- Roofing from corrugated sheets How to remove a rectangular chimney pipe

- Ondulin coating

- Extraction through a soft roof

- Passage through ondulin

- Elastic penetrations

- What is the goal?

- Pipe waterproofing Basic installation work

Objects that have a heating function from a boiler, stove or fireplace require normal exhaust of smoke to the outside, which is necessary to maintain the protection and safety of residents. Therefore, it is extremely important to know how to make a chimney pipe pass through the roof and roofing, taking into account all standards.

Basic Rules

If your home has heating, you will need to create optimal conditions for removing flue gases. There are several ways to remove the pipe depending on the installation location. Its choice is influenced by many factors, and the chimney can be installed:

- in the ridge itself;

- at a distance from him.

Each of the described methods has its own differences and features, but preference is given to installation according to the second option. To maintain the required draft force, the total height of the smoke channel must correspond to the limits of 5-10 m.

Parameter table

Article d1, mm d2, mm B, mm A, mm N, mm Weight, kg

K2.MU.UPK45.080 80 90 380 520 200 2 K2.MU.UPK45.100 100 110 400 530 200 2.10 K2.MU.UPK45.110 110 120 410 540 200 2.20 K2.MU.UPK45.115 115 125 415 540 200 2.20 K2.MU.UPK45.120 120 130 420 560 200 2.30 K2.MU.UPK45.130 130 140 430 570 200 2.35 K2.MU.UPK45.140 140 150 4 40 580 200 2.40 K2.MU.UPK45.150 150 160 450 590 200 2.50 K2.MU.UPK45.160 160 170 460 610 200 2.50 K2.MU.UPK45.180 180 190 480 640 200 2.70 K2. MU.UPK45.200 200 210 500 660 200 2.90 K2.MU.UPK45.210 210 220 510 680 200 2.90 K2.MU.UPK45.220 220 230 520 690 200 2.90 K2.MU.UPK45.23 0 230 240 530 700 200 3 K2.MU.UPK45.240 240 250 540 710 200 3.10 K2.MU.UPK45.250 250 260 550 730 200 3.10 K2.MU.UPK45.260 260 270 560 750 200 3, 50 K2.MU.UPK45.280 280 290 580 870 200 4.10 K2.MU.UPK45.300 300 310 600 800 200 4.50 K2.MU.UPK45.320 320 330 620 850 200 4.90 K2.MU. UPK45.350 350 360 650 870 200 5.40 K2.MU.UPK45.400 400 41 700 940 200 5.80 K2.MU.UPK45.450 450 460 750 1010 200 6.30 K2.MU.UPK45.500 5 00 510 800 1080 200 6.70 K2.MU.UPK45.550 550 560 850 1150 200 7.30 K2.MU.UPK45.600 600 610 900 1220 200 7.80 K2.MU.UPK45.650 650 660 950 12 90 200 7, 80 K2.MU.UPK45.700 700 710 1000 1360 200 7.90 K2.MU.UPK45.750 750 760 1050 1420 200 8.10 K2.MU.UPK45.800 800 810 1100 1490 200 8.10 K 2.MU. UPK45.850 850 860 1150 1630 200 8.70 K2.MU.UPK45.900 900 910 1200 1640 200 9.70 K2.MU.UPK45.1000 1000 1010 1300 1770 200 10.70 K2.MU. UPC45.1100 1100 1110 1400 1980 200 11.20

