The weight of a cast iron battery, depending on the number of sections, ranges from 7.1 kg to 71 kg.

The cast iron battery is one of the iconic inventions of the Soviet era. An ordinary heating device has become the hero of jokes and a character in films. Although what, it would seem, could be special in an ordinary heating device?

Since the invention of the water heating system in Ancient Rome, humanity has not made much progress in heating its own home.

The heating devices resembled ordinary coils, but the heat did not stay in them for long and in the houses of both ordinary citizens and the palace nobility it was still cold and damp. In 1857, in St. Petersburg, in the workshop of Franz Karlovich San Galli, the first copy of a cast-iron battery was made, which is the progenitor of modern heating devices.

The weight of a cast iron battery, depending on the number of sections, ranges from 7.1 kg to 71 kg.

In shape, it was not similar to the radiators that residents are accustomed to seeing in high-rise apartments. It was a large diameter pipe, at the ends of which disc-shaped protrusions were installed, which were not part of the heating system. It was not by chance that cast iron was chosen as a material for casting; in the 19th century, steel and iron smelting production began to actively develop, so foundry masters and engineers knew a lot about their business: they valued the material for its resistance to external factors, for the fact that it was “ long-lived" and had good thermal insulation qualities.

Thanks to these parameters, the cast iron radiator has taken root in Russia. Changing shape, size and weight, it acquired today's unchanged appearance and proven production technology.

How much do cast iron standard ones weigh?

The common feature that unites them is the material of manufacture, namely cast iron. When we mention cast-iron batteries, the classic cast-iron accordion radiators immediately come to mind, which were installed and still serve well in:

- Preschool and school educational institutions;

- Medical institutions (hospitals and clinics);

- In all residential premises (dormitories, apartments, private houses and cottages);

- State and public organizations.

The classic example of an accordion battery can be found everywhere.

The overwhelming majority are the MS-140 or MS-90 model. There were no other mass production models observed in the past period.

Famous movie characters had to wear radiators of the MS-140-500 series.

So what is the weight of one section of an old-style cast iron battery? What value does the factory manual contain? And here it is impossible to answer with one number, since the dimensions of the section play a role.

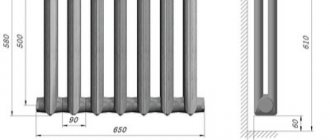

For example, the cast iron battery of the MS-140 series has 2 varieties (center distance):

- 300 mm;

- 500 mm.

Accordingly, if we are talking about MS-140-300, then the average weight of one fin of a cast-iron battery is 5.7 kg. And if we are talking about MS-140-500, then one such section will show 7.1 kg on the scales.

Weight depends on the dimensions of the section.

The MS-90 series is also quite common. In comparison with the 140 series, the weight of the old-style cast iron battery section is 6.5 kg at 500 mm.

For models MS-90 and MS-140, the difference lies in the shallower section depth.

Let's summarize: we have determined 3 different weights of the most common series (MS-90 and MS-140) - 6.5 kg, 5.7 kg and 7.1 kg, respectively. Can these values be considered final?

No, and here's why.

Regulatory document regulating the production of cast iron radiators

The existing standard (GOST 8690-94) describes the main parameters and dimensions of manufactured radiators. As for the weight of the sections, this standard contains a specific gravity value of 49.5 kg/kW.

This standard applies to block and cast iron heating radiators intended for use in heating systems with coolant temperatures up to 150 °C (423 K) and excess operating pressure up to 0.9 MPa (9 kgf/cm2).

To dismantle such a monster, it must first be sawed.

In fact, the manufacturer must comply with the specified values, but the weight of a separate section is not regulated by GOST. In practice, this is expressed by the fact that the products of different enterprises differ in weight.

As of the beginning of 2022, I know the products of several enterprises that produce MS-140 radiators, their modifications and products of our own design:

- Foundry and Mechanical Plant (Ukraine, Lugansk);

- Heating equipment plant (Republic of Belarus, Minsk);

- Boiler and Radiator Plant (Russia, Nizhny Tagil);

- "Descartes" (Russia, Novosibirsk);

- "Santekhlit" (Russia, Bryansk).

Let's look at the product range and determine how much cast iron batteries from different manufacturers weigh.

Nizhny Tagil

The manufacturer issues a passport for each product indicating the number of sections.

