The installation of warm water floors includes the installation of a concrete screed. The main requirement for a floor screed is sufficient density. This indicator completely depends on the brand of concrete. For heated floors, the recommended grade is 150-300.

The mixture for a warm water floor must be of high quality; it is important to know the technical characteristics of the components, the mixing technology, what the thickness of the mortar layer should be, and at what stage of floor construction it should be poured.

Preparatory work

Sometimes, when preparing the surface for screed, people do not pay attention to important details that, in fact, play a big role. The rough surface must be thoroughly cleaned of debris and small stones.

Before properly pouring a heated floor, a damper tape with a thickness of at least 40 mm is laid along the walls of the room in a circle. It is needed in order to prevent future cracks in the concrete layer from the effect of thermal expansion. The damper tape should not be neglected under any circumstances. Cracks in concrete will damage the heating system very quickly. It is necessary to make a heated floor cake on concrete according to all standards.

When the room area is more than 40 square meters. meters, or one of the sides is more than 8-9 meters, the concrete coating must be divided into zones using thermal joints. To do this, use a T-shaped damper tape. It is laid before concrete work begins. Each zone must have its own heating circuit; this should be designed in advance.

Sometimes builders lay reinforcing metal mesh on top of the insulating board. If the heat insulator is durable and the load on the heated floors is not very large, such a mesh can be ignored. The mesh is attached to the concrete through a layer of insulation. The water circuit is twisted with mesh rods. This method is convenient, but not justified in all cases. If the reinforcing layer is laid directly on the heat insulator, the mesh will not withstand the vertical pressure on the floors. It will perform a single function - convenient fixation of the water pipeline.

When using durable insulation (foam glass), the situation will be different. If soft insulation (foam plastic) is used, the screed must be additionally reinforced. Reinforcement, which is placed on top, and not in the concrete itself, neutralizes only horizontal deflections. To prevent the formation of splits, the mesh is placed closer to the center of the concrete covering, above the pipes.

Sometimes they use an option where two meshes are laid: on top of the pipes and under them.

There is another way using one grid. It is raised above the heat insulator by 15-20 mm using pads. The pipes are laid on top.

A screed where the water circuit is completely embedded in concrete will be stronger. But the cost of constructing a heated floor is increasing. The total thickness of the concrete layer will be 20-30 mm greater.

Before starting concrete work, water should be poured into the circuit, creating working pressure in the pipes. Sometimes they use compressed air. It is prohibited to heat the pipes.

Is it possible to fill a heated floor with concrete?

In principle, we have already answered this question in the introduction, but we need to make a small clarification. There are several types of underfloor heating: for example, heating mats, flooring systems, water pipes and electrical cables. Their operating principle is approximately the same. Heating is carried out either by circulating hot water through laid channels, or by electric current. The difference lies in the installation features of these structures.

Without going into installation details, let's say that a screed is only necessary for water pipes and electrical cables. Here, concrete not only protects the system from mechanical damage, but also participates in heat exchange processes. In other cases, the floor covering is laid directly on the heated floor, without pouring a screed.

A mixture of cement and sand

How to properly fill the floor under heated floors with a water circuit? The most common type of screed is made of cement and sand. It is easy to work with; sand particles act as an excellent plasticizer.

Typically, for concrete work in living rooms, cement-sand mortars of grade 150 are used. For installing a water floor, it is recommended to use M200. With increased loads on the floors, you can use a higher brand:

- M200-M250 when installing floors in retail premises or public buildings;

- M300 is used in warehouses and garages.

Factory mixtures, which will be delivered to the repair site, are purchased at mortar units. In stores they are packaged in bags. You can make the mixture yourself. This is a more labor-intensive way, but economical. You need to maintain the dosage of the components and find river sand with a coarse fraction.

Cement-sand mixtures for damp, wet rooms (bathrooms, swimming pools) are made with M400 cement. M500 cement quickly gains strength and is suitable for rooms with dry floors. The recommended thickness of underfloor heating screed is about 40 mm. In this case, laying a water-heated floor in a screed will be carried out without difficulty.

How to properly fill a warm water floor so that it lasts a long time? It must be resistant not only to mechanical, but also to thermal stress. It is recommended to add polypropylene fiber to the solutions: 900 grams per 1 cubic meter. The cost of such an additive is small, but it will increase the level of strength of the screed and prevent the appearance of small cracks. You should be aware that the fiber additive does not replace the reinforcing mesh.

Types of screeds for heated floors

There are two of them: wet and semi-dry screed. Let's figure out how they differ and which one is better.

Wet screed

This is the most common concrete. By the way, many people unknowingly call concrete any mixture that contains cement, water and sand. In fact, one should distinguish between concrete and the so-called cement-sand mortar, or CSP. Real concrete always contains coarse aggregate – usually crushed stone or gravel. If this component is missing, then we are talking about a regular solution.