Article K2.MU.UPK45.080

- K2.MU.UPK45.080

- K2.MU.UPK45.100

- K2.MU.UPK45.110

- K2.MU.UPK45.115

- K2.MU.UPK45.120

- K2.MU.UPK45.130

- K2.MU.UPK45.140

- K2.MU.UPK45.150

- K2.MU.UPK45.160

- K2.MU.UPK45.180

- K2.MU.UPK45.200

- K2.MU.UPK45.210

- K2.MU.UPK45.220

- K2.MU.UPK45.230

- K2.MU.UPK45.240

- K2.MU.UPK45.250

- K2.MU.UPK45.260

- K2.MU.UPK45.280

- K2.MU.UPK45.300

- K2.MU.UPK45.320

- K2.MU.UPK45.350

- K2.MU.UPK45.400

- K2.MU.UPK45.450

- K2.MU.UPK45.500

- K2.MU.UPK45.550

- K2.MU.UPK45.600

- K2.MU.UPK45.650

- K2.MU.UPK45.700

- K2.MU.UPK45.750

- K2.MU.UPK45.800

- K2.MU.UPK45.850

- K2.MU.UPK45.900

- K2.MU.UPK45.1000

- K2.MU.UPK45.1100

- d1, mm 80

- d2, mm 90

- B, mm 380

- A, mm 520

- N, mm 200

- Weight, kg 2

- d1, mm 100

- d2, mm 110

- B, mm 400

- A, mm 530

- N, mm 200

- Weight, kg 2.10

- d1, mm 110

- d2, mm 120

- B, mm 410

- A, mm 540

- N, mm 200

- Weight, kg 2.20

- d1, mm 115

- d2, mm 125

- B, mm 415

- A, mm 540

- N, mm 200

- Weight, kg 2.20

- d1, mm 120

- d2, mm 130

- B, mm 420

- A, mm 560

- N, mm 200

- Weight, kg 2.30

- d1, mm 130

- d2, mm 140

- B, mm 430

- A, mm 570

- N, mm 200

- Weight, kg 2.35

- d1, mm 140

- d2, mm 150

- B, mm 440

- A, mm 580

- N, mm 200

- Weight, kg 2.40

- d1, mm 150

- d2, mm 160

- B, mm 450

- A, mm 590

- N, mm 200

- Weight, kg 2.50

- d1, mm 160

- d2, mm 170

- B, mm 460

- A, mm 610

- N, mm 200

- Weight, kg 2.50

- d1, mm 180

- d2, mm 190

- B, mm 480

- A, mm 640

- N, mm 200

- Weight, kg 2.70

- d1, mm 200

- d2, mm 210

- B, mm 500

- A, mm 660

- N, mm 200

- Weight, kg 2.90

- d1, mm 210

- d2, mm 220

- B, mm 510

- A, mm 680

- N, mm 200

- Weight, kg 2.90

- d1, mm 220

- d2, mm 230

- B, mm 520

- A, mm 690

- N, mm 200

- Weight, kg 2.90

- d1, mm 230

- d2, mm 240

- B, mm 530

- A, mm 700

- N, mm 200

- Weight, kg 3

- d1, mm 240

- d2, mm 250

- B, mm 540

- A, mm 710

- N, mm 200

- Weight, kg 3.10

- d1, mm 250

- d2, mm 260

- B, mm 550

- A, mm 730

- N, mm 200

- Weight, kg 3.10

- d1, mm 260

- d2, mm 270

- B, mm 560

- A, mm 750

- N, mm 200

- Weight, kg 3.50

- d1, mm 280

- d2, mm 290

- B, mm 580

- A, mm 870

- N, mm 200

- Weight, kg 4.10

- d1, mm 300

- d2, mm 310

- B, mm 600

- A, mm 800

- N, mm 200

- Weight, kg 4.50

- d1, mm 320

- d2, mm 330

- B, mm 620

- A, mm 850

- N, mm 200

- Weight, kg 4.90

- d1, mm 350

- d2, mm 360

- B, mm 650

- A, mm 870

- N, mm 200

- Weight, kg 5.40

- d1, mm 400

- d2, mm 41

- B, mm 700

- A, mm 940

- N, mm 200

- Weight, kg 5.80

- d1, mm 450

- d2, mm 460

- B, mm 750

- A, mm 1010

- N, mm 200

- Weight, kg 6.30

- d1, mm 500

- d2, mm 510

- B, mm 800

- A, mm 1080

- N, mm 200

- Weight, kg 6.70

- d1, mm 550

- d2, mm 560

- B, mm 850

- A, mm 1150

- N, mm 200

- Weight, kg 7.30

- d1, mm 600

- d2, mm 610

- B, mm 900

- A, mm 1220

- N, mm 200

- Weight, kg 7.80

- d1, mm 650

- d2, mm 660

- B, mm 950

- A, mm 1290

- N, mm 200

- Weight, kg 7.80

- d1, mm 700

- d2, mm 710

- B, mm 1000

- A, mm 1360

- N, mm 200

- Weight, kg 7.90

- d1, mm 750

- d2, mm 760

- B, mm 1050

- A, mm 1420

- N, mm 200

- Weight, kg 8.10

- d1, mm 800

- d2, mm 810

- B, mm 1100

- A, mm 1490

- N, mm 200

- Weight, kg 8.10

- d1, mm 850

