Features of the production of insulation Izba

Izba basalt slabs are produced in Russia, therefore they are adapted to the climate of the middle zone. Mineral wool thermal insulation is characterized by minimal hygroscopicity and good density.

For this reason, basalt, gabbro rocks, hydrophobic additives and a synthetic binder are used to produce the Izba insulator. The insulation based on basalt fibers was developed in the Russian Federation, therefore it is fully adapted to the domestic climate. Production is concentrated in Russia, in the Sverdlovsk region, which eliminates overpayments by the client for customs declarations of conformity and transportation.

The technical manufacturing process should be considered step by step:

- Extraction of basalt in quarries and its transportation to the plant for subsequent processing.

- Crushing large pieces into small fractions.

- Melting of material. Crushed basalt is heated red-hot and then cooled with a pressurized air stream. The density of the slab depends on the pressure height parameters.

- Formation of wool with short fibers from a viscous mass.

- Plate molding. The quality of adhesion of the fibers to each other is controlled, and special substances are used for tight gluing.

Due to the densely interwoven base, the wool becomes resistant to tensile forces. The matted structure helps prevent sound impact. The insulation is not afraid of mechanical stress, but it can be cut without problems.

The final product in the form of slabs is supplied in packs of 4-8 pieces. Mineral wool slab-type hut is easily cut into strips, square and rectangular elements, which eliminates overspending.

The manufacturer selects the optimal proportions of basalt and auxiliary components, so the products are environmentally friendly.

Advantages and disadvantages

The popularity of the heat insulator is due to a number of advantageous characteristics that the material is endowed with:

- Low thermal conductivity - in combination with high density, the insulation reliably retains heat in the room even in severe frosts.

- Vapor permeability – this indicator ensures unhindered air circulation, insulated surfaces “breathe”.

- Environmentally friendly - the absence of toxic fumes eliminates the negative impact of the insulator on human health.

- Fire safety - stone wool belongs to the class of non-combustible materials.

- Moisture resistance, which is ensured by low hygroscopicity. This allows the insulation to be used for outdoor use and in rooms with high humidity.

- The use of insulation at the stage of building a house allows you to reduce foundation costs due to the relatively light weight of the basalt slab.

- High density, retaining heat with small wall thickness. Thanks to this property, a soundproofing effect is also achieved.

- Resistance to temperature changes.

- Simple installation technology.

- The slab is malleable and can be easily cut into the desired shape.

- Inert to chemical influences.

- Mineral wool is not of interest to rodents and insects; during operation, you can be calm about attacks from them.

- The composition of the material is resistant to microbiological processes, which means that if installed correctly, fungus and mold will not spread along the walls of the building.

The insulator has a long service life. If it is installed correctly during installation, it does not need to be changed until the end of the building’s operation.

High performance characteristics make it possible to use IZBA insulator for cladding the facades of multi-storey buildings

When choosing IZBA slabs for insulating the entire structure or only part of it, you need to take into account the shortcomings of the material in order to eliminate errors and troubles during installation or operation:

- The fragility of the insulator, which is observed during mechanical impact on it during transportation or installation. A damaged slab loses its properties, so it must be handled carefully.

- The weight of a basalt slab, unlike other mineral insulation materials, is more impressive.

What is included in the insulation?

The composition of basalt thermal insulation includes an environmentally friendly mineral board and synthetic fibers with water-repellent components. Together, the elements make it possible to achieve maximum reduction in heat loss, regardless of the purpose of the structure.

Insulation boards are produced by processing natural stone:

- dolomite;

- basalt;

- gabbro

This composition allows us to talk about a set of advantageous characteristics of Izba basalt thermal insulation. These include:

- non-flammability;

- non-hygroscopic;

- resistance to mechanical damage;

- noise absorption;

- environmental friendliness;

- simple installation;

- durability.

The fact that basalt thermal insulation belongs to the group of non-combustible materials is confirmed by a special certificate.

Regardless of the density, the insulation does not release toxins under the influence of high temperatures and is suitable for use in facilities with special fire safety requirements.

