside the boiler or, alternatively, on the chimney. Such a system allows you to cut off the carrier from water for household needs, ensure a more uniform temperature in the system and makes it possible to accurately regulate the temperature in the rooms.

The opportunity to save money on the most expensive area is very attractive for any homeowner, and combining all elements into a single system contributes to more convenient and efficient control of home heating. In addition, the process of recycling used oil is complicated, and the ability to burn it with maximum benefit will be the best option for recycling unnecessary substances.

What is the difference between a long-burning stove and a wood-burning stove?

Fundamentally, the difference between a long-burning stove and a conventional potbelly stove is how the combustion process occurs. A conventional cast iron or steel stove with a grate and a straight chimney is characterized by rapid combustion of fuel. In fact, the name “potbelly stove” itself comes from the exorbitant appetites of the stove. The combustion process in the firebox occurs on a grate, with a large air flow, which, on the one hand, makes it possible to increase draft, and on the other hand, when burning wood, I burn with a large amount of soot and smoke. This state of affairs cannot indicate fuel economy; they simply have to be constantly added to maintain the temperature.

In a long-burning furnace, the process occurs differently. Depending on the design of the firebox and additional equipment, combustion can take the form of slow combustion (smoldering) or pyrolysis - combustion of gases emitted by the fuel.

When smoldering, it is possible to make the combustion process controlled by reducing or increasing the air flow into the firebox. The result is slow combustion of fuel and the combustion process increases in time. It is difficult to judge how economical such heating is, but it is a fact that the combustion time increases significantly.

During pyrolysis, solid fuel decomposes into simple substances under the influence of high temperature. As a result, it turns out that it is not wood that is burned in the firebox, but the gas emitted by the wood. Such long-burning stoves are much more economical and their installation quickly pays for itself.

But, in fairness, it is worth mentioning intermediate designs that combine the advantages of controlled smoldering furnaces and pyrolysis furnaces. These hybrids are basically the most commonly used DIY projects.

Disadvantages of the furnace during mining

Furnaces under development

Of course, such designs have a significant advantage - low cost of fuel. But there are also many disadvantages:

- To ensure uninterrupted combustion of the furnace, constant and sufficiently strong draft is required

- high fire hazard (we will discuss the rules for operating the furnace during mining below)

- frequent cleaning of soot: if you make the body one-piece, after a couple of months you simply will not be able to use the stove - it will begin to smoke mercilessly

- high fuel consumption - you will need at least 2 l/hour

- The heat transfer of devices is not that great; most of the energy, unfortunately, flies into the chimney

Most of these shortcomings can be smoothed out by improving the design - installing a fan to increase the combustion temperature, an expansion tank, etc. But due to these shortcomings, stoves are used mainly for temporary heating of utility rooms.

Even if you make a stove according to proven drawings, in any case you will have to bring it to perfection yourself: adjust the draft force, fan rotation speed and fuel dosing. It’s also not worth making all the holes in the afterburning pipe right away - do the first two bottom ones first, and drill the rest after full setup.

Fuel supply system

We insert a ½ inch water pipe (1) (with a reserve) into the hole at an angle (30 - 40o), weld it to the stove body. The location of drilling the hole does not play a special role, since the evaporator bowl is made mobile and can be turned with the receiving hole in any direction.

We lower the coupling onto the end of the pipe and mark the outreach distance (2), cut it with a grinder, forming a “spout” for more convenient formation of a stream of oil (3).

A regular water ball valve (4) is screwed to the tube, which will be used as an emergency backup to shut off the fuel supply in the event of a failure of the valve on the exhaust tank.

Heat exchanger assembly

I made the stove to heat the garage. I don’t have hot water heaters in my garage, so I decided it would be better to have it immediately heated and circulate the air. If you have water batteries, then you can abandon the air heat exchanger and simply run 4-5 water coils through the upper chamber, connecting them in parallel. In this case, the design must be supplemented with a circulation pump and fan. Such equipment will allow you to heat the entire house with a stove; you just need to allocate a room for installing the stove.

Heat exchanger assembly

Let's go back to my heat exchanger. I installed it between the smoke exhaust pipe and the stove burner - this is where the heat is greatest. I welded an iron plate to the heat exchanger. Thanks to it, the flame will be held better. It will also help distribute the fire inside the stove body.