- d2, mm 860

- B, mm 1150

- A, mm 1630

- N, mm 200

- Weight, kg 8.70

- d1, mm 900

- d2, mm 910

- B, mm 1200

- A, mm 1640

- N, mm 200

- Weight, kg 9.70

- d1, mm 1000

- d2, mm 1010

- B, mm 1300

- A, mm 1770

- N, mm 200

- Weight, kg 10.70

- d1, mm 1100

- d2, mm 1110

- B, mm 1400

- A, mm 1980

- N, mm 200

- Weight, kg 11.20

How to protect your roof from fire

To do this, you need to consider two points:

- Passage through walls and ceilings. Here it is necessary to use polyurethane foam with mineralite, since the outer pipe of the sandwich heats up to a temperature of 200*.

- When passing through the roof, roof trim and all other associated elements are required.

According to the standards, the minimum permissible distance between the chimney and load-bearing beams or rafters should be 130-250 mm. The inside of the structure is filled with heat-resistant material.

You can find passage diagrams in the Ferrum catalog in the “advertising and printing products” section of the website.

Possible mistakes

Faced with inexperienced craftsmen or without studying all the detailed information about installation, some owners encounter problems during operation. There is an explanation for these troubles; the most common mistakes are worth noting:

- During the work, a single-wall structure was used, rather than a sandwich pipe.

- The docking points are not sealed.

- To save money, the box was filled with sand, instead of expanded clay or any non-flammable component.

- Ceiling cutting does not imply the presence of a box.

In most cases, the pipe can be mistakenly wrapped and installed close to the ceiling, the joints coated with asbestos and claimed that it is reliable.

The ceiling-passage chimney assembly will not work as efficiently as possible in such a situation. It is impossible to avoid a fire without adhering to generally accepted installation rules.

Passage node

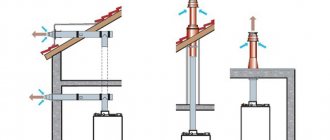

One option is to pass through the ridge.

But most often, the installation of a chimney pipe through the roof and roofing is carried out not through the ridge, but at a distance from it. According to SNiP requirements:

- The total length of the smoke channel must be at least 5 m. The only exceptions are houses that do not have attics, but subject to the presence of stable draft.

- The height of the chimney above the roof is at least 0.5 m.

- The chimney rises half a meter or more above the ridge. But if the horizontal distance between it and the ridge ridge does not exceed 105 cm.

- The mouth should be level with the ridge or higher, when the horizontal width is in the range of 1.5 - 3.0 m.

- The chimney outlet must be no lower than the line laid from the ridge towards the eaves overhang at a slope of 10º relative to the horizon.

The disadvantage is the need to compare the height of the chimney, which leads to additional costs. Professionals do not recommend doing it through the valley due to the fact that snow deposits often accumulate in such places, thereby compromising the waterproofing and causing leaks. There are also difficulties in organizing the box. Localizing the chimney in the lower section of the slope also has a significant disadvantage - the likelihood of damage when snow melts.