As a rule, DSP has less strength and is not used in critical work (for example, when pouring the foundation of a house). However, the absence of coarse aggregate in the solution also has its advantages: such a mixture is easier to prepare and lay, and the surface of the screed is very smooth.

To install a wet screed, you can order the delivery of ready-mixed concrete at the factory or prepare the mixture yourself. True, in the second case it will be problematic to achieve ideal proportions.

Among the advantages of this type of screed are:

- Optimal cost

- High heat transfer

But there are also disadvantages:

- Quite a large weight of the structure

- Labor intensity of pouring

- Long term concrete strength gain (up to 28 days)

Semi-dry screed

It is a mixture of sand and cement with the addition of a minimal amount of water. Most often, semi-dry screed is sold ready-made and delivered to the customer’s site using pneumatic blowers. Then it is laid and processed with a trowel. The result is a perfectly flat surface on which the flooring can be installed almost immediately.

Advantages:

- Light weight design

- Rapid strength gain (after 24 hours you can walk on the screed)

- Less dirty work compared to pouring wet screed

Flaws:

- High cost (4-5 times more expensive than a conventional screed device)

- Low density and, as a result, worse heat transfer

- Requires special equipment (pneumatic blowers and trowels)

Sometimes a third type of screed is mentioned - dry. It is a compacted layer of expanded clay on which the flooring is laid. But this type of tie is not used for water pipes and electrical cables. Expanded clay has low thermal conductivity, so the system will not work effectively with it.

In recent years, the semi-dry variety of screed has become increasingly popular. A construction team can lay up to 100 square meters of such covering in one working day. At the same time, you will not need to wait a whole month for the concrete to gain strength: installation of floors can begin in 3-5 days. On the other hand, the high cost of semi-dry screed and the inability to lay it yourself force in most cases to give preference to traditional pouring with concrete or a cement-sand mixture. It is this option that we will talk about in the continuation of the article.

Screed from dropouts

If you pass crushed stone through a construction sieve, you will get a fraction of particles up to 1 cm in size. This is screening. It is similar to sand with a coarse fraction, but the grains of sand are round in shape, while the particles of screenings are chipped, with sharp edges. This structural feature significantly increases the strength of the mortar compared to sand. This solution is more difficult to install, but the effort is ultimately worth it.

A warm floor under a solution with this composition is reliable. You can save money by using the M150 mixture. No fiber need to be added.

The inconvenience is that it is difficult to find a concrete layer from screenings at mortar units. Large fractions may be present in the purchased solution. This will significantly complicate the process of leveling the screed. Pebbles larger than 2 cm are acceptable according to GOST, so manufacturers produce such a solution in accordance with the standards.

If you are concerned about the question of how to properly fill a heated floor in a house, it is more advisable to prepare the solution using a home concrete mixer, using fine screenings.

Expansion joints when pouring screed

Expansion joints are needed only in the final screed and only if the room is large (if the screed area is more than 40 m2; but it is better to play it safe and do it on a smaller area, for example, every 20 m2 of area). Expansion joints are needed to prevent cracking of the screed due to thermal expansion when heated. It is clear that the rough screed does not heat up, because between it and the heated floor pipe there is insulation, and therefore expansion joints in the rough screed are useless...

How to make an expansion joint?

This is illustrated by the following photo:

The pipe passes through the seam material (in fact, this is the same damper tape, only not along the perimeter of the room, but somewhere in the middle). At the passage point, the pipes are enclosed in corrugation. There is a corrugation with an internal diameter of 16 mm, but it can be difficult to fit onto the 16th pipe; so it’s better to take one size larger with a small margin in diameter.

The diagram shows the correct and incorrect location of the expansion joint:

Self-leveling solutions

You can use a self-leveling mixture to screed a warm water floor.

This building material is not cheap. Labor costs are noticeably reduced. Simply add water to the dry mixture, stir, pour it onto the floor and you don’t need to do anything else. The mixture will even out on its own.

The advantage of self-levelers is the harmoniously selected components of the solution, mixed in the factory. The mixture is already enriched with the necessary additives and plasticizers.

The finished leveling solution is poured onto previously prepared floors and stretched over the beacons. If you follow the manufacturer's recommendations, you will get a durable surface that is resistant to temperature changes.

There are some subtleties that you should know about before purchasing a self-leveler. It sets very quickly, and you will need a lot of solution. If you fill the floors in small bathrooms, then there will be no problems. The mixture can be stirred with a drill mixer. But how to quickly mix, at one time, a cubic meter of solution for a room of more than 20 square meters? This is impossible to do in a regular trough. If you fill it in parts, in layers, the quality characteristics will deteriorate. To make such a solution, you need special equipment, a compact mortar mixing plant.