The company produces 4 models from cast iron:

| Product | Exact weight of the cast iron section of the radiator, kg |

| MS-140-M-300 | 5,40 |

| MS-140-M2-500 | 6,65 |

| MS-90 | 5,475 |

| T-90 M | 4,575 |

Manufacturer from Belarus

"Barelief" is a single-channel sectional radiator of modern design.

This manufacturer offers 9 types of cast iron radiators:

| Product | Exact weight of the cast iron battery fin, kg |

| MS-140M | 6,7 |

| B-Z-140-300 | 5,4 |

| 2K60P (two-channel sectional) | 3,7 |

| 2K60 | 5,1 |

| 2KP100-90-500 | 5,5 |

| 1K60P-60x500 (single-channel) | 3,84 |

| 2KPM-90X500 | 4,6 |

| 2K60P-300 | 3,7 |

Santekhlit

The company has been idle since last year, but its products are still sold in stores.

Let's find out how much one rib of a cast iron battery weighs - the former "Lubokhonsky Iron Foundry":

| Product | Exact weight, kg |

| MS-85 | 4,45 |

| MS-140M | 7,1 |

| MS-140-300 | 6,1 |

| MS-110-300 | 4,45 |

| MS-110-500 | 5,6 |

Answer for the impatient

For those who do not like to read for a long time, I will immediately indicate in the table the weight of a section of an old-style cast iron battery, and I will also write how much modern analogs made of aluminum and bimetal weigh:

| Illustration | Parameter |

Cast iron standard:

Non-standard - from 3.7 to 14.5 kg/section | |

Aluminum.

| |

Bimetallic.

|

I foresee your question regarding weight - why is there no accurate data on cast iron? After all, you need this value to determine whether you can remove the old 10-section radiator from your apartment or house with your own hands?

The issue of weight is far from idle - you need to calculate your strength before agreeing to work on storing old radiators.

The thing is that in operation there are models of different series, identical in purpose, but different in weight. In addition, there are a lot of models on the market that differ in size and shape from each other. Today there are more than two dozen traditional cast iron models alone, and there are almost no counting of designer floor models.

The photo shows 15 models of cast iron radiators, the weight of each varies significantly.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Basic power calculations

To obtain a heat source that will supply the room with the required amount of thermal energy, you need to accurately calculate the number of sections included in the radiator. And this, in essence, is a calculation of the power of the device.

There is a standard approach to calculation, which is based on the ratio - for 10 m² of heated area, you need to use 1 kW of thermal energy with a ceiling height of no higher than 3 m. It turns out that 100 W need to be spent per 1 m². By calculating the area of the room, you can say with great accuracy which heating radiator should be installed in it based on power.

True, experts make reservations. For example, a room has two external walls. And this is an increase in heat loss and, accordingly, an increase in power consumption. Or the room has not one, but two windows. That is, when focusing on the design, location of the room, and the presence of places through which cold air can penetrate inside, amendments should be included. They will help bring the calculation to maximum accuracy.

The power of a cast iron radiator is measured by the total power of the sections of which it consists. The standard indicator is 0.15 kW or 150 W. However, much will depend on the shape and quality of the casting. Typically, the power of a section is directly proportional to the heat transfer area. And since modern cast iron batteries come in a variety of shapes, the power of one section can change in one direction or another.

Heat transfer will largely depend on the quality of the coolant and its temperature. So 150 W is just a standard that takes into account two temperature conditions:

- indoor indoor;

- inside the heating system, that is, this is the temperature of the coolant.

Cast iron radiators MS-140 and MS-90

Their difference determines the value of the indicator. If this difference is 50°, then we can assume that the cast iron section emits 150 W of thermal energy. But here again there is a caveat - at a coolant temperature of +70C.

- Firstly, at this temperature indoors it will always be +20C.

- Secondly, the coolant temperature is rarely higher.

- Thirdly, the delta cannot be, for example, 70° for the simple reason that the temperature of the hot water is not very high, and the properties of cast iron cannot provide the heat transfer necessary for normal temperatures.

Returning to heating, we add that a battery with 10 sections is installed in a room of 15 m². But only if there is only one window in such a room. Adding a window means adding 1 or 2 sections to the radiator. Why does this depend? Mainly on the design of the window, the material for its manufacture, the number of double-glazed windows, and so on. If the heated area is more than 20 m², it is necessary to install several batteries, and it is better that they are located separately. One battery, even if you increase the sections, will not be enough.

