Izolon PPE is a modern insulation material obtained by foaming polyethylene with propane. It is a physically cross-linked polyethylene foam.

To enhance thermal conductivity of some types of isolon, a foil or metallized film is attached to one side of the sheet in production.

The structure of the material is not uniform. Its light weight and low density are caused by the presence of air bubbles in the isolon composition.

Isolon NPE has a non-crosslinked gas molecular structure and is produced by extrusion . Izolon PPE is more expensive, lasts longer and has higher strength and quality.

The material can be used to insulate almost any surface - floors, walls, ceilings, balconies and loggias, industrial premises and does not require special skills for installing sheets or slabs. It is also used for soundproofing elements of car interiors.

Types of insulation

The material comes in the following types : roll, sheet, foil and isolon tape.

Rolled isolon has a thickness from 2 to 10 mm, width from 80 to 150 cm, length from 50 to 200 m.

is marked as follows: the first 2 digits indicate the foaming ratio, and the second - the thickness of the sheet.

For example, Isolon 3005 has a thickness of 5 mm, a foaming ratio of 30 and a density of 33 kg/m³. Table 1 . Characteristics of rolled isolon

| Izolon PPE | Thickness, mm | Density, kg/m³ | Roll length, m | Sheet width, m |

| 3003 | 3 | 33 | 170 | 1,5 |

| 3005 | 5 | 33 | 100 | 1,5 |

| 3008 | 8 | 33 | 60 | 1,5 |

| 3010 | 10 | 33 | 50 | 1,5 |

Important : Izolon of various thicknesses with a foaming ratio of 30 differs in the number of meters per roll, but has the same density and sheet width per roll.

Indicators of the expansion factor of foaming are poorly understood by the buyer, so you can use the table of the dependence of the expansion factor on the density of the material.

Table 2 . Density and foaming ratio of rolled isolon

| Density, kg/m³ | 200 | 100 | 66 | 50 | 33 | 29 | 25 |

| Foaming ratio | 5 | 10 | 15 | 20 | 30 | 35 | 40 |

Leafy . Available in slabs 1*2 m or 2*1.4 m. Thickness can range from 15 to 100 mm.

Foiled . Available in both rolls and sheets. It is distinguished by the presence of a foil layer on 1 or 2 sides, attached by lamination. Therefore, the letter “l” appears in the marking. Width - 1.2 m, length - from 80 to 300 m.

Isolon tape . It is distinguished by the presence of an adhesive layer with a protective paper membrane on 1 or 2 sides. The roll width is 1 m, length - 10, 20 or 30 m.

Kinds

The following types are available:

- uncrosslinked – NPE;

- cross-linked – PPE, which is divided into subtypes: chemically cross-linked PPE NX and physically cross-linked PPE NR.

In terms of its characteristics, isolon NPE is inferior to cross-linked ones.

Izolon PPE is resistant to aggressive influences and has higher heat, sound and moisture insulation values. It is possible to combine different types in one product.

To reduce losses from radiation of heat waves absorbed by the internal surfaces of the room, a fairly simple but very effective method is used - covering the isolon with foil. The role of foil is its ability to reflect infrared rays. This significantly increases the importance of isolon in its fight against heat loss.

Please note: Mineral wool characteristics and properties

Foil-coated isolon comes in the following modifications:

- “A” – one-sided foil coating;

- “B” – coated on both sides at once, which increases resistance to external influences;

- “C” – self-adhesive;

- “ALP” – self-adhesive, with a protective film.

Insulation with foil must be laid in such a way that its metallized layer “looks” into the insulated room. When laying foil-coated isolon with a protective film, it should be carefully removed, freeing the surface with the applied adhesive composition. If a non-self-adhesive option is used, then you should use glue that is suitable for this purpose in terms of its properties. Some varieties of isolon have a high wettability value, which facilitates the use of glue for their fastening.

Information. Foil-coated isolon increases the heat-reflecting properties of the surface by up to 98%!