The installation work is also influenced by the material that forms the basis of the chimney pipe. This can be a metal, brick or ceramic base. Each of the listed options has a different combustion temperature, which you need to know when creating a project. Based on the pipe cross-section, the outlet can be shaped like a square, circle, rectangle or oval. Knowing how to properly vent a chimney through the roof, its installation is carried out in three successive stages, carried out by a specialized specialist:

- Additional rafters are installed on the sides.

- Laying horizontal beams at a distance identical to this hole (calculated according to SNiP and corresponds to the range of 140-250 mm).

- Filling the inner surface of the box with non-flammable insulation material.

To prevent disruption of normal ventilation, it is recommended to install a separate ventilation system.

Roof aerators

Ventilation aerators are special devices for ventilating the under-roof space and removing moisture and water vapor to the outside. They are used on flat roofs, preventing swelling of the covering roll material due to temperature changes, and on pitched roofs for effective ventilation and condensation removal.

Vanes (aerators) are produced in different sizes and designs. They are considered the most effective elements of ventilation systems. On a flat roof, they are installed evenly over the entire surface at the joints of the slabs. On pitched structures they are placed closer to the ridge (0.6 m from it) or in places where valleys pass (on complex roofs).

On pitched roofs, aerators are installed closer to the ridge or in places where the roof breaks.

The manufacturing material is AISI 316 stainless steel or durable polypropylene, thanks to which they can withstand a wide temperature range from -40 to + 90 °C.

Installation of aerators on a flat roof

When covering with two layers of rolled materials, aerators are installed in the bottom layer:

- A hole along the diameter of the aerator tube is cut through the screed and layers of insulation.

- Cover with gravel and attach the aerator to hot mastic.

- After cooling, fix with self-tapping screws.

- The top layer of the roofing is fused in such a way that the aerator is at the point of overlap (15 cm) of the sheets, and the junctions are sealed.

Video: DIY aerator installation on a two-layer soft roof, part 1

In single-layer flooring, aerators are installed on the screed, making a hole up to the vapor barrier. The coating is laid on the skirt of the aerator, hot mastic and a patch are applied on top, covering the skirt and extending about 15 cm onto the coating. The aerator is then secured with self-tapping screws, and the joint is treated with sealant.

Video: installation of an aerator on a two-layer soft roof, part 2

Installation of aerators on metal tiles and corrugated sheets

The installation of ventilation outlets on roofs made of metal tiles and corrugated sheets is the same and is associated with damage to the roofing covering, so it must be carried out especially carefully so as not to have to change damaged sheets of covering material.

- Apply the template (included in the kit) to the installation site, outline and carefully cut a hole along the intended line.

- The seal is secured with screws and sealant is applied.

- Install the aerator, secure it with hinges and additional screws.

- From inside the attic, the passages of ventilation pipes are puttied with sealant.

Smoke exhaust outlet through various types of roofing

Below are recommendations for installing a smoke exhaust duct depending on the roof material.

Tile roofing

In this option, to process the passage, professionals resort to the use of corrugated, self-adhesive, sheet aluminum or lead.

Exiting a pipe with a cross-section in the shape of a square or rectangle

If the smoke exhaust hole has a brick base, then due to non-standard dimensions, before removal, a small part of the covering sheets must be removed or cut to a larger size. To ensure waterproofing, elastic tapes with an adhesive base are used. They are glued by a specialist to the pipe base and roof sheathing. The upper edge is secured with a metal strip, and the existing connections are sealed with a sealed substance.

To prevent precipitation, it is recommended to install an additional tie.

Passage of a round chimney through the roof

This is achieved thanks to a special cap, which is responsible for the smoke exhaust hole. A small and even hole is made in the coating, according to the pipe dimensions. A master flush is put on it, and the existing connections are sealed with a sealed substance.