An air swirler was installed inside the heat exchanger. There are no engineering delights in such a swirler, but it copes with its task one hundred percent. When operating at maximum power, the metal of the case heats up to a scarlet color, and the heated outgoing air even penetrates the glove. You can see the swirler itself in the photo.

I'm making a swirler I'm making a swirler I'm making a swirler I'm making a swirler

Next, I took a duct fan and placed it on one side of the heat exchanger. By the way, you can connect a thermal relay to the fan for automation. This will allow you to set the temperature yourself and save resources. For example, I decided to use a thermal relay from Autonics - I just had it lying around idle. But you can also take some budget model, for example, Vemer KLIMA. I tried it too, it works great.

I supercharged it and this is what happens

Heat is concentrated in the firebox compartment.

Preparatory activities

At this stage, materials and tools are selected, as well as a place for installing the oil heat generator is found and arranged.

What is needed to make a stove?

Having decided on the design, you can prepare everything you need. Here is a list of tools you will need later:

- “grinder” or angle grinder (angle grinder);

- circles for angle grinders. You will need several cutting discs and one cleaning disc;

- electric drill;

- two drills Ø6 mm and Ø9 mm;

- diamond cutters Ø60 mm and Ø100 mm;

- welding transformer;

- autogen or plasma cutter.

Of course, working with new materials is much easier and more enjoyable. However, if you have a certain amount of metal accumulated in your backyard or workshop, you can always save money by using suitable blanks. The list of required materials looks like this:

- sheet steel 4 mm thick;

- steel pipe with a diameter of 100 mm and a thickness of 4–5 mm;

- sheet steel 6 mm thick;

- chimney pipe;

- profile metal pipe 40x20 mm.

If the appearance of the equipment you use is important to you, we recommend stocking up on a special heat-resistant primer and paint. A painted potbelly stove will look no worse than industrial designs.

How to choose a place to install a liquid heat generator

The site intended for the installation of a potbelly stove must meet both practicality requirements and safety regulations. In our case, the situation is complicated by several factors. Firstly, when reaching the maximum mode, the walls of the heating device become white-hot, which poses a threat of fire to nearby objects. Secondly, you have to deal with a rather dangerous type of fuel - liquid. Thirdly, the requirements put forward for the installation site apply not only to the potbelly stove itself, but also to the chimney - the temperature of its horizontal section often exceeds 300 °C. Therefore, in order to ensure safe operation of the unit, a number of mandatory requirements will have to be met:

- ensure that the walls of the heating device are at least 0.5 m away from non-combustible surfaces, and 1 m from combustible surfaces. In this case, the latter must be protected by a heat-insulating screen made of heat-resistant material;

- Placing shelves and niches above the potbelly stove is not allowed;

- the stove burns a lot of air, so it is necessary to have supply and exhaust ventilation in the room;

- the unit must be located away from air flows;

- The storage location for used oil must be at a safe distance;

- it must be possible to disconnect the chimney for maintenance.

Most often, a potbelly stove is installed in the corner of the room. Among other things, this installation method allows you to optimize the space of a small room.

Placing a liquid heat generator in a corner will help save space, and a heat-reflecting screen will increase heating efficiency

Having decided on the location, you should prepare a reliable foundation for installing the heat generator. If the floor of the room is a concrete slab, then no additional work will be required. Otherwise, you will have to make a cement-sand screed measuring 1x1 m. To do this, you may have to remove part of the wooden floor if such flooring is located in the place where the heating device is installed.

At the preparatory stage, another essential part of the work is performed - they prepare the blanks for the future unit. Since all its parts are welded from metal 4–6 mm thick, it is extremely difficult to carefully cut out parts with a grinder, especially when it comes to round elements. Therefore, it is better to seek help from the nearest car service center or the nearest enterprise. As a rule, even in small industries there is always a gas cutter, or, even better, a plasma cutter. For little money, an experienced specialist will cut the blanks in full accordance with the drawings. All that remains to be done after this is to carefully sand the edges of the parts on an emery wheel.

If you were unable to use third-party help, do not despair. You can make parts using a grinder, but it will take much more time.

Parts ready for assembly

Required materials and tools

To make a potbelly stove with your own hands you will need:

- welding tool (or any other welding machine if you have relevant experience);

- chisel;

- soft cloth (you can use rags);

- hammer;

- sandpaper (fine-grained).

The list of materials depends on what container the potbelly stove will be made from. This could be a gas cylinder or a milk flask. If you have some experience working with metal, then a potbelly stove can be made from sheet material. However, you definitely need to take care of the availability of:

- refractory bricks;

- steel pipes;

- metal wire;

- grate bars (in some cases you can do without them);

- pipe with weather vane;

- door hinges.