Izba insulation is non-hygroscopic, which means it is absolutely unaffected by moisture. The material can be used in conditions of high moisture, since excess liquid is naturally removed outside before the slabs are exposed to its negative influence.

An excellent property of insulation is its resistance to mechanical damage. The material is not subject to shrinkage and does not lose its geometric shape throughout the entire service life declared by the manufacturer.

Regardless of the density, the material guarantees a high level of noise absorption, primarily due to the special porous structure of the mineral wool included in the composition.

As already noted, Izba is an environmentally friendly insulation material that is easy and quick to install with your own hands, practically and without waste. The service life stated by the manufacturer is 50 years with maximum resistance to the influence of aggressive environments and microorganisms.

Types and characteristics of hut insulation

Thermal insulation “Izba” has a “speaking” name. It stands for “basalt insulation” and directly indicates what this material is made of. It has numerous advantages and in some respects is superior to popular mineral wool. To verify this, just take a corner of a slab of this brand and shake it, then a slab of mineral wool and repeat the process.

The result of the experiment will prove that the latter is much less durable. When shaken vigorously, a weighty piece of cotton wool will remain in your hand. But this will not happen with basalt. To be more confident in the strength of these slabs, you can stomp on them and mineral wool ones. The results will again be in favor of the former. Therefore, there is no doubt that their insulation will be of higher quality.

Hut facade

Basalt insulation of the “facade” category is intended for external gluing of load-bearing walls. The manufacturer offers sheets with a thickness of 135 mm and 150 mm.

The slabs are so dense that you can attach a metal or polypropylene mesh to them and plaster the facade over it.

Despite the different thicknesses, these materials have the same vapor permeability indicators - 0.3 mg/m*h*Pa. But their thermal conductivity is different. Insulation with a thickness of 135 mm has an indicator of 0.043 W/(m°C), and a 150 mm slab has an indicator of 0.041 W/(m°C). Product sizes are the same:

- length 100 cm;

- width 60 or 100 cm.

Izba Light

The “Light” series includes products that are looser and softer than all those produced under this brand. There are 3 types of slabs in the series:

- super light-30;

- light-35;

- light-40.

It has the high-quality properties of the thermal insulation parameters “Izba Super Light”, but within the framework of its series. In all respects it is inferior to materials intended for facade work. The table of comparative characteristics of “Light” series slabs will help you choose the most suitable insulation.

| Index | Super light-30 | Light-35 | Light-40 |

| Thermal conductivity (W/(m°C,) | 0.038 | 0.038 | 0.038 |

| Compressibility (%) | — | 20 | 20+ |

| Vapor permeability (mg/m.h.Pa,) | 0.3 | 0.3 | 0.3 |

| Water absorption (kg/m2) | 1 | 1 | 1 |

Izba StandardLight-50 is the “golden mean”, which is why it is popular.

There are 3 types of slabs in the “standard” series:

- standard-45;

- standard-50;

- standard-60.

The proposed description of the “hut standard 50”, the characteristics of which exceed those of the “light” series materials, allows us to understand the versatility of this insulation.

| Index | Standard-45 | Standard-50 | Standard-60 |

| Thermal conductivity (W/(m°C,) | 0.038 | 0.038 | 0.037 |

| Compressibility (%) | 12 | 10 | 8 |

| Vapor permeability (mg/m.h.Pa,) | 0.3 | 0.3 | 0.3 |

| Water absorption (kg/m2) | 1 | 1 | 1 |

Sandwich hut Standard-50 is in higher consumer demand.

Izba Sandwich - three-layer insulation. The manufacturer offers 3 types of materials in this series. The thickness of the slabs is 100, 110 and 120 mm. Each insulation consists of a core (basalt fiber) and galvanized steel sheathing glued to both sides. It can be of different colors. Sandwich series slabs are used as wall and roof panels.

