- July 16, 2020

- Tools and equipment

- Daisy Angel

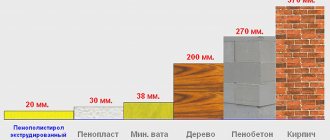

Relatively recently, the building materials market has been replenished with a new product. Foil insulation today is widely used for noise, hydro and thermal insulation of ceilings, walls, facades and roofs. This material can be used for finishing partitions, baths and pipelines. If you are interested in knowing what foil insulation is called, you should first understand the main types of this thermal insulation.

This is a combined thermal insulation covered with foil, which can be based on different materials. The aluminum component reflects heat, leaving it inside the building. Some studies claim that the reflection effect is as high as 97%. Modern insulation of this kind is thin and has water-repellent characteristics. They don't get damp.

Main types and characteristics

If you, like many consumers, are wondering what insulation with foil is called, you should know that it can be based on different materials. This should include:

- mineral wool;

- expanded polystyrene;

- basalt wool.

There are a huge variety of foil insulation products on sale today. They differ not only in characteristics, but also in application features. When asking yourself the question of what the insulation with foil is called, you should know that if it is based on polyethylene foam, then this name in the store will sound like this: foil polyethylene foam.

This product is sold in rolls, and the layer thickness can vary from 2 to 10 mm. Polyethylene has a foil layer on one or both sides. You can find self-adhesive options. On one side there is an adhesive layer, as well as a protective film. This insulation is used when finishing floors, ceilings or walls, as well as arranging ventilation systems.

Using polyethylene foam foil insulation, you can equip a heated floor, arrange a finishing base for linoleum, or organize thermal insulation in a bathhouse. This material can also be used to create shoe insoles. There are different types of such insulation on sale. If you are interested in knowing what insulation with foil based on polyethylene foam is called, then you should know what to look for in the store:

- ecofol;

- isolon;

- penofol.

The price will depend on the thickness of the insulation.

How to lay it correctly

The presence of foil on the insulation dictates a slightly different installation technology. Therefore, we will consider some features of performing thermal insulation work with unusual insulation.

Which side should the insulation be placed on the structure to be insulated?

The answer is short: foil insulation indoors can only be placed with the foil facing out. When installed on the contrary, there is no reflection of heat waves back into the room. On the façade also, outwards. The metallized layer in this case is primarily a wind and vapor barrier, and only secondly helps the base of the insulation to retain cold air.

Floor insulation

Floor insulation is carried out using two technologies:

- "floating screed";

- “floating floor” - used mainly when installing “warm floors”.

"Floating screed"

Before laying the insulation on the concrete base of the floor, the following preparatory work is carried out:

- the concrete floor is freed from the old screed;

- repair work is being carried out to restore the surface of the concrete slab;

- the base of the floor is primed;

- waterproofing work is being carried out, etc. Detailed instructions for preparing the floor for pouring screed are given in the article “Preparing the floor for pouring screed”.

When using insulation without a self-adhesive side, the concrete base and insulation are lubricated with glue for the selected type of base. The edges of the slabs are also treated with adhesive. If the glue is contact (for Penofol), a pause is made for about 30-40 seconds, during which polymerization of the open surface of the glue occurs. After the specified time, the mats are fixed.

For better adhesion, the surface is carefully smoothed with smooth movements with little effort. Thin (2-3 mm) “Penofol” is placed on the walls to a height of 5-7 cm, and overlapped in the middle of the room. Thick slabs (5-10 mm) are mounted tightly to each other, without gaps. The joints are taped with aluminum tape (insulating aluminum tape). A fiberglass reinforcing mesh is attached to the laid insulation layer, after which the screed is poured.

Under "warm floor"

When installing a “warm floor” with heating elements placed inside a cement screed, the work is performed in the same sequence as when insulating a floor under a “floating screed”.

Under the infrared film, 3 mm thick insulation is attached to the base of the floor. A heating element is placed on it, and logs or sheets of plywood or OSB are attached on top of it. For this option, experts recommend buying ALP type insulation.

