Today's heating equipment market offers a wide range of electric and gas boilers, but solid fuel units remain in demand. They are cheaper, allow heating large areas, operate autonomously, and fuel is available for them. In order for the device to work properly and remain safe, a chimney through the wall must be installed. How to do this correctly – we will consider further.

A chimney brought out through the wall Source dimohod.spb.ru

Main design components and principle of operation

A chimney is a structure used to eliminate exhaust gases after combustion of fuel to the outside. It is located vertically and has a cavity inside. The structure performs the following tasks:

- releasing toxic gases into the street (they are dangerous to humans);

- eliminating soot particles deposited on furniture and entering the body;

- removal of water vapor;

- fire prevention.

Before bringing the chimney through the wall , you should consider the principle of its operation. It lies in the physical properties of gases: when heated, their density becomes less, they become lighter and rise upward. As a result, the air in the firebox becomes thinner and fresh oxygen enters it. Good draft ensures constant combustion.

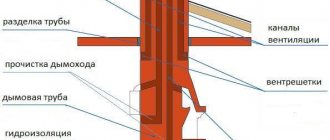

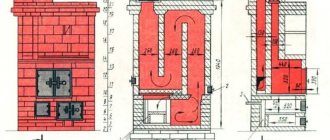

All chimney structures have the following components: a horizontal section (from the boiler to the wall), a vertical box, valves and inspection hatches (they are required for periodic cleaning of the walls from soot). At the top of the chimney, a cap is placed on the pipe to prevent precipitation from penetrating inside.

Components of a chimney Source dymoxody.ru

At what height should radiators be hung?

The installation height of heating radiators is an important criterion for their efficient operation. There are a number of regulatory requirements for the installation of heating batteries that must be observed during their installation. At what height to hang radiators - this question is answered by the material in the article presented to your attention.

Heat transfer from a heating radiator is divided into 2 components - convective and radiant heating. Convective heating of air is realized based on its thermophysical characteristics. Cold air is in the lower part of the room, hot air always rises to the upper part. The presence of a gap from the bottom of the radiator to the floor ensures the normal movement of portions of air into the convective channels of the radiator sections.

Air enters the sectional space, heats up from the walls of the battery and rises. A portion of new cold air takes its place. This type of movement is observed on an ongoing basis (provided the radiator is operating).

Regulatory requirements state that the minimum distance from the radiator to the floor must be at least 60 mm, the maximum - up to 120 mm. The calculations and tests carried out prove that a distance to the floor in the range of 6 – 12 cm is optimal for organizing convective air movement.

It should be noted that the distance from the bottom of the battery to the floor must be maintained not only when installing the radiator on a wall, but also when installing it separately - on the floor. Some brackets (legs) are height adjustable - both for radiators and convectors.

In addition to the distance to the floor, there are other regulatory requirements that also affect the efficiency of the radiator:

1. The distance to the window sill (when installing the device under a window) must be at least 50 mm from the top of the device;

2. The distance from the rear plane of the battery to the wall should be within 20 - 50 mm;

3. Heating radiators installed in the same room or on the same floor must have the same installation height at the top points of the devices.

The minimum distance to the window sill of 50 mm ensures the normal exit of heated air from the sectional space of the radiators, while the window sill does not block the flow. The gap between the wall and the radiator involves the entire surface of the battery - if it is not observed, the convective movement of air flow along the rear surface of the device is disrupted.

A number of manufacturers offer customers not only rigid brackets, but also adjustable products. They allow you to change the distance from the radiator to the wall - it becomes possible to configure the optimal operating option.

In addition, experts recommend installing a sheet of thermal insulation with a reflective layer on the wall behind the radiator - it will direct the thermal radiation of the battery into the room (and not into the wall).

When installing in the same room, it is imperative to maintain a single-level arrangement of radiators - the top points of the devices coincide. If any individual batteries are mounted higher, air will constantly accumulate in them.

Classification of chimney structures

Before installing a chimney pipe through a wall, you should consider the types of construction. By design, it can be single-walled or double-walled. The first option is made of sheet steel. It is inexpensive and suitable for installation in country houses and cottages. The disadvantage of the product is its short service life. For effective operation, the structure will have to be insulated.