Creation options

Creating a vertical oven

Algorithm of actions:

- The cylinder is placed vertically and the neck is cut off.

- Using a marker, make marks on the surface. Mark the locations of the firebox, chimney, vent, etc.

Markings on a gas cylinder to create a vertical oven.

- Using a cutter or grinder, cut out the intended holes.

- Next, proceed to installing the grate. It is made from cut reinforcement. The parts are welded inside the body to the intended location in a snake or in a row.

- Door hinges are welded to the cylinder body and cast iron (metal) doors are installed. Latch bolts are attached to them or a sliding mechanism is constructed.

- If the potbelly stove will be used for cooking, then a metal sheet cut to size is welded to the top of the tank. This strip will be the hob.

- Seams and joints are cleaned and checked for strength and tightness.

- The opening for installing the chimney pipe is made on the side or at the top of the cylinder. The size of the opening must be equal to the diameter of the pipe. Often the smoke exhaust is made from above through the central hole in the cylinder. When installing on the side, the elbow is first welded to the cut-out opening, and then the pipeline itself is welded. It removes combustion products through the roof or wall of the room.

About

Supercharged furnace design

Supercharged furnace design drawing

Such a unit is considered safer - after all, the combustion zone in it is completely closed. The supercharging method helps reduce fuel consumption - it will no longer be needed two, but one and a half liters per hour. Plus, the power in such a furnace can be easily adjusted. The device is also less demanding on the height of the chimney. And you won’t have to clean it so often.

You can use an old VAZ 2108 from the furnace as a fan. The Chinese equivalent will also work. You can adjust the fan speed using an inexpensive PWM controller.

Perhaps the only drawback of a supercharged mining furnace is severe burning of the metal in the place where the flame jet is deflected

But for a collapsible structure this is not so important - a burnt sheet of metal can be easily replaced

Projects of country houses for 6-10 acres: 120 photos, description and requirements | The most interesting ideas

Design features of the furnace, dimensions and drawings of existing units

As noted above, a two-volume potbelly stove consists of several main elements:

- lower container with air damper;

- upper heat exchanger with baffle and outlet pipe;

- vertical diffuser with perforation;

- supporting elements of the structure.

The lower and upper modules are cylindrical containers with a diameter of 35–45 cm, which are connected by a thick steel pipe with a diameter of at least 100 mm. Its length must be at least 40 cm, otherwise the unit will not provide conditions for saturating oil vapors with oxygen. For the same purpose, drillings with a diameter of at least 9–10 mm were made across the entire surface of the vertical chamber, which were placed in a checkerboard pattern.

The lower tank rests on four legs 10–15 cm long, made of a profile pipe measuring at least 30x30 mm. On its upper surface there is a hole with a diameter of 50–70 mm, which is closed with a rotary valve.

Drawing of an easy-to-make two-chamber potbelly stove

Inside the upper module, closer to the outlet pipe, a metal strip is installed, which is necessary to reduce the gas flow rate. Since the heated gas rushes upward, the partition is mounted on the top cover. There should be a gap of at least 25–30 mm at the bottom of the tank, which will be enough for a complete gas outlet.

The stove pipe is connected to the unit through a pipe cut into the side wall of the upper module. A detachable connection is necessary in order to periodically clean the smoke channel from soot and carbon deposits. By the way, the height of the chimney must be at least 4 m, otherwise the draft will not be enough for intense combustion. In order to increase heat transfer, part of the chimney pipe is laid horizontally. In this case, even a segment of 0.5–0.8 m will be enough to enhance convection heat transfer. As for the material of manufacture, at a distance of at least 1 m from the outlet pipe of the stove, the chimney must be made of thick steel pipe. Next, the channel can be expanded with any available materials - galvanization, tin, ceramics, etc.

All parts of the potbelly stove are made of steel with a thickness of at least 4 mm. The upper module and vertical chamber are welded together with the casing of the lower tank. These elements must be fitted to the fuel module body as closely as possible. Of course, it would be possible to make the potbelly stove non-separable, but subsequently simplifying the design will result in difficulties when cleaning the unit from carbon deposits.

