The most important question that owners of country houses have when installing a new heating system or reconstructing an old one is how not to make a mistake when choosing a boiler and where to put it. Wall-mounted or floor-mounted, conventional (convection) or condensation, single/double-circuit, with natural draft or coaxial chimney. The choice is actually huge. And for it to be correct, you need to have a rough idea of the design features and basic operating algorithms. Therefore, we will figure out which one is better and why.

What is a double-circuit gas boiler

A double-circuit gas boiler is an installation that is a device capable of producing energy in the form of heat created by burning gas. This energy heats the coolant, which passes through the core of the boiler and goes further, obeying natural or forced circulation in the heating circuit, and also heats the water in the boiler and used for household needs.

There are two types of such boilers:

- double-circuit wall-mounted gas boiler;

- gas boiler, double-circuit, floor-standing.

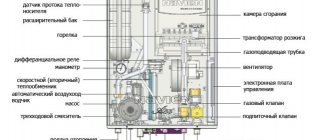

Such a heating structure consists of the following elements:

- gas stove;

- igniter first and main;

- heat exchanger;

- heating circuit;

- DHW circuit;

- a pipe used as a chimney through which combustion products are ventilated;

- expansion tank;

- pump that creates circulation;

- automatic device that controls the boiler;

- safety monitoring device.

All of the above elements are collected in a single box. It is covered on top with a metal plate, usually available in two colors:

- white;

- metal.

The housing is attached to the wall with the bolts included in the kit, and the unit is sold assembled with the necessary adapters so that the boiler can be installed in the heating system. The equipment usually depends on the model.

Combustion chamber and smoke exhaust system

Dual-circuit gas heating systems are characterized by two design types:

- with an open combustion chamber;

- with a closed combustion chamber.

Boiler equipment with an open combustion chamber is low-performance due to the use of natural convection, and requires constant ventilation of the room. It is more suitable for small country houses.

Boilers with a closed combustion chamber are high-performance devices. They take in outside air to form a combustible mixture. This reduces the impact of the unit on the microclimate in the room where the device is installed.

Air is pumped by a special fan. Therefore, the devices are perfect for large and medium-sized residential premises with the need for domestic hot water.

A passive smoke exhaust system is unsafe, and therefore forced exhaust is widely used. Solutions with coaxial chimneys (of the “pipe-in-pipe” type) have also become widespread. This design simplifies the installation process. The coaxial pipe simultaneously takes in air and removes combustion products.

Specifications

Due to their external aesthetic qualities, double-circuit gas boilers fit perfectly into any interior design.

Technical data suggests that such a device can simultaneously function in two areas, such as:

- heating water;

- space heating.

If the user purchases a wall-mounted gas boiler, then he significantly saves usable space and there is no need to build a separate room for the selected model. If it is necessary to place a floor-standing boiler, then it is necessary to build, in accordance with all the rules, a separate building in which the boiler room will be located.

The most important advantage of double-circuit gas boilers is that they have the technical ability to connect a boiler, which single-circuit units do not have. To heat the water there is a water heater that works like a flow-through one.

The power of such devices ranges around 30 kW.

The heated area should be no more than 180-280 square meters. m.

According to manufacturers' recommendations, it is worth installing such a system as close as possible to the points where water will flow, so that the heating process begins immediately. It is also necessary to place rooms one after another where hot water will be distributed.

It is extremely inefficient to install points with hot water distributors in different directions, because then it will take much more fuel to warm up and supply water at the required temperature.

You might be interested >> Operating principle of a Baxi single-circuit gas boiler

Model differences in power

Double-circuit boilers are divided by power into single-stage and two-stage. Single-stage devices always operate at a constant power level and use the same amount of fuel resource year-round.

This is not effective and entails excessive gas consumption, because a house or apartment requires high-quality heating for no more than 5 months a year. At all other times, running the equipment at full power is neither reasonable nor economically profitable.

When installing equipment with a base power of 30 kW, you should know that these types of devices should not be located in residential premises, but in separate rooms equipped with a high-quality ventilation system, individual access to the street and a full-fledged chimney

The functionality of two-stage devices is wider.

With it you can:

- regulate the gas flow regime and rationally consume fuel;

- reduce the number of on/off switches, thus reducing equipment wear and extending its service life;

- reduce the volume of harmful emissions into the air to a minimum.

Additionally, the device is equipped with a smooth switching module, which reduces energy consumption and allows you to simultaneously operate a boiler and a boiler of any capacity, installed separately.

Types of double-circuit gas boilers

The type of gas boilers is divided according to several criteria:

- According to the principles of using combustion products:

- convection;

- condensation

- According to the design provided in the heat exchanger:

- separate;

- bithermic.

- By type of combustion chamber:

- closed;

- open.

The first type has a number of advantages and disadvantages, namely the fact that thermal energy is not used to its full potential is attributed to the disadvantages. The advantages include relative ease of use and budget price.

The advantages of the second type include a separate design, since if any of the parts fails, it can be replaced - this will be very problematic with a monolithic block. The disadvantages include the following: when a person takes a shower, the water must be turned on a little in advance, because it heats up to such an extent that you can get a thermal burn.

For combustion chambers, a closed type chamber is preferable, as it is safer.

Conclusion

To understand how to choose a double-circuit boiler, you need to remember that gas boilers, like any other equipment, have their disadvantages and advantages. First of all, you should rely on your personal budget, and only then study the advantages of a particular system

Above are recommendations and evaluation of popular double-circuit designs. By studying them, you will definitely come to the right choice. Also visit popular online stores to find out the price and possibly find the right solution.