Double-wall chimneys are sandwich systems that are recommended for installation in wooden houses. The chimney is multilayer and has low thermal conductivity, which is extremely important for highly flammable materials.

Depending on the material used to make the structure, there are:

- Brick . Often, their construction requires a foundation, and for proper laying, certain construction skills. This option is acceptable when building a fireplace in the house.

- Steel . Stainless steel material is cheap, but requires external thermal insulation. If this is not done, condensation will accumulate inside the pipes, which will affect the quality of traction. Moisture can also get into the firebox and extinguish the flame. It will be difficult to light the boiler again.

Steel chimney Source krovlyamoya.ru

- Asbestos-cement . Such products are heavy and fragile. A foundation is required for their installation. Under the influence of hot gases and moisture, such products deteriorate faster.

- Ceramic . Such a chimney can withstand temperatures of more than 100 degrees, but requires thermal insulation and careful operation. Installation of such pipes is difficult, and they are expensive.

- From sandwich pipes . The preferred option for building a chimney on the street. To produce the product, two pipes are taken, placed inside each other. There is a thermal insulation layer between them. The system is installed simply and quickly.

When choosing a material, not only its technical characteristics are taken into account, but also its decorative properties.

How to select batteries for a room

The volume of batteries should be enough to heat the room

The heating system is a complex structure, so it as a whole and its individual elements, such as heating radiators and pipes, require proper installation and appropriate selection of a product suitable for a particular room.

Regarding the heating radiator, there are recommendations on the installation of pipelines, the height of radiators (maintaining distances from the floor) and their correct location.

As a rule, radiators are installed in places of greatest heat loss

As for the choice of location for installing radiators, as a rule, these are places with the greatest heat loss. In almost all houses or apartments, such places are windows and doors, regardless of the use of new technologies. It is not always possible to install a radiator above the door, so they are often mounted under the windows.

To prevent dampening of the wall under the window, and to ensure that warm air is evenly distributed throughout the lower part of the room and then rises, it is necessary that the size of the heating radiator be 70-75% of the window in this room.

Rules for installing radiators

If the radiator is located under the window, then install it strictly in the middle

For heaters, not only size is a reference requirement, but there are also a number of other recommendations that should be followed both when choosing a heating element and when performing installation work.

These requirements include:

- the heating device must be installed strictly in the middle of the window, equidistant from the edges;

- the installation height of radiators from the floor should not exceed 15 cm, otherwise cold zones will form above the floor, and if you lower the heater below 8-10 cm from the floor, then cleaning under such a device will be problematic;

- Radiators should be placed at a distance of 12-18 cm from the window sill; if the device is placed closer, there may be a loss of heater power due to the influx of cold air from the window opening;

- the distance from the back wall of the device to the wall covering should be 3-7 cm, this is necessary for proper air convection.

General requirements for construction

Since you can remove the chimney correctly yourself, you should take into account the technological requirements. The cross-section of the smoke exhaust ducts depends on the power of the heating equipment. With lower parameters, draft will deteriorate and combustion products will be removed more slowly.

Placing the pipe inside the box Source petropech.ru

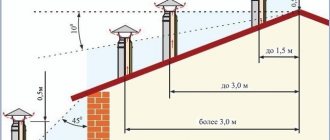

To create normal draft, it is better to use a round chimney. The number of bends should be reduced. The minimum allowed height of the structure is 5 m. If the roof covering is prone to ignition, then a spark arrestor is placed on it in the area of contact with the chimney.

High-quality ventilation is installed near the boiler. The length of the inner part is no more than 1 m, otherwise this area will quickly become clogged with soot and traction will deteriorate. The chimney is equipped with a reservoir to collect accumulated condensate and a window for maintenance. Do not make 90° bends.

Advantages and possible disadvantages

Before leading the pipe from the stove through the wall, you should consider the positive and negative aspects of the design. The following are its advantages:

- saving space indoors;

- the construction is not at the initial stage of construction of the building, but after its completion (this is the best option if it is necessary to reconstruct the house);

- ease of maintenance and repair;

- less construction work;

- ease of regulation of the chimney if necessary to change the draft force;

- high level of fire safety of the building and heating equipment;

Fire protection of a chimney Source krovlyaikrysha.ru

- there is no need to violate the integrity of the rafter system, there is no need to make holes in the ceiling or roof;

- optimal level of safety in terms of leakage of toxic gases.

