External insulation of the facade is an effective way to reduce heating costs and allows you to preserve the living space of the house. The choice of thermal insulation depends on which finishing method is chosen - for example, if you plan to use a leveling mixture, only 2 materials are suitable: mineral wool and polystyrene foam.

Polystyrene foam is moisture-proof and cannot be used for wooden buildings, but mineral wool under plaster is suitable for almost all types of facades.

Why she?

Stone wool for facade insulation (another name for mineral wool) is a non-flammable insulation material. For example, according to the manufacturer Rokwool, their mineral wool slabs can withstand temperatures of 1500 degrees WITHOUT FIREING or MELTING!

Alas, cheaper foam plastic cannot boast of this. There is a second important nuance. Vapor permeability. Mineral wool allows steam to pass through better, which means that in a sense it can be called a breathable insulation. Of course, insulation with mineral wool will cost more. You can see more about the properties of this material in the video on the topic: how to insulate the facade of a house with mineral wool.

Mineral wool for plaster is produced by different companies:

- Knauf,

- TechnoNIKOL,

- Rockwool,

- Izovat,

- URSA,

- Paroc.

To insulate the facility, the customer provided TechnoNikol mineral wool for façade insulation.

According to the manufacturer Rokwool, their mineral wool boards can withstand temperatures of 1500 degrees.

Insulating the facade with foam plastic

It is polymeric materials that have become insulation materials with the longest periods of successful operation in difficult climatic conditions. Research and special testing were carried out, which confirmed excellent results: the foam does not lose its original technical characteristics even under conditions simulating 80 cycles of temperature changes.

What are the unique performance characteristics of foam? After all, almost all builders know: foam type insulation cannot boast of serious resistance to external influences. They do not tolerate the influence of ultraviolet rays well, they can dry out quite quickly, lose their original structure and even completely collapse. But the façade of the building is directly exposed to ultraviolet rays.

Insulation of facades with foam plastic

It turns out that the main secret to the effectiveness and practicality of polystyrene foam as insulation is its combination with a layer of plaster. The material must be plastered in full accordance with technological principles. Then it will acquire excellent performance characteristics.

- A layer of plaster will protect the foam from the negative effects of moisture. The insulation itself takes a long time to dry, and when left in a humid environment for a long time, it becomes too fragile, completely losing its performance properties. Plaster completely eliminates this negative factor, turning polystyrene foam into durable insulation that is resistant to atmospheric influences.

- Polystyrene foam is a rather fragile material. A layer of plaster prevents the formation of dents, scratches, cracks and other damage to the insulating layer. Together with plaster, the foam is already quite reliably protected from mechanical influences.

- When plastering polystyrene foam, the fire safety level of the facility increases. The foam insulation catches fire on its own, and the plaster prevents the spread of fire. However, builders note that the professionalism of the plasterer will matter here: the layer must be even, continuous, and of sufficient thickness.

- Exposure to sunlight is detrimental to polystyrene foam, since ultraviolet radiation destroys it and makes it brittle. But the foam + plaster option completely solves this problem.

It is obvious that when plastering an insulating foam layer, builders are primarily guided not by aesthetic, but by practical goals. The combination of polystyrene foam with plaster significantly improves the performance properties of the latter.

Insulation of walls with foam plastic from the outside

Plastered foam

Excellently plastered polystyrene foam façade

Prices for foam plastic

Styrofoam

Good foundation - good design

The next important step when insulating with mineral wool is preparing the wall. Considering that we are working at a new facility and the walls are quite smooth, no special preparation is required. But still, most of the objects are houses with old walls. Run your hand along the wall; if anything falls off, you need to prime it. In some, especially “difficult” cases, it is necessary to plaster the walls to level them, but this happens rarely or plaster is only partially needed. Use a facade primer, for example Ceresit CT 17.

