Until recently, an asbestos chimney pipe was considered the best option for arranging heating boilers in a house, bathhouse and other buildings that require heating. The main argument in favor of this decision was that the material is non-flammable, resistant to moisture, and most importantly - inexpensive. These factors contributed to the fact that asbestos chimneys were installed in almost every private household. The heads of small utility companies and agricultural organizations did not ignore this simple solution to current problems.

Is a chimney made from an asbestos-cement pipe really such a universal means of removing combustion products? To understand this, it is necessary to dwell on the technology of manufacturing asbestos cement, its advantages and disadvantages, and the possibility of assembling chimneys from asbestos pipes with your own hands.

Is it possible to use an asbestos pipe for a chimney?

The question of whether it is possible to make a chimney from an asbestos pipe arises for a very reasonable reason - the price of this material is the lowest. If you take an interest in user reviews, you can find a lot of both laudatory and critically negative reviews. The truth, as always, is somewhere in the middle.

The time has come when irrigation and land reclamation were given a long life, but the asbestos cement pipes intended for this remained. With the onset of the construction boom, thanks to low prices, they began to be actively used for chimneys. But the pipe, which is not intended for this purpose, cannot withstand heating up to more than 300 degrees. In addition, its inner surface is rough and readily deposits condensate from flue gases and soot.

The use of asbestos pipes for chimneys has a number of significant limitations

Moisture evaporates from the firewood and actively mixes with various gaseous oxides in combustion products. As a result, not just water, but chemically active liquids are deposited on the walls of the pipe. They, in turn, deposit particulate matter from the smoke on themselves, forming soot and tar. Thus, plaque quickly accumulates on the internal surfaces, reducing the cross-section of the pipe. In addition, such plaque can ignite, and the temperature reaches 1100 degrees. Not every material can withstand such heating, which results in a large fire that is difficult to extinguish.

The rough surface of the inner walls of an asbestos pipe contributes to the active formation of soot deposits on them

Safety

When building a chimney in a bathhouse, you first need to think about safety issues. After all, if something is done incorrectly, wooden structures can catch fire very easily. The problem must be approached carefully, then the bathhouse will last a really long time, and there will be no risk to people’s lives.

All the necessary requirements that chimneys must meet are established by the relevant sanitary rules and regulations. They specify the distance that must be maintained between the pipe and flammable parts of the roof slabs. This value depends on the pipe parameters. If you are planning to make a chimney in a bathhouse, you should familiarize yourself with SNiP 41-01-2003, which approves the rules for the installation of ventilation, heating and air conditioning

In this case, pay special attention to paragraph 6.6.22, which contains all the necessary information

To ensure that the chimney is completely safe, you need to use appropriate materials for thermal insulation:

- mineral wool;

- basalt cardboard;

- mineralite

Non-flammable mineral wool with long service life

Fire-resistant plasterboard and glass-magnesium sheet are also suitable for this purpose.

Fire-resistant drywall can withstand exposure to direct fire for about an hour

Glass-magnesium (glass-magnesite) sheet (SML), moisture-resistant, fire-resistant, frost-resistant, environmentally friendly

You need to pay attention to some other points

So, it is important to choose the right materials from which the chimney itself will be made - they must be resistant to high temperatures. For example, if you decide to use a metal pipe to construct a chimney, it must be made of non-galvanized material

The fact is that when heated to high temperatures, zinc begins to evaporate, and its evaporation is extremely harmful to health.

For example, if you decide to use a metal pipe to construct a chimney, it must be made of non-galvanized material. The fact is that when heated to high temperatures, zinc begins to evaporate, and its evaporation is extremely harmful to health.

When are chimneys made from asbestos pipes used?

Most often, asbestos pipes are used as a temporary solution for a chimney. However, they cannot be used directly near the firebox. The part of the solid fuel chimney made of brick or metal adjacent to the stove serves not only to remove combustion products, but also for heat exchange inside the room, increasing the efficiency of the heating unit. The temperature of the exhaust gases there can significantly exceed the permissible limit of 300 oC. And only after passing through the channels of the convective zone and rising to the level of the ceiling with the attic, the escaping gases are cooled to a safe 200–250 degrees. There you can build up a chimney with an asbestos pipe, which is several times cheaper than a brick or any other pipe.