Types of devices by weight

It is usually customary to divide radiators into standard and non-standard. The mass range of 1 rib in the first ones, with their characteristic center distance of 300 mm and 500 mm, is 4−5.7 kg and 5.5−7.2 kg, respectively. For non-standard ones, 1 section can weigh on average from 3.7 kg to 14.5 kg.

It is possible to apply another classification. Cast iron models currently produced by manufacturers and popular among consumers can be divided into three main types

- classic (or old style);

- vintage;

- lightweight.

Classic radiators are easily recognized by their name. They are always designated by the letters “MC”, followed by two numbers separated by a dash - the depth of the sections and the center distance. Some of the most common standard models

- MS - 140 - 500;

- MS - 140 - 300.

The weight of 1 section of the first is usually 7.1 kg, and the weight of 1 rib of the second is 5.7 kg.

Representatives of the vintage type are now at the peak of popularity, despite the fact that they are the heaviest radiators of all. The weight of 1 rib can be 12 kg. Due to their heavy weight, vintage devices are classified as floor-mounted devices. These batteries look very attractive. They are produced using artistic casting technology, which makes them not just heating equipment, but a real decoration of the interior of the room.

Effect of equipment gravity

As already noted, the weight of the cast iron radiator section and the battery as a whole determines the installation principles and complexity of installation. Only based on this parameter, it is possible to determine the required carrying capacity of the transport for delivery and the sufficient number of loaders and workers.

The heavy weight of the batteries causes some difficulties during installation and installation

You cannot carry the equipment alone - only two people and with the utmost care and caution. Despite its weight and apparent strength, cast iron is a rather fragile material.

Even a light impact can cause microcracks. Subsequently, under the influence of the coolant, these microdamages will increase, which will result in depressurization of the heating equipment.

But if the base of the wall is made up of light porous blocks, this is almost impossible to do. In such circumstances it will be necessary to install the heating device on the floor.

The weight of a cast iron battery, depending on the number of sections, ranges from 7.1 kg to 71 kg.

The cast iron battery is one of the iconic inventions of the Soviet era. An ordinary heating device has become the hero of jokes and a character in films. Although what, it would seem, could be special in an ordinary heating device?

Since the invention of the water heating system in Ancient Rome, humanity has not made much progress in heating its own home. The heating devices resembled ordinary coils, but the heat did not stay in them for long and in the houses of both ordinary citizens and the palace nobility it was still cold and damp.

In 1857, in St. Petersburg, in the workshop of Franz Karlovich San Galli, the first copy of a cast iron battery was made, which is the progenitor of modern heating devices.

The weight of a cast iron battery, depending on the number of sections, ranges from 7.1 kg to 71 kg.

In shape, it was not similar to the radiators that residents are accustomed to seeing in high-rise apartments. It was a large diameter pipe, at the ends of which disc-shaped protrusions were installed, which were not part of the heating system. It was not by chance that cast iron was chosen as a material for casting; in the 19th century, steel and iron smelting production began to actively develop, so foundry masters and engineers knew a lot about their business: they valued the material for its resistance to external factors, for the fact that it was “ long-lived" and had good thermal insulation qualities.

Thanks to these parameters, the cast iron radiator has taken root in Russia. Changing shape, size and weight, it acquired today's unchanged appearance and proven production technology.

Surface treatment: sanding

Such radiators require frequent painting , as scratches or chips remain on them.

If you change the color of the heating device, repairs may be needed in all rooms. The process of changing the color of a heating device is divided into a couple of stages.

The first stage includes surface preparation. First, wash the battery very thoroughly, remembering to remove traces of dirt between sections.

After that, remove the layer of outdated paint - for this there are a lot of specialized solutions that do not harm the metal. Apply the solution to the heating device with a dry brush and wrap the heating device with film. After an hour, the paint is removed using a spatula. Afterwards, carefully sand the surface of the battery with fine-grained sandpaper and degrease it with a solvent. If there are areas touched by rust on the battery, they are processed to bare metal.

Applying a primer will complete the process of preparing the product - after which they begin painting. The paint will lie on the surface in an attractive, even layer. And the primer will also help fight corrosion.

Coloring

Paint for heating appliances must meet many requirements:

- be resistant to wear and non-toxic;

- maintain a temperature of more than one hundred degrees , for example, which contains iron powder, is the most heat-resistant;

- must be suitable for painting metal surfaces;

- fit under the primer;

- help protect the product from corrosion processes;

- serve for a long time , maintaining color.