Description of mineral wool properties

Mineral wool is a very multifunctional material, with a huge number of features. Mineral wool is made from molten rocks. Mineral wool is also extracted from metallurgical slags and their mixtures. Global manufacturers of mineral wool products often use rocks as raw materials.

When long-term and reliable operation of buildings and structures is required, the mineral wool that is obtained in high quality is used. Guaranteed use for a long time.

Benefits of mineral wool

- Low thermal conductivity, which makes it an excellent insulator in work.

- Fire safety is one of the most important factors in construction.

- Resistant to extreme temperatures, allows use in different regions.

- The material does not lose shape when heated and cooled to high temperature changes.

- High percentage of microchemical and microbiological resistance.

- Good vapor permeability, thanks to which the material “breathes”. This eliminates the possibility of fungus, which is one of the important aspects of construction quality.

- Easy installation.

Flaws

- Treatment with water-repellent agents is required to reduce moisture absorption. When moisture is absorbed, the thermal insulation is reduced and cold bridges appear.

- The weight is greater than polystyrene, which increases material costs.

Preparing the stove

The technology of façade insulation with mineral wool involves the use of a special adhesive solution. For example, you can use a mixture of Ceresit CT 180. How exactly to apply the glue can be seen in the photo below.

Note. If you apply the adhesive composition in exactly the same volume, you will end up with a large overspend. This was a special case for one slab; this photo shows only the principle: the amount of glue should be reduced by 1.5–2 times. As a base, using a spatula, apply a thin layer of adhesive to the entire inner surface of the slab. And after that, make large spot applications of the mixture. After this, you can attach the slab. The slabs at this site are quite heavy, so it’s difficult to install them alone; it’s easier with two people.

In places where the slab borders a window, the edge of the window opening must not coincide with the joint of the slabs. Otherwise, cracks will appear in the finished structure. The slab should “flow around” the window. For some areas you need to cut out “interesting” designs.

After the first row of slabs is installed, it's time to think about how to install the next one.

What tools will you need?

To carry out installation work you will need:

- guide profile elements;

- construction level;

- adhesive composition;

- mineralized wool;

- mesh for reinforcement;

- spatulas, plaster composition for the facade;

- dowels

Fastening with dowels

If for polystyrene foam someone considers fastening with dowels-umbrellas only as reinsurance, then for mineral wool this cannot be said for sure. Its weight is at least twice that of foam, which means additional fixation is simply necessary. However, please note that these elements do not need to be attached immediately, but at least a day (24 hours!) after gluing. When insulating the facade of a house, carefully follow the instructions for the building materials. Dowels can be attached at least 24 hours after the board has been set on the adhesive. How many dowels are needed? For polystyrene foam, 4–5 is considered acceptable, for mineral wool, 8 and above. How to fasten with dowels? First you need to drill a hole for the anchor. It should be 15–20 mm deeper than the dowel itself. After this, the fastening element itself is inserted and hammered or screwed. Where should I place each dowel? Usually, the center of the slab is also attached to the “bandaging” areas. That is, in the place where the vertical seam abuts the top plate, a hole is drilled. If we are insulating the facade with mineral wool under the plaster, it’s time to move on to the plaster itself. And for this you need a reinforcing mesh.

Suitable place to work

When insulating the façade of a building with mineral wool, it is convenient to use special scaffolding. In addition, this design is an additional element of safety for people who carry out repair work. It is better to assemble scaffolding without haste, carefully checking the stability of each structural element. The supports must stand firmly on the ground; you can use thick pads. Don't forget to install barriers along the edges of forests.

Strengthening the structure

The first stage of reinforcement is patches. These are elements that hold the structure in particularly vulnerable places. Namely: corners of window openings, corners of a building, doorways. In such places, an adhesive solution is applied to the slabs, over an area slightly larger than the mesh itself. At least 200 by 300 mm. After this, the mesh itself is embedded in the glue. Let's make a reservation here right away. You can’t do the opposite: fix the mesh and throw glue on top. The mesh should be embedded in the glue. The mesh is placed on the adhesive solution and embedded in it. Now that the weakest structural elements have been strengthened, we move on to installing the main mesh. Its installation is similar to the installation of “patches”, but only in larger sizes. Apply a layer of glue and, using a spatula at least 35 cm long, level it over the surface of the facade. After this, we gradually recess the mesh into it and close it so that it is not visible. Below is a video showing how to work correctly with a spatula at this stage of insulating a facade with mineral wool and the technology for applying glue.