Asbestos pipes can be used in the upper part of the chimney, where combustion products enter already cooled

However, most modern thermal units, especially those running on natural gas, are characterized by high efficiency, which indicates the rational use of thermal energy. This applies to geysers, boilers and pyrolysis furnaces, the outlet temperature of which does not exceed 250 oC. Naturally, with such thermal devices it is quite logical to use inexpensive asbestos pipes. The only obstacle can be the increased ability of smoke channels to form condensation. Devices for its collection only partially solve the problem, so accelerated soot formation is inevitable here. The situation can only be corrected by regularly cleaning the smoke channel, which is extremely inconvenient during the heating season.

Another problem is the impossibility of installing inspection windows in asbestos pipes. For this reason, installation of such chimneys is possible only on straight sections.

Summarizing everything said above, we point out the circumstances that prevent the use of asbestos pipes for chimneys:

- High probability of destruction at temperatures above 300 oC.

- Fire hazard due to cracking of the chimney walls with combustion products escaping outside.

- Reduced draft force in the chimney due to the lack of heat capacity supporting it.

- Accumulation of condensation on the walls with increased soot formation.

- Inability to install inspection hatches in asbestos pipes.

- The requirement to install such products only in a vertical position.

- The need for regular inspection and cleaning of the chimney from soot.

When heated above 300 degrees, asbestos pipes burst and sometimes even explode

It is advisable to use asbestos pipes only as interfloor protective sleeves when installing a chimney.

Heating from DESIGN PRESTIGE LLC View water here resant.ruotoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

In order for the pipeline to serve for a long time and not have any problems with it, it is necessary to initially install the structure correctly, as well as connect asbestos-cement pipes as best and as efficiently as possible, using the necessary connecting elements, fittings and devices designed to compensate for various deformations and vibration processes .

In order to make a choice on a specific type of connecting elements, it is necessary to determine for what purposes the product made from asbestos-cement pipes will be used

It is important to determine the specific function of the pipeline structure

Manufacturing plants produce asbestos-cement couplings with two teeth, which are similar in size to the asbestos-cement elements found in the pipeline structure. These connecting elements are widely used in water supply systems. The process of combining parts occurs in a simple way, using a dense rubber ring.

In the case of connecting pipes that will not be subject to pressure during operation, asbestos-cement couplings are used. They are made from a pipe with thick walls and a large diameter. In addition, in water and gas pipelines that are made from asbestos-cement pipes, “Zhibo” couplings made of cast iron can be used.

For laying cable connections, high-pressure polyethylene couplings are used to fasten asbestos-cement products that will not be subject to pressure.

Fragment of joining: 1,2 - chrysolite-cement pipe; 3 - coupling; 4 - rubber sealing ring

Such a main element in a product as a connecting node must have the following:

1. When working with significant pressure, as well as in the case of the formation of a vacuum space, it must exhibit stable strength and have density properties.

2. Do not be influenced by an unfavorable environment.

3. Show yourself as a convenient and simple material that is not worth spending a lot of time and effort on.

Circumstances of using asbestos pipes

However, the use of this material continues. And this happens due to its low cost and in cases where the flue gas temperature does not exceed 200–250 oC. Such conditions are typical for the operation of gas thermal units. It is also important that when burning gas fuel, the formation of solid non-combustible particles occurs more slowly than when burning wood. A similar temperature regime of flue gases is also inherent in pyrolysis solid fuel furnaces, but they are characterized by the formation of a large amount of condensate, which is destructive for asbestos pipes.

It is allowed to construct only vertical sections of the chimney from asbestos pipes, which significantly reduces the possibility of their use even with economical gas boilers

When installing asbestos pipes on a chimney, the following circumstances must be taken into account:

- When installing an independent smoke exhaust system, asbestos pipes are used only when installed through transition sleeves between the firebox and the chimney.

