The under-roof space is used in different ways; living rooms or storage systems are equipped here. Thermal insulation work, which requires little labor and financial investment, makes it possible to get additional living space that will never be superfluous. More than half of developers use mineral wool as a thermal insulator. Let's talk about the process of insulating an attic from the inside with your own hands using mineral wool, and the video at the end of the article will help you better understand this issue.

Pros and cons of mineral wool

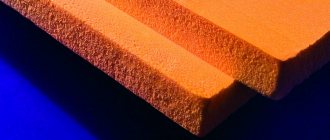

Mineral wool is a heat insulator with a fibrous structure made from mineral raw materials with the addition of synthetic binders. Depending on what raw materials were used, three types of material are distinguished.

Types of material

- Stone or basalt. It is made from molten rocks: diabase, basalt, gabbro. Clay, limestone or dolomite is added to them. The binder is a small amount of formaldehyde resin.

- Slag-like. Produced from melted blast furnace slag. This is waste resulting from the smelting of cast iron and other metals. May be toxic.

- Glass wool. The raw materials for its production are limestone, soda, sand, dolomite and borax. Broken glass and glass production waste are often used.

All types of fiber insulator have different densities. Available in the form of slabs, mats or rolls. The last two varieties are less dense. This is not always convenient at work.

Rockwool stone wool

Advantages

- Fire safety. The insulating coating does not ignite or smolder.

- Low thermal conductivity values for all types of wool.

- Resistant to temperature changes. The fibers do not deform when cooled and heated.

- High vapor permeability, which allows the insulator to “breathe”.

- Biological and chemical stability. Insects and rodents do not live in mineral wool. Exposure to chemicals does not destroy it.

- Convenient and simple installation.

In addition, the relatively low price of the insulator is attractive. But you also need to be aware of its shortcomings.

Flaws

They are few, but they are significant.

- High hygroscopicity. In conditions of high humidity or when water enters, cotton wool absorbs a lot of moisture. At the same time, its properties change. The thermal conductivity of a wet coating increases. Moreover, the more water that gets into the cotton coating, the worse it retains heat.

- The material is heavier than light insulators: polystyrene foam, extruded polystyrene foam, etc.

- All cotton wool is prone to dust during operation, for this reason protective equipment is required.

- When choosing insulation for the attic, you must take into account that this is a living space. Therefore, a security certificate is required.

Instagram trivita.uaIt is better to choose stone wool; slag wool can be toxic. Glass wool is safe, but very dusty. Its small fibers are very sharp, their exposure is harmful to humans.

Instagram nastroenie_rudnyi

Waterproofing installation process

Ideally, waterproofing is installed as follows:

- material wraps the rafters;

- laid close to the insulation.

Waterproofing is often rolled out over the rafters to save money, not stretching, but creating a sag of several centimeters. This option can also be considered good, since moisture falls on the surface, after which it rolls down and leaves the roof. Another important point is the exit of the membrane into the drainage gutter. Due to this, moisture will move out from the under-roof space.

A number of aspects of membrane installation can be highlighted. It is laid across the rafters starting from the bottom. The first option is launched into the gutter. The next layer is rolled out to the ridge. On the membrane ridge, the material is pulled on both sides along the upper edge, after which it is fixed. A strip is rolled out lengthwise along the ridge. It goes down from one and the other side of the roof. A coating is formed along which water can flow directly to the drainage gutter.

Features of thermal insulation of the attic floor

The technology for insulating a mineral wool attic from the inside involves creating an obstacle to the outflow of heat and reducing air exchange with the cold street. This is a feature of the isolation process. As a result, warm, moist steam remains inside the room. In such conditions, it is necessary to reliably protect the cotton wool from moisture, otherwise it will quickly get wet and lose its properties.

Another problem is the dew point shift. If you insulate an attic roof from the outside, the dew point will be on its outer side. In this case, the resulting condensate will evaporate into the atmosphere. But if the insulator is laid from the inside, this does not happen. Therefore, it is very important to leave an air gap of 50-100 mm between the roof and the insulator. It is necessary for the evaporation of condensate.

For effective insulation you need a roofing pie of five layers. If you look from the roof, they are located in the following sequence.

TechnoNIKOL Rocklight stone wool

Layers of roofing cake

- Ventilation gap 50-100 mm.

- Vapor-permeable membrane, moisture and wind insulation.

- The insulating layer is laid between the rafters.

- Vapor barrier film or membrane.

- Attic ceiling.

For vapor barrier, it is best to choose special membranes. On one side they are rough, the other side is smooth. Thanks to this feature, condensation does not form on them. If there is no membrane, lay a film of polypropylene or polyethylene, glassine. For moisture and wind protection, other membranes are chosen: double-layer film, porous and superdiffusion. The last option is considered the best.

Instagram ekovata58

Instagram doktor.khlus79

Instagram aliancess_ryazan

Dew point problem

Ideally, the roof in the attic should be insulated from the outside at the stage of forming the roofing pie. However, often this is done the other way around from the inside, when the house is already covered with a roof. And here certain problems arise.