Features of this design

Sandwich is a good option for a chimney pipe with insulation. Insulation provides you with the following advantages:

- the possibility of functionality of the chimney pipe when located in a zone of low temperature conditions;

- provides the pipe with the necessary fireproof properties (inside the building).

Standard versions of such chimneys have an external galvanized coating. There are also options made of stainless steel, as well as painted in any color suitable for you.

Existing versions of sandwiches made of stainless steel are covered with a special protective film on the outside. The main thing is to remember to remove it before using the chimney for its intended purpose. There are also special adapters on sale that you will need when connecting the boiler and pipe. Be careful when choosing elements for a sandwich chimney.

Scheme of a sandwich pipe.

The necessary tools for work are:

Video material: tightness of a brick chimney through a metal tile

Corrugated roofing

This is a relevant material, often used in construction work. However, when using it, there is a risk of leakage, especially if technical rules are not followed. To prevent this outcome, it is recommended to place it in a vertical position. The roof hole is made with a grinder, but it is necessary to ensure that the resulting corrugated sheet does not have nicks or other irregularities.

How to remove a rectangular chimney pipe

In this situation, professionals recommend using galvanized sheet:

- Cutting four strips for further mounting on each side.

- Laying from the bottom edge to the cornice.

- Attach the strips and bottom fastening to the sheathing.

- Ensure tightness.

Exhaust of a chimney with a cross-section in the shape of a circle

In this case, installing a chimney through the roof requires rolled bitumen insulation or foil tape of the same name. After this, a penetration is installed, glued to the sheathing, and sealed with a heat-resistant sealant. If it is made of a rubber base, there is an increased risk of melting, so it is worth placing a clamp and gasket underneath that can withstand relatively high temperatures.

Fighting joint leaks

To create the maximum possible tightness of the junction of the roofing material and the pipe at the points of contact, an internal apron is made using the lower strips.

Installation of a chimney passage through the roof.

To make an internal apron, you need the following tools:

- marker;

- long metal ruler;

- grinder with a disk 2 mm thick;

- pliers;

- hammer.

In order to do this, the plank is applied to the walls of the chimney pipe, making marks for the top of the plank. The next step is to punch a groove along the previously marked line.

Installation of the inner apron should start from the bottom wall. The edge of the apron is inserted into the groove, after which it is installed on the remaining walls. The overlap should be 15 cm. Then the edge of the film inserted into the groove is sealed. Having trimmed the lower strips, they are installed and then secured with self-tapping screws.

After installing the lower apron, you can begin installing the tie, which is a sheet of waterproofing material placed under the elements of the inner apron from below. The main function of a tie is to drain water.

After completing the installation of the tie and apron that protect the joints, the roofing material is laid. Then the outer apron is installed. To do this, use the upper abutment strips.

The installation of the apron on the outside is similar to the installation of the apron on the inside. The difference is the absence of a groove and the upper edge is fixed directly to the chimney wall.

Important: today the building materials market offers products that are designed specifically for chimneys with a round cross-section. They are roofing passages that consist of a base (flat steel sheet) and an apron cap

A circular chimney is installed inside the passage.

Video material: tightness of a pipe on a roof made of ondulin

Extraction through a soft roof

A distinctive feature of the material is that it belongs to the category of combustible building materials. Therefore, it is necessary to leave space between the coating and the hole for the chimney (approximately 13-25 mm). Waterproofing is done identically to other options. The difference is the use of a valley carpet or the installation of the coating itself on the pipe.

How to install a chimney through the roof

The work carried out by a specialist proceeds in several stages:

- Determining the best localization of the passage site.

- Installation of the box.

- Cutting a hole in the slope.

- Folding the roofing material outwards and the moisture insulation towards the inside.

- Fixation.

- Sealing the box and filling it with thermal insulation.

- Creating a seal using sealants.

