Our life never stops. Technical developments that were considered new yesterday are now becoming obsolete. Heating systems are no exception. Designs with liquid coolant, once considered the only option, have long no longer satisfied the demanding consumer.

They are being replaced by many promising developments. One of them is the PLEN heating system, which has proven to be an effective way to heat a home. But what is its peculiarity and can it justify the money spent on installing film heating?

Let's look at these issues together - in our article we looked at the design of the system, its pros and cons. We also paid attention to the issue of the benefits and harms of infrared heating and separately focused on the effectiveness of PLEN in domestic conditions.

General information about PLEN

PLEN – film radiant electric heater. In it, electrical energy is converted into infrared radiation, which heats the floor and, from it, the room. The system itself is multilayer, where there are non-conducting polymer films and resistors connected to each other.

This film is usually sold in rolls

When electrical energy passes through the resistors, they heat up and transfer heat to a highly conductive surface. It then transmits the received and converted thermal energy into infrared waves with a length of 9 to 12 microns. These rays heat another surface, which warms the room.

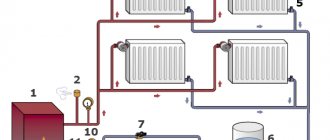

Connection diagram for film electric heater

The film electric heater operates from a 220 V, 50 Hz power supply. Connection – parallel . Connection of heaters with two terminals is made according to a two-wire circuit : Phase L, Zero N. See fig. for the wiring diagram. below.

Connection of a film electric heater with 3 or more terminals is also carried out using a two-wire circuit, but taking into account the factory marking of the terminals : Phase L, Zero N, fig. below.

If the heater has a ground (for example, ZEBRA EVO-300), then the connection is made in parallel using a three-wire circuit : Phase L, Zero N, ground PE.

Heating PLEN

What is this

Today, consumers place a fairly wide range of requirements on heating systems: reliability and long service life, efficiency combined with high heat transfer, and compliance with all safety requirements.

Until now, there has been no system that meets all these requirements, and users have always been faced with a choice between heating that meets some characteristics and completely unsatisfactory consumer needs in other respects.

But not so long ago, an alternative appeared in the form of Plen systems operating through infrared radiation. But today they simultaneously meet absolutely all the parameters of an “ideal” heating system.

Principle of operation

The principle of operation of electric heaters of a film-radiant design lies in the features of infrared radiation. Due to the fact that it is invisible to the human eye, and is capable of being reflected, scattered and absorbed by materials, passing through them in the conditions of an ordinary home, it will spread through the air over the entire area of the room practically without loss, reaching all objects, being absorbed by them and giving them thermal energy. energy.

It must be understood that after the radiation is absorbed by objects, they themselves will become a source of secondary radiation. Its intensity is mainly determined by the molecular structure of the material from which the object is made and its temperature.

A film radiant electric heater consists of a pair of very thin film sheets, between which a resistive-type heat-emitting element is placed. Many such elements form a heating system, when turned on in the electrical network, the resistors heat up to 45-50 degrees Celsius and begin to emit radiation in the infrared range, which, due to its characteristics, disperses equally well throughout the entire area of the room, gradually being absorbed and heating the objects in it and even a person .

Under normal conditions, it takes several hours to warm up the room, after which, when a comfortable temperature in the room is reached, the system begins to operate in energy saving mode, turning on for 3-15 minutes only to maintain it.

Precautions during operation

Some people get injured due to ignorance of installation basics or neglect of the rules. Unfortunately, safety rules are rarely included in product boxes, and here are the main ones:

- Start working when the temperature is above +5 degrees Celsius.

- Do not connect rolled film to the network under any circumstances!

- When installing a heated floor, turn off the power while the work is being done.

- Be extremely careful to ensure that no moisture gets on the film.

- Do not allow the film to come into contact with electrical appliances and communications.

Of course, it is possible to install a heated floor system yourself, but it will be safer if the work is performed by a qualified installer.

Advantages and disadvantages of the PLEN heating system

The following list shows the advantages, features and some important parameters of quality systems in this category:

- The conversion of electricity into heat is carried out efficiently, without unnecessary losses. Efficiency reaches 90-95%, which is 15-20% better than standard oil heaters.

- The temperature of the external surfaces of PLEN heating films does not exceed +50°C. This means that no additional measures are required to comply with the most stringent fire safety regulations.

- It is acceptable to place the PLEN film heater close to wooden and plastic parts. This simplifies installation and selection of suitable structural elements and finishing materials.

- At this temperature, mechanical particles contained in the room atmosphere do not burn.

- Convection flows are minimal for any placement of the PLEN heating system. This prevents the movement of dust, contamination of premises, and the occurrence of allergic reactions.

- The small thickness of the film means economical use of free space.

- IR emitters of this type are hidden behind decorative panels and functional coatings. They do not have any impact on the aesthetics of the interior.

- To connect such a heating system, you do not need proximity to a main gas pipeline.

- Laying cable routes is cheaper than installing pipes. Working operations are simplified by the low weight and high strength of film structures.

- Ceiling infrared heating performs its functions without chimneys, circulation pumps, boilers and boilers.