In order to fill large volumes, you can buy or rent such equipment. But under normal conditions, for apartment renovation, this is impractical. The self-leveler will still have to be leveled manually.

Such a solution will pay off on site if you have an unlimited budget. Or when laying heated floors in a small area. There are brands of self-leveling that can be laid in a thick layer. You should know: despite the fact that such a solution sets quickly, it reaches “standard” within 7-15 days, no less.

Pouring concrete under a heated floor

Now let's talk about how to properly install a concrete screed for a heated floor.

The whole process consists of the following steps:

- Preparation of tools and materials

- Preparing the base

- Installation of a heated floor system

- Installation of beacons

- Preparation of concrete mixture

- Filling the screed

- Care of hardening concrete

Step 1: preparing tools and materials

You will need:

- Rubber boots

- Construction gloves

- Damper tape

- Polyethylene film thickness from 200 to 250 microns

- Foamed polyethylene with a heat-reflecting foil layer or extruded polystyrene foam (5-10 mm). Density – minimum 35 kg/m2

- Steel mesh with cells 10x10 or 15x15 cm

- Laser level

- Cement, sand, crushed stone (if you want to prepare concrete and not CFRP), water

- Plasticizer and fiber (for DSP)

- A container for measuring out the components of the solution (for example, buckets)

- Concrete mixer or container for manual mixing (trough, basin)

- Bayonet shovel

- Deep vibrator

Step 2: preparing the base

By base we mean a rough screed, which should have fully gained strength by the time work begins. The first step is to clean the surface of the screed from debris. Please note that any unevenness or foreign objects may negatively affect the quality of the finishing coating.

A damper tape with a thickness of at least 40 mm to the height of the screed is installed around the perimeter of the room. It will compensate for the expansion of concrete under the influence of temperature, and also prevent heat from escaping into the walls.

If the area of the room exceeds 40 m2 and is not divided by partitions, or if the length of any of the walls of this room exceeds 8 meters, it is necessary to install expansion joints. They are also made using damper tape.

Then a waterproofing layer is installed. To do this, a polyethylene film is laid on the screed with an overlap of 10-15 cm. The film is secured with mounting tape.

Foamed polyethylene or expanded polystyrene is laid on top with a height of 3 cm for residential premises and 9 cm for basements or outbuildings. Expanded polystyrene acts as a heat insulator. Without this layer, the warm floor will heat not only upward, but also downward, which will lead to loss of efficiency.

Now you need to mount the fasteners for pipes or electrical cables, and also install the reinforcing mesh. Please note that the mesh should not be located on the insulation, but above it - at a height of 10 mm. Otherwise, there will be no reinforcing effect.

Step 3: installation of a heated floor system

We will not describe this stage in detail, because it all depends on what specific system you have. As a rule, underfloor heating manufacturers provide detailed instructions for their products. There you will find all the information regarding installation.

After laying pipes or cables, you can lay another layer of reinforcing mesh for additional strength.

Step 4: installing beacons

In the center of the room it is necessary to pour semi-dry concrete, and then compact and level it - so that you get a small platform 8 cm high. A laser level is placed on it.

Further along the perimeter of the room and throughout its entire area, the same concrete embankments are made for future lighthouses. It is best to place them at a distance of no more than a meter from each other. Or focus on the length of the rule: it should be greater than the distance between the beacons.

After installing the beacons, leave them for 3 days so that the concrete has time to harden. If deadlines are tight, you can skip this step.

Step 5: preparing the concrete mixture

The setting reaction of concrete begins after you mix water with cement. Next, you will have 1 to 2 hours to lay the solution; after this time, it will harden and completely lose its plasticity. Therefore, you need to work quickly. Organize your space so that you have quick access to all components of the mixture.

When laying concrete, it is important not to allow the hardened screed to come into contact with fresh mortar, as this will greatly reduce the strength of the structure. Accordingly, if you are pouring the floor in several rooms, you need to plan the work so that by the end of each day you do not have any under-filled areas within one room.

To prepare the mixture, it is most convenient to use a concrete mixer. A volume of up to 90 liters will be quite enough. Otherwise you will have to do the kneading manually. To do this you will need a construction trough or basin.

First, cement and sand are poured into the container. They must be mixed to a homogeneous consistency without lumps. If you don’t have a concrete mixer, you can work with a shovel. Next, water is gradually poured in. It is better to add it in small portions until the solution becomes thick enough. The resulting mass is mixed very well for 5-6 minutes. Plasticizer and fiber are added according to the manufacturer's instructions.

At the end you will get a cement-sand mixture. If you need to prepare concrete, then now crushed stone should be added to the container with the remaining components. It is always added at the very end, because mixing large stones is quite difficult. It is necessary that absolutely all grains of crushed stone are covered with the solution.