28.06.2017

Return to list

Principle of operation

Such boilers are the most interesting and budget option for heating a home, since gas is one of the cheapest types of fuel. Even if we compare the costs incurred by a house in which there are many apartments, then in the case when it is connected to the gas main, the economic cost item will be much lower than where everything is based on power from electrical networks.

By moving to a permanent place of residence outside the city and connecting gas to their heating system, people save significantly, since they pay, instead of mythical utilities, the real price for the availability of fuel. At the same time, the owners can regulate the duration of fuel use themselves, that is, turn the device on and off as needed. Because the operating principle of such an installation as a gas double-circuit boiler for heating a private house is as follows:

- A double-circuit gas installation, if it is installed in a wall-mounted version, then it is not very important where it will be located. But if a floor-standing option is used, then a separate boiler room will be needed. But there are two important points. Firstly, it must be possible to connect the boiler to the main gas, and secondly, it is necessary to install a chimney system through which combustion products, such as smoke and carbon monoxide, will freely escape outside.

- Also, a thermal circuit must be connected to the boiler, through which the coolant (water or antifreeze) will circulate; such pipes are usually marked with blue arrows in the direction in which the fluid circulates.

- Hot water is distributed as follows to the bathroom or shower; And after that the circuit closes. That is, such premises should be located one after another, priority is not important here.

- for kitchen needs;

- and in other places where it is also necessary to supply water.

- The pump, which helps the coolant circulate, is in most cases structurally located inside the heating installation. It sets the movement of the heated liquid inside the circuit.

- The type of objects that accumulate heat may vary depending on the model of the boiler unit itself. The following types of batteries are sometimes used:

- conventional radiators;

- warm water floor;

- any convectors;

- It is also possible to connect additional elements, such as a heated towel rail.

You might be interested >> How to properly clean a gas boiler

That is, from this diagram it becomes clear that about five different pipes are connected to a double-circuit gas boiler, regardless of its type:

- Main gas.

- The circuit to which the heated coolant is supplied, then follows through all heating points.

- Return.

- Tap water, or rather, providing an entrance for it. The outlet pipe through which hot water flows to the distribution unit and is then directed to water intake points, providing the ability to obtain hot water for a variety of needs.

As for the choice of coolant, it is necessary to consider the manufacturer’s recommendations. Because in a double-circuit unit it is permissible to use different coolants, but it all depends on the type of boiler, because, for example, antifreeze can be used in a cast-iron boiler, but in others it is undesirable.

What are the differences?

Single- and double-circuit boilers have common elements. But if the pipelines or gas burners are almost the same, then the heat exchanger differs in design.

In single-circuit devices, a simple type is installed, representing a pipe. Dual-circuit models often use thermal systems. That is, the pipe is placed in another one with a larger diameter. This allows you to create 2 circuits needed to perform the functions.

The difference is the 3-way valve. Basically, these are installed only in dual-circuit models. Three-way valves are designed to change the direction of hot water. Therefore, when using liquid for domestic needs, heating of the room stops. The valve shuts off the coolant supply to the radiators.

Advantages and disadvantages of a double-circuit gas boiler

Such gas installations have very impressive advantages:

- the user can, using a single unit, both heat the house and heat water for any purpose;

- no need to buy a boiler separately;

- the installation is quite compact;

- the wall version generally fits perfectly into the interior design of the corridor or kitchen;

- significant savings on utility bills;

- convenient adjustment of water temperature.

But, despite these advantages, there are still disadvantages, and they should be taken into account:

- if you simultaneously use hot water at several liquid outlet points, the heating efficiency of the main coolant will significantly decrease for a short time;

- the volume of hot water will depend on the size of the boiler;

- it is necessary to install filters at the liquid inlet inside the heat exchanger, because if the water is of low quality, then the holes in the heat exchanger themselves become dirty and break quite quickly.

Organization of hot water heating in boilers with one circuit

Despite numerous desires, it is impossible to turn a single-circuit boiler into a double-circuit one in the literal sense of the phrase. But you can retrofit a single-circuit boiler with an indirect heating boiler, sacrificing space and money, but providing hot water supply without all the disadvantages of double-circuit boiler models.

VIESSMANN gas floor-standing boiler in combination with a Vitocell-V 100 indirect heating boiler for 200 l.

The principle of operation is simple: inside the boiler with sanitary water there is a coil of the water heating circuit of the boiler; the coolant constantly circulates through the coil (as throughout the entire heating system of the house), maintaining a constant temperature. With this scheme, it is possible to ensure a relatively stable hot water supply not only when using a gas or electric, but even a solid fuel single-circuit boiler. With basic knowledge and skills, you can carry out the modification yourself.

Indirect heating boilersDouble-circuit BoilersSingle-circuit

Features of installing such a boiler

When installing a gas boiler, many important points must be observed to ensure safe and accurate operation of the heating installation:

- The installation location of the unit must be approved by gas services and comply with all standards.

- The system connection project must initially be drawn up on paper and then agreed upon with the gas company employees.

- Specialists from the relevant service must install meters to monitor fuel consumption.

- Before installing the boiler, it is recommended to check its complete configuration.

- First, you should mark on the surfaces all the points where the equipment will be installed.

- Next, connect all systems in series.

- After this, the first test filling of the circuit with coolant is carried out.

- Then a test firing of the boiler is carried out.

- If there are any problems during the first start-up or you smell gas, it is better to call a specialist to inspect the system.