- Film emitters provide fast heating and operate completely silently.

- Their minimal inertia, together with the control principles, are well suited for inclusion in modern control complexes of the “smart home” category.

- With appropriate equipment, it is not difficult to maintain the temperature in individual rooms with high accuracy (±1-1.5°C).

- Good protection from external influences combined with gentle temperature conditions ensure a long service life. Modern models retain good consumer characteristics for 50 years or more.

“Pros” of PLEN: simple installation, inexpensive components, rational distribution of air temperature

As reviews indicate, a film heater really has many advantages. However, for an objective analysis it is necessary to consider the “cons” that are mentioned by the owners and some specialists in the field.

The heating area is limited by the direction of radiation. Outside the corresponding zones, the air temperature is noticeably lower. To maintain uniform temperature in the room, it is necessary to cover large areas with film emitters.

Despite the high efficiency and relatively low consumption per 1 sq. m. PLEN will have to take into account significant operating costs. The cost of heating using electricity is higher these days compared to gas. To connect, you will need a power source of appropriate power.

You can save additional money if you install a simple “potbelly stove” and engage in illegal logging

A serious analysis will help more accurately estimate the real costs when comparing PLEN with alternative heating systems. You can do it yourself, taking into account individual needs and operating conditions. Please pay attention to the following nuances:

- To use liquid heating systems, you need to purchase and install radiators, pipes, shut-off devices, a boiler, and other components.

- When using such equipment, it is necessary to provide reliable protection against freezing and prevent the formation of scale.

- To store relatively inexpensive solid fuel, you will need a warehouse. Handling it is accompanied by additional labor costs.

For your information! Some comments cite the following “disadvantage”: mandatory insulation of premises in accordance with the standards of current SNiP. But in fact, such measures are necessary when equipping any heating system. They increase the energy efficiency of the facility.

Efficient operation of film heating

The manufacturer claims that its products will work economically and efficiently. However, you need to understand that this is only true for certain conditions.

If, for example, the building is not insulated, it is at least pointless to expect effective operation from the PLEN film heating system. What requirements must be met to get the most out of infrared equipment?

One of the main ones is thorough thermal insulation of walls, doors and windows in the building. If everything is clear with the latter, then there are some nuances regarding the thermal insulation of walls.

Wall insulation should be done from the outside. For this, various materials can be used: thermal insulation followed by plastering, sandwich panels, etc. To get acquainted with the types of insulation for the walls of a house outside, follow this link.

If you insulate the walls from the inside, infrared heating will be useless.

For the most efficient operation of infrared heating, it is important that the walls of the building are insulated from the outside. Walls insulated from the inside will not be able to accumulate heat.

Walls covered with heat-insulating material will not accumulate or release heat, since the insulator will prevent this. To install an effective heating system, it is not necessary to completely cover the floor or ceiling with infrared film.

If it is assumed that such heating will be the main one, it is enough to cover 70-80% of the area of the ceiling or floor surface.

To arrange additional heating, it will be quite enough to cover 30-40% of the area. It is important to choose the correct mounting height for the thermostat. For the ceiling installation of the film, it should be at a height of about 1.7 m from the floor level.

For floor installation, it is raised 10-15 cm above the floor. If you make a mistake with the mounting height of the device, the system will not work correctly.

Another important point is to ensure sufficient current power for the full functioning of the system. This must be done, otherwise the efficiency of the plan will decrease significantly. To solve the problem, it will be enough to install a special load distribution unit.

The device allows you to alternately turn on different circuits of the heating system, thereby increasing the power supplied to each of them.

The figure shows the installation diagram of film heaters

The film heater should be installed only on a special substrate. It has reflective properties and does not allow the base on which the film is laid to absorb infrared radiation.

It is redirected in the opposite direction, which ensures the most efficient operation of the equipment. Without such a substrate, some of the infrared waves are absorbed by the base, which leads to unnecessary energy losses.

Installation of infrared film heaters must be carried out only on a special substrate, otherwise heat loss is inevitable

Another important point is the height of the heated room if the system is mounted on the ceiling. Standard models of film emitters are designed so that the infrared wave will travel a distance of no more than 3.5 m.

If it is larger, the radiation does not reach the floor. And, accordingly, the system will not work correctly.

Thus, if the room has high ceilings, you need to choose a floor mounting option or look for more powerful non-standard models of film heaters.

Scope of application of the PLEN heating system

The use of high-quality infrared emitters is harmless to human health, pets, and plants. It does not damage decorative coatings and functional parts of building structures. The absence of significant restrictions predetermines a wide scope of application.

We recommend: How to choose a hot water boiler (for heating)

PLEN heating is used to equip apartments and cottages, offices and kindergartens, public and industrial facilities. When installed in warehouses and other large premises, the emitters can be mounted only above workstations, in aisles. Rational placement of equipment will help create comfortable conditions without unnecessary installation and operating costs.

Taking into account good protection from adverse external influences, it is permissible to use PLEN heating in a wide range of humidity and temperatures. The exact boundaries are set in the manufacturer's accompanying documentation.