However, this design also has disadvantages:

- requires mandatory thermal insulation;

- low efficiency (heat from them enters the atmosphere);

- at high altitudes, operation of the structure is difficult due to the large windage, so additional fastening is required;

- with a large number of bends, the rate of removal of combustion products decreases.

To prevent water from the slope from entering the chimney, it is necessary to install special ebbs. Sometimes the design can disrupt the exterior of the building.

Distance from the floor to the radiator and battery: SNiP standards from window sills

› Construction › House

05.12.2018

Ensuring a comfortable temperature for people living in a private house or apartment in winter is a priority task for every owner. When organizing individual heating or heat supply in an apartment building, all elements are important, starting with what should be the distance from the floor to the heating radiator, and ending with the fluid pressure in the system. Before starting work, you should study the building codes and regulations (SNiP) relating to the organization of heat supply, and also find out at what distance experts recommend hanging the heating device.

Standards

SNiP standards are advisory in nature, but when replacing batteries in an apartment in an apartment building with a central heating system, their implementation is mandatory. This is due to the fact that when designing the house, all the conditions for its further maintenance were taken into account, including, among other things, economical heat supply.

According to established standards, a brick or panel house requires the following:

- The distance from the floor to the battery or radiator should be within 80–140 mm. A smaller installation height will make it impossible to carry out wet cleaning under the device and will provoke the accumulation of dust that is undesirable for human health; a larger one will reduce the useful heating zone.

- The distance between the battery and the window sills should be 100–120 mm. If the distance from the radiator to the window sill is reduced, the conversion of air masses will decrease and the efficiency of the heating battery will decrease.

- Installing heating radiators from the wall more than 30–50 mm is not recommended due to the fact that, as in the previous case, the conversion is reduced and the accumulation of dirt is provoked with minimal possibilities for its elimination.

The radiator must be hung above the floor exactly in the center of the window opening. This will ensure the creation of a heat shield in the area of the glass filling of the window, while maintaining the aesthetic appearance of the room.

Connection diagrams

Several schemes for connecting radiators into a single thermal system have been developed and are used. They are presented in the following types:

- maximum thermal output occurs with a lateral connection, which involves installing the input in the upper sector of the battery, the output is at the bottom on the same side;

- if the heat sink is of significant size, the best option is considered to be a diagonal connection, where water enters through the upper pipe and is discharged through the lower one, on the opposite side;

- When installing hot water supply pipes hidden under the floor surface, a bottom connection scheme is used, popularly called “Leningradka”.

If the heat supply pipes are placed in a rough screed, then significant heat losses should be expected due to contact with the concrete and the ceiling of the lower floor.

Types of heating batteries

The efficiency of heating a room will depend not only on how far from the floor the radiator or radiator is hung, but also on their connection diagram, the material and design of the heating devices themselves. The following models are available on the market today:

- Cast iron batteries. The adult generation probably knows them firsthand. During the Soviet Union, only these models were used in heating systems. Today they have a more presentable appearance. They are characterized by a high level of heat capacity, long-term heat transfer, absence of consequences from water hammer, and they also have an increased service life.

- Steel radiators. They have low heat transfer rates - heating occurs quickly, but they cool down no less quickly. The welded structure is sensitive to hydraulic shock. There is no way to add sections yourself. At the same time, the weight of the product and ease of installation attract many homeowners. Products of the German brand “Kermi” are in particular demand.

- Aluminum radiators. They are characterized by low weight, beautiful shape, and increased thermal output. They are presented on the market in two versions, where in the first the design consists of one monoblock, with a volume that provides different powers, in the second - a stacked sectional one.

- Bimetallic batteries. The innovative design of the placement of heating collectors made it possible to achieve the level of heat transfer of aluminum models, as well as the strength and reliability of their cast iron counterparts.

The radiators purchased must meet GOST standards. They check compliance by reading the documents for the goods in the store. Their absence may serve as a reason for refusing to purchase a product at this outlet.

Preparing for assembly

Before installing a stove in a country house with a pipe exiting through the wall, you need to prepare. Work requires special clothing and gloves. If you will be cutting metal products, it is advisable to wear safety glasses.