Preparing the walls

The first step is to do a little cleaning of the surface. This is done in order to improve the adhesion of the glue and remove dust and dirt as much as possible. Otherwise, the mineral wool, like a sponge, will absorb everything that remains under the insulation layer.

The façade preparation process is as follows:

- We dryly clean with a brush with stiff bristles all remnants of masonry mortar, efflorescence and traces of paint;

- Using a roller we apply a deep penetration primer to the façade walls. There is no need to save money; the better the surface is saturated, the easier it will be to glue the slabs.

Priming is performed twice, and you should try to apply the second layer in the direction perpendicular to the first treatment. It is better to work in the absence of wind and sun; it is believed that in such conditions the primer dries more slowly, penetrates well into the wall material and does not collect dust.

Primer

To apply a high-quality finish to mineral wool under plaster, you also need a primer. Choose a good primer mixture, for example, the Ceresit CT 17 already mentioned above. If you apply the primer carefully and slowly, you will not have to apply it in two layers.

Now all that remains is to apply the finishing layer, which will give the building a finished look. Someone seeks to insulate a house with mineral wool under the siding; this topic is discussed in another article. In our example, the final finish will be peach-colored “Bark Beetle” Ceresit CT 175.

For the sake of fairness, it is worth saying that mineral wool is also used for facade glazing of large buildings. But insulating a house with mineral wool with your own hands is also not a rare case. We examined the basic, general principles of the technology of facade insulation with mineral wool. We have identified 3 important stages:

- how to insulate a facade with mineral wool - how to fix the slab to the surface;

- How to apply a layer of glue to the slab;

- And first we highlighted the advantages of insulation with this material.

Finally, you can look at a gallery of 28 photographs, which shows all the stages of insulating facades with mineral wool using technology:

What is this process

Cotton wool for insulation is used when finishing the façade parts of a house to increase thermal protection, comfort, and maintain a stable indoor microclimate. When performing work, experts recommend following the sequence of the process to create a single multilayer structure.

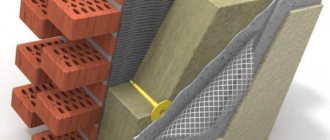

Standard technology includes the application of 3 main layers:

- heat insulating;

- reinforcing;

- decorative (finishing).

Mineral wool insulation for finishing wall panels outside the house is made in the form of slabs with dimensions of 0.6x1.2 or 0.5x1 m. The thickness of the mineral wool reaches 50-150 mm. Facade finishing will increase the fireproof characteristics of the building and improve the level of sound insulation in the premises.

When performing external insulation of a building before applying decorative plaster, it will increase the aesthetics of the house. The strength of mineral wool differs depending on the brand of building material and is (0.08-06 kg/sq. m). Manufacturers offer materials with different densities (35-100 kg/cubic m) for various types of buildings and climatic conditions of the region.

We insulate only from the outside

Wherein:

- the internal area of the premises remains unchanged;

- the cost of heating the house will decrease: the wall material will act as a heat accumulator, which means that in winter there will be less cost for heating, and in summer - for air conditioning;

- the rooms will become quiet: the noise of car alarms and passing traffic, neighbors with karaoke and lawn mowers - all these sounds will remain outside, because fiber insulation is good sound insulation;

- the windows will stop “crying”, and the rooms will become easy to breathe, as excess moisture will escape through the walls.

- the durability of the timber structure will increase: load-bearing structures are not destroyed by moisture, fungus, low temperatures and sunlight;

- If desired, you can easily change the appearance of the facade by replacing the exterior finishing material.