Important! When developing a system, official recommendations on the operating parameters of thermostats and other components should be taken into account. The required degree of security is checked taking into account IP classification standards.

The specially designed switch performs its functions reliably even in open spaces

Recommendations when choosing a system

For ease of installation, films are available in different lengths and widths. The length varies from 1 to 5 meters , and the width is 35-65 cm .

The films are installed on approximately 80% of the ceiling surface. The area of the occupied floor depends on the amount of furniture. It is not advisable to install a heating system under upholstered and cabinet furniture, since natural heat exchange with the air will not occur.

also affect the efficiency of film heaters . If your home is located in a windy climate, you should choose a more powerful heating system, since heat loss will be significant in this case.

Important! Before installing the PLEN system, take care of the thermal insulation of the room. All surfaces should be insulated - floor, ceiling, walls, insulate windows and doors, and in a private house - the roof and basement. Otherwise, the operation of the PLEN will be associated with high energy costs.

Main technical characteristics of PLEN heating

When choosing emissive films, pay attention to the following parameters:

- Power supply. As a rule, these products are designed for connection to a standard single-phase 220 V network. Some manufacturers indicate the permissible voltage deviation range (in %), which ensures that the nominal technical characteristics are maintained.

- The maximum current consumption will help you select the correct residual current devices for individual electrical circuits.

- Radiation flux density is indicated in W per 1 square meter. This value determines the efficiency of the device and allows you to correctly assess the capabilities of the heating system to heat a particular room.

- The power of one element is useful for calculating total consumption.

- The temperature on the surfaces of modern models does not exceed +45°C.

- Dimensions are needed to calculate the required number of PLEN heaters.

- The minimum thickness of a typical PLEN (approximately 0.3 mm) can be neglected when developing a project.

Some manufacturers offer thermostats and GSM units as a set or separately for creating a heating system. The parameters of these products are checked taking into account individual needs. If necessary, purchase analogues of other brands with better performance.

Recommendations for using infrared heating films

The main feature of such heating is the absence of energy losses during transportation from the source to the radiating surface. This film can be laid on any surface, including floors, walls or ceilings. In the latter case, it occupies approximately 2/3 of the total area, which allows for good heating uniformity. If desired, the film can be further decorated. It is important to remember that combining panel heaters with a stretch fabric or PVC ceiling is prohibited. It is recommended to build a plasterboard platform on top of the device. When using decorative finishing, you should avoid the presence of metal elements in it.

The main advantages of heating films are:

- Lack of communication wiring.

- The infrared panel heater is powered from the household network, without the need for an additional boiler and pipeline.

- The system will not freeze if idle at sub-zero temperatures.

- The heating film is very mobile: it can be removed at any time and attached to another place.

- The operation of such a system is very simple, and special maintenance is not required.

- The operation of the film is not accompanied by noise or combustion products.

- The circuit tolerates voltage surges well.

- If all rules are followed, infrared film can last at least 20 years.

The disadvantages of film heating usually include significant energy consumption, so it cannot be called economical.

Types of PLEN systems according to the method of placing heaters

In fact, film IR heaters can be installed on any more or less flat, straight surface. But most often they are placed on the ceiling or under the floor covering. Wall mounting is an extremely ineffective solution and can only be dictated by the technical need to heat a specific location. The same elements, methods of fastening and connecting them are used for both the floor and the ceiling.

Ceiling systems

When PLEN panels are placed on the ceiling, the IR radiation will be directed straight down. Thus, the main absorption area will be on the floor, which will act as the main element that accumulates and then releases heat. In accordance with the law of convective heat exchange, the air heated by the floor surface will rise upward. At the same time, the temperature at a height of 1.5 m will be 1.5÷2°C lower than on the floor surface. This temperature distribution is considered optimal from a medical point of view. An additional advantage of ceiling placement is the ability to install any type of decorative covering: plasterboard, lining or suspended ceilings, provided they are placed at some distance from the heating element.

Complete heating of the attic space using infrared film PLEN systems installed both on the ceiling and on the walls

For film placed on the ceiling, the risk of mechanical damage is significantly reduced. However, if ceiling infrared heating is located in an apartment in a multi-storey building, you should take care of reliable waterproofing as protection against flooding by neighbors above. There are also certain technical limitations; installing film IR heaters is not economically feasible if the ceiling height in the room exceeds 3.5 m.

Floor systems

Almost any materials can be used as flooring: laminate, parquet, carpet, some types of linoleum. When choosing them, you should pay attention to the mark. After switching on, IR radiation is absorbed by the flooring material, which, after heating, transfers heat to interior items. In fact, regardless of the installation location of the heating elements, the heating of the room is carried out by convection. The main advantage of the floor arrangement is the lack of exposure to infrared rays on residents and household appliances.

Warm floors are completely safe and can be used in rooms with moderate humidity

Important! Neither manufacturers of household appliances nor laboratories testing them have provided convincing evidence of the negative impact of infrared radiation on modern consumer electronic devices. However, many users are confident that IR waves are the reason for the rapid failure of household equipment.