Selection of tools and materials

To complete the work, the following tools are required:

- drill, equipment for cutting material;

- heat-resistant sealant;

- riveter;

- clamps, dowels, corners;

- foil construction tape;

- screwdrivers;

- level, plumb;

- knife;

- ladder;

- When working with concrete walls, you will need a hammer drill.

Components for installing a chimney Source vse-postroim-sami.ru

The materials you will need are a steel pipe, with which the horizontal fragment is connected to the boiler. You also need a tee for connecting pipes, an elbow (with its help the structure is directed upward), and a support console. Brackets and dowels are used to mount products on the wall. The connection of several pipes is carried out using clamps. You also need thermal insulation material and a protective cap.

See also: Catalog of companies that specialize in the installation of fireplaces, stoves and utility networks.

Choosing a location

The house has central and side walls. The second is located on the side of the slopes and under the roof overhangs. Liquid gets onto this part when it rains (if the drainage system is not fixed). There is a small roof overhang above the central walls, so the risk of liquid entering from the roof is minimal.

It is better to mount the smoke exhaust structure on the front wall. Here it is taken into account that there should be no windows or balconies on it along the line of the chimney. If you have to install a pipe through an overhang, then high-quality fire protection is installed.

Choosing a location for the chimney outlet through the wall Source stroychik.ru

Calculation of chimney height

Since it is possible to correctly bring a chimney through a wall to the street in a wooden house only if technical requirements are met, the first parameter that is taken into account is the height of the structure. It depends on the number of floors of the house. If the height of the building does not exceed 5 m, then the minimum parameter for the height of the structure is 5 m. If this value is neglected, the structure in the house will smoke in the house, the draft will deteriorate, and the performance of the heating device will decrease.

If the pipe is too long, fuel consumption will increase. When the height of a building exceeds 10 m, the main reference point is its ridge: it should be 0.5 m below the chimney. This characteristic is affected by the cross-section of the pipes and the power of the heating equipment.

Chimney height Source vosaduly.ru

Pipe diameter calculation

The internal diameter of the structure must correspond to the dimensions of the pipe. Any narrowing of the internal volume of the pipe affects the formation of draft. The presented value is affected by the power of the equipment: the higher it is, the larger the internal diameter. You need to follow standard building rules:

| power, kWt | Internal section, cm | Minimum diameter, cm |

| up to 3.5 | 14×14 | 15,8 |

| 3,5-5,2 | 14×20 | 18,9 |

| 5,2-7 | 14×27 | 21,9 |

If we take into account all the technological features of installation, the structure will last for decades without significant problems.

Installation of a heating device

Let's look at how to properly install a heating radiator under a window. The technology is simple, but requires compliance with the rules to ensure uninterrupted functionality of the system, maintaining the highway in working order without the need for intervention from the owner. All work is done with your own hands, but if the units are made of cast iron, you will need an assistant.

Installation technique for floor batteries

Heating devices with a large weight - cast iron, copper - are installed on the floor. When filling the internal volume with coolant, connecting pipelines, the weight of the structure can reach critical values, the old walls will not withstand the weight

It is especially important to calculate the load in houses with wooden or backfill walls - these are private buildings, as well as multi-apartment buildings of old buildings

Floor-standing appliances are equipped with additional legs with or without wheels. If the supports are on wheels, they need to be fixed; stationary supports are attached to the floor. Fixation with self-tapping screws, dowels with a plastic head or dowel-nails.

Also, floor-standing units are attached to the wall, for which hanging brackets or hooks are used. Additional fixation is needed to hold the heating device in a vertical position. The screw-in height of the wall hooks is equal to the distance from the floor to the upper radiator manifold, taking into account the width of the gap to the window sill. Before starting installation, you need to mark the openings, level the horizontal screw-in of the brackets, and only then fix the device. The most convenient way is to put the battery in place, mark the fastening points, remove the radiator and then attach the hooks.

Installing a wall radiator

Wall-mounted heating appliances are supplied with a set of hangers that fix the product on the wall. The brackets are selected taking into account the weight of the battery with coolant and connected pipeline. If the included hooks are too short or soft, you should replace them with stronger ones.