Photo gallery: drawings of two-volume potbelly stoves

Drawing of a two-volume heating device under development

Drawing of a potbelly stove with forced air supply

Drawing of a unit for working on engine oil

The diagrams and drawings that are presented to your attention allow you to determine the amount of material required and understand the design features. If for some reason the dimensions of the potbelly stove do not suit you, then they can be changed in any direction, observing the basic ratios. By the way, it is not necessary to make a device with cylindrical tanks. If you make the containers rectangular, then you can save time and effort when cutting out the parts of the stove with a grinder. Nevertheless, let us warn those who immediately jumped at this idea. The fact is that corners are places where combustion products accumulate, so cleaning such a stove will be much more difficult.

Types of garage stoves

You can find gas and electric appliances on sale; they are effective, but expensive and require regular refueling and careful handling. The most popular options use the energy of combustion of wood, diesel fuel or waste oil.

From a gas cylinder or pipe

The option is attractive due to its ease of manufacture. Located vertically, these ovens are very compact. A gas cylinder can be found at a landfill or metal collection point, after which it can easily be converted into a stove.

The design of the furnace can be vertical or horizontal. The first option is more compact, in the second case it is more convenient to stack long firewood. The wall thickness is at least 3 mm, preferably 5–6 mm.

The chimney should also not be too thin. Such a stove will serve for a very long time, and it can be heated with wood waste, chipboard, sawdust, pellets, and coal.

You can use a system of two barrels located one inside the other, the gap between them is filled with pebbles or sand. The structure takes longer to heat up, but it emits even heat and does not cool down for a long time. In general, there is no standard for making a conventional wood stove.

The main thing is to follow simple rules: use a thick steel wall, a firebox and ash pan, grates to improve combustion and an exhaust pipe with a diameter of at least 10 centimeters.

Advantages of wood stoves:

- ease of operation;

- low cost of the device itself and fuel for it;

- installed without a foundation in any suitable place;

- high efficiency and very fast heating of the garage;

- can be used for cooking.

Wood burning design

In order not to frequently throw firewood into the firebox, stoves with limited access of air to the combustion zone were invented; such devices can operate for up to 12 hours on one refill. The same gas cylinder is used as the body.

Photo 1. A homemade wood-burning stove in the garage, which is convenient for heating dishes, such as a kettle.

Combustion occurs from top to bottom under the influence of the load, resulting in the combustion of the firewood itself and the pyrolysis gases formed during heating. The efficiency of such a stove is high, and the wood in it burns with virtually no residue.

Oil burner and diesel heaters

The idea of using old motor oil led to the development of a device capable of burning it, releasing a large amount of heat.

The lower container of the device serves as a reservoir for fuel, and the main combustion process occurs in the upper half, so its wall thickness should be higher. The heating temperature can reach 850–900 °C.

Photo 2. Oil stove in the garage. The device is small in size, with good heat transfer properties and no soot.

Advantages of using mining:

- fuel availability;

- absence of smoke and soot during the combustion process;

- safety and environmental friendliness, only oil vapors burn;

- compactness;

- good heat dissipation.

Important! The chimney must be up to 4 meters high to ensure good draft and stable operation. The design of a diesel fuel furnace is similar to a unit operating in mining. The design of the diesel fuel furnace is similar to the unit operating in mining

The design of a diesel fuel furnace is similar to a unit operating in mining.

To increase efficiency, simple nozzles at the bottom of the burner can be used.

Such furnaces are used:

- diesel or heating oil;

- fuel oil;

- kerosene;

- transformer, machine oil.

Advantages and disadvantages of a potbelly stove

There are different models of these heating devices, but they all have certain advantages:

- quickly melt and warm up the room;

- fairly high efficiency;

- heat spreads throughout the room evenly;

- can be purchased at a relatively low cost;

- most of these products have a hob;

- Costs less to operate than using electric appliances or wood stoves.

All models also have common disadvantages:

- the room is warm only when the stove is heated;

- fuel must be added constantly;

- Requires a tall chimney that needs to be cleaned frequently.

Operating principle of the device

Fuel combustion in a potbelly stove during processing occurs in two main stages. Initially, the poured oil burns in the tank, after which the gases are mixed with air, enter the second chamber, where they are burned and ensure the maximum possible efficiency of heating the room. At the same time, fuel consumption is significantly reduced, and the need to constantly refuel the unit disappears.

A properly assembled oil stove will consist of two separate compartments. The first chamber is a small tank into which used oil is poured. Fuel combustion occurs at a relatively low temperature. There is an afterburning chamber on top, where the resulting gas mixes with air and burns at a temperature of about 800 degrees. The metal walls of the potbelly stove become hot, and the thick metal effectively retains heat, quickly heating a small room.