If possible, you should ground the foil through a Euro socket - if the infrared heater film breaks down, the aluminum foil will be energized. Cases of electric shock have not been written about on the forums, but such a possibility exists. Therefore, it is better to play it safe.

And we also note that many experts advise first reinforcing the insulation, and then attaching a reinforcing mesh over the heating elements. This is exactly the case when “you can’t spoil porridge with butter.”

Wall insulation

Foil insulation for walls can be based on fiberglass or polyethylene foam. It is attached to the surface using glue (in this case, only vertical slats are stuffed for fastening sheets of gypsum plasterboard, plywood or OSB) or placed in the cells of the sheathing.

The connecting seams are taped with metallized tape (adhesive tape). The gaps between the slats and the insulation are foamed with polyurethane foam, but it is better to avoid them. Vapor barrier work is not carried out - foil serves as a barrier to vapor molecules. From above, everything is covered with a protective screen made of plasterboard, plywood or OSB.

Ceiling insulation

Thermal insulation of the ceiling is carried out mainly by Isolon, 2-5 mm thick, type B (foil on 2 sides) or C (self-adhesive).

In the first case, the lathing is placed directly on the ceiling, in the second - on top of the heat-insulating layer. In both cases, the insulation is fixed with glue. In addition, you can use special self-tapping dowels with a large plastic head. When installing a stretch ceiling, no other types of work are performed. If the ceiling is to be painted or wallpapered, then plasterboard is attached to the sheathing.

Bath insulation

Rolled glass wool of medium thickness is ideal for insulating the ceiling and walls of a bathhouse. Insulation work starts from the ceiling and ends on the walls. Quite often they play it safe and attach parchment paper to the ceiling - it serves as an additional barrier to the penetration of steam into the insulation.

The insulation scheme includes:

- lathing device;

- laying insulation in the cells of the frame;

- gluing the joints with special tape (metalized);

- A counter-lattice is attached on top of the frame. The goal is to create a ventilation gap and a base for attaching the finishing trim.

Roof insulation

For thermal insulation of the attic space, foil mats made of mineral fiber are best suited. The order of work is as follows (enlarged):

- on the roof, all detected cracks are sealed with tow and foam;

- a counter-lattice is placed on the boards;

- a class B vapor barrier film (with the smooth side facing the room) or glassine is attached to the created frame with glue or a construction stapler;

- At the bottom of the rafter system, strips are placed behind which the thermal insulation will be laid;

- foiled mineral wool mats or expanded polystyrene slabs are laid;

- connecting joints are glued with metallized tape.

Insulation from outside

To insulate the facade you will need:

- foil mineral wool of medium thickness;

- reinforcing fiberglass mesh;

- wooden planks for lathing;

- glue;

- dowels with self-tapping screws.

According to the instructions, technological operations are performed in the following sequence:

- wooden slats are attached vertically to the wall using dowels in increments equal to the width of the insulation. Experts advise reducing this distance by a few mm so that the insulation fits tightly between the studs;

- sheets are glued to the wall;

- a reinforcing mesh is attached on top of the thermal insulation layer;

- The finishing work on the facade is carried out using the grid: siding is installed or decorative plaster is applied.

Minvata

This material has a foil layer on only one surface. The product is produced in the form of slabs or rolls. The layer thickness here is slightly greater, and the minimum value is 5 cm. Basalt wool or fiberglass can be used for production.

If you want to know what shiny wall insulation is called, then you should know that in this case we are talking about foiled mineral wool. It has limitations in its use, since cotton wool can negatively affect health. This insulation is used in non-residential premises or for exterior decoration. The products have certain properties that are suitable for thermal insulation of baths, ceilings and walls.

Useful tips

Thanks to the properties of foil, its correct use when baking gives any dish a special aroma and juiciness. This happens due to the fact that the products are baked in the oven quite slowly and are well saturated with their own juice. Since they are practically hermetically sealed, and the foil does not allow odors to pass through, the aroma of both the main product and the spices used remains inside.