- When installing a chimney on the outside of the house, special sleeves and adapters made of the same material are used for installation.

- Such products are also used to lengthen the existing chimney when there is insufficient draft in the furnace.

Asbestos pipes can be used to build up a chimney in areas of low temperatures of exhaust gases and in the above-roof part with insufficient draft - Asbestos cement pipe can be used as a liner for an existing brick chimney if the brickwork begins to deteriorate. The same lining can be used in the construction of a brick chimney.

- Installation of asbestos pipes is carried out exclusively on brickwork or reinforced concrete base.

- Passing the chimney through the ceiling is only possible when using a fluff.

When passing through the floors, it is necessary to install heat-insulating structures - fluff and otter - At the intersection of the chimney, an otter device is required.

- Pipe joining is done only with high-quality couplings with an asbestos cord running along the thread as a seal.

- Insulation of an asbestos chimney is mandatory. It is made by covering the pipe with basalt wool and a casing made of galvanized metal. It can be tied together with wire or strip ties of a special design.

Video: what happens when an asbestos chimney pipe explodes

Why were they popular in the past?

During Soviet times, there was an acute shortage of all types of building materials. Asbestos pipes were a real boon for private developers. The purlins met all safety standards, had no worthy alternative, and were distinguished by their strength, tightness and affordable price. The links were used in furnace making, arrangement of water supply systems, sewerage systems and construction of wells.

Over time, GOST requirements were replaced by TU. Changes were made to the production technology, which negatively affected the quality characteristics of the products.

They can only be used for a gas boiler, installed in the middle and end of the chimneys of saunas and baths. But, it is better to abandon this idea and use pipes made according to specifications for arranging low-pressure communications and protective structures for laying cables.

Asbestos chimney size

When selecting asbestos chimney pipes, you need to be guided by the following considerations:

- The use of this material is only possible for gas boilers and pyrolysis heating units, which are characterized by a low flue gas temperature. It should be taken into account that the smoke of pyrolysis furnaces is oversaturated with products that contribute to the formation of condensation, and therefore soot.

- The diameter of the asbestos chimney pipe should not be less than the outlet pipe of the heating unit.

- The total length of the chimney must be at least 5 meters, while the excess above the roof ridge must be at least 0.5 meters.

- Significantly exceeding this indicator will also lead to undesirable consequences due to a decrease in the speed of gas movement in the pipe. This will increase the amount of condensate formed.

The effectiveness of a chimney made of any material depends on its correct installation on the roof of the house

Disadvantages of asbestos pipes

Despite its popularity in private construction, a chimney made from this material has many disadvantages.

The quality of the pipeline installation also matters. Let's consider the characteristic disadvantages of asbestos-cement chimneys and the reasons for their occurrence.

Burnout and bursting

Initially, the products were developed for mass production for use in land reclamation, construction of sewers and low-pressure gas pipelines. The designers did not provide for their operation at high temperatures. Emphasis was placed on tightness and ease of installation of highways.

The basis of the material is cement, and it is a porous material. It absorbs creosote, which is a flammable material. With strong heating, the process of its combustion begins, as a result of which the structure of the walls changes, they become thinner and burn out.

With further heating, the pressure of the air enclosed in the walls of the purlins increases. Products crack, burst and even explode.

Maintenance difficulties

The high strength of asbestos cement is a myth that many people want to believe.

Working with links requires increased caution and accuracy. The lack of steel reinforcement makes them extremely brittle and brittle, regardless of diameter and type

And that's not all...

Chimney maintenance is associated with the following difficulties:

- the need for regular cleaning, since pipes literally attract soot;

- the inability to make inspection windows to reach hard-to-reach areas;

- sensitivity of products to shocks and loads;

- Frequent replacement of insulation, which is destroyed by chemically aggressive condensate.