Here's how to make sure you've prepared the right mixture: Scoop up the solution with a shovel and then let it drain back. If the concrete does not stick to the shovel, it means its plasticity is too low. It will be very difficult to fill it. Add a little more water and stir. If, on the contrary, the mixture turns out to be too fluid, the amount of cement and sand should be increased. However, this way you will most likely violate the ratio of components and will not get the required strength.

Step 6: pouring the screed

Please note: if you are installing a warm water floor, then you must fill the pipes before laying concrete. Otherwise, during pouring, they may become deformed under the weight of the solution.

The concrete mixture should be laid in small sections - from the far wall of the room towards the exit. Each section must be leveled using a rule.

The concrete must be very well compacted. The fewer voids there are, the more reliable the screed will be. Typically, the bayonet method is used for compaction. To do this, a shovel or reinforcement rod is repeatedly immersed in the solution. Under its own weight, the concrete is compacted, and excess air comes to the surface.

But when laying the mixture on pipes or cables, it is important not to damage them. Therefore, the only way to compact the solution is to use a deep vibrator. They need to walk several times in different directions throughout the entire area of the room.

At the end, the beacons are removed. The recesses from them are also filled with solution.

Step 7: Caring for Hardening Concrete

As we have already said, the screed will gain full strength only after 28 days. It is very important to provide the concrete with optimal conditions for hardening in the first 7 days. To do this, after pouring, the floor is covered with plastic film. Every day you need to remove it and wet the concrete with water. If this is not done, the top layer of the screed will dry out too quickly and become covered with cracks.

In addition, during the first week the concrete should not be exposed to loads or sudden temperature changes. Do not try to speed up the hardening of the screed by turning on the floor heating. This will have the opposite effect.

The evenness of the coating is checked using a two-meter strip. It is laid on the floor and the clearance is measured - it should not exceed seven millimeters. If the gap is larger, it is necessary to apply a leveling layer. To do this, you can purchase a self-leveling filling mixture.

How to fill with a “wet” screed

If a lot of water is added to the solution, you get a “wet” screed. The solution will be plastic.

The component ratios are as follows:

- When laying heated floors in a dry residential area, an M200 solution using M500 cement is suitable. You will need 1 part cement, 3 parts sand and 1-1.4 parts water.

- When laying heated floors in a damp room (in a bathroom), you need an M200 mortar based on M400 cement. Take 1 part cement, 2.5 parts sand and 1-1.4 parts water.

- In reality, the volume of liquid depends on the moisture level of the sand and the amount of dust in it. In this regard, water is added gradually, mixed and plasticity is controlled. The result should be a mixture similar to thick sour cream.

- The solution is leveled between the pipes and compacted, removing air bubbles.

Metal-plastic pipes can become deformed if you walk on them. Polyethylene is more durable in this regard.

The process of leveling the mixture is facilitated by a long rule and pre-placed beacons. The recesses are filled with the mixture and leveled again.

The screed is made from the screenings in the same way. But everything is done more carefully, more labor will be required. The advantage of the “wet” method is the plasticity of the solution, which is easy to level with a rule.

Brand of concrete for underfloor heating screed

Some builders recommend using concrete class B22.5 (corresponding to grade M300). It is capable of withstanding pressure up to 325 kg/cm2, and its frost resistance reaches grade F200 (up to 200 freezing/thawing cycles without loss of quality).

To more clearly explain what kind of material this is, it is enough to mention this fact: B22.5 concrete is used for pouring the foundations of multi-story buildings and as road surfaces. Let us also clarify that the density of finished structures from this brand is 1,900-2,500 kg/m3. A 10 mm screed with an area of 6 m2 will weigh up to one and a half tons.

The disadvantages of B22.5 concrete include poor workability. Due to its low plasticity, the solution requires careful compaction. Otherwise, there will be voids in it that can destroy the screed. On the other hand, intensive compaction can damage the pipes and cables of the heated floor, which is also unacceptable.

In fact, using such strong and dense concrete to screed a heated floor is in most cases impractical and unprofitable. It makes sense to use the M300 brand only in rooms where serious loads will be placed on the coating - for example, in a garage.

Now let's look at other brands of concrete that are suitable for pouring heated floor screed.

Concrete B3.5 (M50)

This is the lowest grade, so its use in construction work is very limited. It is not suitable for installing a full-fledged screed: it can only be used to level the surface for laying the floor covering.

Concrete B10 (M150)

This material has a low cost due to its low cement content. This brand does not withstand heavy loads, but can be used for pouring heated floors in small rooms (bathroom or kitchen). Due to its relatively low density, such concrete has good thermal conductivity.