In this video you will learn useful information in making a potbelly stove:

Advantages and disadvantages of a potbelly stove

There are different models of these heating devices, but they all have certain advantages:

- quickly melt and warm up the room;

- fairly high efficiency;

- heat spreads throughout the room evenly;

- can be purchased at a relatively low cost;

- most of these products have a hob;

- Costs less to operate than using electric appliances or wood stoves.

All models also have common disadvantages:

- the room is warm only when the stove is heated;

- fuel must be added constantly;

- Requires a tall chimney that needs to be cleaned frequently.

How to make a potbelly stove from steel

Potbelly stove of convection type.

If you need to heat a house in the country and cook food, you should definitely know how to weld a potbelly stove yourself from sheet steel. This design will not require a lot of fuel. This is achieved through the installation of partitions in the firebox, reliable fastening of the doors and the ability to adjust the air flow. To make such a device with your own hands, you will need to prepare the following elements:

- sheet metal 4 mm thick or more;

- metal 8-12 mm thick, from which the partitions will be made;

- lattice;

- chimney pipe;

- corners from which the legs will be constructed;

- welding device.

Sequence of manufacturing actions

From the steel sheet, the first thing you need to do is cut out elements for the body and several partitions that will be mounted in the upper part of the firebox. They will be able to create a labyrinth for the smoke, which will increase the efficiency of the stove. In the upper part you can make a recess for the chimney structure. The recommended recess diameter is 100 mm. Next, you will need to make a recess for the hob with a diameter of 140 mm.

Potbelly stove made of sheet steel.

Using a welding device, you need to attach the side elements to the bottom of the structure. You will need to attach thick strips of metal to the side walls. As a result, it will be possible to attach the grate. This can be a sheet of metal with recesses with a diameter of about 20 mm. The lattice can be made of reinforcing bars. At the next stage, you need to attach supporting elements from a metal strip to the side walls. After this, the partitions are installed.

Doors for the firebox and ash pan should be cut out of metal. They can be installed on ordinary hinges. However, a more reliable option is to use curtains made of steel pipes and rods. They can be secured to wedge latches. The elements are cut out of a stainless steel sheet and then secured with bolts. In order to be able to adjust the intensity of fuel combustion, a recess must be made on the door that closes the ash pan for mounting the damper.

A sleeve 200 mm high must be attached to the recess for the chimney structure, on which the pipe will be mounted. A damper in the tube will help retain heat. For it you will need to cut a circle from a metal sheet. One extreme part of the steel rod needs to be bent. After this, you will need to make several parallel holes in the tube. Next, the rod is mounted, after which a round damper is welded to it.

Diagram of a brick fence for a potbelly stove.

The chimney pipe should be installed at an angle of 45°. If it passes through a recess in the wall, the part must be wrapped in fiberglass in this place, and then secured with a cement mixture.

To prevent burns from touching a hot stove, you will need to build a steel protection screen on several sides and place it at a distance of 50 mm. If there is a desire to increase the thermal efficiency coefficient, the structure can be covered with brick. After the firebox is finished, the brick will continue to heat the house for some time. The laying should be done at a distance of 12 cm from the metal body.

A pillow of air can act as a heat protector.

To implement it, holes for ventilation must be made in the masonry at the top and bottom.

Long burning stoves

The cylinder is used to create not only ordinary potbelly stoves, but also long-burning stoves. Today there are several ways to create such heaters. Bubafonya stoves are especially popular. The design has many advantages, among which it is worth highlighting:

- simple design;

- high efficiency;

- the ability to use various types of solid fuel.

If desired, the stove can be connected to a water heating system. The only drawback is the difficulty of maintenance. To get the ash, you need to turn the case over.

Ready-made long-burning boilers

Design

Furnaces of this type use top combustion. Thus, the wood burns from above and the flame spreads downwards. The principle of operation is explained very simply. The flame comes on slowly, but this does not reduce the heating efficiency. Within a few minutes after starting, the oven will begin to release a sufficient amount of thermal energy.

Often a vertical round furnace is made, which makes it possible to use a gas cylinder or barrel as a workpiece. The design has only a bottom

The secret of the furnace lies in the presence of an important element - the load. This is what ensures air circulation

The firebox has a simple design

The load is presented in the form of a circle with a pipe, which is welded in the center below. Corners or channels are welded from below along the radius. The structure is covered with a lid in which there is a hole for a load pipe. The chimney is installed on the wall closer to the top.