Using foil is not difficult, you just need to know some of the nuances.

When choosing a material, you should give preference to domestic products, since safety requirements in different countries are different.

Using low-quality products can negatively affect your health. The foil should be strong enough, dense, but thin, since it is important that the juice does not leak out. If the material is too thin, then several layers need to be made. It is important to wrap the foil correctly

If you plan to bake the dish on a baking sheet, then you need to arrange the sheets overlapping so that the edges of the bottom layer protrude beyond the edges of the baking sheet by about 2 centimeters. You need to do the same with the top layer. Then carefully align the edges and fold tightly twice. To properly wrap a large piece of meat or a whole fish, you need to cut 2 fairly long sheets, lay them out crosswise, place the product in the middle and wrap tightly, first in one sheet, then in the other. When wrapping, there should be no holes or holes left, otherwise the juice will leak out and burn, and the dish itself may turn out dry, and the expected effect will not be achieved. It is better to make 2 layers, but do not compress the packaging too tightly. To prevent the foil from burning and nothing sticking to it, you can grease the inner surface with vegetable oil. Not all foods can be baked in foil. This is contraindicated for cereals and grains, green and soft vegetables, and fruits. This method is not very suitable for beef - you can just get a boiled piece of meat. But veal and especially pork are perfectly baked. It is better to cook wild meat according to special recipes. It is better to take meat for baking in one large piece weighing at least a kilogram, only in this case it will be juicy and tender. With less weight it may turn out to be dry. Any fish can be baked. It is advisable to cut off the fins and tail - they can tear the foil. If you want to bake the whole fish, then you need to wrap it in several layers, but do not pack it too tightly. When roasting chicken, it's a good idea to first wrap the ends of the legs and wings in pieces of foil, shiny side out, to prevent them from charring, and then wrap the whole chicken. Vegetables for baking (potatoes, peppers) are wrapped separately. Vegetable stew is prepared in a heat-resistant container, which is covered with a “lid” of foil. The oven must first be preheated well for half an hour. For vegetables, the temperature should be at least 100 degrees, for meat and fish - at least 200. During the cooking process, it is better not to open the oven again, as it cools down quickly. To ensure that the dish is covered with a delicious crispy crust, two methods are used. You can make holes in the top of the package. This must be done very carefully to prevent juice from leaking out. Or you can cut the foil on top 10-15 minutes before the end of cooking, move the edges apart and put it back in the oven to brown.

Application area

Foil insulation is represented by different base materials, which determines the area of their use. For example, foamed foil polyethylene is a self-adhesive material that is used in technological equipment to create a heat-insulating layer in air ducts and pipes.

If you are interested in knowing the correct name for foil insulation, you should pay attention to its base. If it is mineral wool, then this is its foil version. It is available in the form of rolls, cylinders and slabs. Mineral wool has a high degree of fire resistance, so it is widely used for insulation:

- walls;

- saunas;

- chimneys;

- baths;

- roofs

If you see foil polystyrene foam with double-sided coating, you can be sure that the material is resistant to temperature fluctuations over a wide range, which is why it is most often used when constructing heat-insulating layers in heated floors. If you need to insulate the space under the roof, foil polystyrene foam is perfect for you.

Basalt foil insulation is more resistant to aggressive environments than all other types of foil insulation. The properties of this thermal insulation do not change even when exposed to large temperature differences - from -190 to +600 °C. Foil-coated basalt thermal insulator is used in aircraft manufacturing, the heat and power industry and in the construction of gas stations.

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

- thermal conductivity - the ability to conduct heat (solids);

- convection - heat transfer through the air due to different densities of cold and warm air currents;

- radiation - any body with a temperature above zero emits heat waves, which are absorbed by walls and ceilings (surfaces), converted into heat and transferred to the cold external environment. This exchange accounts for about 60-90% of heat loss.