Concrete B15 (M200)

This brand is optimal for most residential premises. The screed can withstand loads of about 175-225 kg/cm2, and this is enough to install a heated floor in an apartment or private house. For basements, garages and other outbuildings, it is better to choose a higher grade.

As you can see, B10 or B15 concrete is mainly used for screeding. These two varieties have good quality and reasonable cost. If the floor will be exposed to serious loads of more than 500-600 kg, it would be more advisable to use B20 (M250) or B22.5 (M300) concrete.

Our own concrete production and laboratory, as well as a large fleet of equipment guarantee high quality products and accurate delivery times

Concrete - production and delivery

Concrete pumps - rent

Read more about us here

7 904 179–31–56

Valentin Yurievich Shvets

Director of BetonStroy

"Semi-dry" method

There is much less water in the solution for the “semi-dry” method. If the mixture is made correctly, it will be moist but not runny.

They check it this way: squeeze a little semi-dry solution in your palm. It should form into a plastic lump without cracks. This is the consistency of a factory-made solution. It is more difficult to level, but then you can rub it to a shine, and ultimately get a surface that is dense and durable in structure.

If you order such a solution ready-made, you need to explain for what purposes it will be used. This concrete layer can withstand heavy loads. It is of higher quality than when laying concrete using the “wet” method.

You will have to rub it very carefully; this requires skill and patience. You will need a long grater or trowel. Semi-dry mixtures from screenings are practically not amenable to smooth grouting, so it is ground with sandy mortar.

Plasticizer is an important component of screed

It is recommended to use a plasticizer as part of the screed. Its use will have only a positive effect on the design:

- The setting time is significantly reduced.

- Low pressure is created with each subsequent batch.

- If the mixture has a low cement to water ratio, the hardening period will increase and the setting process will slow down.

- The use of a plasticizer will make it possible to achieve hydraulic self-compacting concrete with great strength.

The use of a plasticizer occurs in several stages:

- The plasticizer is added immediately with all the components that are included in the solution. All components should be thoroughly mixed in a concrete mixer. The result is a homogeneous mixture.

- The prepared solution is poured into the designated area. The most important thing at this stage is to evenly distribute the suspension over the entire surface of the area being poured.

- After two weeks, you can put furniture on the surface, and after another week you can walk.

How to properly lay a “semi-dry” concrete screed

In order for the concrete layer to be perfectly smooth, you need to position the beacons correctly. The distance between the beacons is left such that the one and a half meter rule can be used. That is, a distance of no more than 140 cm should be maintained between the beacons.

Types of beacons:

- Mortar beacons made of narrow ridges of cement-sand mortar (gypsum cannot be used). Not the most effective method, since the ridges must dry out, and this takes time. In addition, a rule can accidentally “knock down” such pointers.

- Lighthouses made of metal pipes. Pipes or other rigid profiles are strengthened at the required height. A day after laying the concrete, they are removed and the recesses are filled with mortar. Pipes are used several times for this purpose. The only condition is that they must be perfectly even. Both round and rectangular profiles are used.

- Galvanized guides for plaster. The stronger the beacons, the better. The optimal size is 1-1.4 cm. After they have performed their function, they can be left in place or removed after the solution has set. Such beacons are disposable. If you have the skills, you can set them as evenly as possible. Strengthen with mortar, adjusting it to the level using a piece of tile or a brick fragment. The distance between the beacons is 40-50 cm. Sometimes they are installed on special supports that can be adjusted.

Video description

In this video you will see the secrets of good screed pouring: The mixture is laid out in small slides. A shovel is used to level them. Pouring a heated floor with a perfectly flat surface is not always possible. Therefore, in order to achieve this result, the solution is laid above the established profile. The next morning they come and remove the excess. But you don’t need to wait until the mixture hardens completely. It should harden a little.

Upon completion of the work, they begin to remove the guide profiles. The places where they were are treated with cement mortar and leveled.

Finally, a small amount of water is applied to the surface and covered with a polyethylene film. This will prevent the base from cracking. To prevent the floor from drying out too quickly, it needs to be moistened for at least 3 days.

What thickness should the screed be?

To understand what the thickness of the concrete screed for water heated floors should be, the following points should be taken into account:

- The concrete layer should not interfere with thermal radiation. The water circuit must perform its function.

- In order for the screed to be strong enough, the thickness of the self-leveling compound should not be less than 2.5 and 4.5 cm.

- The thickness of a regular concrete layer reaches 6-7 cm.

- In total, the thickness of the water heated floor will be 15 cm.

- If you increase the thickness of the screed, this will lead to the risk of splits in the concrete layer. To prevent this from happening, it is necessary to provide expansion joints.

Calculating the thickness of underfloor heating layers

It will be necessary to check that all underfloor heating systems are covered with concrete during installation.