How does the stove work?

The body is filled with fuel and set on fire. A lid is placed on the pipe. When the wood is burning, install the lid. The pipe provides the air needed to maintain combustion.

The weight circle has a slightly smaller diameter than the furnace body. This ensures the movement of combustion products, which generate a lot of heat. To ensure sufficient air flow, the lid must be leak-proof.

The efficiency of the stove is ensured by the ignition of gases, which provide heat no less than firewood. Exhaust gases are discharged through the chimney. When the wood burns out, a new stack is carried out. After combustion, a small amount of ash remains, which must be removed after several deposits.

The operating principle is based on the movement of gases

Manufacturing

The oven is manufactured in the following sequence:

Rinse the container and cut off the top part. It will be used as a lid. Therefore, cut off a few centimeters from the walls. File the cut areas.

It is important to wash the bottle thoroughly

- Remove the valve and adjust the hole. A pipe will pass through it. Weld a metal strip around the perimeter of the lid, which will ensure reliable fastening to the stove.

- Cut a circle from a metal sheet, the diameter of which will be slightly smaller than the diameter of the cylinder. File the edges.

The balloon is cut very carefully

- Weld a pipe to the circle and make a hole. Secure the corners that will not reach the edge. The welding must be well done. This will determine how efficiently the air in the furnace chamber will flow.

- Cut a hole on the top of the body and secure the iron chimney. Check the seam for tightness.

At the final stage, handles are welded to the body and lid. All that remains is to assemble the structure and test it in operation.

The valve is removed as the pipe will pass through it

Improvements

We are talking about the introduction of modern techniques that ensure ease of use and maintenance of the structure. The main disadvantage is that for cleaning you need to turn the structure over. Therefore, an ash pan and grates are additionally made. The door must be airtight to prevent unnecessary suction.

The improvement also affected the corners that are welded to the load. It is recommended to use curved strips instead. Thanks to this shape and quantity (6-8 pcs.), uniform air distribution is ensured.

Modern models of fireboxes are somewhat improved

Useful tips

A potbelly stove will be easy to use if you listen to the recommendations of experts:

- To check the quality of welded joints, the first ignition is carried out outdoors.

- To ensure tightness, the chimney running inside the garage is made from an all-welded pipe without horizontal sections.

- There should be a box of sand and a fire extinguisher next to the stove.

- The places where the chimney pipe passes through the wall or ceiling are insulated with fireproof material.

- A brick screen lined on 3 sides of the stove will protect against accidental burns and retain heat after the fuel burns out. The distance from it to the walls of the potbelly stove should be 5 - 7 cm.

Despite its simple design, a potbelly stove is considered the most reliable and cheapest way to heat a garage. Even garbage can be burned in such a stove. When choosing, it should be taken into account that horizontal structures last longer than vertical ones.

Installation recommendations

Self-installation of a stove in a garage must be carried out according to certain rules. Firstly, you need to ensure the operation of the heater, and secondly, take fire safety measures. As for the first point, it concerns the correct installation of the chimney, which must create normal draft. Here are the recommendations:

- pipe height - at least 4 m, counting from the grate;

- turns - no more than 3, avoid setting knees at 90º, try to use 45 or 30º;

- if there is a horizontal section, then its length is no more than 1 m;

- It is better to insulate the section of the pipe on the street with basalt wool to prevent the formation of condensation;

- Attach the chimney to the wall so that it does not load the body of the stove.

When installing a wood or oil stove yourself, follow fire safety requirements. Here is their list:

- Place a sheet of metal on the floors under the stove, protruding 1 m from the side of the door;

- combustible wall structures near the stove must be protected with metal or brick screens;

- when passing a wooden ceiling through the chimney, ensure a gap of 250 mm between it and the pipe, filling it with basalt fiber;

- in order to protect the flue from being blown in by the wind, install a deflector or a special nozzle on it;

- Natural supply and exhaust ventilation must function in the garage.

Case manufacturing

I will make a stove from this cylinder

I used a used cylinder. There was no more gas in it, but just in case, I opened the valve and left the cylinder outside overnight.

Then I carefully and slowly drilled a hole into the bottom of the cylinder. To prevent sparks from appearing, I pre-moistened the drill with oil

Hole

Then I filled the bottle with water and drained it - this removed the remaining gas. Work carefully, try not to spill gas condensate, as... It stinks very strongly and for a very long time.

