Pros and cons of water heaters

The benefits of using gas pool water heaters include the following:

- high efficiency and heating speed;

- ability to work autonomously;

- absence of combustion products;

- simple operation;

- wide selection of models.

Disadvantages of the device:

- the need for a constant gas supply of acceptable pressure;

- constant monitoring of gas leaks;

- strict requirements for the room where the device is installed;

- complexity of connection (services of qualified specialists are required);

- the need for professional service;

- regular monitoring of equipment performance.

Heating by gas boiler

Gas boilers are used to heat large swimming pools. The principle of operation of such water heaters is similar to fuel ones, however, it is not wood or coal that burns, but natural gas or propane. In such devices, water from the pool is pumped into the boiler storage tank. The burning gas releases heat to the liquid. The heated water returns to the pool. Fluid circulation occurs.

Heating with a gas boiler is needed for large swimming pools.

The advantage of this device: even if there is a lot of water in the pool, it will heat up quickly. The disadvantages of gas boilers include the need to obtain permission to install equipment. Installation should only be carried out by a specialist.

Design and principle of operation

The gas burns in the heater, releasing heat, which is transferred to the water passing through the circuit of the device.

The heat exchange device does not heat the water directly. This is an optimization element that increases the efficiency of heat exchange between 2 media: water in the pool and coolant operating from a heat source.

Inside the heat exchanger, they are separated by a system of thin tubes or plates made of a material with high thermal conductivity. The larger the area of this contact, the greater the amount of heat that manages to move from a more heated environment to a less heated one.

A high degree of efficiency and cost-effectiveness of equipment is achieved through the use of natural fuel. The power of the gas heater starts from 115 kW. Propane ensures stable maintenance of a comfortable water temperature for a long period of time.

Heat exchanger for swimming pool

The heat exchange heater has a cylindrical reservoir and a coil, the inlet and outlet of which are connected to the heating system. Water is taken from the pool and pumped into the tank. Here it is heated and released back into the pool under pressure. To regulate the heating process, such devices are equipped with a thermostat.

The pool heat exchanger has a cylindrical tank.

Advantages and disadvantages

The advantage of heat exchangers is low energy consumption, because Connection to the electrical network requires only a pump, which pumps water into the tank and pushes it back into the pool.

In addition, the positive aspects of the device include:

- high reliability;

- efficiency;

- unpretentiousness to operating conditions;

- long working life.

The main disadvantage of the system is the slow heating of a large volume of water.

Operation of the heat exchanger is possible only in the autumn-winter period, i.e. during the heating season.

How to choose?

Gas heaters have the following technical characteristics:

Maximum operating temperature: shows how hot the gas heater coolant can be.- Thermal power: depends not only on the contact area between the two media, but also on the type of liquid being processed.

- Throughput (measured in cubic meters per hour): this parameter shows the time during which the entire volume of water in the pool will pass through the heat exchanger.

After determining the appropriate parameters for the technical characteristics of the gas heater, the required power of this device should be calculated.

To do this, you need to take into account factors:

- pool volume;

- volume of constant heat loss;

- heat source power;

- coolant temperature;

- desired pool water temperature;

- the time period during which water needs to be heated, provided that it has just been collected.

It is advisable to select the power of the equipment corresponding to the maximum level of heat loss. This is enough to maintain an acceptable water temperature during peak loads on the system.

The rules for saving resources are also observed. The lower power limit is selected with a coefficient of 0.7 from the volume of the pool bowl.

Next, you need to calculate the acceptable power of the heat exchanger. To do this, use the formula P = ((V*C * ΔT)/t1) + q*S, where :

- P – required heat exchanger power (W),

- C – specific heat capacity of water at a temperature of 20°C (W/kg*K);

- ΔТ – difference in temperature of cold and hot water (оС),

- t1 – optimal time for heating the entire pool (hours),

- q – heat loss per hour per square meter of water surface (W/m2),

- V – volume of water in the pool (l).

The obtained result is compared with standards. For example, for an outdoor pool, the acceptable power of a gas heater is 1000 W/m2; if the pool is partially closed (a canopy or part of a building), the power should be 620 W/m2. For indoor pools, the described parameter should correspond to 520 W/m2.

An important parameter is the operating time of the heat exchanger to heat the water in the pool to the required value. The calculation is carried out using the formula t = 1.16 * V * T / P, where :

- t – required time in hours;

- V – volume of water in the pool in cubic meters;

- T – required temperature difference in degrees;

- P – declared power.