True, to carry out such work it will be necessary to install scaffolding around the log house. But this is perhaps the biggest drawback of this method of insulation.

How to insulate the outside of a log house

Insulating a log house from the outside

You should start insulating the walls of a log house only if all other manipulations aimed at insulating a wooden house, including the interfloor ceiling, have already been completed. If previous efforts have not brought the required result, then action should be taken immediately to avoid damage to the façade of the building. External walls should be insulated, as this is due to the natural characteristics of the material used (wood), which is capable of accumulating moisture and breathing. If you insulate the façade of a building, dampness will not accumulate indoors, but will gradually flow out into the street. Such manipulations can only be carried out after the building has completed shrinkage.

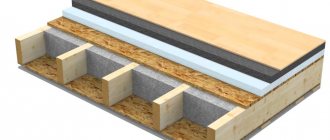

Making the façade ventilated

Ventilated facade

After the walls of the wooden house have been insulated from the inside using mineral wool, you can begin external work. You can insulate a log house by installing a ventilated façade in accordance with available technologies. Thus, the tree will not only retain its ability to “breathe”, but also give up the existing moisture. First of all, the surface is treated with solutions against fungi and fires. A sheathing is installed on top, inside of which the insulating material will be placed. The insulation boards used are laid between the sheathing and tightly filled into the openings. You have to go from top to bottom.

Often the surface is not leveled beforehand, and based on the specifics of the technology used, there should be no gaps between the surface and the material. In this case, all voids can be filled with insulation such as basalt or jute.

A waterproofing membrane is attached on top. Next, you should install a sheathing on which you can place siding, block house or any other material. Thus, a small gap (5 cm) will remain between the facade and the membrane, which will serve as ventilation. For free circulation of air flows, it is necessary to take care of the vents.

Caulk of log type walls

Insulation of the walls of a wooden house

Before you begin insulating the entire building, you should caulk all the external walls of the house. First you need to find all the cracks (an ordinary candle and calm weather will help to detect sources of drafts in residential areas). In winter, you should take time to look for “bunnies” - places where frost forms due to heat loss. Caulking should be done in the absence of rain. For this you will need:

- roll insulation (hemp);

- jute;

- tow.

The material is pushed into the cracks and pushed as deep inside as possible using caulk.

Choosing insulation for a wooden house

Thermal insulation of timber walls can be carried out using facing bricks, concrete or ceramic stones, and small blocks. The only thing is that between the cladding and the surface of the wooden wall there must remain a designed air gap, which is provided in order to remove excess moisture from the wood.

The following can also be used as heat-insulating materials:

Stone wool is a heat-insulating and sound-insulating material that is made mainly from igneous rock melts. It is a type of mineral wool. Gabbro-basalt rock is the raw material for making material fibers;

Expanded polystyrene is an inexpensive, hygienically and sanitarily safe, lightweight but rigid material. Its insulating properties fully satisfy common requirements, but the possibility of cracks forming due to thermal expansion to which the walls are exposed does not allow us to call it the best solution for insulation;

Ecowool is an absolutely natural, environmentally friendly, ideally soundproofing material made up of cellulose and antiseptics based on borax and boric acid. The material is moisture-resistant, hypoallergenic, and can be installed without creating seams or voids. Does not require the use of a vapor barrier layer when insulating timber walls;

Basalt wool is characterized by excellent vapor permeability. Basalt is a non-flammable material, which provides fire protection for a wooden log house. The material has good noise insulation characteristics;

Foam glass is foamed glass made up of thousands of cells of glass. The material is elastic, moisture-resistant, environmentally friendly, fireproof, very durable and can withstand any temperature fluctuations. It does not attract insects and prevents the formation of mold and mildew. Disadvantages include the lack of steam conductivity, high fragility and high cost of the material;