The correct and ideal roofing pie is several layers of different materials laid on top of the rafters tightly on top of each other without gaps. Such a sandwich ensures that the dew point will be located on its outer side. As a result, all condensate formed outside will quickly evaporate into the atmosphere.

When insulating an attic roof from the inside, it is extremely important to leave a gap between the insulation and the existing roof for ventilation and evaporation of condensate formed due to temperature changes

By doing insulation from the inside, after installing the roof, it is impossible to form the exemplary roofing pie described above. It will not be possible to press the insulation onto the roof so that there are no voids left between them.

But steam always moves towards cold air. And then, each of the formed cavities will begin to accumulate condensation and moisture. And this is a direct path to damage to the thermal insulation material and wooden elements of the rafter system.

When insulating an attic internally, the dew point has to be shifted into the space between the laid roof and the insulation, leaving an additional 5–10 cm gap there for ventilation. Only such a technology and such a cake will avoid moisture in the insulating material.

To achieve proper air exchange in the under-roof space, it is recommended to install deflectors on the ridge and provide special holes in the eaves

To reduce the amount of water vapor in the insulation, its installation should be done using a vapor barrier film. A vapor barrier is installed from the inside of the attic on top of the thermal insulation material.

The steam must first encounter this film and mostly remain in the room. The less of it gets into the insulation layer, the better.

Recommended thickness of mineral wool for an attic roof

What thickness of mineral wool should I choose for an attic roof? This question can be answered accurately only after calculations have been carried out. It is difficult to carry them out on your own, since knowledge of standards and formulas is required. They are given in the set of rules on thermal protection of houses. Having spent time studying it, you cannot be sure that the calculations will be carried out correctly. A person without special education can only use average values or determine the thickness using a special program.

The second option is preferable. There are many such offers on the Internet. There are online versions and desktop applications. It is better to choose an independent product rather than the development of some thermal insulation manufacturer. To obtain the result, you will need to indicate in the filter table the brands and thickness of all components of the roofing pie, as well as the region where the building was erected. This is the only way to get an accurate calculation.

Stone wool TechnoNIKOL Technovent Standard

If it is not possible to calculate what layer of mineral wool is needed when insulating an attic, developers use averaged data. This is the simplest method, but it also produces the most errors. Thus, it is believed that, on average, a layer of material of 280-300 mm is required to insulate an attic floor. But depending on the region, it may decrease or increase.

Instagram stroyka_ufa

Instagram dewalt_nn

Let's start insulation - work technology

Let's start with the first problem - insufficient thickness of the joists if you insulate the attic after the construction of the entire house and installation of the roofing. Why is that? Let's take a closer look at this issue.

Thus, attic insulation can be divided into basic and additional. Basic is insulation, which is carried out during the construction of the roof of the house and involves the use of lightweight insulation directly into the rafter structure. But additional insulation already turns an uninhabited attic into a full-fledged attic.

With basic insulation, the main task is to minimize the heat loss of the house through the roof, and such basic insulation can easily replace additional internal insulation, if only you choose the insulation wisely, do not skimp on its thickness and think through the rafter system well. This is often done by those builders of their own houses who understand that 20 rooms may not be enough in the future, and additional space for a billiard room, library or sauna cannot interfere. And therefore, it is better to initially build it completely residential, and not finish something later.

But, if during the construction of your house you decided to make do with basic thermal insulation and now you have enthusiastically taken up the task of arranging a habitable and cozy attic, then the only option for you is additional internal insulation with all its nuances, the main one of which is the insufficient thickness of the rafters, which were not originally designed for dense internal insulation. But the problem is completely solvable, to prove which we have prepared a detailed master class for you:

Now let’s move on to more insidious aspects that are no less important: proper vapor barrier and waterproofing, which you may have to redo.

How to properly insulate an attic with mineral wool

Thermal insulation technology is simple. Sometimes they do the work with their own hands, even without assistants. Let's look at the sequence of installation of insulation.

1. Preparation for installation

Before forming an insulating cake, you need to protect the wood of the rafters from harmful influences. They are treated with antiseptic and fire retardants. Strictly comply with all the requirements of the manufacturer of the composition, thoroughly dry the wood. Experts recommend installing the insulator on the sheathing, which is nailed under the rafters. This way, cold bridges will not appear, but the usable area of the under-roof space will noticeably decrease.

Therefore, most often the heat insulator is placed in the space between the beams. It is, as it were, inserted into the frame formed by the rafters. It is important that the thickness of the insulation matches the size of the beams. If it protrudes outward, preliminary stuffing of bars will be required, which will level out this difference.

Instagram elesan.teplo

Instagram elesan.teplo

Forming an insulating cake

Layer the layers correctly. Otherwise, thermal insulation will not be effective.

Moisture and wind protection

Its task is to prevent moisture from the street from penetrating the heat insulator and at the same time allowing steam to escape from it into the atmosphere. Special membranes cope with this task better than others. On one side they have fine perforations. They are laid horizontally. The strips are overlapped so that the row lying above overlaps the row lying below from the outside by 100-150 mm. The joints must be taped with tape.