Izba venti

Izba Venti is an insulation material designed for heat and sound insulation of façade ventilation systems. Recommended for filling gaps in door and window openings, fire ducts. The material of this series is less susceptible to wind than all other types of slabs of this brand, therefore it can be installed without additional wind protection in the form of membranes and films.

Hut roof

The characteristics of this heat-insulating material are slightly inferior to similar technical indicators of façade slabs. The material of the “roofing” series is intended for arranging roofs, attics and basements.

IZBA Super Light, Light

This category includes slabs of low density (from 30 to 40 kilograms per cubic meter). The areas of application for such non-load-bearing insulation are pitched roofs, attics, attic floors, ceilings, internal partitions, as well as floors (for installation between joists as thermal insulation).

| Characteristic | IZBA SUPER LIGHT – 30 | IZBA LIGHT – 35 | IZBA LIGHT – 40 |

| Density, kg/m3 | 30 (± 10%) | 35 (± 10%) | 40 (± 10%) |

| Thermal conductivity at 283 K (10°C) W/(m°C), no more | 0,036 | 0,036 | 0,036 |

| Water absorption at full immersion, % by volume, no more | 3,0 | 2,5 | 1,5 |

| Water absorption during partial immersion, % by weight, no more | 20 | — | — |

| Content of organic substances, % by weight, no more | 3,5 | 3,5 | 3,5 |

| Humidity,% by mass | 0,5 | 0,5 | 0,5 |

Specifics of operation

The ministove is supplied in branded polyethylene packaging TM Izba. Shrink film ensures long-term storage in indoor conditions. The universal heat insulator is used to provide thermal protection:

- load-bearing wall surfaces;

- roofing structures;

- attic spaces;

- floor and ceiling coverings;

- internal partitions;

- window and door openings;

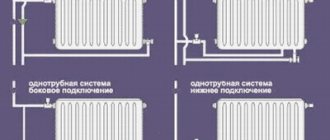

- ventilation and heating lines.

Mineral slabs can be used as noise insulation.

Properties of basalt insulation Izba

The reason for the high quality of insulation is its production based on rock. Due to the processing of the stone, the insulation has similar properties.

- High strength. The insulation has a long service life. During use, the original appearance of the insulation is not lost. It remains without various deformations and compactions.

- Heat resistant. The insulation can withstand high melting temperatures. It is often used for the installation of gas ducts, where combustion temperatures can reach up to 1000 degrees.

- Moisture resistance. Izba insulation has a low moisture permeability, which leads to high moisture resistance. This property is irreplaceable when insulating wet rooms, such as a bathhouse.

- The material breathes. Steam passes through the insulation, which increases the service life of basalt insulation. This property has a beneficial effect on the indoor microclimate.

- Soundproofing. Builders do not attach much importance to this property, which is a wrong opinion. Sound insulation is important in the design of a room. Everyone is pleased when there are no extraneous sounds.

Izba insulation can withstand high loads due to the production method. The threads that make up basalt insulation are arranged in a chaotic manner, which leads to an increase in overload.

Advantages and disadvantages

The basis of the Izba insulation is basalt. Hence the name, which means a merger of the words “basalt insulation”. Since the base is stone, the insulator is also called stone wool. Basalt is mined in quarries, after which it is transported to the plant, where the processing process takes place.

Izba mineral wool is used for thermal insulation of walls and ceilings, floors, roofs and attics, as well as plaster facades. It has a porous structure and at the same time has a high density. This means that, despite the small thickness of the product, it does an excellent job of both insulation and sound insulation.

- The insulation is fireproof and non-flammable; it can withstand temperatures up to 1000 degrees due to the fact that it is created from molten rocks. A special certificate also confirms the non-flammability of the material. The products are non-toxic and do not emit harmful substances when exposed to high temperatures, therefore they are recommended for use in various types of objects. In addition, they are moisture resistant, treated with special compounds and are absolutely impervious to liquid. This makes it possible to use the material in rooms with high humidity.