The resistance to mechanical stress and humidity of some brands of PLEN panels is high enough for them to be used for heating the soil of greenhouses

Selection of equipment and materials

The infrared floor is connected according to the following scheme:

- preparation of the base;

- fastening of insulating material;

- laying film/mats;

- installation of protective material;

- flooring (with or without screed).

How to lay infrared heated floors depends on the type of heating system. There are film and rod structures. The basis of the former is a heating carbon or bimetallic element that supplies IR rays and anions to the room. It is protected from external influences on both sides by additional layers. The material is produced in rolls of a certain width and length. Heated infrared film floors can be installed in the shortest possible time. Of all heating systems, it is the most economical in terms of size and floor load. By the way, the film can also be used for walls with ceilings.

The basis of the rod structures are flexible carbon rods connected by wire. They come in the form of mats that look a bit like a rope ladder. Installation of an infrared floor of this type can be carried out either with or without a finishing screed. The advantages of rod systems are the ability to self-regulate and the ability to install in high humidity areas. That is, the film cannot be placed in areas where heavy objects will stand, or in the bathroom, but mats can.

In both cases, the installation of infrared heated floors is carried out according to the above scheme. Damage to the coating is also eliminated in the same way: by replacing the problem area (strip or mat). Rod systems are much more expensive than film systems. Their energy consumption is approximately comparable, and directly depends on the quality of the thermostat and temperature sensor.

Thermostat

The connection diagram for an infrared heated floor through a thermostat is classic. There is an option to activate the heating elements directly through the network by connecting to the panel, but such a solution can hardly be called practical. Firstly, you have to turn the system on/off every time, which in itself is inconvenient. Secondly, manual control leads to unnecessary energy consumption.

Connecting an infrared heated floor to a thermostat is not that expensive, so such a device is almost always installed. Using temperature sensors, the thermostat automatically turns off or activates the system. The regulator can be:

- electromechanical;

- electronic;

- programmable.

If you need to decide how to connect an infrared heated floor to a programmable controller, it makes sense to seek help from specialists. These are expensive and complex devices that are very sensitive to any error. Such a device is capable of controlling the system according to a given program. Such models help to use energy most efficiently.

If the installation of infrared heated floors is carried out in a technical room, bathroom or on a balcony, a cheap and reliable electromechanical regulator is quite suitable. Electronic thermostats are the “golden mean” in terms of cost and functionality, therefore they are always in stable demand. Thermostats are usually installed on the wall, at a height of 1.0-1.5 m. The power of the device is determined by the parameters of the heating system. It is recommended to use a separate thermostat for each room.

Finish coating

Installation and connection of infrared heated floors must be carried out taking into account the finishing coating. This equipment can be considered universal. It is suitable for heating tiles, parquet, porcelain stoneware, laminate, as well as soft carpet and linoleum. For heating systems located in bathrooms, toilets, and kitchens, tiles are usually chosen. If you plan to install infrared heated floors yourself, then in this case it is better to lay mats. The rays they generate easily pass through the screed and dense surface material. The tiles can also be laid on film structures.

Types of infrared heating

Classic film heater

- The basic basis of the heater is film;

- Requires at least 80% ceiling coverage

- The maximum power of the film electric heater is 175 W/m²

- Heating temperature 45-50°C

New modular heating Zebra

- The basic basis of the heater is an aluminum membrane

- Ceiling coverage of at least 60% is required

- The maximum power of Zebra EVO-300 is 225 W/m²

- Heating temperature 45-50°C

Design features

- Power wires;

- Polymer dielectric film;

- Heating elements (resistor);

- Reflective screen (aluminum foil);

- Transparent field for attaching the heater;

The size of one section of the film heater varies from 1 to 5 meters in length and 0.35/0.51/0.65 in width.

View prices for film heaters

- Branch wires (phase, zero);

- Ground contact;

- Branded ZEBRA EVO-300 emblem and behind the laminated sticker indicating the working side of the heater;

- Heating elements;

- Fields for fastening;

- Cutting line.

The size of one section of the Zebra IR heater is 0.6 m long and 0.5 m wide. The modules can be connected to each other to any length.

Similarities and differences between electric heaters from foreign and domestic manufacturers

Similarities of low-temperature film electric heaters:

- radiating element – PET film;

- the operating principle is based on the Joule-Lenz law;

- main operating voltage 220 V, 50 Hz;

- scope of application – heating systems such as heated ceilings and/or heated floors;

- used in places for special purposes (wood drying, high-power heaters for heating, etc.);

- Manufacturers' warranty 10-15 years.

Differences between low-temperature film electric heaters:

- Material . The following heating elements are used: carbon (heating film TM), wire resistor (ZEBRA EVO-300), strip resistor.

- Manufacturing technology . Foreign manufacturers of film electric heaters have a fully automated production line. Domestic manufacturers use semi-automated production lines.

- Price policy . The cost of electric heaters from foreign manufacturers is 20-30% lower.

Options for production forms of PLEN heaters

Assortment of domestic manufacturer of film IR emitters

Standard products are produced with a width of approximately 0.5 m, a length from 1 to 5 m. It is not difficult to choose a set that exactly matches the size and configuration of a particular room. Please note the modification marked with an arrow. This is an autonomous film heater that can be mounted on the wall in any desired place.