Thus, heat loss is inevitable. It turns out that to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer. And the optimal material was found - foil insulation, known for its reflective and low-emissivity properties.

Reflective thermal insulation works across all heat transfer processes: radiation, convection and conduction, inhibiting heat loss.

Why else should you choose this insulation?

Now you know what shiny insulation is called and what its varieties are. Despite the fact that there are differences in the compositions of these materials, they are united by certain technical characteristics, namely:

- moisture-repellent properties;

- high efficiency;

- heat reflection;

- resistance to temperature fluctuations;

- high vapor permeability;

- high sound insulation properties.

As for vapor permeability, this figure is 0.001 mg/(m h Pa). You may also be interested in the ability of the material to reflect thermal radiation. The average thermal conductivity is 0.037 W/(m °C). As for sound insulation properties, sound absorption can reach 68 percent. Foil is also good because it protects the types of insulation materials presented with it from radon and solar radiation. Thermal insulation materials of this type do not require treatment with chemicals, which has a positive effect on environmental cleanliness.

Top foil cover

Cooking vegetables and baked goods does not always require completely wrapping the dish in aluminum film. It is enough to cover a large number of prepared products on top. To do this, vegetables are placed in a heat-resistant container and covered tightly with metal paper. This technique is good for casseroles or vegetable stews. These measures allow you to preserve vitamins and nutrients that are destroyed during normal cooking.

Flour products prepared at home need protection from overheating. To do this, place a sheet of foil on top of the baking sheet. The matte side comes into contact with the baked goods, while the glossy side reflects the high temperature. It is better to perform this procedure shortly before the end of baking the dish in order to see how the cooking process is progressing.

Penofol: application, types and characteristics of the material

Thanks to insulation with foil, it has become possible to protect the house from vapor and liquid moisture. This thermal insulation may consist of polyethylene foam. The two components are connected to each other thanks to thermal welding.

If you are still wondering what insulation with foil on one side is called, you should pay attention to penofol. One-sided foil protection is designated in the specifications by the letter “A”. Such thermal insulation can have a thickness from 0.2 to 4.4 mm. If necessary, you can purchase a foil type of penofol 10 mm thick.

The material is used for external and internal insulation of walls of buildings for various purposes: hangars, attics and basements, heated and unheated warehouses, children's, medical institutions and trade pavilions. If you are interested in knowing what foil insulation for floors is called, you should know that penofol is excellent for this purpose.

Briefly about the main thing

Reflective insulation works according to a special principle based on a layer structure. The main layer consists of a porous or fibrous material; on top (sometimes on both sides) it is complemented by a layer of aluminum foil or metallized film.

It is the shiny surface that does the main job of retaining heat in the room. Additionally, it serves as a steam, hydro and sound insulator, and if the installation technology is violated, it causes the appearance of a thermos effect.

Common foil materials include polyethylene foam, basalt and glass wool, and foil polystyrene foam. To fix the material on the surface, you need a stapler or dowels; the joints are fixed with aluminum adhesive tape.

Types of foamed foil polyethylene

This insulation is offered for sale in several varieties, which differ in letter marking. If you are wondering what foam with foil is called, you should know that it is polyethylene foam. If you see the letter “A” in the marking, you should know that this is a material with a one-sided coating; it is used with other types of insulation, for example with foam plastic.

The type marked “B” has a double-sided foil coating and is used exclusively independently. If you see materials marked “C”, then this is insulation, on one side of which there is foil, and on the other, polyethylene foam itself with a moisture-resistant contact adhesive mixture. The material can be used without the use of installation tools.

Once you know what insulation with foil and foam rubber is called, it’s time to get acquainted with the main pros and cons of this material. Among the advantages should be highlighted:

- safety and resistance to rodents;

- ease of transportation;

- fire safety;

- ease of installation;

- excellent sound insulation characteristics;

- small thickness.

