Comfort in modern country houses is ensured in several ways, including high-quality insulation of walls, roofs and floors. Among the various insulating materials, Rockwool “Light Butts” mineral wool slabs stand out, the technical characteristics of which make the house warmer and more reliable. I have worked with thermal insulation from the Rockwool line more than once, and then I will tell you about its properties and differences from stone wool from other brands.

Source roofingcenter.rf

About the Rockwool line

The line of insulation from the international company Rockwool is stone wool products designed for thermal and sound insulation, as well as fire protection. They are used in private housing construction, for all types of buildings and structures, as well as in more specific areas (for example, in industrial equipment, shipbuilding). Regardless of where they are used, materials improve quality of life:

- prevent heat loss, which helps save energy and reduce costs;

- increase the resistance of structures to fire;

- improve sound insulation of rooms;

- extend the life of the house until major repairs.

In the private housing construction sector, the following types of material are especially popular:

- Rockwool "Light Butts". The name hides slabs of light weight mineral wool. The lightweight material is designed for use in apartments and private homes, where the weight of the material sometimes becomes an important criterion.

Source teletype.in

- Rockwool "Venti Butts". Rigid slabs made of stone wool are used in two ways. If a suspended facade system is chosen for a house, then they play the role of a thermal insulation layer, separated from the facade finishing by an air gap. If the insulation is double-layered, they become the outer layer of the cake.

- Rockwool "Facade Butts". Facade material in different designs: for example, “Facade Optima” slabs are used in insulation systems with a thin plaster layer, and “Facade Butts Pilaster” mineral wool rolls are needed for thermal insulation of protruding wall fragments (with a curved surface).

Installation work

Rockwool's thermal insulation material is a market leader and has the highest international safety certificate: ECO Material Green.

To install Light Butts insulation, it is not necessary to have construction qualifications. Ease of installation is one of the important advantages of this material.

It is important to correctly calculate the required amount of insulation so that there are a minimum number of gaps. Each gap is a potential “cold bridge” through which warm air can escape

Installation takes place using the frame method. Flexi technology makes it possible to avoid the appearance of gaps. When installing insulation boards, you should use protective equipment:

- gloves;

- glasses;

- closed clothing and shoes.

Where is it used?

In private housing construction, the material is used in the following types of structures and work:

- Thermal insulation of frame and siding walls, partitions, ceilings, pitched roofs, attic rooms, balconies and loggias.

- Soundproofing of residential premises, including floors and floors with joists.

- Insulation of fireplaces according to SNiP rules to ensure fire safety in the house.

- Protecting the walls of baths and saunas from heat loss, maintaining a comfortable microclimate (especially important for steam rooms).

Source line-home.ru

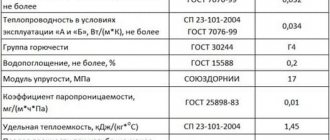

Table of technical characteristics and prices for Rockwool insulation (prices are current as of 02/01/16)

| LIGHT BUTTS SCANDIC* | LIGHT BUTTS* | ACOUSTIC BUTTS* | FLOR BUTTS* | FIRE BUTTS* | SAUNA BUTTS* | BUTTS FACADE* | WIRED MAT* | TECH BATTS* | RUF BUTTS* | |

| Density (types, separated by commas), kg/m3 | 30 | 35-37 | 45 | 125 | 100 | 40 | 145 | 50, 80, 105 | 90, 110 | 115, 135, 160, 190 |

| Thermal conductivity, W/(m K), λ10 | 0,036 | |||||||||

| Thermal conductivity, W/(m K), λA | 0,042 | |||||||||

| Thermal conductivity, W/(m K), λB | 0,045 | |||||||||

| Peel strength of layers, kPa | from 4 to 15 depending on the type of insulation* | |||||||||

| Compressive strength at 10% deformation, kPa | from 20 to 65 depending on the type of insulation* | |||||||||

| Vapor permeability, mg/m h Pa | 0,3 | |||||||||

| Water absorption, no more than kg/m² | 1 | |||||||||

| Service life more than 50 years | Yes | |||||||||

| Flammability degree | NG | |||||||||

| Types of construction insulate: | ||||||||||

| attics | + | + | ||||||||

| balconies | + | + | ||||||||

| loggias | + | + | ||||||||

| frame walls | + | + | ||||||||

| partitions | + | + | + | |||||||

| floors | + | + | ||||||||

| roofing | + | + | ||||||||

| floors between floors | + | + | ||||||||

| ceilings with joists | + | |||||||||

| ceilings between floors, under cement screed | + | |||||||||

| fireplaces, stoves, high-temperature equipment | + | + | + | |||||||

| piping systems, air ducts | + | + | ||||||||

| walls in steam rooms, saunas, baths | + | |||||||||

| building facades | + | |||||||||

| vertical and horizontal surfaces | + | |||||||||

| roofing | + | |||||||||

| Price per package, rub (thickness 50 mm) | 475 | 598 | 733 | 761 | 2781 (30mm) | 682 | 796 | 1230 | 925 | 955 |

* - You can always find detailed information and current prices in the Rockwool product catalog.