In this design, PLEN becomes an element of interior decorative design

Film heaters

Film heater

Film IR heaters are devices used for general or partial heating of a room. They consist of film, foil and heating elements that produce long-wave infrared radiation. The devices also have special sensors that turn off the system when the air temperature reaches a predetermined level, and when it drops below the minimum acceptable level, the heater is activated. Thanks to this, electricity is saved - the device does not just work.

Some film heaters have thermostats with the ability to program the temperature for 24 hours. In this case, while there are no people in the room, the IR device does not turn on, and some time before the owners return, the device starts working and manages to warm up the house. However, such heaters cost significantly more than simple models.

Optimal selection criteria

Acting as an “earth-sun” model, the PLEN system, when installed in May or October, will simply maintain the thermal regime that the house was saturated with during the summer-spring period. This heater also works effectively in rooms with good thermal insulation.

We recommend: 10 best steel heating radiators - 2020 rating and tips for choosing

This saves energy, and the heating can be turned off periodically. And less time will be spent heating the resistor film - a reduction of approximately 10% of the main time costs. The heating turns off once the space has reached the desired temperature. You will need to turn it on periodically and only for 3-15 minutes.

What other types of infrared heating are there?

Ceiling infrared panels do not take up much space. They can be used in rooms with a height of more than three meters. They are distinguished by quiet operation, environmental safety and the ability to organize heating of a specific area. Panels for heating rooms are convenient to install and operate. Some cassette ceiling manufacturers complete their products with special heaters.

In addition to the significant consumption of electrical energy, ceiling heating panels have another drawback: they are not always able to maintain the overall aesthetics of the room. As for wall-mounted infrared heating panels, they are a good replacement for traditional batteries. Due to its small thickness and light weight, such heating can be installed independently.

Nuances of the installation process

It should be noted right away that the PLEN heating system is installed on foil insulation, which will not only create a thermal insulation layer, but also reflect emitted waves towards the room using foil. Therefore, the surface on which the heating film will be mounted must be covered, for example, with isolon.

Izolon must be placed under PLEN

Now, regarding the mounting of the heater itself. Everything will depend on what material it will be attached to.

- If it is wood, then the best option is metal staples and a stapler. In this case, you can use nails or wood screws.

- If it is concrete, then you will have to drill holes in it, insert plastic dowels into them, and screw screws into them through the film.

As for the principle of laying the film, first of all you need to decide in which direction the connection to the current supply will be located. The shorter the distance between the connection points, the less cables you will have to use for wiring. And this is savings.

Depending on the chosen model and size of the heater, its coverage area is determined. This indicator varies between 50÷100%, but 80% is considered optimal. A gap must be left between the film heater and the tension or suspended structures. The gap size is within 10÷15 cm. All work related to the connection is strictly carried out according to the electrical diagrams supplied with the PLEN.

Gap between PLEN and ceiling trim

Connection nuances

Depending on which voltage devices were selected, their own circuits are used:

- If films with a voltage of 220 V are selected, then they are connected to each other only in parallel.

- If 110 V devices are used with a connection to a 220 V network, then they are connected to each other in pairs. The latter are connected to each other in parallel.

- The same is with PLEN heaters with a voltage of 73 V. They are connected to each other in series, 3 pieces at a time.

That is, in any case, the output should be 220 V: 110 + 110 = 220; 73x3 = 219.

Correct connection of films to each other

Installing a thermostat

This device controls the indoor air temperature by turning the PLEN system off and on. There are three nuances to correctly installing a thermostat:

- It is embedded into the phase wire.

- The installation location is on the wall at a height of 150 cm. An important component is that the device must be installed on the internal wall, and not on the external one, which is in contact with the street. It is best to install it away from windows and doors so that the sun's rays do not fall on it.

- If the total load from the entire system exceeds 9 A, then the thermostat is connected through a special modular contactor. The latter simply reduces the load.

Attention! It is better to install the thermostat on a material with low thermal conductivity. For example, on a wooden plank that is attached to the wall.

Installing a thermostat

The essence and advantages of the method

Traditionally, wood and gas stoves, convector heaters, and water heating are used for heating greenhouses and greenhouses. All these methods require large material and physical costs for installation and maintenance.

Features of infrared heating

The infrared heating system for greenhouses differs from the traditional methods listed above in that it does not heat the air, but all objects located in the radiation field - the ground, plants, walls, etc. This radiation is similar to solar energy: heated earth and other objects emit infrared photons, which are reflected back by the walls of the greenhouse.

All other methods are aimed specifically at heating the air, the warm vapors of which rise upward, practically without warming the soil and leaving the plants cool.

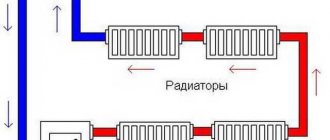

The fundamental difference between convective and infrared heating is clearly visible in the diagram

For reference. The situation can be corrected by installing water pipes buried in the ground. But the price of such a system is very high, which increases the cost of grown products, and it is quite difficult to control the soil temperature.