Humidification of the pipeline is fraught with unpleasant consequences, both for communications and for the building as a whole.

Condensate

The main purpose of the products was the laying of open and underground water pipelines of various lengths. Asbestos-cement pipes are resistant to water, but quickly collapse when in contact with chemically active liquids. They are the ones that form on the surface of the chimney during the interaction of soot and condensate.

The aggressive solution flows onto the roof and is absorbed into its surface. As a result, stains, unpleasant odors and cracks appear. Watching the video below will help you understand the extent of the damage caused by condensation. This issue can be resolved with the help of properly carried out insulation.

Asbestos chimney installation

The chimney is installed in the following order:

- An asbestos pipe should never be removed directly from the kiln; it should rest on a concrete or brick base. The supply to the heating unit is made through a metal adapter. This part of the chimney is equipped with a flat damper or disc damper to regulate the draft by reducing the passage in the smoke exhaust channel.

- When installing a chimney, a container is provided in its lower part to collect condensate, which must be periodically emptied of black liquid with an unpleasant odor.

For asbestos pipes, plastic or metal condensate collectors of suitable diameter can be used - The upper end of the chimney must be equipped with a cap, and in the best case, with a deflector.

- At the junction with the chimney, a hatch is cut out in the ceiling, which is at least 15 centimeters larger than the dimensions of the pipe. A sheet metal damper is fixed to the ceiling below. Basalt wool is placed tightly into the resulting opening from above and covered with the same metal sheet on top.

When a pipe passes through the ceiling, a protective box of steel sheets is installed - Crossing the roofing pie is done in the same way. Only on the outside of the roofing you need to install an otter - a device to prevent water from entering through the pipe into the under-roof space. On the construction market it is easy to purchase a ready-made structure that matches the size of the pipe and the slope of the roof.

It should be remembered that chimneys made from asbestos pipes should absolutely not be used when installing heating in a bathhouse due to stoves with extremely high heating temperatures.

Fire safety

The requirements for a safe chimney installation do not differ from those for other systems:

- The passage of the smoke duct closer than 70 centimeters from the load-bearing structures of the building is not allowed.

- Chimneys cannot be painted with oil or enamel paint. If necessary, you can use lime or a special bitumen varnish.

- When a chimney passes through a wall, it must be finished with non-combustible material, and the passage itself must be sealed in the same way as a ceiling passage.

It should be remembered that the industry does not produce asbestos-cement pipes specifically for chimneys and the owner himself bears responsibility for their use in the heating system.

Video: consequences of improper use of an asbestos chimney

An asbestos chimney should be inspected monthly and, if necessary, cleaned of soot.

What is especially important is that for chimneys made of asbestos pipes on solid fuel stoves, some preventive measures aimed at preventing planting are categorically not recommended. Do not use high-temperature fuel (aspen) or walnut shells to burn soot in the chimney, even in pyrolysis furnaces.

For this purpose, you need to use potato peels, rock salt or a blue mixture, which chemically destroys the soot layer.

Insulation of asbestos chimney

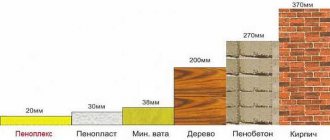

The purpose of insulating an asbestos chimney is to increase the temperature of the flue gases to reduce the amount of condensate released. The possibilities of this technique are not limitless, since at temperatures above 300 degrees the asbestos pipe begins to collapse.

- The outer part of the pipe is insulated with mineral or basalt wool, on top of which a galvanized steel casing is placed. The advantage of this method compared to brick otter is the large difference in the weight of the structures.

- The internal parts are insulated in the same way; the construction of a protective shell is not necessary here.

Step-by-step insulation technology

Due to the fact that chimneys come in different types and designs, we will describe how to properly insulate a chimney pipe made of brick, asbestos cement and steel.