Features of insulation

Rockwool thermal insulator is made from basalt fibers. Therefore, its advantages automatically become durability, environmental friendliness and biostability. Also, a characteristic of Rockwool Facade Butts (like other products) remains fire resistance. The materials do not smoke or ignite even in direct contact with fire, when the temperature reaches +700°C. Due to their fire resistance, they are especially useful in areas with a high fire risk.

The fibrous structure of compressed basalt fibers contains enough air spaces to provide not only excellent thermal insulation, but also good sound dampening. This is a significant plus for residential premises. To insulate a house using basalt slabs, you do not need special skills or special fasteners. In addition to the inherent qualities of all construction wools, some products in the Rockwool line have additional advantages.

Source aviarydecor.com

Tips and tricks

For any work with stone wool insulation, it is necessary to use personal protective equipment - a respirator, gloves, special suits. Despite the high level of environmental friendliness and safety, this will prevent the development of allergies, since there is a small risk of dust during installation.

The durability and strength of the structure directly depends on correct and competent installation. Thus, an adhesive solution or special disc anchors are suitable for attaching rigid insulation. For lightweight structures, installation against frame sheathing is quite suitable.

If for some reason the work is not carried out immediately after purchasing the material, then the insulation should be stored only in indoor areas, avoiding interaction with high humidity. It is allowed to store packages on top of each other, but only on a flat, dry surface.

Characteristics of "Light Butts Rockwool"

The main difference between “Light Butts” and other slab heat insulators is the use of “flexi” technology. The presence of technological improvements is highlighted by markings along one of the long edges of the insulation. The 5 cm wide marked edge can spring back, making installation work easier.

When installing standard mineral wool slabs, gaps often remain between the house structures and the insulation; this requires the use of additional materials. On sloping areas, additional fasteners are often required, and on roofs with complex geometry, two people often need to work: one installs and holds the slab, the other fixes it.

Thanks to the spring edge of Light Butts products, installation can be carried out by one person. In this case, no gaps are formed, since the fit of the insulator to the frame is complete; adjustment becomes unnecessary, simplifying the process. Installation of "Light Butts" is carried out in three stages:

- The raw (hard) edge is inserted into a niche or frame.

- The flexible edge is tucked in to install the entire slab material.

Source euro-modul.com.ua

- The slab is finally straightened. The density of “Light Butts” and the light weight of the material allows it to hold even in places with a large angle of inclination, and does not require immediate fastening.

Calculate the insulation of your home

A cozy home is, of course, a warm home. The level of heat loss depends on correctly calculated thermal insulation. To reduce it, it is necessary to correctly calculate the required volume of material for wall insulation and, in fact, calculate the optimal thickness of wool for insulation. The calculation of rockwool insulation for a facade can be determined in three ways:

- by contacting special construction organizations;

- on one's own;

- using an online calculator.

Of course, the easiest way is to choose the first option and save a lot of time by getting only a number. But in this case, you will have to pay a considerable amount for such services, and this, as you know, is an extra expense during construction or renovation, because you can calculate the amount of insulation yourself. Of course, it will take some time, but the result will be just as accurate.

For example, we have a brick house, the wall thickness is one and a half bricks. The work is planned to be carried out using “Light Butts” or “Scandic”. In order for thermal insulation to be effective and heat to be retained during the cold season, the wall must have a thermal resistance of at least 3.5 m2*K/W. To determine optimal thermal insulation, it is necessary to make certain calculations:

First, we determine the current thermal resistance of the existing wall. Its thickness is 37 cm, and the thermal conductivity coefficient is 0.56. This applies to red clay bricks. So, for different types of material, thermal conductivity is usually different.

- We calculate the current thermal resistance. To do this, the wall thickness in meters must be divided by the thermal conductivity coefficient. As a result, we get: 0.37/0.56=0.66 m2*K/W.

- We are not enough to reach the optimal value of 3.5 m2*K/W: 3.5-0.66=2.84 m2*K/W.

- Next, it became possible to calculate the required thickness of the stone wool layer: 2.84 * 0.045, where the second value is the thermal conductivity coefficient of the insulation itself. Thus, we get the value in meters – 0.127. We find the value in millimeters - 127 mm. This is the required layer thickness for thermal insulation with Rockwool “Light Butts” and “Scandic” stone wool.

Characteristics of "Venti Butts" Rockwool

The difference between the product is the use of phenol-formaldehyde resins in the manufacture of slabs. This binder component provides additional strength, rigidity and low water absorption. This is also the reason for using the material primarily for external thermal insulation (in suspended ventilated facades).

The product is available in four varieties, differing in density and hardness parameters. To protect against cold air, the outer layer is compacted in all brands of Rockwool Venti Butts, and the technical characteristics are as follows:

- The package contains from 1 to 8 sheets.

Source stroy-podskazka.ru

- Length: 100 or 120 cm, width: 60 or 100 cm. Thickness: from 3 to 20 cm.