Infrared heating systems for greenhouses are distinguished by the fact that their radiation is directed from top to bottom and affects plants and soil, which is important for rapid germination, development and fruiting. Numerous studies have proven that, thanks to them, seed germination increases by 30-40% precisely due to warming up the soil, in which the air does not heat up so much

In addition, infrared heating for greenhouses can also be installed under a layer of soil - special films are designed for this.

Advantages of the method

The main advantage of an infrared heating system for greenhouses is its high efficiency, reaching 95%. This impressive result is explained by the fact that all the radiated heat is spent on heating the soil and plants, and not the air surrounding them.

It, in turn, warms up due to the reflected energy. Other advantages are no less significant.

This:

Significant reduction in heating costs both due to directed radiation and due to the small amount of electricity consumed.

Note. Compared to convector-type heaters and cable electric heating, infrared heating systems for greenhouses consume 40-70% less energy

- There is no need for additional air humidification, since these heaters do not dry the air.

- The operation of the system is similar to solar radiation and therefore is completely safe for both plants and people working in the greenhouse.

- The heaters do not make noise and do not glow, so they do not create any discomfort.

- Fast heating: you can raise the air temperature in the shelter to the specified parameters in a matter of minutes.

- The ability to create several zones with different temperature conditions in one greenhouse. Depending on the needs of a particular crop, you can change the power and height of the heaters above them, thereby creating the optimal temperature in the growing area.

The photo shows that the radiation extends only to the area under the heaters

- Simplicity of installation and dismantling - heaters are easy to install with your own hands or with the help of one electrician, which also allows you to save money compared to installing heating systems.

- The presence of a thermostat (see Thermostat for a greenhouse - choosing the right one) is a very important option for growing plants that require different regimes at different stages of the growing season.

- Fire safety due to the absence of open flames and heating elements.

- Mounting on walls or ceilings frees up valuable greenhouse floor space.

Saving space is especially important for small greenhouses

Procedure for installing a warm ceiling

The warm ceiling is installed in the following stages:

Laying thermal insulation

Thermal insulation is laid on the profiles in order to eliminate the possibility of heat radiation upward. To prevent the heat-insulating mats from sliding off the wings of the profiles, throughout all spans, at certain intervals, it is worth sticking safety pieces of technical tape, as shown in the following photo. In the spans the mats are laid end to end. There should be a gap between the end of the mat and the wall.

Almost the entire surface of the suspended ceiling is laid with mats.

Laying electrical wiring

The central span is laid last with heat-insulating mats. Before laying it, electrical wiring is thrown onto the thermal insulation, which will provide power to the entire warm ceiling.

There should be a “window” in the suspended ceiling in the middle of the room through which the wire of the lighting fixture hanging from the ceiling will pass. Because of this "window", the heating film laid in the central span consists of two separate sections. This must be taken into account when organizing their power supply. Therefore, the power cable with two sockets must fit into this window. The rest of it is laid along the wall.

To power the ceiling electrical wiring, the supply cable can be laid down the wall in a groove or in a cable channel. The photo shows that a hole is drilled in the wall, and the cable is pushed through it to the apartment meter.

Installation of heating film and electrical connections

During work, the heating film can be secured to the ceiling using double-sided tape. To do this, tape is pasted at certain intervals throughout the room across the profiles.

Then the protective film is removed from the double-sided tape as the work is completed and the heating film begins to be fixed. Moreover, they glue it strictly BETWEEN the profiles. If the film gets on the profile, it can easily be damaged by screws when attaching drywall, and the system will not work.

In the central span, as mentioned above, the heating film is installed in two separate panels. This allows you to create a lighting fixture for installation.

Through the formed “window”, two central panels are connected to the power supply system. All wires are laid on top of heat-insulating mats. A lighting lamp is also released into the created “window”.

Then all the power wires hanging from the wall are connected to the sockets of the electrical wiring laid on top. In this case, all wires must remain above the profiles.

Checking the integrity of the warm ceiling system

Having completed all the connections, we go into the next room where the supply wiring was terminated. Taking the wires coming from the warm ceiling, we measure the value of its resistance. If it is expressed by a specific number, we can conclude that there is no damage to the system. As you can see in the photo, the resistance is about 45 ohms. Therefore, the system is working properly.

Upon completion of work, this measurement should be repeated to once again ensure that there is no damage.

Installation of vapor barrier film

A vapor barrier film is necessary to protect the electrical system of a warm ceiling from condensing moisture. Its installation is again done using double-sided tape, which this time is glued directly to the profiles.

The film itself is attached with tape across the profiles. Moreover, all adjacent panels must overlap to ensure the necessary tightness and moisture protection.

Fixing plasterboard sheets

To lift and support drywall sheets, it is very convenient to use a sheet lifter.

We recommend: Malfunctions of the Junkers gas boiler: error codes and methods for eliminating them

The sheets held by the sheet lifter are fixed, as usual, with self-tapping screws screwed into the profile.

Having secured the drywall along the edges, it is necessary to mark the location of the remaining profiles. With additional fixation, this will prevent you from accidentally damaging the heating film with a self-tapping screw.