First you need to decide at what height from the floor to hang heating radiators in a private house. The standard of 120 mm from the floor covering to the lower collector is not always observed, for example, if there is a coolant supply pipe on the floor in the room or there are protrusions. It is permissible to reduce or increase the distance by 20 mm.

The work algorithm is as follows:

- find the center of the window opening;

- mark the center point of the heating device;

- combine two marks;

- measure the distance from the lower radiator manifold to the upper one, add 120 mm, set aside the height from the floor at the point where the hangers are screwed in;

- check the horizontal position of the hooks;

- fix the mounting hangers on the dowels, having previously drilled holes in the wall;

- If the hooks are adjustable, then you can adjust the position of the battery by tightening the brackets.

There are no particular difficulties in installing heating devices. The technology is the same for batteries made of any material; the differences relate only to the types of suspensions and the technique of fixing the brackets.

Installation instructions

Now you should directly consider how to install a chimney through a wall. The technology may differ slightly depending on the material used to construct the building.

Brick base

If the walls are brick, then installation involves the following work:

- Determination of the exit area of the structure. It should not disturb the exterior of the house.

- Marking the wall. First, the installation location of the boiler is determined. Next, the height of the boiler and the outlet pipe is measured. At the same time, we must not forget about fire safety standards for organizing heating. The pipe outlet is marked in the required location. The parameters are checked several times.

- Making a hole. This requires a hammer drill. The hole is insulated with fireproof material. For concrete walls or brick structures, mounting foam and asbestos sheet are suitable.

- Box insert made of fire-resistant material.

Battery Installation Standards

Organization of heating is necessary in any country house, and each stage of this work must be carried out in compliance with all technical requirements. Therefore, the correct installation of heating radiators is very important; failure to comply with fundamental requirements will lead to a violation of the technology and reduce the efficiency of the system.

When installing heating radiators in Moscow and other regions, you need to remember not only the correct method of connecting devices, but also the correct selection of the type of heating equipment.

Heating battery installation diagrams

Before you begin installation, you need to decide on the connection diagram. There are the following options for installing heating radiators:

- Lateral connection is the most popular today, since with its help you can achieve the greatest heat transfer. In this case, the inlet line is connected to the upper branch pipe, and the outlet pipe to the lower one. If this rule for installing heating batteries is not followed, the power, and with it the efficiency, of the system will decrease.

- The diagonal connection is great for long radiators, as it will allow the battery to be heated evenly. In this case, on one side, the inlet pipe is connected to the upper pipe, and on the other side, the outlet pipe is connected to the lower one. When supplying coolant through the lower pipe, the power is reduced by 10%.

- The lower connection diagram is used if the heating system runs under the floor. Compared to a side connection, this method reduces heat transfer by 5-15%.

Installing radiators: instructions

After choosing the type of connection, you can begin installing the batteries, taking into account the recommendations of SNIP

In addition, when installing heating radiators, the instructions supplied by the manufacturer should also be taken into account, since if the rules for installing heating radiators are not followed, the right to warranty service will be lost, and you will have to solve problems yourself

According to the installation standards for heating radiators, installation is possible without removing the protective film, this way you will protect the devices from dirt and dust, as well as from scratches during installation. Installation of SNiP heating radiators requires compliance with the following indentations.

- According to the standards for installing a battery, a distance of 100 mm is required from the bottom of a niche or window sill; if the distance is less than ¾ of the depth of the battery, the heat flow will be less and it will be difficult for heated air to enter the room.

- The installation height of heating radiators should be 120 mm from the floor to the bottom of the radiator; if the offset is less than 100 mm, then heat exchange will be difficult, and cleaning the floor in this area will also cause difficulties. If the offset exceeds 150 mm, the temperature difference in height will be greatly increased, this will be especially noticeable in the upper part of the room.

- Correct installation of heating radiators requires a distance from the wall plane of at least 20 mm. When installing the battery close to the wall or with a gap of less than 20 mm, heat transfer will deteriorate, and a dust trail will appear on the top of the radiator.

Installation of heating radiators, photos, videos will help you not to make mistakes during the installation process and organize a reliable and efficient heating system in your home.

SNiP also regulates the procedure for installing heating devices.

- First, the space for the brackets (at least 3) is marked.