Chimneys made of asbestos cement

Asbestos cement pipe

To understand how to insulate a chimney from an asbestos pipe, we will analyze the entire procedure step by step, following the recommendations of professional builders:

First, you need to thoroughly clean the work area from dust and dirt; The next step is to make a special folding casing for the insulation (made from galvanized iron)

When determining its parameters, it should be taken into account that at least 6 cm should remain between the pipe and the iron for insulation; Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m; First of all, you should secure the lower part of the casing and carefully fill it with sealant. Then, the second part is put on and the procedure is repeated. This design must run along the entire length of the asbestos pipe.

This design must run along the entire length of the asbestos pipe.

Thermal insulation diagram from a home craftsman

This is what an asbestos chimney with a casing looks like

Often, many cottage owners do without a casing. The pipe is simply wrapped in a roll of mineral wool and secured with staples. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we seem to have sorted out the asbestos pipes, now let’s see how to insulate the metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, take a pipe of smaller diameter and insert it into a pipe of larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then we can recommend basalt chimney insulation, which in its structure resembles mineral wool, but is much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than an asbestos pipe, so there should be no problems here.

Brick chimney

Brick chimney

Insulating a brick chimney is perhaps the most complex type of all presented in this article. Now we will present several options, from which everyone will choose for themselves how to insulate a brick chimney:

Plastering method. To do this, you will need to attach a reinforced mesh to the chimney. Then prepare a solution of lime, slag and a small portion of cement. Spread the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which should be at least 3 cm).

When the solution dries, you can add a few more layers and immediately cover up the resulting cracks. To give an attractive appearance, the pipe can be whitewashed or painted in the future.

Thermal insulation diagram of a brick chimney

Insulation with mineral wool. To do this, you will need to take a roll of basalt wool and cut it into pieces that correspond to the dimensions of the chimney area. Then, the insulation is glued to the pipe using tape. The last step of the work is to lay insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

The process of thermal insulation of a chimney with mineral wool

Good luck!

User reviews and questions

I am considering installing a chimney from a solid fuel boiler using an asbestos-cement pipe with a diameter of 150 mm. The stove maker recommends making a chimney from refractory bricks. Brick and the work of laying it are much more expensive than installing an asbestos-cement pipe, but the experience of a stove maker brings certain doubts to the asbestos-cement option. Or is the master still disingenuous, lobbying for a job? What could be the advantages of a brick chimney?

Velov

https://houseinform.ru/forum/_asbestotsementnaya_truba_dlya_dyimohoda

Asbestos-cement pipes are installed on heating stoves with a temperature not exceeding three hundred degrees; these may include gas devices of low power or sections of the chimney in the upper part where the temperature has already dropped below the specified value; in your case, the stove maker advises correctly.

Baxtoon

https://houseinform.ru/forum/_asbestotsementnaya_truba_dlya_dyimohoda

Ac is hydrophobic. Not durable. Does not withstand high temperatures. Easily overgrown. Not heat intensive. The baker is right.

Masha

https://houseinform.ru/forum/_asbestotsementnaya_truba_dlya_dyimohoda

The stove-maker is not lying; the chimney needs to be made of refractory brick; an asbestos-cement pipe will not withstand such a high temperature and may burst. They sell special ceramic pipes for such purposes; my friend bought one, and it cost him more than the boiler. In addition, if the chimney exits through the roof and is a round pipe, then the hole will be difficult to seal from water leakage. (I have my own bitter experience, no matter how much I smear it, it leaks, I read that you need to remove it from the brick with a rectangular masonry and then put on a metal apron)

strah https://houseinform.ru/forum/_asbestotsementnaya_truba_dlya_dyimohod

If you want it to explode sooner or later, set it... It explodes “beautifully”... I saw it myself...

shuttlehttps://www.stroiteli.info/archive/index.php/t-2975.html

Materials used in manufacturing

The main materials used in manufacturing are cement and asbestos fiber. To obtain asbestos fiber, asbestos is first crushed. The resulting powdery mass is divided into fibers and added to the cement mortar.