- Mineral wool “Izba” withstands mechanical stress quite well . At the same time, its slight elasticity is noted, which is expressed in the fact that the product can be deformed with strong pressure. At the same time, the product does not shrink and retains its shape throughout its service life. And due to the porous structure, which contains fibers of various lengths, the insulation has excellent sound insulation properties, in addition, it has low thermal conductivity.

Thermal insulation line - possible options

The heat insulator Izba is figuratively divided into categories: Super Light, Standard (thickness 50, 100, 150, 200 mm) and Izba Facade 150. Thermal insulation boards Super Light

and Standard are designed for insulation:

- wooden floors on wooden blocks;

- walls and attic floors;

- partitions;

- pitched roofs;

- equipment used in industry;

- air conditioning and ventilation systems;

- pipes;

- heating systems at operating temperatures up to 400 degrees Celsius.

In the case of installing multilayer thermal insulation, Izba Super Light

and Standard play the role of a layer below.

Thermal insulator Izba

Façade 150 is suitable for both single-layer and double-layer insulation types. In the first option, they talk about insulating the facades with an essential air gap and improving the sound insulation of the room as a bonus. In another, the heat insulator plays the role of the upper outer layer, without requiring additional wind protection.

Installation method

Since the heat-insulating material Izba is produced in a slab version, the entire installation process is carried out using slab installation technology. And here are several methods: along the frame, along a horizontal or pitched plane. In the first case, fastening is carried out without fasteners. That is, the frame elements are installed so that the basalt slab fits between them with tension.

If the ceiling is insulated under a suspended structure (plasterboard, plastic panels, etc.), then direct hangers can be used as fasteners. Izba slabs are attached to a vertical wall without a frame with mushroom-shaped dowels. On a pitched roof, elements of the rafter system or counter-lattice are used as fasteners.

Material characteristics

Linen insulation is made from natural raw materials - appropriately processed technical flax fibers. It is characterized by the following main parameters:

- Thermal conductivity determines the ability of a material to retain heat. The lower the indicator, the better the material. The thermal conductivity coefficient of linen insulation is about 0.038 W/mK. This is an analogue of mineral wool.

- Soundproofing. Sound absorption ability. Flax is superior to mineral wool by a third.

- Vapor permeability. The ability of insulation to remove water vapor and not accumulate moisture in its volume. This reduces the risk of mold and the development of harmful microorganisms. Breathable insulation helps create comfortable climatic conditions in the protected area.

- Fire resistance. Flax itself is highly flammable. As part of the insulation, it is impregnated with substances that stop combustion. The smoke released during smoldering does not contain toxic substances.

- Specific gravity. Based on the insulation model, it varies in the range of 15-85 kg/m3

Separately, it should be noted that the material is environmentally friendly. It is made from natural raw materials and uses a minimum of harmful substances during production. The design service life of the insulation is set at 75 years. It can be reused.

Basic concepts about the material

Firstly, it should be noted that this insulation is nothing more than basalt wool, which contains synthetic binders. It was this symbiosis of two raw materials (stone and polymer) that created a number of characteristics that brought the heat insulator to the forefront on the shelves of hardware stores.

Secondly, thermal insulation of buildings can be carried out both outside and inside. Some insulation materials require careful treatment, that is, protection using moisture-resistant materials. Manufacturers of Izba insulation approached this issue specifically. There are models that can only be used indoors, and there are types that can only be used outdoors. More on this below.

Thirdly, there is a certain price range by which one can determine whether the material will be in demand among the general mass of consumers. Thermal insulation of the Izba brand is the optimal ratio of both price and quality.

Types of thermal insulation Izba

The manufacturer produces several series of insulation materials, which differ in density, thickness and scope of use.

Izba Facade

The Façade brand has the highest density and is intended for insulating external walls. Thermal insulation of the Façade line is distinguished by noise-insulating properties and is laid on the external surfaces of buildings up to 16 m high. Compatible with plaster and ceramic tile cladding.

The façade line includes the following series:

- MS is a lightweight material with a density of 95 to 105 kg/m3 for low-rise buildings.