- Next, the brackets are strengthened using cement mortar or dowels.

- Installation of Mayevsky tap, plugs, adapters, etc.

- Then they begin to install radiators.

- Next, connect the batteries to the pipes of the heating system.

- After this, an air vent is installed; according to SNiP, it must be automatic.

- Lastly, the radiators are freed from the protective film.

If you follow these rules, radiators will provide warmth in the room during the cold season and will last a long time.

Video description

How to pass a pipe through a wooden base is shown in this video:

- Making a hole for the box. At this stage, the diameter of the product is taken into account, as well as the space for the insulating material (basalt wool inserts).

- Pipe installation. An asbestos sheet is laid between its walls and the box. The element is displayed strictly at a right angle. Any deviation will impair the operation of the boiler.

- Attaching a protective screen outdoors. This is a steel plate fixed to the outside of the wall. It protects the wood from overheating and reduces the risk of fire.

Pipe protection with insulating material Source petropech.ru

- Tee installation. A vessel for collecting condensate is attached to its lower part.

- Installation of support. It is screwed to the wall or rests on the ground. Its task is to maintain the vertical part of the structure.

- Chimney connection. Condensation should not get into internal joints. Every meter the structure is fixed to the wall with brackets. During fastening, a building level is used to maintain the strictly vertical position of the pipe. The last clamp is installed under the roof.

Lastly, a protective fungus is put on the pipe.

Video description

You can see the chimney outlet through the wall in a bathhouse in this video:

- the upper part of the structure is located slightly above the roof ridge so that the smoke is blown away by the wind;

- there should be no other communications or wires near the box through which the pipe is inserted;

- Regardless of the material of the chimney, its horizontal part is inserted into the wall at a right angle.

Before making a chimney through a wall in a wooden house, you should treat it with an antiseptic and a liquid that increases its resistance to fire.

Heating of non-residential premises (greenhouse)

In non-residential spaces, the rules for installing pipes are less strict. Practical benefits rather than safety are taken into account here. Polypropylene and metal pipes are laid according to strict regulations only if they conduct gas, which is used to heat the greenhouse. Water radiators and polypropylene pipes are not subject to strict regulations unless it is a commercial site.

The optimal distance between heating pipes in a greenhouse is a gap of 120 mm, where there are no trays with plants. Such passes help to evenly warm the soil without drying it out. Parallel laying is the most effective. With it, the greenhouse will produce the most fruit, since the trays are heated evenly.

Selection of insulating materials

So , how to properly install a stove in a house with a chimney through the wall is already clear, so you need to consider the issue of insulating the outer part of the structure. If a sandwich system is used, then this procedure need not be carried out (except for the place where the element passes through the wall). The insulation must be fireproof. It is allowed to use the following materials:

- Stone wool. This is the best option for a wooden house. The material is easy to use, does not contain harmful substances, does not burn or smolder. Cotton wool not only does not burn, but also prevents the spread of open flames.

Insulation of structures on the street Source teplo.guru

- Asbestos. Many masters refuse to use it. The material contains toxic carcinogens. However, it has high insulating qualities and does not come into contact with humans in any way.

- Superpower. Modern insulation, which does not burn, provides good insulation. The disadvantage of the material is its high cost.

- Basalt cardboard. It is characterized by a long service life. The insulator is relatively cheap and resistant to high temperatures. The material contains no toxic substances, and its quality is better than mineral wool.

The insulated structure may not look very presentable, but this stage cannot be avoided. Without insulation, condensation will collect inside the structure. It will not only deteriorate moisture, but will also have a negative effect on the metal.

Technical characteristics of sandwich pipes

- Material. Basalt fiber (mineral wool) is mainly used as a thermal insulation material. This type of insulation is resistant to high temperatures and chemicals. Mineral wool has excellent thermal insulation/sound insulation properties and is laid with a thickness of 30-60 mm. Due to their fireproof properties, multilayer pipes can be used in houses built from any material. More expensive alloys with a high degree of heat resistance are used for the inner casing.

The inner layer of the sandwich pipe is mainly made of galvanized steel, and the outer layer can be made of copper, brass, stainless steel, etc. The scope of the pipe and the price depend on the content of alloying materials, various alloys and the thickness of the heat-insulating layer.