Benefits of Reflective Insulation

Effective reflective insulation has a number of significant performance advantages:

- To produce high-quality insulating material, polyethylene foam and foil are used, made from the same raw materials from which products that come into contact with food are produced. This indicates that the material fully complies with the highest hygienic standards.

- Chemically pure polished aluminum foil used in the production of reflective insulation reflects 95-97% and emits no more than 5% of thermal energy. When thermal radiation is reflected, the surface of the foil remains cold.

- A layer of air bubbles contained in polyethylene foam provides the creation of additional thermal resistance, preventing heat loss due to thermal conductivity.

- The insulation fully complies with fire safety requirements, since it belongs to low-flammability, low-combustibility materials.

- Due to its low weight and thickness, the material is packaged in compact rolls that take up little space, so it is convenient for transportation and storage.

- The use of reflective thermal insulation makes it possible to minimize heat loss in a building, thereby reducing heating costs. But, in addition, the use of foil materials can reduce the cost of insulating a room compared to the use of other materials.

Minuses

But like every material, it has its drawbacks. Firstly, it is too soft, so it does not have the necessary rigidity. It is not suitable for finishing plastering work or subsequent wallpapering. When pressure is applied to the material, it will bend.

Secondly, sound insulation is quite difficult to attach, with the exception of type “C” with a self-adhesive surface. But to install such insulation you need to use different adhesive mixtures. You cannot nail the sheets, as you will worsen the thermal insulation efficiency.

Thirdly, the effectiveness and versatility of this thermal insulation does not allow it to be used for external buildings. The material can act as an additional layer and reflect incoming thermal energy. In addition, it can only protect the walls from moisture.

Building structures insulated using reflective insulation

Reflective thermal insulation can be used on almost any surface that is free of dirt and dust, has excellent adhesion, and is effective for use on complex surfaces with corners, differences and bends.

- When insulating walls from the outside, the maximum effect is achieved by creating an air gap of 15-20 mm on the foil side of the reflective thermal insulation. Reflective insulation combined with traditional insulation works effectively for high-rise and low-rise frame structures. In this case, the thermal resistance of the walls increases sharply without increasing their volume.

Installation of insulation can only be carried out end-to-end without overlaps. The seams should be taped with foil tape.

- When insulating a wall indoors, two options are possible. In the first option, two air gaps are provided: between the external wall and the insulation, and between the insulation and the wall covering, for example, plasterboard sheets. In this case, reflective thermal insulation with double foil is used. In the second option, one air gap is provided - between the external wall and the thermal insulation. In this case, a material is used that is foil-coated on one side. The foil faces inside the room.

- Reflective insulation installed on the roof provides not only heat but also effective vapor control. The insulating layer protects the under-roof space from moisture penetration.

- When insulating a ceiling, reflective insulation is attached to the installed sheathing. It is especially effective to use reflective film for thermal insulation of the bathhouse ceiling. It is also necessary to provide a small gap between the insulating and cladding material. In this case, insulating material is used, foil-coated on one side, directed into the room.

Using foil in cooking

In dishes cooked in foil, more microelements useful for the body are retained, because the food is cooked in its own juice, and heat treatment occurs evenly. There is no need to pre-marinate a piece of meat, a whole chicken or fish for many hours. Usually the housewife rubs the food with spices and, wrapping it in foil, puts it in the oven.

Foil allows you to reduce cooking time; the meat will be baked at a temperature of two hundred degrees, within half an hour. Vegetables and fish can be served in just twenty minutes; the oven only heats up to one hundred degrees, which also saves electricity.

Until the microwave was invented, many people heated food in the oven, wrapped in foil, which was quick and safe. The dish will remain warm for a long time if you cover it with foil and a towel. Baked and cooled cuts of meat will stay fresh longer if they are wrapped in foil and left at room temperature.

A good housewife knows that in order for baked goods to bake evenly, they first cover it with foil. A few minutes before the end of the cooking time, remove so that the pie can get a golden brown crust.