Connecting the thermostat and checking the integrity of the “Warm ceiling” system

The diagram for connecting the wires to the thermostat is shown on the back of the device.

The wires coming from the warm ceiling are connected to the side terminals. It is on them that the system resistance is re-measured. If there are no faults in the system, then its value should be equal to that previously measured.

The indicator part is attached to the thermostat with latches.

The indicator is a rather multifaceted device. It displays not only the current temperature, but also the time. With its help, the desired temperature is set or programmed.

Electrical appliances for IR heating

The abbreviation PLEN means “film radiant electric heater” or simply “film electric heater”. It is permissible to use IR heating film as both an additional and the main source of heat.

In fact, it is a film with internal heating elements that emit infrared waves as a result of the passage of electric current through them.

Advantages of the infrared principle

Heating of air masses in a room from one source or another can be carried out due to:

- thermal conductivity;

- convection;

- thermal radiation.

The first two principles of heat transfer are used in water and oil radiators, as well as fans with heating coils.

In them, a certain working surface is first heated using a coolant or heating element, from which the room air is then heated in its immediate vicinity. Then, using natural or forced convection, air exchange occurs throughout the room.

Film IR heaters refer to heating systems that heat not directly the air in the room, but first the surfaces of the walls, pieces of furniture, floor and ceiling in it

Thermal radiation involves the transfer of heat from a source using electromagnetic radiation in the infrared spectrum. Air cannot be heated directly by infrared rays.

They can only heat surfaces made of solid materials. That is, first, as a result of the operation of the PLEN heating system, the furniture and decoration in the room are heated, and then they give off heat to the air.

IR rays are often called “thermal radiation” because the effect of infrared equipment is perceived tactilely by humans as a feeling of warmth and does not cause any discomfort.

Infrared heat is electromagnetic waves in the range of 0.74–2000 microns. If you look at the Sun, about 40% of its radiation to the Earth comes from visible light, and about 10% and 50%, respectively, from UV and IR rays.

IR-type film electric heaters generate thermal energy with a wavelength in the region of 9.2 microns. For humans, such rays are completely safe and natural, since they most closely resemble “sunlight.” After all, the human body itself emits heat in the infrared spectrum with a wavelength of 9.6 microns.

Film heating system design

IR film electric heaters include three main elements:

- heating;

- transmitting;

- radiate.

The first converts electrical energy into thermal energy. The second distributes the generated heat over the entire area of the PLEN, and the third emits infrared rays.

In addition to the heating IR film, the film heating system also includes a thermostat with one or more temperature sensors and cables for connecting the heater to the power supply.

The heating element in PLEN is made of a conductor with high resistance. Usually this is a thin strip of nichrome (spirals in heating elements are made from it) or carbon. At the same time, almost all manufacturers of film IR heaters have now switched to the second option. Carbon is more economical, cheaper and more efficient.

The transmitting element is a layer of aluminum foil, which has high thermal conductivity. It is located on one or both sides of the IR film. Also, a number of manufacturers do not use aluminum at all, relying only on the emitting material.

The top layer of the film heater in question on both sides is made of PET (polyethylene terephthalate). The film made from this thermoplastic has a high IR emissivity coefficient, can easily withstand temperatures up to +2000C and is an excellent dielectric.

The film cleans the internal heating elements from condensation and moisture, forms a single heating system from disparate components, and also reduces the risk of electric shock to almost zero.

The IR film is designed so that the heating elements inside it can only heat up to +55º C. Temperatures higher than this are practically excluded; such heating is only possible for a short time in an emergency situation with a sharp surge in voltage in the network

Calculation and installation of an IR film heater are made taking into account that the film will not heat continuously, but at short intervals from several seconds to several minutes.

That is, such an infrared heater quickly raises the temperature of the surfaces in the room to the required values, and then turns off the thermostat. And then it is again powered from the mains only from time to time as the room air cools.

Calculation of film material for the ceiling

We present a sample of how to calculate PLEN for a heating ceiling.

Conditions:

- Total heated area 100 sq.m.

- Walls made of foam block 300 mm, wall insulation 100 mm, ceiling and floor insulation 150 mm.

- Ceiling height: 2.7 m.

- The allocated power is 15 kW.

Recommended minimum specific power of PLEN per 1 sq.m = 120 W/sq.m of heated area. We calculate the total installed power at the facility: 100 sq.m x 120 W/sq.m = 12,000 W = 12 kW. Taking into account the demand coefficient of 0.6, in severe frosts = 12 kW x 0.6 = 7.2 kW will be used.

We determine the specific power of the heaters depending on the ceiling height at the facility (2.7 m). For this height, it is recommended to use Plen 150, 170 or 180 W/sq.m. For example, PLEN 170 W/sq.m.

At this power, it is necessary to install 70% of the total heated area on the ceiling, which is: 100 sq.m x 0.7 = 70 sq.m Plen.+

Note! This is a preliminary approximate calculation of the number of PLEN. For a more accurate calculation, we recommend contacting specialists.