For example, the initial temperature of the water in the pool is 20 degrees Celsius. It needs to be heated to 26 degrees. The temperature difference is 6 degrees. The volume of the bowl is 30 cubic meters. A heat exchanger with a capacity of 6 kW is also installed. By calculation we get the value 34.8 hours.

The simplest solar water heater - DIY instructions

From scrap materials you can make simple solar water heaters that are highly efficient in the summer. Cellular polycarbonate and plastic bottles will serve as a good basis for creating such devices.

Made from cellular polycarbonate

First, a frame is made from a wooden beam. Then a coil is welded from copper tubes in which water will circulate. At its ends, fittings are installed to connect the supply and discharge pipes.

The water heater can be made of cellular polycarbonate.

Plywood is attached to one side of the frame, and insulation is placed on top of it. After this, the coil is fixed to the frame. The top of the structure is covered with a polycarbonate sheet. The finished collector is connected to the pump. In addition, a pipe is installed that drains the liquid back into the pool. You can then turn on and test the system.

From plastic bottles

For the manufacture of the device, containers with a volume of 1.5 liters are better suited. A hole should be drilled in the bottom of each of them, the diameter of which should coincide with the neck. Then one bottle is inserted into the other, secured together with a drilled cap. The connections should be soldered so that they are airtight. In this way, 5-6 containers are fastened in a row.

You need to make at least 5 of these batteries. They are connected to each other with a hose to form a coil. The bottles are painted black. Then the formed coil is placed in a pre-made housing, in which the inlet and outlet holes are made. The top of the heater is covered with transparent polycarbonate or glass.

Boiler models for heating water with gas, prices

Popular models of gas heaters for swimming pools are the following:

Vanward Tankless

Affordable gas pool heater made in China. Suitable for small medium bowls for home use . Compliance with ISO9001 standards certifies the high quality and safety of the product.

The compact size of the device allows it to be installed in limited spaces. The average cost of such a heater is from 15,000 to 16,000 rubles.

Volcano

Gas heaters of the Vulcan brand are compact, easy to use and efficient . Suitable for stationary, quickly installed and swimming pools.

The supply type of heater requires its connection to a water filtration system, the productivity of which should be in the range from 2 to 9 thousand liters per hour. The cost of the model is 30-35 thousand rubles.

Davey

Davey gas heaters are suitable for large-volume amateur and professional pools. They are used in SPA centers, swimming establishments and private residential properties (country houses, cottages, dachas).

HSI (hot surface ignition) technology has been introduced, which reduces fuel consumption by reducing pilot light consumption. The average cost of the model is about 220-250 thousand rubles.

How to connect to the tank?

Installation and configuration of such equipment for the pool requires highly qualified specialists. Connection is carried out in accordance with the attached instructions. In general, the connection algorithm consists of the following steps:

- Installing the heater on a flat surface near the pool.

- Connecting the hose from the filter system to the lower pipe of the heater.

- Turning on the filter system and releasing air from it.

- Connecting the reducer to the gas cylinder.

Heating a pool with a heat pump

Heat pump heaters are a complex design in which water drawn from the pool passes through a filter system and then enters a pump. Inside it, it moves along a coil.

Air pumped from outside collides with the refrigerant, which leads to the formation of a large amount of condensate. This substance, under the influence of temperature differences, quickly turns into steam, and then is pumped into a compressor, where it is compressed to 20-25 atm. This process is accompanied by the release of heat. Such systems are compact.

How to use?

To start heating, it is enough to provide gas supply to the device and turn on the equipment with the appropriate switch. Next, after the operating time of the heat exchanger, previously calculated by the appropriate formula, you need to check the temperature in the pool.

It should correspond to the expected value: swimming pools, sports pools - from 24 to 26 degrees Celsius, children's pools - from 28 to 30 degrees Celsius, pools for hydromassage and similar water treatments - from 32 to 38 degrees Celsius.

Warming up the room

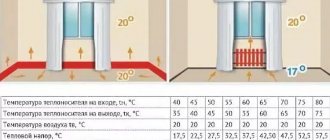

In an indoor pool, for a comfortable stay, it is necessary to maintain the air temperature 2-3 degrees higher than the water temperature.

Note! To prevent condensation from forming in the room and making it not stuffy, the humidity level should be between 50 and 60%.

To heat the air in the indoor pool, the same systems are used to heat the house. When installing a swimming pool in the house itself, the heating circuit is brought to the room. It is better to install radiators along external walls, under windows.