Then I cut out a couple of openings. In the upper opening I will make a combustion chamber and install a heat exchanger, in the lower opening there will be a burner with a tray. The chamber at the top is specially made so large that, if necessary, it can be heated with wood, pressed briquettes, etc.

Shown how I cut a balloon Shown how I cut a balloon Shown how I cut a balloon Shown how I cut a balloon In the end, this is what happened

Then I once again washed the opened gas cylinder from gas condensate.

Secrets of successful operation of a potbelly stove

In order for a potbelly stove running on waste oil to be effective and safe, you need to follow a few tips. The oil must settle before use. You need to fill it into the oil tank to 2/3 of its volume.

For safety reasons, all elements of the stove should be cleaned regularly. To simplify this task, its top module should be removable. This will provide access to the chamber where the combustion of the mixture occurs. To remove soot from the walls of the chimney, it should be tapped.

To extend the service life of the combustion chamber and the furnace as a whole, it must be painted using paints that are resistant to high temperatures. The potbelly stove should be installed on a non-combustible base. Do not place it in a draft, under the influence of which a flame could escape.

Warm brick

A potbelly stove using wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to build a screen of baked clay bricks around it with your own hands. If you look carefully at the drawings of such a mini-building, you will see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and, if desired, around the chimney.

Bricks require a foundation. Do you want the masonry to last a long time? Then fill the base one at a time to form a monolith. It is better to take concrete as the material for the foundation, which should be reinforced with steel reinforcement yourself. It is advisable to place the reinforcement layer at a distance of approximately 5 cm from the surface of the concrete pad.

Ventilation holes are made at the bottom and top of the brickwork, which will ensure air movement (heated masses will go up, cold air flows will come from below). Ventilation also prolongs the life of the metal walls of the potbelly stove, delaying the moment of their burning due to cooling by circulating air.

Bricks laid around the stove accumulate heat and then release it for a long time, warming the air in the room even after the stove goes out. In addition, brickwork additionally protects objects surrounding the stove from fire.

If desired, you can completely lay out the stove from brick. Such a structure is advantageous in that it will last for many years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite labor-intensive and is suitable only for those people who have experience in masonry with their own hands;

- a brick stove is quite expensive, as it requires the use of fireproof materials, including fireclay bricks and special clay for mortar.

In order to get a small potbelly stove with wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber, rows 2-4 are laid out of fireclay bricks. An ordinary fired clay brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or potbelly fireplace with your own hands, whether you make them according to a drawing or by eye, the main thing is that at the end you get an effective heating device, and in an expanded configuration also a hob for cooking. Look around for suitable materials (barrels, sheet iron, etc.) and go ahead to your own homemade stove or even a potbelly stove!

How to make a wood splitter with your own hands? How to install a sandwich chimney with your own hands It’s not difficult to build a chimney for a boiler with your own hands Do-it-yourself metal stove How to make a smokehouse yourself at home or in the country

Potbelly stove plus water circuit

Any home could benefit from having an emergency heat source. Its role can be played by an ordinary, but slightly modernized, potbelly stove. You can improve the stove in two ways - put a water jacket on the burner pipe or wrap its body with a coil of copper tubes.

The coil turns are placed at a distance of about 5 cm from the perforated body of the potbelly stove and connected to the general heating system. A reflective screen is installed around the coil. For its manufacture, sheet aluminum, galvanized steel, and tin are used.

The water jacket is a tank on the upper chamber of the potbelly stove. There should be 2 fittings in its body - one for water supply and the other for drainage. In general, the design resembles a samovar. The volume of the water jacket depends on the length of the heating system and the method of circulation of the coolant.

If a pump is built into the system, the volume of the tank is small, but with natural circulation it has impressive dimensions. To control water parameters, a pressure gauge and thermometer are installed on the tank.

How to make a drip stove from a balloon

As a rule, an exhaust stove with a drip supply of oil into the bowl is made from a pipe with a diameter of 200 mm or an old propane gas cylinder. The latter is better to take the Soviet model, where the wall thickness is up to 5 mm.

When making a firebox from a pipe, you will have to make and weld a bottom and a lid to it. In this regard, a gas cylinder is more convenient: you need to unscrew the valve, fill it with water and cut off the upper part with a grinder. After this, follow the instructions:

- Make holes in the housing for the chimney and in the lid for mounting the afterburner. An inspection opening can be cut in the lower part of the cylinder, closed with a bolted lid, as shown in the drawing.