Acrylic-based enamels containing organic solvents will give radiators a high-gloss shine and long-lasting color But they have a significant drawback - a sudden foul odor during the paint coating process.

Alkyd-based enamels are laid out evenly and are resistant to abrasion. However, they have an unpleasant odor not only during application, but also for a certain period of time after complete setting when the heating device is heated.

Photo 1. Jar of heat-resistant alkyd enamel for heating radiators, 0.5 l, manufacturer Dali.

To prevent paint drips from spoiling the already painted surface, it is recommended to start painting from the top of the battery.

Main. You need to understand that you cannot paint hot batteries.

Applying a second layer

When the first layer of paint dries (the setting time depends on the quality of the paint, but as a rule, the average is twenty hours ), apply the next layer. This makes it possible to hide irregularities on the surface of the heating device, will increase the resistance of the painted surface to environmental influences and will improve the beautiful appearance of the heating device.

Attention! Do not turn on the batteries until the paint has completely set. You should not artificially speed up the setting process - this will lead to bad consequences.

Weight of cast iron battery section

A cast iron battery is considered one of the most profitable devices for heating a home, because in addition to excellent heat transfer, it is highly resistant to corrosion, has a long service life (50 years and older) and is undemanding in terms of the quality of the heat carrier. These factors encourage many people to include it in their individual heating system. At the same time, when creating a heating system, they are forced to take into account its features. One of them is the weight of the cast iron battery.

This indicator is very important because it allows:

- choose the optimal mount;

- choose the right type of battery depending on the design features of the house.

Classic batteries

These include the MC 140 battery. It is known to everyone, because it became most widespread during the Soviet Union. Today it is also actively bought. It has several modifications, but one section of the most used version weighs 7.12 kg. It is designed for 1.5 liters of water. Therefore, the total mass of one battery sector is 8.62 kg. It is this figure that must be taken into account when calculating the mass that the mount must withstand

If we take into account only the weight of the battery itself, then the mount, having received additional pressure from the mass of water, may not withstand

To heat a room of 20 m², you need to install a battery with 12 sections. This means that the weight of an empty heating device will be 85.4 kg, and a radiator with water will be 103.4 kg.

Such a battery must be installed on a mount fixed in the wall. That is, it turns out that the wall must withstand an additional load of almost 104 kilograms. If the wall is built of brick or concrete, then such a cast iron radiator can be safely hung on the wall.

However, if the owner decided to save on building a house and built it from foam concrete, aerated concrete or SIP panels filled with foam, then the classic hanging of a 100-kilogram structure on such walls is a very bad idea.

The classic installation method involves fixing horizontal brackets with hooks at the end to the wall. The latter are equipped with a battery. Walls made of porous materials or SIP panels simply will not withstand high pressure, and the radiator will fall to the floor.

Of course, there is a way out in such a situation. There are even three of them:

- You need to use a special mount, which should be fixed at many points. This is an extra waste of your time and effort. This option is definitely not to the liking of every owner.

- It is necessary to install cast iron batteries of modern modifications. They are lighter and more efficient in terms of heat exchange.

- Choose models that can be installed on the floor.

Modern options for cast iron radiators

They consist of lighter sectors. Thus, one of the Czech manufacturers offers a radiator, one section of which weighs 3.8 kg. At the same time, it can hold 0.8 liters of water. As a result, the total mass of the sector is 4.6 kg.

To heat the above room you need to take a radiator with 14 sections. It will weigh 64.4 kg. This figure includes the mass of cast iron and water.

Such a radiator will still be heavy for walls made of porous material, but if you split it into two parts and place them on different walls, then you can forget about the need for additional fastenings.

Domestic manufacturers offer radiators with a lighter sector. Its characteristics are:

- Weight - 3.3 kg

- Volume - 0.6 l.

- Total weight with water - 3.9 kg.

However, they have worse heat transfer. As a result, to heat a room of 20 m² you need to take 22 sections. This means that the mass of the radiator will be 85.8 kg. This weight is not entirely suitable for modern houses made of foam blocks. Radiators with legs can save the situation. The legs have only the first and last sections.

Algorithm for calculating radiator weight

It is worth saying that modern manufacturers offer many modifications of cast iron radiators. Therefore, in order to answer the question of how much a cast iron battery weighs when evaluating each option, you need to follow these steps:

- Find out the weight of the section itself.