- The variety popular among buyers is 5 cm thick and weighs 2 kg.

- Water absorption does not exceed 1.5%.

- Average density: 95 kg/m³.

- Thermal conductivity: 0.035-0.041 W/m*K.

- Ultimate strength: 10 kPa (if deformation does not exceed 10%).

Source sprb.by

About the properties of Rockwool stone wool in the following video:

Dimensions

Slabs are produced in a large and varied range of sizes:

- thickness 150, 50 mm;

- 1000x600x100 mm;

- 100, 800x600x50 mm;

- 1200x600x150 mm;

- 1000x600x100 mm;

- 1200x600x100 mm.

The minimum area of a Rockwool “Light Butts” slab in the format 1000x600x50 mm is 6 square meters. If you consider that there are ten pieces in the package, it is easy to calculate how much material is needed to insulate the area.

“Scandic Butts” comes in a pack of 12 pieces, its price is noticeably lower.

Scandic Butts has an advantage in the field of logistics, since it takes up less volume; construction organizations are more willing to purchase it. Recently, XL size has appeared, which is in high demand. “Light Butts” is more suitable for private households due to its economic feasibility and has obvious functional advantages.

The price lists of trading platforms indicate prices, which may include different units of measurement:

- pieces;

- Cubic Meters;

- kits.

Packaging costs from 580 to 890 rubles. Before purchasing, you should definitely find out how much Rockwool “Light Butts” insulation you need to purchase.

Briefly about the main thing

Mineral wool boards from Rockwool are high-quality materials that make your home comfortable and extend the life of structures. The assortment includes several types of slabs, differing in size, density and hardness. This variety makes it convenient to choose a heat insulator for a specific object.

All Rockwool materials do not require additional processing. For some brands, innovative technology has been developed that simplifies installation work.

Question

Write in the comments what you think - in what cases should the compression ratio of the slabs be taken into account (the elasticity of different brands differs quite significantly)?

Customers' opinions

“I bought Rockwool Light Butts slabs for internal insulation of a pitched roof, I’m happy with the material. After unpacking, the mineral wool quickly regained its volume; there was no need to shake it.”

Alexey Ponomarev, Ekaterinburg.

“I used Rockwool to insulate the walls of the balcony, the installation was completed in 1 day. Despite the high density, the insulation was easily cut with a knife, while the edges remained smooth and were not painted. It took 2 packages of 10 cm thick products for the entire balcony, I think the cost of the investment is justified.”

Igor, Moscow.

“I insulated the roof with Rockwool, and when choosing a variety I settled on Light Butts. In my opinion, this is the best option for pitched roofs; three layers of slabs were quickly and easily placed in the space between the rafters; no additional fixation was even needed.”

Sergey, Nizhny Novgorod.

“I decided to purchase Rockwool to furnish the attic space; I was pleased with the insulation. The advantages include convenient sizes, rigidity and density, lack of shrinkage and comfort. In addition to preventing heat loss, mineral wool protects the attic from the heat in summer; the room is now used as a living room. I didn’t find any other disadvantages with the material besides the high cost.”

Vadim Avtushko, St. Petersburg.

Installation nuances

The recommended method of laying insulation is in at least two layers, with overlapping joints. The presence of a springy long edge simplifies the process of placing the slabs; in particular, they do not need to be trimmed in narrow areas or when adjusting the dimensions. After installation between the rafters or other guides, the insulation straightens and fills the entire internal space. It is easy to identify the desired side - it is marked with red stripes. The edges of the mineral wool are hard enough so that the fibers do not fall out, but at the same time they fit well together, cold bridges and drafts are practically eliminated.

Important installation nuances include the need to protect Rockwool from direct exposure to moisture and condensation; in particular, when thermally insulating roofs, a special membrane is laid on top of the mineral wool (with obligatory overlap and gluing of joints for tightness). Rockwool should not be left open to avoid stone fibers and particles from entering the room. Therefore, insulation boards are covered with a vapor barrier film, siding paneling, sheets of gypsum cardboard or plywood. During work, personal protective equipment must be used: respirator, goggles, gloves, closed clothing.

Price

| Name of Rockwool insulation, purpose | Material dimensions, mm | Slab area, m2 | Number of pieces per package | volume, m3 | Price, rubles |

| Light Butts, hydrophobized thermal insulation boards with marked flexed edges. Recommended for insulation of pitched roofs, frame and siding structures, partitions and joists. | 1000×600×50 | 6 | 10 | 0,3 | 570 |

| 1000×600×100 | 3 | 5 | |||

| Light Butts Scandic, compressed slabs, in contrast to the previous type, compression reaches 70%, which reduces transportation costs by 3 times. This brand has all the advantages of Flexi technology and is suitable for thermal insulation of the same structures | 800×600×50 | 5,76 | 12 | 0,288 | 470 |

| 800×600×100 | 2,88 | 6 | |||

| 1200×600×100 | 4,32 | 0,432 | 710 | ||

| 1200×600×150 | 3,6 | 5 | 0,54 | 900 |