Passage through ondulin

The most important task is to fill the internal cavity with fire-resistant materials as much as possible. Insulation is provided by an apron that goes under the roof. For this purpose, it is worth taking a closer look and purchasing self-adhesive tape “Onduflesh”.

Extraction of a smoke channel in a constructed roof by a master

- Choosing a suitable location.

- Forming a box from beams.

- Creating a hole in the roof.

- Filling the box with non-flammable material.

- Sealing joints with a sealant.

Strengthening the rafter system

Often when installing a chimney, the question arises about strengthening and strengthening the rafter system, because it is necessary to form a hole in the roof pie for the pipe. That is, you will need to install a couple of spacers. When creating a roof made of metal tiles, the pitch between the rafters is rare, and the formed opening or the distance between the rafters may be too large. Therefore, it is necessary to install vertical spacers.

Sometimes you have to break the integrity of the rafter leg, that is, cut it. Then, in certain situations, purlins or crossbars are also sawn. In this case, at the place where the rafter leg was cut, it must be fastened to adjacent, undamaged ones. For this, additional spacers are also used, between which bars are inserted vertically. Their function is to replace the rafter leg at the chimney passage.

Round pipe

The difference between installation work is the need to use special cutting. The professional conclusion is as follows:

- Arrangement of the box.

- Cutting a hole for the chimney.

- Fastening an iron sheet or installing a ready-made part.

Elastic penetrations

Since it is problematic to install a chimney through the roof without professional help, it is important to pay due attention to the selection of each detail.

Distinctive characteristics are:

- Resistance to adverse weather conditions.

- UV resistant.

- Flexibility.

- Tight fit.

- Aesthetics.

Hard penetrations

There are two main types:

- One-piece - inserted into the upper edge of the chimney, after which a cap or cone is put on top.

- Detachable - its upper part is put on the chimney, and a sealed substance is applied along the edges; strong fixation is ensured with the help of a clamp.

UE marking

Today, the industry produces eleven standard-sized types of ventilators, including those for ventilation of seam roofs and corrugated sheets. For original designs of ventilation systems and aerators, non-standard versions of CP are manufactured.

Typical designs of units are marked with alphabetic and numerical designations that define their characteristics and elements:

- The letter combination UP indicates a passage node.

- Numbers 1 and further 01-10 indicate typical sizes of units without a condensate ring and valve (for example, UP1-01).

- Numbers 2 and further 01-10 indicate typical sizes of units with a valve, but without a condensate ring (for example, UP2-01).

- Numbers 3 and further 11-20 indicate typical sizes of units equipped with a valve and a condensate ring (for example, UP3-22).

Important! The choice of ventilation units for ventilation outlets in one design or another is made by designers. The type of UP is directly related to the environmental climate, the need to install an aerator, the design of the seam roof and corrugated sheeting

The type of UP is directly related to the environmental climate, the need to install an aerator, and the design of the seam roof and corrugated sheeting.

The roof structure with a built-in control unit for the ventilation duct exit is often called a roof penetration. The passage unit is fixed on the roof using braces secured with brackets and clamps. The UP branch pipe is connected to a flange, fixed to the concrete glass with an anchor as a support. Often, a “skirt” is constructed on the roof penetration to protect the joints from water getting inside.

The outlet of the ventilation duct and ventilation of a soft roof (as opposed to a seam roof) has some features in the installation of the UP. It is made from galvanized steel sheet along with mineral wool, which serves as a heat insulator. Deflectors (also galvanized) or umbrellas are installed inside to protect against moisture.

Advice! If there is a fan in the unit, it is recommended that the internal part be made of perforated steel sheet.

The power supply output is placed in plastic casings. The design of the ventilation unit on the attic roof in this embodiment will perform a sound-absorbing function.