- Add the weight of water that can fit in the section.

- Analyze the heat transfer and, based on it, determine the required number of sections.

- Multiply the number of sections by the total mass of one sector.

Cast iron or bimetallic batteries Selection of heating batteries according to the area of the apartment Number of kW of one segment of a cast iron radiator How to calculate the heat transfer of cast iron radiators

Comfortable temperature in a single home

Let us give an example of calculating the number of heating radiators for a detached residential building with an area of 80 square meters. meters. Only the area will not be enough for us; we also need to know the height of the ceilings and the heat losses of the house itself.

To do this, we will use the simplest formula:

K=(P/M1)*100

K - how many sections should be in the battery;

P – area of the room to be heated

M1 – battery section power

Multiplying by 100 in the formula has a logical basis. Long-term operation of cast iron radiators made it possible to identify a pattern per 1 sq. meter, you need 100 watts. One constant is missing here: the power of one section. The use of cast iron radiators for many years gave an average power of one section - 150 watts. It turns out that for 80 sq. meters of area we will need at least 53 sections. It is worth considering that heat losses in corner rooms are higher, there are two external walls, so a coefficient of 1.2 is added to the formula, and it takes the following form:

K=(P/M1)*100*1.2

A corner room with an area of 12 square meters will require a radiator of 10 sections for heating, according to the formula it turns out to be 9.6, but such half radiators are not produced. It is worth noting that the formula is intended for rooms whose height does not exceed 2.7 meters. Having calculated the number of sections, we select cast iron radiators MS 140 500 whose technical characteristics will be acceptable to us. The choice of this particular radiator is justified: the weight and height do not create difficulties when installing the heating system. It must be emphasized that the weight of 1 section of the ms 140 cast iron radiator is taken into account both during transportation of the product and during installation.

The brackets with which the batteries are attached to the walls are designed for a certain load. Incorrect calculation will lead to an emergency. You can also choose a non-standard version of the MS 140m 500 cast iron radiator, the characteristics of which will completely suit you, but the temperature in the house will be uncomfortable. The reason will be incorrect or poor-quality installation. It is better to entrust the heating installation in your home to organizations specializing in this because... upon completion of the work they will provide you with a warranty. This is especially important if the heating system is installed in a multi-story building. When installing it yourself, or hiring a “traditional craftsman,” you take all the risks upon yourself.

How much water is in one section of an aluminum radiator, methods for calculating volume

Nowadays, replacing old cast-iron batteries with new models has become not a tribute to fashion, but a vital necessity. Concern for the safety of the heating system and attempts to reduce the cost of utilities have led to more and more consumers choosing aluminum radiators, which differ from other types of heaters in both technical characteristics and price. One of the important parameters is the volume of the heating radiator.

Parameters of aluminum radiators

The technical characteristics of heating batteries are the first thing a consumer pays attention to before purchasing. The most important indicators of a truly high-quality product are:

- The level of heat transfer of one section, since it depends on:

- First, how many elements are needed to heat one room.

- Secondly, how warm the room will be thanks to the radiator.

- Thirdly, what will the microclimate in the room be like?

- Resistance to water hammer and operating pressure of an aluminum radiator.

- Cost of the finished product.

The volume of one section of an aluminum radiator indicates its power and largely depends on how it was manufactured.

If the aluminum battery was made by pressing, then its parts were connected using glue, which makes it vulnerable. Such a radiator is not afraid of corrosion, but increased pressure can damage it.

The capacity of one section of an aluminum radiator, regardless of the method by which it was produced, is almost the same, but the fact that the cast model is stronger and more durable, heats up faster and can be adjusted in size puts them in first place in sales.

Types of coolants

As a rule, the question of what coolant is used in a centralized heating system is not asked, since water always flows through the heating pipe there. Another thing is autonomous heating, where you can choose the best option for a particular house, taking into account the climate of the region where it is built.

Why is radiator volume important?

Calculating how many liters are in one section of an aluminum radiator is important for several reasons:

Considering how many factors are affected by the volume of heating batteries, this parameter should be taken into account when choosing aluminum products.

Calculation of the volume of an aluminum radiator

There are two ways to determine the capacity of a heating battery:

This, although a very labor-intensive method, is the most reliable and accurate, since manufacturers can overestimate or underestimate the parameters of their products in the technical documentation.