Infrared heating systems can be used for outdoor heating. They can effectively heat the area adjacent to the pool.

Efficient heating is provided by floor or wall convectors. When using floor-standing equipment models, preference should be given to convectors with forced ventilation.

You will feel comfortable and comfortable in the pool if the lower zone of the pool is as warm as the upper one. Heated floors will help you with this, as they will become the main source of heat. Radiators or fan coils can be installed as auxiliary equipment. First, you need to lay a layer of heat-insulating material on the floor covering, and then pipes for hot water are laid at the same distance from each other, combining them into one circuit. After completing the installation of the pipeline, a concrete floor screed is performed.

It is best to use ceramic tiles as flooring. It has maximum heat transfer. The indicators are slightly lower for floors covered with carpet or linoleum. It is not recommended to use a wooden coating due to low heat transfer and possible rapid drying.

When installing heated floors, polymer pipes are used. Working with them is easy and simple. The connections are high quality and reliable. The pool floor will last you more than 50 years. Effective pool heating is a properly selected boiler and high-quality installation of the heating system.

Other methods of heating an artificial reservoir

Let's look at what devices can be used to heat the water in the pool.

Geyser

The water in the pool can be heated using a household gas water heater .

However, it must be taken into account that this method is only suitable for small-volume remote pools. They are installed on a temporary basis at dachas or on the territory of a country house.

The power of the column must be at least 20 kW. You can easily purchase such a product in any specialized store at a cost of 3 to 6 thousand rubles.

Gas cylinder

Gas can be supplied from a gas cylinder . To connect equipment to such a cylinder, you should first of all pay attention to the thread of the nut (in many heater models the nut has a left-hand thread) that secures the heater connection point. You need to screw it counterclockwise as tightly and carefully as possible.

Next, open the cylinder valve. To do this, you need to rotate it counterclockwise. At this time, you should finally make sure that there is no gas leakage from under the nut.

To make sure that gas does not flow into the burners, you need to unscrew the fuel supply control screw located on the reducer. This is also done counterclockwise until the value on the pressure gauge reaches 0 MPa. Next you need to light the burner.

Before starting you should check:

- is the water circulation turned on?

- are there any leaks;

- is a reducer connected to the cylinder;

- Is the valve open?

Ignition is carried out with a special gas lighter. This is the easiest and safest way to properly light a burner.

When turned on, it is brought to the burner and at the same time the gas supply screw is rotated clockwise. After ignition, you need to set the value to 0.1 MPa on the pressure gauge for stable operation.

How to make a solar collector for a swimming pool with your own hands

With your own hands and from scrap materials, you can make a simplified version of a flat-plate solar collector. But the design is suitable for use only in summer; in winter it is ineffective. It is extremely important to assemble and connect the device correctly.

Necessary materials

To make the collector you will need:

- plastic pipes;

- wooden beam with a section of 5x5 cm;

- thin slats;

- plywood;

- black paint;

- metal corner;

- metal sheets;

- self-tapping screws;

- small water pump;

- geoglass;

- tees;

- mineral wool.

- Exhaust valve;

- drain tap.

To make the collector you will need plastic pipes.

To create a cushion under the system you will need sand, gravel and geotextiles. You need to purchase consumables for the welding machine in advance.

Build process

The manifold assembly process includes the following steps:

- Make a frame from wooden slats and cover it with plywood.

- Place insulation on the bottom and make a sheathing of thin slats.

- Attach thin metal plates to the surface.

- Paint the entire structure black.

- Cut the pipes and connect them together with fittings and angles to form a coil.

- Mount pipe fasteners on the surface of the shield.

- Fix the coil on the frame and paint it black

- Carry out a hydraulic test.

- Equip the inlets and outlets of the coil using tees and shut-off valves.

- Cover the top of the structure with geoglass.

From steel corners you need to weld a platform on which the entire system will be mounted.

Installation and connection of the solar collector

First of all, you need to choose a good site for installing a solar collector. Homemade structures are often less efficient than professional ones, so it is better to place them in close proximity to the pool - this will reduce heat loss during water circulation.

Connecting a solar collector reduces heat loss.

The selected place should be prepared: remove the top soil layer and form a sand and gravel cushion. Then the surface is carefully leveled and a layer of concrete is poured. If desired, the platform can be made from paving slabs.

After this, a metal frame is installed.

The next step is to install the collector on the platform. It is important that it faces south. Then a medium-power pump is connected - it will ensure a slow flow of water through the system and better heating.

At the final stage, the efficiency of the collector is checked.