The amount of fibers in the solution does not exceed 15% of the total weight, but this results in a material with low weight and low thermal conductivity. Reinforcing concrete mortar with asbestos makes it possible to obtain a material with a strength that is 40% greater than that of conventional concrete products.

Asbestos pipes

Estimated cost of products

The approximate cost of products depends on the type, diameter and purpose of the pipe. The prices of some products are listed below:

- The cost of a free-flow type with a nominal bore of 100...600 mm, a length of 3.95 m is 450...2200 rubles, when equipped with a coupling of the appropriate diameter, the price increases by 40-210 rubles.

- For a pressure product with a pressure of 0.9 MPa, nominal bore 250, length 5 m, the price will be 4,300 rubles, and for Du-400 it will already be 7,100 rubles.

- The price of a coupling equipped with rubber rings will be 260-950 rubles.

These prices are approximate; they may differ depending on the region where you are located and the season, but you can use the estimates for a rough estimate.

Asbestos-cement products are used in many industries and among private households. They are especially in demand when arranging sewer systems, which makes it possible to increase the service life of such communications several times.

Sewerage laying

If water is supplied through pipes, then over time the wall becomes stronger due to the compaction of the cement component. According to research by scientists in a number of countries, the use of such products for drinking water is safe for humans. If asbestos particles enter the body, it is quickly eliminated from the body without any harm.

Well, the main disadvantage of asbestos-cement materials is their fragility. They can easily be damaged during transportation, careless unloading or impact from a heavy object. To prevent this from happening, care must be taken to maintain their integrity during transportation and installation.

Characteristics of asbestos cement

Asbestos cement pipes are made from a mixture of asbestos paste and cement, compressed with steel rollers to form a high-strength laminated material. Their throughput remains almost constant, as when they were first laid, regardless of the water quality.

Asbestos pipe can be drilled and used for joints, but is not suitable for threading. However, this difficulty can be solved by screwing the ends through fixed iron seats at the service point. Asbestos cement is not suitable for use in sulfate soils.

In most cases, good pipe routing and the use of flexible connections are more important in preventing bending failure than the strength of the pipe itself. The flexible joint is used at regular intervals to allow pipes to be repaired if necessary.

Pipes are manufactured with nominal diameters from 80 to 600 mm with test pressure from 5 to 25 kg/cm2, meet general water requirements and are classified as class 5,10,15,20 and 25, which has test pressure 5,10,15,20 and 25 kg/cm2 respectively.

The operating pressure should not exceed 50% of the test pressure for pumping networks and 67% for gravity systems.

How to increase draft in ventilation: a review of methods and devices for increasing draft

Clean air is vital for any person, and it is completely natural to want to use technological advances and the experience of craftsmen to build an ideal ventilation system in your home. And as a result, every owner is faced with the question of how to increase ventilation draft so that polluted exhaust air easily gives way to fresh flows.

If you have problems with ventilation or are just building a new house, use the advice of our experts and the list of draft accelerators they prepared, and the ventilation in your home will be normalized.

What is ventilation?

People, while in their apartment, cook, clean, wash and simply breathe during the day, thereby saturating the air with excess moisture and odors, polluting it with carbon dioxide. During the process of replacing air masses, all this happens unnoticed with normally functioning ventilation, but results in considerable problems in the event of a failure of the air exchange system.

Without proper ventilation, the corners of the apartment become moldy, there is dampness, condensation on the windows, and a musty smell.

You can check the performance of the channel in a simple and effective way: by deflecting or moving a small piece of paper near the ventilation grill, or by the absence of dirt and dust on it if the ceiling and walls are smoked.

Air exchange and types of ventilation

Air exchange is the directed movement of air masses of different temperatures, which occurs due to draft in the exhaust ducts.

Air movement is carried out according to two elementary rules:

- air moves to an area of lower pressure;

- heated air moves upward.

Traditional natural ventilation is becoming less and less effective over time due to the different nature of the materials used in the construction of modern buildings.