It is advisable to purchase all materials needed for installation from one manufacturer. Otherwise there may be problems. One brand suggests that the membrane fabric and glue will not harm each other and will last a long time. Products from different brands may conflict with each other.

Properly laid moisture and wind protection forms a continuous sheet. If moisture gets on it from the side of a leaky roof, it will roll down without getting into the insulation pie.

Instagram garant_dom_stroy

Instagram beliy_39

Insulation

The next stage is laying mineral wool in the space between the beams or sheathing elements. First it is cut out. If roll panels are installed, they are cut into strips corresponding to the distance between the rafters. Be sure to make an allowance for laying, that is, the width of the strip should be 20-30 cm greater than the distance between the beams. In this case, the panel will lie as tightly as possible.

Rockwool stone wool

The slabs are cut in the same way. The plates prepared in this way are laid in the space between the rafters. To ensure that the slab lies flat, it is inserted with little force, pressing on the edges. The panel laid between the beams must be secured. This will prevent it from sagging. This is done using a thin synthetic cord, which is stretched between the supporting elements.

Vapor barrier

On the inside of the attic space, the heat-insulating layer is covered with a vapor barrier. It prevents moisture from getting inside the insulation. Film, glassine or membrane are chosen as an insulating coating. It is laid according to the same scheme as the moisture and wind protection. The strips are mounted horizontally with an overlap of 100-150 mm. The top edge covers the bottom.

Particular attention is paid to joints. They are glued with mounting tape. There should not be a single crack left, otherwise steam will penetrate into the insulating layer. In areas adjacent to structural elements, pipes, and cables, adhesive tape is additionally used to strengthen the fastening. The film is attached to the base with small nails with wide heads or staples of a construction stapler.

Sometimes foil film panels are chosen for vapor barrier. This is a good solution to save on heating costs. The metallic side reflects heat, directing it back into the room. Lay the foil insulation so that the shiny side is turned into the room. Otherwise, the entire effect of its use will be lost.

Instagram krovelnie_raboti_nalchik

Instagram evgenii_stone

Headlining

Thermal insulation technology involves installing a sheathing on top of the vapor barrier. It is stuffed from bars, the thickness of which is from 15 to 25 mm. They will not only hold the skin in place, but will also form a small gap for ventilation. At the same time, the lathing will additionally fix and press the vapor barrier membrane to the insulating coating. This will improve the quality of the roofing cake.

The height of the wooden blocks should be the same, so the surface will be smooth. Before installing the sheathing, it is advisable to treat the elements with an antiseptic. The pitch of the lathing is chosen depending on what kind of finishing of the walls and ceiling is planned in the future. It cannot be more than 500-600 mm. The bars are sheathed with wooden boards, plasterboard, plywood, etc.

We also suggest watching a video showing all stages of the process.

We figured out how to insulate an attic with our own hands from the inside with mineral wool. These are general recommendations that must be followed when arranging the under-roof space. It is possible to transform the attic floor into a warm and cozy living space. And you can do it yourself if you follow the rules.

Insulating the attic from the inside if the roof is already covered: preparing the room

An attic is not just a lived-in attic. There are some standards that distinguish these two premises from each other. First of all, the attic roof must have a slope. In addition, the height of the room established by the standard must be at least 2.5 m.

Various materials are used to insulate the attic, such as mineral wool, polystyrene foam, etc.

Focusing on the attractive appearance, many decide to arrange an attic. But in reality, you have to deal with some nuances, which it is advisable to familiarize yourself with before starting work:

- the materials that were used to build the attic directly determine further heat loss in this room. Therefore, their choice should be approached very responsibly;

- Properly selected engineering solutions, which make it possible to provide all the necessary communications on the upper floor, have no less influence;

- The shape of the roof plays a significant role. It can be single-pitch, gable or broken;

- in order to hide the load-bearing elements of the roof, you will have to use your imagination;

- the attic can be located not only on the territory of the house, but also extend beyond its boundaries, supported by columns.

Each of these aspects has its own impact on the approach that will be required for high-quality roof insulation. But the main role still belongs to two main materials - heat and water insulation. On the one hand, the space under the roof is in the coldest zone of the building. On the other hand, a strong difference between the temperature inside and outside often causes condensation to appear, which has a destructive effect on materials.

When insulating an attic, you should pay attention not only to the ceiling, but also to the walls

Calculation of insulation density

There is a special formula for calculating the density of insulation. It looks like this: Rreq=(1/A1)+(L/k)+(1/A2)

;

A1

is the heat transfer coefficient of the inner surface of the wall (8.7 W/m oC),

A2

is the heat transfer coefficient of the outer surface of the wall (23 W/m oC),

L

– is the thickness of the insulation (m),

To

is the thermal conductivity coefficient of the insulation.

First you need to determine what the optimal thickness of the wall of a house in a given region should be ( information is in SNiP 02/23/2003

) taking into account the type of building material, and then compare the resulting figure with the actual thickness of the walls of your house.