How to calculate the power of IR heaters

In this section we will mainly talk about ceiling heaters, which are planned to be used as the main heating of the room.

If the area of the room is large enough and the ceiling is not too high, as is often the case in unheated country houses, it makes sense to install several less powerful ones instead of one powerful heater. This will, firstly, make the heating more uniform, and secondly, eliminate the possibility of overheating a separate section of the floor.

The general recommendation for the total power of heaters is 80-100 watts per square meter of area. It is clear that this value is approximate; it can be influenced by many factors: ceiling height, wall insulation and much more. But as a starting point, such a value is quite suitable.

As for other types of heaters, calculating power does not make sense for them, because they are used only for additional heating.

How to make a warm ceiling in a house with your own hands?

Installation of infrared film on the ceiling occurs in several stages:

- ceiling insulation;

- calculation of film area;

- installation of film, thermostat and sensor;

- connecting to the network and checking functionality.

Before installing the thermal film, it is necessary to complete all construction and finishing work on the ceiling, excluding finishing work. Also carry out all work on laying communications and lighting wires.

Now let's look at the stages of installing a warm ceiling in more detail.

Ceiling insulation

It is necessary in order not to heat the attic or neighbors on the floor above. A properly insulated ceiling will return all the heat to the room, thus increasing the efficiency of the device and reducing energy costs. Thermal insulation with a reflective layer is attached to the entire surface of the ceiling and extends a few centimeters onto the walls. This will prevent heat loss through the gaps between the ceiling and the wall. The joints in the thermal insulation material are sealed with tape. The material itself must have a thickness of at least 5 mm.

How to calculate the area of infrared film?

To correctly calculate the required area, you need to consider the following:

- how well the building itself is thermally insulated. For a brick house or a light frame building, these data will vary;

- whether you plan to live in the house in the winter, permanently or on short visits;

- volume of heated area. This can be either the entire room or part of it;

- whether infrared heating will be primary or additional.

If a warm ceiling is planned as the main type of heating, it should occupy at least 70% of the area of the entire ceiling. As an additional option, this figure can be reduced according to the power of the main heating system. The average film power is approximately 0.2 kW per 1 square meter. By dividing the power of the thermostat by this number, you can find out the area of the film that can be connected to it.

Installation of thermal equipment

Thermal film can only be cut along the special lines marked on it. Each type of film has its own maximum cut length. This information can be found in the attached documentation or asked from the seller. There should be no gaps or air gaps between the film and the ceiling insulation.

Next, you need to connect the copper contacts of the busbar with the electrical wires using contact clips. One half of the clip should be located on the copper busbar, and the other half should be located inside the heater. After this, the ends of the film are insulated on both sides with bitumen tape.

The sensor is attached to the cutout of the thermal insulation and connected to the regulator and heating elements.

Electrical connection

The thermal film should be connected to the network through the regulator in parallel. If the warm ceiling has more power, it is better to connect it through a separate circuit breaker.

When turned on, a correctly installed warm ceiling should emit comfortable, uniform heat, not overheat anywhere, and turn off in a timely manner when the set temperature is reached.

Finishing

Next, the final finishing of the ceilings is carried out. This can be a suspended ceiling with special micro-perforation. It transmits infrared waves perfectly. In this case, the suspended ceiling is mounted along the edges of the wall, without affecting the ceiling itself.

You can also cover the structure with a suspended ceiling: plasterboard sheets, clapboard or plastic panels. A small gap should be left between the suspended or suspended ceiling and the infrared heating system. For finishing the ceiling, you should choose waterproof materials with a thickness of no more than 16 mm.

The infrared heating system for ceilings is the most modern, safe and efficient of all electric heating options. If installed correctly, it will last a long time, filling the house with warmth and comfort while remaining completely invisible.

Review of manufacturers

Of course, you want the system to be durable and work properly, so we have prepared for you a list of companies you can trust:

- Heat Plus. The product combines quality and durability (the melting point of this film is more than 150 degrees, which is much higher than that of competitors). The company has service centers all over the world, the price of goods is not much higher than the price of competitors. In addition, most product reviews are positive, which indicates the quality of the product.

- Caleo. Also a Korean company. The uniqueness is that the products can be purchased in a box and with installation instructions, which allows you to save on a specialist visit.

- In-Therm. The company has service centers around the world, as well as inexpensive and high-quality infrared films. Interestingly, the company specializes in other products besides heated floors.

Adviсe

The decision to install a particular heating system in a private home should be made carefully, since few people decide to redo the entire property. If there are problems with the gas supply, then you can choose an alternative - PLEN heating.

Laying PLEN on the floor

It is easy to install it yourself, but do not forget about the choice of finish. And also correctly calculate the required power and location of the thermostat. During operation, you will appreciate all the benefits of “warm film” in your home.

Results

As a result, we can say that heated floors are definitely not suitable for round-the-clock heating; it is most effective to install a floor with infrared film in the hallway and bathroom, and use electric radiators in the room. You can read more about them here: (link here). Thank you for your attention, if you liked it, save the article and share it with your friends. Subscribe to our blog, and if you have any questions, ask us in the comments! See you again here on our blog!