The most important question that owners of country houses have when installing a new heating system or reconstructing an old one is how not to make a mistake when choosing a boiler and where to put it. Wall-mounted or floor-mounted, conventional (convection) or condensation, single/double-circuit, with natural draft or coaxial chimney. The choice is actually huge. And for it to be correct, you need to have a rough idea of the design features and basic operating algorithms. Therefore, we will figure out which one is better and why.

Design features, fundamental differences

A single-circuit boiler is used for heating premises by heating the coolant using 1 heat exchanger built into the boiler. Gas boilers, the design of which involves two heat exchangers, i.e. separately heating the coolant water for heating and hot water supply - called double-circuit.

Photo from ktl.by

Devices are classified:

- by location - floor and wall;

- in terms of energy efficiency: conventional, using a low calorific value and condensing, designed to consume a higher calorific value of fuel with the additional use of thermal energy released with condensate from water evaporation;

- according to the design of the gas burner - with an open and closed combustion chamber.

We also recommend reading: floor-standing or wall-mounted gas boiler, which is better and Top 10 best floor-standing gas boilers

When operating a gas boiler room, it is necessary to remember that gas is not only a benefit, but also a source of increased danger. Therefore, independent installation of equipment can lead to gas leaks and irreparable consequences.

To put it into operation, you must obtain a package of permits and consult with a specialist. It’s even better to entrust heating installation to professionals. You should not save on the health of your loved ones.

Prices

Not only functionality and design features, but also cost, directly depend on the purpose, power and model of the condensing boiler. All single-circuit models are used exclusively for heating, and double-circuit designs also allow for water heating.

- wall-mounted gas condensing models Protherm “Lynx” – costing from 35 thousand rubles;

- wall-mounted gas condensing boilers BAXI - costing from 48 thousand rubles;

- wall-mounted gas condensing models Ariston – costing from 60 thousand rubles;

- wall-mounted gas condensing boilers VAILLANT – costing from 58 thousand rubles.

It should be noted that today the line of gas condensing equipment is produced by most manufacturers, and can be represented by premium, middle class or economy class models.

The first option is represented, as a rule, by German brands, and is distinguished by ease and safety of operation, stylish design, silent operation and compliance with all European environmental standards.

Demonstrating the benefits of condensing boilers

The mid-price category includes models produced under the BAXI brand. Such designs are comfortable, economical and environmentally friendly, and can be single- or double-circuit, wall-mounted or floor-mounted. Economy class is represented by Korean and Slovak manufacturers.

Such models, adapted for use in Russian conditions, are distinguished by simple functionality and a minimum number of complex options.

The main advantages of economy class equipment include adaptability to pressure drops and frequent failures in the electrical supply system.

Differences in the design of single and double circuit units

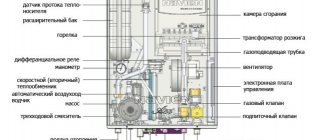

What is the difference between the design of units with 1 circuit and with 2 circuits? If we talk about the main components, then the basic principle of operation is the same for both types of equipment:

- pipelines through which water is supplied from a well (water supply);

- expansion tank;

- smoke exhaust or coaxial pipe and burner.

One of the main things that distinguishes a single-circuit gas boiler from a 2-circuit one is the design of the heat exchanger.

If in a 1-circuit it is a pipe through which water is heated due to the exchange of heat from a gas burner, in a 2-circuit it is two double heat exchangers made of pipes and plates or one bithermal (to make it clearer, this is a pipe inside a pipe).

- primary, heating heating circuit;

- secondary or plate, responsible for heating the water.

Photo from https://teplowood.ru

However, the key difference is the 3-way valve, which is responsible for the direction of water. When the heating circuit heats up, the valve is in its normal position. However, when the DHW tap is opened, the device’s automation is activated due to the pressure difference. The valve blocks the access of hot water to the heating circuit. Then the coolant begins to circulate inside the boiler. At this moment the room is no longer heated.

User manual

The connection to the gas main is carried out by employees of the gas industry.

Gas boilers are used for heating and hot water supply of apartments, private residential and country houses, and public buildings. In this case, it does not matter at all whether the system is connected to the main gas pipeline, since the units can operate on liquefied fuel, which is supplied in cylinders.