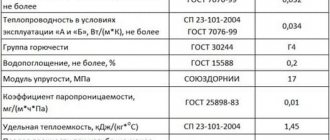

Technical characteristics of isolon

Main technical characteristics:

- The thermal conductivity coefficient is 0.031-0.037 W/(m*C).

- Vapor permeability coefficient - 0.001 mg/(m*hour*Pa).

- Moisture absorption coefficient - 0.2-0.7%.

- The density of isolon PPE ranges from 25 to 200 kg/m³.

- Compressive strength - 0.031-033 MPa.

- The operating temperature range of the material is from 60 to +75 °C.

- Heat reflection rates - from 95 to 97%.

- Sound absorption rate - up to 68%.

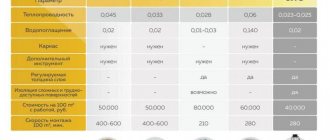

Table 3 . Comparison of the characteristics of various materials used for insulation

| Options | Izolon PPE | Penofol | Poliizol |

| Thermal conductivity coefficient, W/(m*C) | 0,031-0,037 | 0,039-0,051 | 0,044-0,051 |

| Vapor permeability coefficient, mg/(m*hour*Pa) | 0,001 | 0,001 | 0,0023 |

| Density, kg/m³ | 25-200 | 25-50 | 25-50 |

| Moisture absorption,% | 0,2-0,7 | 0,35-0,7 | 0,25-0,43 |

| Sound absorption | excellent | excellent | high |

The table shows that isolon PPE has one of the lowest thermal conductivity and vapor permeability, and has excellent sound absorption .

Main advantages

The main advantages of the building material are its technical characteristics:

- Density 33 26–45 kg/m3.

- Specific thermal capacity 1.8–1.95 kJ/kg*s.

- Water absorption ≤0.1 ≤0.1%.

- Use temperature -80 +80 °C.

To facilitate the process of applying material to a surface that has complex geometry, you can purchase an insulator that has an adhesive composition. Isolon as a material is very often used for finishing the interior of a car.

Due to the fact that it is impervious to moisture, it is able to protect the metal from corrosion. To treat the motor section, you need to use foil-coated isolon, which is attached to mastic.

It is often used during interior finishing work. When making self-leveling floors, they use thin isolon to prevent leakage to the floors below. This layer performs the function of heat protection and water barrier, and this is very popular, relevant and necessary for apartments, houses and other multi-storey buildings.

Advantages and disadvantages

Advantages of insulation:

- Excellent thermal insulation characteristics.

- Low vapor permeability.

- Water absorption is less than 1%. Moisture is not absorbed into the internal structure of the material, so it does not need waterproofing.

- Excellent sound insulation.

- Easy to cut and install. You can insulate your home yourself, without hiring specialists.

- Increased flexibility and elasticity of the material.

- Environmentally friendly. Izolon PPE does not emit toxic substances and does not harm humans and the environment.

- Hypoallergenic. The material does not cause allergic reactions on the skin.

- Izolon is not very heavy.

- The service life of the material is up to 100.

- Recyclable.

Important : the main disadvantage of isolon PPE is its high price, otherwise it is an excellent material for insulation.

Features of the material

The basis of the material is closed-cell fine-cell polyethylene foam. The porous structure provides good thermal insulation properties with minimal weight. Unlike another popular foam insulation - expanded polystyrene - isolon is plastic (the main disadvantage of EPS is fragility).

Many models are laminated with aluminum foil up to 14 microns thick, which gives the insulation reflective and heat-reflecting properties, as well as water resistance. The foil can be on one or both sides.

There are types reinforced with polypropylene mesh. The reverse side of the material is self-adhesive or without glue. Combined types are treated with foil on one side and glue on the other. To avoid gluing during transportation and storage, the adhesive surface is covered with a protective film.

Floor insulation technologies

The technology for installing isolon on the floor has 2 options for carrying out the work.

Option 1 - insulation with isolon together with another insulation (most often mineral wool). Stages of work:

- Removing old flooring and cleaning the subfloor.