Sandwich pipes galvanized and stainless steel

- Connection type. Sandwich pipe elements are connected in two ways: corrugated edges and sockets. The advantage of a corrugated connection is ease of installation, but to ensure tightness, a large amount of sealant is required, and this increases the cost of the chimney. With a socket connection, a high degree of tightness is achieved due to the presence of a wider chamfer on one side of the pipe. The advantage is a high degree of tightness, due to which the design can be used for gas boilers. But the downside is the complexity of installation and the need for very precise adjustment of all parts.

Types of sandwich pipe connections

Fire safety rules

The distance from the brick wall to the chimney is 130 mm. If the structure is wooden, then this parameter increases to 260 mm. When pipes pass in close proximity to rafters or through flammable materials, these places must be insulated.

Fire protection of a chimney Source petropech.ru

When using solid fuel equipment, the chimney is equipped with a mesh metal spark arrester, regardless of the material from which the building is constructed. The cell size does not exceed 5*5 mm. In addition, there are other rules:

- the chimney head must be positioned correctly relative to the roof;

- to reduce moisture condensation, the temperature at the outlet of the structure should be 15°C higher than the dew point temperature (60°C);

- if the chimney height is less than 5 m, then the installation of an electrically driven smoke exhaust is required.

The outer wall is separated from the structure by an asbestos-cement sheet or basalt overlay.

Where can I find official information?

SNiP 3.05.01-85 entitled “INTERNAL SANITARY SYSTEMS” (incomplete name of the document) regulates in detail the laying of water supply pipes, including heating ones, as well as the relative position of the radiator, floor, and underwater pipes. You only need to pay attention to a few points, since this document is a universal paper for different types of plumbing fixtures, as the name suggests.

Radiator installation diagram

The “HEATING” section begins with paragraph 3.18 and ends with number 3.33. The most significant points are 3.20 and 3.22. This is where the relationship of the radiator with respect to all elements of the room, as well as the distance between adjacent pipes, is described.

Distance from wall

Errors in chimney installation

Since it is not always possible to correctly install a stove in a house and route the pipe through the wall, you should consider the most common installation mistakes in order to avoid them. Incorrect robot design is possible in the following cases:

- Insufficient amount of insulation at the junction of elements. In this case, the pipe will overheat.

- The presence of joints where they pass through a wall or roof overhang. Such installation increases the risk of fire in a capital structure.

Video description

This video clearly shows an example of violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically. When insulating main walls with foam plastic or mineral wool, long dowels are used to secure the chimney.

- There is no ebb on the side roof slope. In this case, precipitation can get on the insulation and impair its functions.

- Insufficient overall vertical height. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use these expert tips:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure; it is enough to remove the horizontal pipe;

- a horizontal section that is too long helps slow down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes Source krovgid.com

Inspection openings are installed not only on the outer part of the structure, but also on the internal horizontal element.

Why is there a gap between the device and the wall?

It is not clear to a person who does not understand heating engineering why the correct installation of a heating radiator under the window is so important. You need to understand that if you hang the radiator incorrectly, this can lead to increased heating costs for the building.

External enclosing structures are constantly in contact with cold air masses, which is why they become very cold. If the radiator is mounted close to the outer wall, then most of the thermal energy will be spent on heating the building envelope, but not the air in the room

This is why it is so important to maintain the normal distance from the battery to the wall.

Service life of the external chimney

The service life of the structure depends on the material of its manufacture and correct installation. When used correctly, ceramic pipes will perform their function for up to 40 years. A brick chimney can be used for more than 50 years. Stainless steel will have to be replaced after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A high-quality sandwich system will last up to 20 years. Structures last longer if heating equipment runs on gas or pellets.

Briefly about the main thing...

Chimneys can be single- or double-walled. Based on the material of manufacture, metal, brick structures and structures made of sandwich pipes are distinguished. The last option is optimal for private houses. When installing a chimney, the rules for its placement in the room are observed. Its functionality, as well as the presence of draft in the heating equipment, depends on the correct determination of the diameter and height of the structure.

The installation technology through a wooden and brick wall is the same, but there are some nuances: wood is more susceptible to ignition and requires maximum protection. During installation, you must comply with fire regulations, and also take into account possible errors.