When choosing the type of radiator, you should pay attention to the difference in the parameters of domestic and foreign manufacturers. Some indicators may look very attractive, but are not suitable for the centralized Soviet heating system. You also need to think in advance which coolant in the network will be used, and make calculations indicating its viscosity

You also need to think in advance which coolant in the network will be used, and make calculations indicating its viscosity.

To summarize, we can say that the volume of an aluminum radiator is an important parameter that must be taken into account in order for the system to work truly efficiently in the future.

Briefly about the main thing

The weight of the heating battery is one of those parameters that are important for transportation, installation and trouble-free operation of the heater. It depends on the dimensions of the device - its height, depth and width, which differ from manufacturer to manufacturer. As well as the internal volume filled with coolant and creating additional load. The total weight of a working battery consists of the weight of all sections included in it and the mass of water contained in them. If it is very large, it makes sense to think about dividing the battery or changing the installation technology.

Read later

We will send the material by email

What is the weight of one section of a cast iron radiator?

Cast iron radiators appeared more than a hundred years ago, and are still in demand. Of course, the peak of their popularity is behind us - it occurred in the middle to end of the last century. Despite the fact that cast iron batteries have obvious advantages, they have disadvantages. More precisely, there is only one drawback - a lot of weight. The weight of one section of a cast iron heating radiator is seven and a half kilograms, respectively, an average-sized battery consisting of seven sections will weigh 50 kilograms.

General characteristics of cast iron radiators

An ordinary cast iron radiator usually consists of 5-10 sections. The number of sections depends on the desired thermal effect. The more sections, the greater the heat transfer and temperature in the house. Moreover, you can install a radiator consisting of any number of sections: cast iron batteries, as well as bimetallic ones, can be divided. This will create the most comfortable environment.

Radiators of Soviet apartments

Heavy weight is not a problem during operation: the main thing is to install the battery correctly. You can find out how much a cast iron radiator weighs in 10 sections by simple calculations. One section of a modern radiator weighs 7.1 kilograms, which means 10 sections will weigh 71 kilograms.

Despite the fact that the popularity of cast iron batteries is no longer so great, one cannot fail to mention their advantages.

Here are some of them:

- resistance to corrosion;

- thick walls, which are a guarantee of durability;

- the ability to use coolants of any quality;

- excellent heat storage capacity;

- long service life;

- large internal cross-section, thanks to which cast iron radiators do not have to be cleaned often.

MS-140 batteries made in Belarus

Standard models of cast iron batteries have a center distance of 300 or 500 millimeters. However, there are also models that have a greater height - the center distance of which reaches 800 millimeters. In addition, intermediate models are produced in which the center distance is 350 millimeters. The depth can be different - 110, 99 or 92 millimeters. The width of cast iron radiator sections ranges from 35 to 60 millimeters.

The situation in the modern market

Although not on the same scale as since the times of the USSR, cast iron radiators are still produced today. For example, cast iron radiators MS-140, which are in high demand, are manufactured in Minsk and Lugansk. The radiators have almost the same characteristics, with the exception of one thing - color. Minsk residents produce red radiators, the Lugansk plant produces gray ones.

Modern antique radiator

Modern cast iron radiators are made from high quality cast iron. This largely determines their parameters and stability of characteristics, including weight. In particular, regardless of the delivery batch, the weight of 1 section of the MS-140 cast iron radiator is 7.1 kilograms. Thanks to this, during the design calculations it is possible to determine the load that will be experienced by the walls to which the heating radiators will be attached.

Belarusian and Ukrainian factories, of course, are not the only enterprises producing cast iron batteries. Since recently such products are in increasingly high demand, radiators are produced in various colors and sizes. In addition, batteries decorated with casting and imitating antique products have recently appeared on the market. This significantly increases interest in products of this type.

Calculation of thermal power

To organize space heating, you need to know the required power for each of them, and then calculate the heat transfer of the radiator.

The heat consumption for heating a room is determined in a fairly simple way. Depending on the location, the heat value for heating 1 m3 of a room is accepted; it is 35 W/m3 for the south side of the building and 40 W/m3 for the north. The actual volume of the room is multiplied by this value and we obtain the required power. In order to calculate aluminum or bimetallic batteries, you need to start from the characteristics specified in the manufacturer's documentation. In accordance with the standards, the power of 1 radiator section is given at DT = 70. This means that 1 section will give the specified heat flow at a supply coolant temperature of 105 ºС, and in the return – 70 ºС. In this case, the calculated temperature of the internal environment is assumed to be 18 ºС.