- BC - with density parameters from 105 to 125 kg/m3 and thermal conductivity of 0.036-0.043 W/m·K.

- 135 – slabs for plaster without reinforcement.

- 150 – with a thermal conductivity coefficient of 0.037-0.046 W/m·K.

Izba Light

Izba Light is used to insulate internal walls, ceilings and floors. Minslab is used for structures that are not subject to load. Using the material, you can insulate the attic, floor or walls of a private house, cottage, or industrial workshop. Non-flammable thermal insulation boards have dimensions of 100x60 cm and are 50-200 mm thick. Depending on the series, the hydrophobized material differs:

- density from 32 to 42 kg/m3;

- thermal conductivity 0.035 W;

- vapor permeability 0.3 mg/Pa;

- moisture absorption from 1 to 1.5%.

Izba Venti

Venti - insulation for arranging a ventilated facade with subsequent finishing with siding. Mineral wool insulation for installation on ventilated facades. The density parameters allow the formation of several layers with a total thickness of 8-9 cm. The series is characterized by increased sound insulation and fire resistance, and is presented in several options depending on the density:

- 25 kg/m3 – mats that are light and loose;

- 30 kg/m3 – absorbs 3% moisture when completely immersed, therefore it requires additional hydro- and vapor barrier;

- 35 kg/m3 – water absorption is 2.5%, compression is 20%;

- 40 kg/m3 – suitable for insulating floors and interior structures.

Izba Roof

Using this series, the roof is insulated in two layers. Mineral wool is presented in three categories:

- for the top - slabs with parameters density 175-190 kg/m3 and thermal conductivity from 60 to 70 kPa;

- for the bottom - the density is from 100 to 110 kg/m3, and the rigidity allows you to withstand the top layer;

- for screed or roll waterproofing - the density of the material ranges from 135 to 150 kg/m3.

Izba Standard

The Roofing and Standard brands are medium-hard slabs for use inside and outside the building. Insulation from the manufacturer Izba Standard series is presented in several models:

- Medium hardness. The density of the slabs is 60 or 70 kg/m3, which allows them to be used for attics, walls outside and inside, and sloping roofs.

- Lungs. Materials with a density of 40 or 50 kg/m3 are used for interior partitions and lightweight layers of suspended facade systems.

The series is characterized by thermal conductivity of 0.035-0.038 W/m·K, compressive density from 6 to 12% and water absorption of 1.5%.

Thermal insulation thickness Standard – from 50 to 200 mm.

Comparative analysis

So, Izba brand basalt insulation is at the peak of popularity. To understand why this happens, it is necessary to compare it with other thermal insulation materials. For example, with the equally popular polystyrene foam boards. Since the best way to insulate buildings is externally, it makes sense to compare polystyrene foam of the Penoplex and Facade-Izba brands.

The first has a thermal conductivity of 0.041 W/m K. And this is higher than that of the Izba. That is, basalt insulation is a winner. This means that you can use a heat insulator with a smaller thickness, and this already saves money. The density of Penoplex is 35 kg/m³, which is four times less than that of Izba. That is, the second material can withstand heavy loads. Water absorption by volume for Penoplex is 40%, for Izba-Facade 20%. Again a plus.

But what both options are similar is that they can be coated with plaster mortar. And there is no need to install wind protection under a ventilated façade.

Types and characteristics of hut insulation

Thermal insulation “Izba” has a “speaking” name. It stands for “basalt insulation” and directly indicates what this material is made of. It has numerous advantages and in some respects is superior to popular mineral wool. To verify this, just take a corner of a slab of this brand and shake it, then a slab of mineral wool and repeat the process.

The result of the experiment will prove that the latter is much less durable. When shaken vigorously, a weighty piece of cotton wool will remain in your hand. But this will not happen with basalt. To be more confident in the strength of these slabs, you can stomp on them and mineral wool ones. The results will again be in favor of the former. Therefore, there is no doubt that their insulation will be of higher quality.