- Make an afterburner pipe by drilling holes according to the drawing. Use a cutting wheel to make 9 grooves at the bottom end.

- Make a steel bowl, possibly from a car brake disc, as shown in the photo. Place it on the bottom of the firebox, lifting it 3-5 cm.

- Replace the afterburner and put on the cylinder cap. Insert the oil line into the pipe so that its end is above the bowl.

- Make a fuel tank with a fitting (for example, from a heating expansion tank) and hang it on the wall near the stove. All that remains is to connect the chimney and you can start igniting.

If you want to make an exhaust furnace with a water circuit, then place a coil made of a thick-walled tube inside the firebox, preferably stainless steel. Place it in the upper zone, and lead the ends of the tubes out through the holes in the walls. Then they can be connected to the garage water heating batteries, as shown in the photo.

Details about the design of a drip furnace using waste oil, made with your own hands from a gas cylinder, are described in the following video:

Types of garage stoves

To make a stove-stove for a garage with your own hands, first of all you need to familiarize yourself with the possible models. The most popular types of garage stoves are brick and iron stoves. Heating devices made from improvised means are not inferior to them - from a barrel, a gas cylinder, etc. Stoves are also divided depending on the fuel used - wood, coal, waste oil, etc.

Potbelly stoves “in service” are often found in the garage, because every car enthusiast always has unnecessary engine oil in large quantities. This oven does not emit unpleasant odors or harmful fumes. A potbelly stove using waste oil can quickly heat a small garage space. In terms of its power, it can be compared to an electric heater. This potbelly stove is suitable for those who do not want to spend extra time cleaning the ash pan, ventilating, etc. After all, during operation of the furnace, the oil completely burns out, and the likelihood of an explosion or ignition is practically eliminated.

A potbelly stove using waste oil is a popular model among garage workers. Often its installation is due to the fact that car enthusiasts always have used engine oil on hand.

You can heat a wood-burning stove with purchased wood or regular firewood. The efficiency level of such a potbelly stove is quite high. If you don’t have wood on hand, you can also use charcoal.

Potbelly stove in the garage using wood. You can use small ready-made bars, fallen branches and trees, and charcoal as fuel.

Select a drawing

Drawing of the most efficient potbelly stove using waste oil.

Let's look at the details - before us is a stove consisting of three main parts. Part one, the lowest, is a container with a small hole for pouring fuel and ignition. This container plays two roles - it acts as a tank and works as the primary combustion chamber. The container lid also serves as a kind of combustion intensity regulator.

The next part is a tube with holes that is welded to the lower container. The holes are used to take in secondary air. It mixes with the evaporating waste, resulting in the formation of a combustible mixture that burns to form a high-temperature flame. When the potbelly stove warms up and reaches operating mode, the pipe will literally hum under the pressure of the fire. The final combustion occurs in the upper chamber.

The upper chamber of our potbelly stove is round. But nothing prevents you from making it rectangular (like the bottom one). By increasing the area of the upper surface, you can create a kind of hob so that you can boil a kettle and warm up with a cup of warm drink. In the upper part of the second chamber of the potbelly stove we see a small pipe - it serves to connect the chimney. That's the whole scheme - simple and unpretentious.

Do-it-yourself potbelly stove for a bath

These days, saunas and steam baths are very popular. They have been worn for a long time to receive complete healing and cleansing. And we all know that the heart of any bathhouse is a stove, the operation of which determines the quality of procedures, temperature conditions, steam intensity and air humidity.

A potbelly stove can be considered the simplest and cheapest type of household stove. It is quite possible to make it yourself. They are made with closed and open heaters, round and square in shape, located both horizontally and vertically.

To make a potbelly stove for a bath you will need:

- Sheet steel from 8mm thick;

- Pipe, diameter 50cm, wall thickness 1cm;

- Grate bars;

- Rod, 10mm thick;

- Chimney pipe;

- Bulgarian;

- Welding machine.

We cut a hole in the pipe for the ash pan within 20x5 cm. We weld a mount for the grate on the inside of the pipe, install the firebox door and make rods for the heater. On the other hand, we cut a hole in the heater for water. You need to cut out a cover from a metal sheet in which you make a hole for the chimney pipe. Then you need to weld it to the heater. The oven is ready. Experts recommend adding a tank for heating water.