With the listed numbers on hand, it will be possible to calculate the thickness of the entire floor, but it is worth keeping in mind that the “pie” in any case must have a thickness of at least 140 mm, counting from the top of the base to the surface of the rough screed. It will also be necessary to make adjustments for the thickness of the gravel “pillow” and the overlap of the first floor.

It is worth taking into account the purpose of a particular room, for example, the same screed in residential premises should not exceed 100 mm, as for warehouses, shopping pavilions, as well as car centers, it should not exceed more than 200 mm. If you need to heat an aircraft hangar, you will already need a 300 mm screed.

It will be necessary to check that all underfloor heating systems are covered with concrete during installation. To do this, the minimum thickness of the screed must be 65 mm. It is imperative to remember that a warm water floor screed differs from a conventional screed by the presence of expansion joints in them.

Other points of mandatory inspection of underfloor heating systems before use are:

The choice of screed materials must be made responsibly

- checking the functionality before laying the pipeline screed;

- checking the pipeline for hydraulic density;

- checking the heat-reflecting layer placed under the pipeline system in order to avoid losses.

In order for the screed to be of high quality, the choice of materials for it must be made responsibly, only in this case the warm floor will work for a long time and effectively. At the same time, you need not to overdo it with its thickness so that the heat can function normally in the room.

In the case when the described heating system will operate in a non-residential premises, you need to pay special attention to the strength of the heated floor covering. For this purpose, it is imperative to carry out the reinforcement procedure

It is the reinforcing mesh that will help you make the floor durable and at the same time highly functional.

Caring for wet screed

After the concrete layer is poured, the screed requires maintenance. The room temperature must be maintained at least 5 degrees above zero. The screed must not be allowed to dry out. A day after installation, it is covered with plastic film. The concrete needs to be moistened from time to time for about a month. The strength of concrete depends on this. You can begin installing the water circuit for heated floors no earlier than 28 days later. All this time, the working pressure must be maintained in the pipes, but the heating cannot be turned on.

Rough preparation

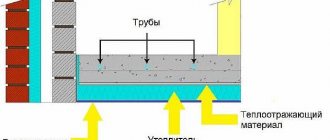

A warm floor is formed in several layers:

- Rough screed;

- Sound and heat insulator;

- Heating elements;

- Finishing screed (upper part of the structure).

The rough layer is leveling. It is not required if the base is a flat floor slab, like in an apartment. In a private house, floor heating is often installed on the ground; in this case, a self-leveling solid foundation is necessary.

To properly fill, you need the following materials:

- dry mix or cement mortar;

- reinforcing composition (can be replaced with a reinforcement mesh with medium-sized cells);

- waterproofing and insulating materials;

- fasteners;

- container where the solution will be mixed;

- construction mixer (can be replaced with a drill if you have a suitable attachment);

- putty knife.

Subfloor

Installation technology

Before pouring the solution:

- Make sure that the temperature at the work site is between + 5°C and + 25°C.

- Clean the working surface (the presence of debris will impair the adhesion between the solution and the base);

- Repair all cracks in the base;

- Line the perimeter of the wall with damper tape to the depth of the screed;

- Install level beacons.

After this, you can move on to the main part of the work:

- Prepare the mixture;

- Fill it, strengthening it with reinforcing mesh if necessary;

- Wait 24 hours, cover the dried concrete with polyethylene;

- After a week, remove the film (further hardening will occur without it).

Expert opinion Sergey Permyakov Heating systems engineer

The minimum thickness of the rough screed must be at least 3 cm; a thinner layer will crack and collapse. There is no point in pouring more than 5 cm under a warm floor; exceeding this limit will lead to a noticeable reduction in the volume of the room.

You can start the next stage of work in a week. The strength of the screed will be about 70%, this is enough to withstand the load. It will take 28 days for the base concrete coating to dry completely. During this time, concrete gains 100% strength.

By lighthouses

If the room is large, then beacons must be installed before pouring the heated floor. They represent levels - guidelines, based on which you can level the screed.

Types of beacons for heated floors:

Pin. Usually these are self-tapping screws on dowels. Pin beacons are suitable for semi-dry screeds and self-leveling floors. Their length should be 2-3 cm greater than the estimated height of the screed.

Beacon self-tapping screws are installed one for every 1-3 m2 and connected with a fishing line, which should be located exactly at the level of the future leveling layer. After this, the composition is poured. When the work is completed, the beacons are unscrewed so as not to damage the screed.

From mortar piles. To make such beacons, use the same solution as for pouring. Their height should also slightly exceed the expected level of the screed. They are most suitable for working with wooden bases, since they do not harm the insulating layer.