The manual for the use of gas equipment is a set of requirements and rules, compliance with which makes the operation of the device safe and efficient. Initially, the device is connected to the gas main, as well as to the water supply pipes, heating system, and electrical network. The device is connected to the main line only by qualified specialists authorized to perform such work.

If there is a need to replace parts of the device, only original spare parts are selected. If a malfunction occurs, the unit is immediately disconnected from the gas supply. It is prohibited to carry out any service work to eliminate breakdowns yourself. Before the start of the heating season, the condition of chimneys and air ducts is checked. When the equipment is turned off for a long time, the gas valve is closed.

Do not use aggressive chemicals to clean the unit. Before turning on the boiler, you need to make sure that there is coolant in the heating system, that the burner, safety valve and automation are working properly. During operation of the unit, you need to ensure that there is no smell of gas in the room. The burner is periodically cleaned of dirt.

Comparative review of gas boilers

Boilers with one heat exchanger are responsible only for supplying heat to the room; organizing hot water supply is not their task. In this regard, they are inferior to devices with two heat exchangers. The installation of an indirect heating boiler will allow you to expand the functionality, but then additional expenses are inevitable.

Also read with this article: Connection diagram for a single-circuit and double-circuit gas boiler with an indirect heating boiler

For clarity, we structure the information according to comparison criteria and present it in the form of a table.

| Single-circuit | Single-circuit with indirect heating boiler | Dual-circuit | |

| Possibility of installation (floor/wall) | +/+ | +/+ | +/+ |

| Additional expenses | – | + (for the purchase and connection of a boiler) | – |

| Economical | + | + | – (constant operation of the second DHW circuit when using water) |

| Compactness | + (in the absence of a boiler) | – (requires additional space for the boiler) | + |

| Comfort | – (when connecting the DHW circuit, the DHW and heating temperatures are not regulated) | – (temperature does not change at all points of DHW use) | – (when using more than two points, the water temperature may change sharply) |

Read about saving blue fuel in the article: How to save gas when heating a private home

Do I need to reduce power?

In modern models of gas boilers equipped with highly sensitive automation, there is no need to independently reduce power indicators. In equipment of earlier production and the simplest units, similar measures are carried out:

- in case of alteration of the heating system with a significant decrease in the level of overall performance;

- in case of refusal of certain additional functionality, including dismantling the hot water supply system and “warm floors”.

If there are significant differences in the received and minimum power indicators, the equipment “clocks”, accompanied by constant turning on and off of the boiler. In this case, accelerated wear of working components such as the burner, three-way valve and pumping device is observed. In order to prevent boiler failure, it is necessary to reduce the power indicators in one of the available ways:

- replacement of the burner device with a modulating analogue;

- reducing fuel supply by changing valve settings;

- reducing power through service menu settings;

- regulating the functioning of the circulation pump.

In order to reduce fuel consumption, a thermostat is installed to ensure more accurate operation of the equipment, and weather-dependent automation devices are installed. A necessary condition for maintaining the high quality of operation of a gas boiler is proper maintenance of the unit, as well as increasing thermal efficiency by insulating the premises.

Advantages and disadvantages

When installing autonomous heating, gas equipment becomes the optimal solution. This choice is explained by its high efficiency (90%), variety of models and manufacturers, versatility of use, compactness, ease of maintenance and relatively quick payback.

Before deciding which is better - a single-circuit or double-circuit gas boiler, let's consider the pros and cons of each of them.

Single-circuit units

The main advantage of this type of equipment is its simplicity of design, therefore, unlike double-circuit equipment, it is characterized by higher reliability and fewer breakdowns.

The operation does not depend on the pressure in the water supply system. The advantages include low equipment cost and excellent performance.

When there is no need for hot water, there are practically no disadvantages, but then versatility and functionality are reduced.

If for a comfortable stay you need to provide access to hot water, then there will be a need to purchase and install additional equipment. As a result, the area for its placement will increase and it will be necessary to equip the boiler room.

Double-circuit boiler

This may seem strange, but a 2-circuit boiler is cheaper in price. The difference in cost is small, but it is there.