Hut facade

Basalt insulation of the “facade” category is intended for external gluing of load-bearing walls. The manufacturer offers sheets with a thickness of 135 mm and 150 mm.

Despite the different thicknesses, these materials have the same vapor permeability indicators - 0.3 mg/m*h*Pa. But their thermal conductivity is different. Insulation with a thickness of 135 mm has an indicator of 0.043 W/(m°C), and a 150 mm slab has an indicator of 0.041 W/(m°C). Product sizes are the same:

- length 100 cm;

- width 60 or 100 cm.

Izba Light

The “Light” series includes products that are looser and softer than all those produced under this brand. There are 3 types of slabs in the series:

- super light-30;

- light-35;

- light-40.

It has the high-quality properties of the thermal insulation parameters “Izba Super Light”, but within the framework of its series. In all respects it is inferior to materials intended for facade work. The table of comparative characteristics of “Light” series slabs will help you choose the most suitable insulation.

| Thermal conductivity (W/(m°C,) | 0.038 | 0.038 | 0.038 |

| Compressibility (%) | — | 20 | 20+ |

| Vapor permeability (mg/m.h.Pa,) | 0.3 | 0.3 | 0.3 |

| Water absorption (kg/m2) | 1 | 1 | 1 |

Izba StandardLight-50 is the “golden mean”, which is why it is popular.

There are 3 types of slabs in the “standard” series:

- standard-45;

- standard-50;

- standard-60.

The proposed description of the “hut standard 50”, the characteristics of which exceed those of the “light” series materials, allows us to understand the versatility of this insulation.

| Thermal conductivity (W/(m°C,) | 0.038 | 0.038 | 0.037 |

| Compressibility (%) | 12 | 10 | 8 |

| Vapor permeability (mg/m.h.Pa,) | 0.3 | 0.3 | 0.3 |

| Water absorption (kg/m2) | 1 | 1 | 1 |

Sandwich hut Standard-50 is in higher consumer demand.

Izba Sandwich - three-layer insulation. The manufacturer offers 3 types of materials in this series. The thickness of the slabs is 100, 110 and 120 mm. Each insulation consists of a core (basalt fiber) and galvanized steel sheathing glued to both sides. It can be of different colors. Sandwich series slabs are used as wall and roof panels.

Izba venti

Izba Venti is an insulation material designed for heat and sound insulation of façade ventilation systems. Recommended for filling gaps in door and window openings, fire ducts. The material of this series is less susceptible to wind than all other types of slabs of this brand, therefore it can be installed without additional wind protection in the form of membranes and films.

Hut roof

The characteristics of this heat-insulating material are slightly inferior to similar technical indicators of façade slabs. The material of the “roofing” series is intended for arranging roofs, attics and basements.

How to install insulation correctly

Installation of thermal insulation differs depending on the purpose and type of structure. So, for example, to insulate pitched roofs of various types, the insulator is placed in the inner part of the supporting frame in two or even three layers, trying to prevent the appearance of joints.

The slabs are placed side by side between the rafters with a vapor barrier layer and a membrane to protect against moisture and wind in the top layer with an air gap of 50 mm. To prevent moisture from penetrating into the joints of the membrane, it is treated with mounting tape. The finishing layer is the selected roofing material. Thermal insulation for the attic roof is installed using the same scheme.

To insulate a flat roof, the insulator is placed in even layers between the cells, trying to fill the space without bending. A layer of vapor barrier is installed on top of the slabs, and the structure is covered with roofing material. If it is a metal profile or corrugated sheets, then a distance of 25 mm must be left between it and the insulation; if the sheets are flat, the gap is doubled.

For external thermal insulation of walls, the insulator is laid under the cladding with film protection from wind and moisture and finishing at the final stage. But for internal walls, Izba insulation is not the best option due to the inevitable formation of condensation on the walls.

To insulate concrete floors, a vapor barrier material is installed first, after which Izba insulation with a finishing layer of boards and floor material is attached to the areas between the beams. Wooden floors with an additional windproof layer are also insulated in the same way.