Instead of “breathing” wood and brick, houses are dominated by foam concrete, artificial thermal insulation and finishing materials, soundproofing doors and metal-plastic windows. As a result, air is not able to circulate freely and easily through the rooms; therefore, multifunctional ventilation complexes took the palm.

In the supply part, in the absence of infiltration, it is possible to install supply valves and a fan. Doors with bars will help to achieve flow; exhaust devices are necessary in bathrooms and kitchens.

In addition to conventional classical ventilation, mechanical air exchange methods are used for full functioning. The most popular and in demand method of arranging ventilation is considered to be a supply and exhaust system, which not only removes used air, but also prepares incoming air (filters, warms or cools, cleans).

Factors influencing traction force

Regardless of the type of device, the main indicator of the effective operation of the system is traction, the intensity of which depends on a number of reasons.

The directional movement of air masses from the room to the outside naturally depends on uncontrolled weather conditions:

- numerical difference in temperature indicators in the room and at the outlet of the channel (in cold weather the draft increases, and in the summer it disappears);

- atmospheric pressure;

- wind direction and speed.

However, there are ways to influence the strength and speed of air currents.

Therefore, in the process of planning a ventilation system or its reconstruction, it is necessary to pay due attention to the following factors:

- height of the outlet pipe on the roof;

- dimensions and internal surface of the ventilation duct;

- channel layout;

- installation of deflector type devices.

As everyone knows, air gravity in air ducts occurs due to a difference in temperature and pressure at the inlet and outlet. For the stability of this process, it makes sense to maintain the desired temperature by placing ventilation pipes at least in the interior space, and ideally next to warm pipes or insulating them.

In addition, there are a number of rules and requirements for the height of placement. The used air must leave the building above the roof, and the height of the exhaust pipe above the roof cannot be less than half a meter.

The resulting difference in height leads to normalization of the ventilation system and increased draft, which is lacking for residents of the top floors of multi-story buildings with a flat roof - they have problems with air exchange.

For traction force, not only the height of the ventilation duct, but also the direction of its laying is of great importance. It is advisable to place it only vertically with the least number of turns (each one reduces traction by 10%).

If possible, a pipe of the same diameter is used along the entire length; if a connection is necessary, the deviation angle is no more than 30 degrees.

The most popular type of ventilation pipe is considered to be a round rigid air duct; due to lower resistance and good air flow intensity, it is ahead of the economical rectangular and flexible corrugated ones.

When choosing parameters, it is recommended to use pipes with a cross-section of at least 16 sq. cm - if made of stainless steel, and with a channel side of at least 10 cm, but most often a size of 14 cm is used.

Increasing the pipe parameters will entail increased traction, therefore, it is more profitable to use the maximum possible dimensions of diameter and length. In cases where it is not possible to install channels with the same length, they resort to installing ventilation grilles in all rooms of the building.

Using a deflector for ventilation

One of the most effective ways to solve ventilation problems is the installation of draft accelerators for ventilation, for example, deflectors. Unlike the methods discussed above for increasing traction, which are more convenient to use during construction or major repairs, installation of a device such as a deflector can be done at any convenient time.

In addition, the installation allows you to neutralize the consequences of such difficult-to-correct actions as insufficient channel diameter, small height, difficult weather conditions or poor location.

The deflector is mounted on the outlet ventilation duct above the roof of the building; its size depends on the amount of air emitted and the diameter of the air duct. Available in standard sizes, many manufacturers work to order according to individual parameters.

The most common manufacturing materials are plastic and metals - aluminum, galvanized and stainless steel.

Cutting with a grinder

First, the required length of the cut is marked, and the mark is applied along the entire perimeter. To prevent the product from moving when cutting, it must be secured, but not in a vice, as you may inadvertently squeeze the surface. If you have an assistant, you can hold it with your hands, or install it to fix it between two bars.

When cutting, tiny asbestos dust is formed, the inhalation of which is harmful to health. To protect against dust, you need to wear a respirator or protective mask, and goggles over your eyes. Cutting can be done with a diamond disc of any diameter, sequentially turning the product over to make the disc accessible.