For reinforced concrete roof structures, concrete slabs with ready-made holes for the exit of ventilation ducts are installed at the penetration points. When the size of such an opening cannot provide the required reliability characteristics of the floor slab, the roof penetration and ventilation outlet should be constructed in monolithic concrete.

Installation of a ventilation outlet on the roof

Chimney height and placement

All calculations performed are based on the requirements of SNiP 41-01-2003 and SP (building rules) 7.13130.2009, as well as on recommendations received from manufacturers of heating devices.

When constructing a flat roof, it is assumed to leave a margin of at least 50 cm. For a pitched roof, the following rules from the craftsmen apply, based on the distance between the chimney and the ridge and their location:

- Up to one and a half meters. In this case, the height of the pipe must be at least 50 cm (relative to the last or enclosing parapet).

- Within 1.5-3 meters. Here the height cannot be lower than the ridge.

- If you want to place elements further than 3 meters, then the minimum height will be determined by drawing a line at an angle of 10 degrees relative to the horizon.

The final stage of installation

The design of the unit is completed in the following stages:

- Remove the protective film from the sandwich pipes. It is highly undesirable to free parts from polyethylene earlier - they may be damaged during transportation or installation.

- Seal the joints properly with sealant. Ideally, the composition should withstand temperatures within 1000 degrees.

Which areas need to be coated with sealant:

- seams at the junction of internal sandwich pipes - the plane located on the outer part from above;

- joints of external pipes - the entire outer surface area;

- the junction of sandwich pipes with other components of the system - the entire area or diameter, if we are talking about round pipes.

Do not rush to use the new chimney right away; first check that it is working correctly:

- Turn on the heating device (boiler, stove or fireplace) at low power.

- Now inspect the device to see if it is leaking smoke in the wrong places.

- Check for excessive heating of components of the entire system, especially in the wall or roof transition area.

What is good about a chimney made from sandwich pipes? It looks aesthetically attractive and provides the fireplace with a modern style; even a beginner can assemble it. And also, if installed correctly, it will last a long time and will delight the owners with uninterrupted operation.

Fire safety

Some layers of the roofing pie and the wooden rafter system cannot withstand high temperatures, so the likelihood of fire increases. To eliminate this risk, it is necessary to use a special box along the perimeter of the roof opening.

Pipe waterproofing

Protection from moisture is also an important step that should not be skipped when arranging the passage.

Basic installation work

The box is mounted from timber, located level with the sheathing. Vapor and waterproofing is fixed along its edges. To do this, a cross-shaped cut is made in the canvas and a triangle-shaped piece of material is turned into the inner surface. To ensure fixation, you need to stock up on nails with a wide head or construction staples. You will also need sealants and adhesive tape.

Fixing a roof leak near a pipe

To do this, a drainage gutter must be laid. And the hole itself is covered with internal and decorative aprons.

Insulation with bitumen tape

Provides a high level of sealing of any type of surface. It completely eliminates the negative effects of moisture, as it is characterized by significant strength.

Elements used for output and sealing

- The box is galvanized.

- Ceiling overhead sheet.

- Stainless steel clamps become.

Provided that the technical rules are followed correctly, the passage of the chimney through the roof and roofing is characterized by good thermal insulation, which is achieved by filling the internal cavity with basalt wool or other heat-resistant materials. If possible, it is better to leave a small space with air (5-7 cm) between the insulation and the smoke conductor. If penetrations are involved in the installation of the structure, then you should select the required part taking into account the material that makes up the base.

Master flush

This penetration can be applied to any type of roof - slate, tile, metal roof, asphalt or tile.

Ideal for sealing stove and fireplace chimneys.

Used for straight roofs and for sloped roofs.

This type of product is an excellent combination of price and quality.

Master Flash is distinguished by high professional reliability and functionality - this is achieved through the use of high-quality materials for use.

The main feature of this penetration is the use of reinforced polymer rubber, which can withstand heavy loads (temperatures up to 138 degrees).

Polymer rubber does not become more flexible due to heat.