Such devices are usually low-power and compact. They can be installed not in separate special boiler rooms, but, for example, in the kitchen or hallway. The main thing is that the status of the premises is non-residential. This prevents installation in the kitchen - living room, for example.

The living room is a living space.

There is a huge variety of dual-circuit gas units on the market.

Read more: Top 10 best double-circuit boilers.

This allows you to select the desired power option. At the same time, they fit quite well into the interior. There are consumers who are concerned about the noise when the device operates. However, all the worries are really in vain. The volume of the boiler is comparable to that of a refrigerator. A little time will pass and additional extraneous sounds will be in order.

We recommend reading: Requirements for the room for installing the boiler

Additional advantages of a 2-circuit boiler include the possibility of complete autonomy. You just need to set the temperature, set the time, and the boiler will turn on and off automatically according to the specified settings. Plus, the device informs about any malfunctions and performs an emergency shutdown. See the table below for convenience.

| Advantages | List of disadvantages |

| The device is compact and takes up little space | if the family is more than two people, then prepare for the fact that there will not be enough hot water |

| there is a separate circuit for DHW | water temperature is not adjustable |

| The delivery set includes a circulation pump and a membrane tank | if the cold water pressure is low, then the hot water pressure will be the same |

| with the same parameters, the equipment has higher power | When you open the tap, cold water flows for a few seconds, and only then hot water. You need to get used to this too |

| ease of installation and connection | since heating of the room stops when the hot water system is turned on, then with prolonged use of hot water, the temperature in the heating radiators can decrease noticeably |

| Possibility of use in the warm season without turning on the heating |

However, issues with the order of water procedures can be resolved. As for the rest, if you monitor the technical condition and change components on time, the equipment will last for many years.

Which boiler is better to choose: comparison of differences between single-circuit and double-circuit models

The durability of its operation, the comfort of residents and heating costs depend on how correctly the equipment is chosen.

When the question arises, which boiler is better, you must take into account its power. Most often they start from the fact that for heating 10 square meters. meters requires 1 kW. However, these figures are averaged, and first of all, the heat loss of the building must be taken into account.

Dimensions

Based on the type of installation, they are classified into floor-mounted and wall-mounted. The floor-standing equipment uses a volumetric cast-iron heat exchanger. Although they last longer than wall-mounted ones, they have greater weight and dimensions. In addition, their installation is more difficult. If we talk about the characteristics, the wall-mounted version is better, while the floor-mounted one is simpler, without complex automation.

Selection rules

To choose the right device for your home or apartment, you need to consider the following parameters:

- total heated area;

- energy costs and maintenance costs;

- availability of additional functions;

- device power;

- type of traction

When choosing, the material of the heat exchanger is taken into account, since the duration and quality of operation of the device depends on this parameter. It is better to give preference to the copper option, but it is more expensive.

Improvement of AGV by the manufacturer

The obvious advantages of gas water heating units became the reason for their further production.

But the equipment required serious modifications and improvements, so the design underwent the following changes:

- Fragile glass thermometers were replaced by more reliable Italian instruments.

- American automation from Honeywell began to be used.

- The device is turned on using a piezo ignition system.

- Changing the appearance thanks to the application of coatings using new technologies.

Principle of operation

The system works on the following principle:

- According to the laws of physics, warm water rises up the rising supply pipe.

- Then it goes to the batteries, where heat exchange occurs and the water is cooled.

- The coolant with a lower temperature flows into the return pipe, from where it again goes to the heating tank.

The heating tank in such a system is located above the radiators, which promotes the natural movement of coolant in the system.

AGV heating systems operating on this principle are called thermosiphon or gravity, in which water circulates naturally. When heated, the volume of water increases, and its excess enters an expander installed at the highest point of the system.

The overflow tube helps drain water from the expander back into the system. Consequently, the water in the expansion tank partially compensates for the water lost in the system. And free access of air into the expander regulates the pressure.

To force coolant circulation, you can embed a pump into the system, but for this a power supply must be provided.

An automatic AGV device is necessary to stop the gas supply when there is weak draft, low pressure or the igniter goes out.