Mortar piles are placed along pre-marked lines. The outer rows retreat from the wall by 30 cm, the step to the adjacent rows is 1 m. The heaps located in the same row are spaced 30-50 cm apart. The beacons are given a day to harden, after which they are covered with a primer and the screed begins to be poured.

Linear. They are made from metal profiles, drywall, slats, boards, etc. This type of beacon is used more often than others. The rules for their installation do not differ from those described above. The only difference is that a number of small elements are replaced by one large one. When all the landmarks are placed, all that remains is to fill the screed.

After laying out the solution, you need to level it using the following rule: place the tool on the guides and pull it towards you, moving it slightly from side to side. After a day, the profiles are removed and the holes are sealed with a primer or mortar.

Attention! If the screed is dry, then there is no need to remove the profiles.

DIY installation

Before you lay a heated floor under the laminate, you need to decide on the option for laying it. It can happen as follows:

- According to the lags. To do this, it is convenient to use special modules made of chipboard, factory-equipped with grooves with special channels, heat-distributing metal plates and all the necessary fasteners. They just need to be assembled according to the instructions. But such a kit is very expensive.

- On slats. For this, planed boards, moisture-resistant plywood or chipboard with a thickness of 21-28 mm are used. The distance between the slats is usually equal to their width, and the width corresponds to the distance between the pipes in the circuit.

Preparing the base

When laying a “water heated floor” system on a wooden base, installation must be done after a set of preparatory work, which includes:

- “Opening” the old coating and the underlying base. At the same time, old hydro- and heat-insulating materials are removed, and the base itself is cleaned of traces of dirt, mildew and mold.

- Visual assessment of the general condition of the base. It needs to be inspected for various damages. At this stage, sections of beams that have become unusable should be dismantled, replacing them with new inserts. If severe distortions and blockages of the surface are detected, it must be leveled using metal corners, special overlays and other fixing elements.

- Treating the wooden base with antiseptic preparations. This will avoid further rotting and destruction of this material.

The last stage of preparing the base is to clean it from dust and construction debris. Detailed instructions for preparing a heated floor for laminate can be found in the video presented on the Internet.

Frame making

When laying a warm water floor on a supporting wooden structure with a beam spacing of up to 60 cm, work can be carried out directly on this base. To do this, cranial bars are fixed at the bottom of the beams, acting as supports. Subfloor boards are laid over them.

It is possible to lay a subfloor without cranial blocks. In this case, the boards are fixed directly into the supporting beams from the basement or underground side. The space between the support logs is filled with a vapor barrier material, on which a layer of thermal insulation 15-20 cm thick made of mineral wool, expanded polystyrene or penoplex is laid.

The distance between the primary floor and the heat-insulating layer should be at least 8-10 cm. For additional ventilation in the “rough base” near the wall, it is advisable to leave a small unsewn area.

When making a frame for floors with a beam pitch of more than 60 cm, the skull blocks should be attached at a higher height, since the subfloor in this case will be attached to chipboard or plywood nailed to the support beams.

After the insulation, it is necessary to attach a layer of vapor barrier. You can learn more about how to install heated floors under laminate in the video.

Pipe laying

For the installation of water-based heated floors, polypropylene and metal-plastic pipes are used. Their layout can be done in two ways:

- in a spiral;

- snake

The first method is more preferable, since in this case there is an alternation of “cold” and “warm” circuits.

At home, it is easier and more convenient to lay pipes in a “snake” pattern. They should be laid out in increments of no more than 30 cm. Near the walls, the increment can be minimal: 10-15 cm. This will avoid heat loss at the junction points.

Connection

Connecting heated floors to the heating system can be done using various methods. The most common are:

- Mixing units;

- Collector system.

After this, a pressure testing procedure is carried out, the main purpose of which is to identify leaks and malfunctions in the pipeline. This operation must be carried out before laying the floor covering!

To be on the safe side, it is better to carry out a test run together with specialists. Additional information about connecting heated floors under laminate with your own hands can be gleaned from the video.

Substrate

After the technical part of the structure has been tested under increased pressure, a substrate is laid on top of the pipes, the function of which can be performed by the following materials:

- Cork;

- Foamed polyethylene with foil coating;

- Foil polystyrene;

- Extruded polypropylene.

The listed materials have different prices. For example, the most expensive is a foil polystyrene backing. But it also has the highest thermal insulation characteristics.

Pouring technology

Having understood the subtleties and nuances, let's look at how to make a concrete floor warm. When carrying out floor installation work, the room temperature should be in the range from 5 to 250C. If the base is in good condition, it should be cleaned and dusted. If necessary, a rough screed is arranged.

Preparation

Damper tape is glued over the prepared base and plastered walls.

This is done without fail in order to:

- prevent heat loss due to wall heating;

- avoid destruction of the screed as a result of thermal expansion.