- The slats are attached to the cleaned base with dowels. This provides the necessary ventilation gap. The distance between the bars is 50-60 cm.

- Sheets of mineral wool are laid between the bars, and then sheets of isolon are laid on top under tension with a layer of foil in the middle of the room, attaching them to the slats with dowels.

Important: the joints of the isolon sheets must be placed on slats and taped with metallized tape, which ensures complete sealing of the sheets.

- Next, a second row of slats is mounted on the PPE isolon layer perpendicular to the first.

- At the next stage, sheets of plywood are laid on the slats, securing them with self-tapping screws.

- Finally, the floor covering is installed.

Option 2 - insulation with PPE isolon without the use of a second insulation . Stages of work:

- Isolon is laid directly on the wooden flooring.

- The sheets are laid end to end in one layer.

- The seams between the sheets are taped with metallized tape.

- Plywood sheets are placed on the layer of isolon PPE, screwing them with self-tapping screws.

- A floor covering (usually parquet or laminate) is installed on the plywood.

Areas of application

Due to its low weight and excellent performance characteristics, isolon is used in all areas of construction:

- underlay for parquet, laminate and other floor coverings;

- can be used as a thermal insulation layer when laying heated floors;

- insulation of building structures - walls, roofs, ceilings, basements and attics;

Ceiling insulation - thermal insulation of saunas and baths;

- thermal insulation of warehouse and technical premises - hangars, pavilions, etc.;

- insulation of communications - gas supply pipelines, water supply, ventilation shafts;

- thermal insulation of climate control equipment;

- thermal insulation of vehicles - carriages, cars, isothermal vans.

Installation is not difficult. You need to select a material of suitable thickness, cut the workpieces (can be processed with a regular knife), remove the protective film from the adhesive layer, lay it on the surface to be treated, lightly press and level it. The joints are covered with tape, fixed with a construction stapler or welded.

Tip: Non-self-adhesive material can be applied to acrylic glue.

In addition to construction purposes, it is in demand as a packaging material in various areas of trade - from furniture products to medical equipment, as well as in production.

Wall insulation technology

Insulation technology:

- The bars are attached to the cleaned walls with dowels in increments of 50-60 cm. Sheets of isolon PPE are laid on them end-to-end with the foil side inside the room and attached to the bars using a construction stapler.

- Then a 2nd row of slats is placed on the PPE isolon layer perpendicular to the first row located under the insulation.

Important: the second row of slats serves as the basis for attaching the final finish - plastic or wood panels, or plasterboard sheets.

The latter need to be puttied and then painted or wallpapered .

Recommendations for selection

To solve different problems it is necessary to use different types of insulation. To increase the thermal insulation properties of parquet flooring, you should choose a solution with a thickness of 25 mm. Isolon is often used for thermal insulation of wooden and concrete floors. For high-quality work, insulation with a thickness of 80 mm should be used.

To carry out measures to create high-quality sound insulation between floors, it is best to use 80 mm material. Such a layer will be quite enough to prevent you from hearing soft music and speech coming from your neighbors. In case of severe acoustic discomfort, to eliminate it, it is necessary to install a more powerful layer.

Izolon is a fairly effective solution for high-quality thermal insulation. With its help you can well insulate any room. Certain types of material provide protection from steam and temperature changes. Proper execution of the work allows you to count on a long service life of the installed layer. If violations were made during the procedure, the process of destruction of the thermal insulation layer will begin quite quickly. In this case, the installation of the isolon will have to be done again.