In the case of wooden walls, mineral wool is ideal as a thermal insulator. It meets almost all the requirements for insulation, namely, it has a high thermal insulation coefficient, a minimum thermal conductivity coefficient and low hygroscopicity. She is not afraid of high temperatures, fungus, mold, insects and rodents

It perfectly copes with the removal of vapors to the outside, is non-toxic, non-flammable, breathable and, importantly, durable and can last from 30 to 60 years, based on the declared characteristics of the material. Also suitable for insulation are materials such as:. The following materials are also suitable for insulation:

The following materials are also suitable for insulation:

- Styrofoam;

- extruded polystyrene foam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

Types of insulation

The range of modern insulation materials is very rich and varied, so the issue of choosing a heat-insulating material according to the technical features of the room, the requirements and budget of the buyer will not be particularly difficult.

Safety precautions

The algorithm for insulating building walls with mineral wool requires strict adherence to safety standards. Although the material is classified as environmentally friendly, working with it is potentially hazardous to health. The problem lies in the high volatility of the smallest fragments of insulation. If they settle in human lungs, this can become a starting point for the development of serious diseases.

For this reason, it is strongly recommended not to neglect the use of a protective respirator, gloves and goggles to protect the respiratory system, exposed skin and mucous membranes from contact with material fibers.

When the work is completed, you need to do a thorough cleaning - thoroughly rinse the tools that were used during installation, and also clean the surrounding area with a professional vacuum cleaner, or, at worst, a broom soaked in water.

Mineral wool. Its types. Advantages and disadvantages

This is a modern construction product with good heat and sound insulation properties and a wide range of applications. It is produced by melting raw materials of various mineral components in special furnaces at a temperature range of 1400-1500 degrees Celsius. Sometimes raw materials are mixed with non-ferrous metal processing products. The result is a web of compressed fibers of different lengths and thicknesses. Supplied to the construction market in slabs or rolls.

The main advantages of mineral wool include: it does not burn, it allows air to pass through well, it has waterproof and sound insulation properties, it retains heat well, and is easy to install. Many consider the main disadvantage to be harmful. In the past, this could be accepted because formaldehyde resins were included in the manufacturing process. Today, this drawback has been eliminated, and mineral wool has been recognized as a harmless and safe insulation material.

There is also an opinion that when creating ventilated facades, cotton wool particles can enter the respiratory tract and cause an allergic reaction. Children are especially susceptible to this. Therefore, it is necessary to create good protection for mineral wool from external factors, otherwise the material will begin to deform, collapse and lose its performance properties. Typically, certain types of adhesive solutions or film-based insulation are used for this.

Mineral wool is divided into several varieties:

- Glass wool – characterized by a high degree of elasticity and strength. It has low thermal conductivity and is well suited for insulating external wall surfaces. When working with this material, you must have special clothing and personal eye and respiratory protection.

- Slag wool - has the worst thermal conductivity, so it is not in special demand. The thickness of the thermal insulation layer is large (up to 16 mm). It is not recommended when insulating walls outside a private house.

- Stone - characterized by a fibrous structure and the presence of various mineral impurities (limestone, dolomite, etc.), has good steam permeability and resistance to high temperatures. It is easy to process and cut, does not chip, and does not evaporate substances hazardous to people.

- Basalt is the most effective. It differs from stone wool in that it does not contain any additional inclusions, which allows it to withstand temperatures up to 1000 degrees Celsius in the positive direction and 200 in the negative. Does not burn.

All types of mineral wool are suitable for thermal insulation of facades and insulation of walls outside buildings.

Plastering

If, after the glue has dried, with the reinforcing mesh fixed, large irregularities are visible, then rough plastering needs to be done. It will completely hide imperfections and make the surface smooth.

In cases where there are small differences, decorative plaster is applied immediately. In this case, you need to adhere to the principle of finishing. The method of application will depend on the selected texture.

If the composition did not have a coloring component, then after drying you need to apply 2-3 layers of paint. Here you need to be careful when choosing paint; it must be combined with the composition of the plaster.