If you decide to save money, you can lay strips of thermal insulation, for example, foam plastic, around the perimeter, the effect will be the same.

Important! It is necessary to install a thermal barrier not only between the system and the wall, but also between two systems. If the kitchen and corridor have different heating circuits, a damper tape must also be laid at their junction.

The perimeter of the room must be taped with damper tape

After thermal insulation of the joint area, a waterproofing film and heat-reflecting material are laid on the floor.

System installation

Laying a water floor, or any other horizontal heating system with your own hands, is done in strict compliance with the manufacturer’s recommendations. The instructions always come complete with the elements of the system itself. If a cable or pipe passes through an expansion joint, it must be protected with a corrugated hose.

Corrugated hose for laying a heating system element

After laying and fixing the system, the heating elements are connected. Before pouring concrete into the system, it is necessary to check the operation of all elements of the system. If the test run was successful, work can continue.

The video in this article will show the installation of a water floor.

Finishing fill

It is not always necessary to fill the system with concrete from above. Sometimes other materials are used for this.

- Some apartment owners, in an attempt to reduce costs and reduce the weight of the screed, are trying to fill warm floors with expanded clay concrete. What happens if you fill a warm floor with expanded clay concrete?

- The answer is nothing good. Expanded clay is a heat insulator. By adding it to the concrete solution, you significantly improve the thermal insulation properties of the screed. Therefore, it makes sense to install the floor system on such a base to avoid energy losses.

- There is no point in filling the floor heating from above with such a composition, because this will reduce the efficiency of the system. The fact is that the top layer of expanded clay will prevent the passage of heat into the room. In fact, you will simply be wasting your money this way.

Important! The layer with which the floor heating is poured must have the highest possible thermal conductivity in order to reduce the cost of operating the system.

Expanded clay concrete screed has excellent thermal insulation qualities, but requires a leveling layer

Advantages and disadvantages of the system

- high energy efficiency;

- reliability;

- long, at least 50 years, service life.

The VHP may be the only source of heating in the room. This allows you to eliminate radiators and use room space more efficiently. This point is especially important in small rooms.

Along with the advantages, the system has a number of disadvantages. The most significant is the impossibility of using it in apartment buildings with central heating.

Theoretically, you can submit an application to the organization servicing the apartment building, go through an endless cycle of checks and approvals, and get the go-ahead to install the system. In practice, a positive solution to this issue is rather an exception to general practice.

The refusal of the management company to install a heated floor in an apartment building is quite justified. The pressure and temperature in the centralized heating system are high, so even the slightest error during installation can result in the most unpleasant consequences for the apartment owners and neighbors below. In the event of an accident, the neighbors above will be left without heating for a long time. In this regard, in apartment buildings it is worth choosing to install electric heated floors.

When choosing a solid floor, it is important that the house has good thermal insulation

The disadvantages also include the high cost of the equipment and the duration of the installation process. It takes at least 30 days to lay all the layers of the pie.

Expert opinion Vadim Savelievich Grebnev Heating systems installer

One of the main conditions for the high-quality functioning of a heated floor system is high-quality thermal insulation of the building. Heat losses over 100 W/m2 will make the operation of this type of OS ineffective.

Finish filling on TP

If the rough screed has dried, it’s time to move on to the next steps:

- installation of a heat insulator. Thermal insulating material is mounted only on a clean base (it is best to vacuum it). The heat insulator can be cork, foam, polypropylene, aluminum foil or metallized Mylar film. To secure it, tape, dowels and glue are used.

- Laying damper tape. The damper tape protects concrete from cracking associated with temperature fluctuations. Mounting area: along the perimeter of the room and between the contours of heated floors.

- Laying heated floor elements. Pipes need to be checked for breaks (especially at bends), and when running cables, grounding must be ensured.

- Reinforcement. Reinforcing mesh can be placed under the pipes, above them, or in both places at once. Pipes are easily attached to the lower metal mesh during installation, however, unlike the upper one, it does not provide reinforcement for the screed. If the concrete is of high quality, then this part of the work can be abandoned.

- Pouring finishing screed. Before proceeding to the last stage, you must check how well the heating system is functioning. The screeding solution is poured at above-zero temperatures and in one go. Partial filling is allowed only in rooms with a multi-level floor. The concreting process begins from the far side of the room and ends next to the door.

Pie TP

After finishing the pouring, it is recommended to make several punctures in the coating with a metal knitting needle or similar object. This will prevent the formation of voids.

In the next week, the concrete surface should be moistened with water 2-3 times a day. This will prevent it from drying out while it hardens.

The thickness of the finishing layer can be from 3 to 7 cm in a private house, and in an industrial area - 10 cm.

If a water heated floor is installed, the height of the screed above the pipes should be 3.2-7 cm.

Read more in the article.