Based on our table, the heat transfer of one section of a bimetallic radiator with an interaxial size of 500 mm is 204 W, but only at a temperature in the supply pipe of 105 ºС. In modern systems, especially individual ones, the temperature does not reach such a high level, and accordingly, the output power will decrease. To find out the real heat flow, you must first calculate the DT parameter for existing conditions using the formula:

DT = (tflow + trev) / 2 – troom, where:

- tpod – water temperature in the supply pipeline;

- tobr - the same, in the return;

- troom – temperature inside the room.

After this, the rated heat transfer of the heating radiator is multiplied by a correction factor taken depending on the DT value according to the table:

For example, with a coolant graph of 80 / 60 ºС and a room temperature of 21 ºС, the DT parameter will be equal to (80 + 60) / 2 – 21 = 49, and the correction factor will be 0.63. Then the heat flux of 1 section of the same bimetallic radiator will be 204 x 0.63 = 128.5 W. Based on this result, the number of sections is selected.

https://youtube.com/watch?v=nSewFwPhHhM

How much does a section of an old-style cast iron battery weigh?

The classic cast iron accordion battery can be found everywhere. There is no single weight for such a battery, because several types of factory designs were produced. The cast iron radiator MS-140 had two varieties regarding the center distance: 300 mm and therefore 500 mm. The average weight of one radiator fin is 5.7 kilos. But if we talk about the MS-140 (500) radiator, then the weight of the fin reaches 7.1 kg.

The battery installation must meet the following requirements:

- The battery fins must be strictly vertical;

- The center of the radiator from the center of the window should not deviate more than 2 cm;

- The distance from the floor to the radiator itself must be at least 60 mm, otherwise it will be extremely difficult to clean underneath it.

The distance from the plane of the radiator to the window sill should not be more than 5 cm. This will be convenient, if necessary, to repair the battery and care for it. And dismantling will be convenient when it’s time to change the battery.

Classic as it is

In general, it is worth examining in detail the MS 140 cast iron radiator itself and the technical characteristics of the device. The battery is assembled from several sections, the most common are radiators of 7 or 4 sections, however, this is not an axiom, other modifications are possible.

Parameters that are required for this type of product:

- The depth of the section is 14 cm (reflected in the name).

- Section height is 59 cm

- The width of one section is 9.3 cm.

- Weight not less than 7 kg.

- Section power – 160 Watt

- One section includes at least 1.4 liters. Coolant

It is worth explaining that the coolant, in our case, means the liquid that, when heated in the heating boiler, carries heat to the batteries. The most common coolants are water and antifreeze.

Modern heating radiators made of cast iron

For wall mounting, there are new products made of gray cast iron from various manufacturers, whose weight is much less than traditional MS 140. For example, the Czech heating radiator Viadrus STYL 500, shown in the figure.

Its characteristics are as follows: weight of 1 section – 3.8 kg, water capacity – 0.8 liters, a total of 4.6 kg. With an available heat flux of 140 W, our room of 20 m2 will require 14 pieces, which will weigh 64.4 kg including water. This figure is 40% less than that of MS 140, and dividing it into 2 parts (32 kg each device), it becomes clear that it is possible to install cast iron radiators on walls made of porous concrete without special additional considerations. An even lighter design is offered by a Russian manufacturer that sells its heating devices under the EXEMET brand, namely the MODERN model.

Here, one radiator section weighs only 3.2 kg with a heat transfer of 93 W; a room of 20 m2 requires 22 sections with a total weight of 70.4 kg. This indicator is also quite good, especially considering that the company manufactures these batteries with the possibility of floor installation.

It is impossible not to say a few words about such a product as a vintage cast-iron battery, whose weight is even greater than the Soviet MS 140 and in some cases reaches 14 kg. These heating devices in their appearance resemble the ancient ones installed in residences and estates back in the 19th century.

The EXEMET FIDELIA model shown in the figure weighs 12 kg with a heat output of 156 W, which makes the total weight of the cast iron radiator for our example simply monstrous - 154 kg. But as you can see in the image, here the installation issue is solved differently: the first and last sections have legs for placing the heater on the floor.