Sound absorption

ISOLON® has significant anti-resonance sound-absorbing characteristics, which sharply distinguishes it from a number of thermal insulation materials. It is standardly used by construction companies as a sound insulator when installing “floating floors”. A reduction in the level of parasitic noise occurs already with the use of Isolon 500 and Isolon 300 with a thickness of 5 mm. under the screed - the sound insulation of the interfloor ceiling from impact noise is improved by 18 dB. Recommended as a high-quality underlay for laminated parquet and parquet boards. The soundproofing properties of NPE are a myth. Many building materials slightly dampen noise, but are not declared, are not recommended and will never be used as sound insulation. NPE is used as a substrate for laminated parquet not as a sound insulator, but as a material that levels out an uneven floor base. NPE is not a soundproofing material due to its low density. The fragile cells of NPE are destroyed under loads and become thinner in places to the thickness of a polyethylene film.

What it is

The term isolon appeared thanks to the developments of the Izhevsk Plastics Plant. The material is foamed polyethylene with a porous structure. This feature provides isolon with high quality heat and sound insulation. It should be noted that the material is quite elastic, which greatly simplifies the installation process.

How polyethylene foam with a uniform cell structure is produced

The technological process of isolon production can be divided into three stages:

- All components involved in the process are mixed in one container, adhesion agents and foaming agents are added.

- The finished mass is heated to high temperatures, melts, forming finished sheets.

- The material is sent to the oven, where it undergoes additional heat treatment. At certain temperatures, foaming agents react, creating pores on the surface of the sheets.

If we are talking about the production of foil material, at the final stage, one side of the sheet is covered with thin aluminum foil. Lamination technology is used here.

Thermal conductivity

This characteristic is the main one for all insulation materials. ISOLON® has 0.31-0.32 W/m. K, one of the best indicators among heat insulators. NPEs of different names have a declared thermal conductivity of approximately 0.38 W/mK, which is not entirely true. If you look at real tests of these materials, and not advertising brochures, the thermal conductivity of NPE is 0.045-0.050 W/m.K, and some gas-foamed polyethylenes do not have real thermal conductivity tests at all, since NPE does not need it as packaging. Wanting to get closer to ISOLON® in terms of characteristics, NPE manufacturers provide incorrect data.

Manufacturers in Russia

Here are the best isolon production companies:

The cost of thermal insulation varies, it is determined by the type and size of the finished product. Thus, the price of roll insulation ranges from 100 to 500 rubles per m2. If you buy heat-insulating material in slabs, then you will have to pay from 315 to 1020 rubles per square meter.

Acoustic properties of polyethylene foam

| PPE, according to GOST 23124: sound absorption coefficient, not less than: | NPE | |||

| Frequency Hz) | PPE-L 3010 | PPE-L 3015 | Degree of improvement sound insulation from shock noise (Lw) 18 dB – for seamless cement floors 50mm. | no data. |

| 250 | 7% | 9% | ||

| 500 | 15% | 17% | ||

| 1000 | 24% | 27% | ||

| 2000 | 38% | 43% | ||

| 4000 | 50% | 54% | ||

| 6000 | 60% | 68% | ||

Moisture absorption

This is the most important characteristic of a heat insulator. Traditional thermal insulators, such as mineral wool of all types (both glass wool and basalt insulation) and PSBS foam are hygroscopic, they absorb water, and the thermal insulation properties deteriorate. To prevent moisture saturation, a vapor barrier is used, which entails additional costs. Isolon 500 and Isolon 300 are excellent building materials, virtually absorbing no water (less than 1% of the total volume in 94 hours), they have no capillary moisture absorption, especially Isolon 500. They are even used as buoyancy fillers for life jackets, since remain waterproof even when immersed for 7 days under a layer of water of 1.25 m. Izolon PPE is used to make solid-wound floating floats for pressure pipelines of dredgers operating on the principle of a dredger and floating booms used even at sea, since Izolon is resistant to both sea water and diesel fuel. This is confirmed by the certificate of the Russian Maritime Register and technical specifications - Isolon 500 is recommended for use “as a floating material as a filler for life-saving and floating equipment.” NPE perfectly absorbs water, which has been proven in practice. In the autumn-winter period, during frosts and thaws, the moisture in the fragile cells tears them and the NPE gradually collapses. Due to the low density of gas-foamed polyethylene, the process of its destruction occurs quite quickly and fatally.