External thermal insulation gives a much better effect than insulating a house from the inside. In addition to its main functions, insulation protects walls from precipitation, mechanical damage, and weathering, thereby extending the service life of the entire building. Installing insulation does not require special knowledge or skills, and most homeowners can easily cope with this task on their own. But in order to do everything as efficiently as possible, you need to know what materials are available for insulating walls outside, and how to attach them correctly.

Materials for external wall insulation

Insulation of walls outside

Selection of materials for external insulation

Depending on the choice of material for insulating external walls, components and layers are selected to achieve a thermally efficient and durable result.

Functions of individual layers:

- Glue is the main connection between thermal insulation boards and the base

- A layer of thermal insulation (expanded polystyrene, mineral wool, XPS boards) provides thermal insulation for the entire wall;

- Reinforced layer adhesive is used to fill the mesh and create a durable base layer for facade plaster,

- Facade plaster is a thin-layer coating of a protective and decorative nature that protects all layers from damage,

- Paint is an optional element, used only to enhance the aesthetics of the work.

Insulation methods

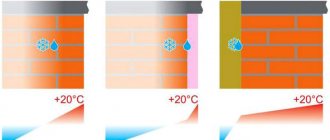

The most effective is external insulation. In this case, the walls are protected from negative external influences and perform the function of heat accumulation, which also helps save on heating costs. At the same time, internal insulation, in some cases, has a positive result.

For a country house or dacha, where permanent residence is not provided and the room needs to be heated quickly only during arrival, internal insulation has advantages. In winter, when the house is not in use and not heated, the walls will still freeze and it is quite difficult to warm them. The internal “jacket” will allow you to quickly heat the air and prevent the walls from absorbing heat.

External insulation of the house helps not only to save heat in winter frosts, but also to maintain coolness in the summer heat.

Materials for wall insulation

Expanded polystyrene and mineral wool are the two most popular materials for thermal insulation in construction. These materials have different parameters and different areas of application. Restrictions on the use of wool and polystyrene are determined by the technical properties of the materials, as well as regulations and legal requirements.

- Due to its weight, facade wool (ordinary) should always be studded - regardless of the thickness of the layer or the height of the building.

- For buildings with a height of more than 12 m, a stud is required, regardless of the type of thermal insulation material and layer thickness.

- This recommendation is a consequence of the possible effect of wind on the insulation system.

- The action of wind in the form of so-called suction, as this can lead to the separation of the entire thermal insulation system from the ground.

- Therefore, fasteners are used in quantities of at least 4 pieces per square meter of wall (in the case of expanded polystyrene and XPS boards) and at least 4-6 pieces in the case of mineral wool boards (in addition, the boards must have a larger diameter when using lamella wool).

- In addition, the number of fastenings should be increased in edge zones, that is, in the corners of buildings and around window and door openings - in these places the wind suction forces are greatest.

One of the most important parameters of thermal insulation materials is their ability to prevent heat loss.

At the same time, mineral wool and polystyrene are characterized by similar parameters, since usually their heat transfer coefficient fluctuates around 0.040 W / (m K) - for wool in the range of 0.045 - 0.032 W / (m K), for polystyrene - above 0.031 W / ( m * K).

Diffusion resistance

What distinguishes cotton wool most from expanded polystyrene is its vapor permeability. Mineral wool has minimal diffusion resistance, which makes it virtually unimpeded by the penetration of water vapor.

However, it should be remembered that the cotton wool is coated with a binder that reduces the diffusion coefficient. In turn, polystyrene provides high, almost complete diffusion resistance.

However, vapor permeability is not a disadvantage or an advantage. The issue is that water vapor does not condense in the wall when the temperature drops. The risk of wall dampness can be reduced by insulating with mineral wool or expanded polystyrene. However, this requires a competent selection of plasters and facade paints.

Soundproofing

The structure of mineral wool contributes to effective noise reduction, providing an effective barrier against sounds from outside and soundproofing rooms inside the building.

On the other hand, polystyrene has slightly worse acoustic attenuation. However, modern polystyrene foam boards with increased noise reduction can be found on the market.

Water absorption

Another important parameter that distinguishes mineral wool from expanded polystyrene is water absorption. Expanded polystyrene has very low water absorption, while cotton wool absorbs water very easily.

For this reason, during insulation work, polystyrene getting wet is not a big problem, and increased moisture content of the wool is unacceptable. Therefore, insulation of buildings with mineral wool is carried out only after the roofing, waterproofing and gutters have been completed.

Modern thermal insulation technologies

Conventional timber frames struggle to meet the latest thermal standards used in modern residential buildings. Fortunately, the latest insulation technology offers several solutions. Owners of frame buildings can choose one of the panel options or use a technique called the “inside-out method.”

Such panels are divided into 3 types:

- Custom built;

- Factory made, filled with polyurethane foam inside;

- Built-in panels for frame construction.

Panel construction has a number of advantages. These include efficient installation, thermal protection quality with multiple thermal bridges.

The inside-out method also has a number of advantages; it is worth considering, if only because this type of home insulation will cost much less. This does not require heavy equipment; all work can be carried out only with the participation of electricians, plumbers, and carpenters.

Mechanical fasteners

According to technical recommendations, mechanical fastening is not necessary for buildings up to 12 m high, provided that the existing foundation is sufficiently strong and stable - then simply gluing the insulation boards with cement adhesive is sufficient.

- There is a recommendation that the maximum thickness of insulation that can be glued without additional fixation is 15 cm.

- The fastening method described above is applicable to systems with expanded polystyrene, possibly with laminated mineral wool.

Polyurethane foam

This material has many similarities with polyurethane foam. Polyurethane foam is applied to a pre-prepared wall using special equipment. A lathing made of wooden blocks serves as the basis for the applied material. The top of such walls is sheathed with plasterboard.

With this application, the material completely fills all the irregularities. Installation is very quick, but special equipment is required, so you will have to invite a specialist.

Rules for selecting fasteners

Fasteners are selected depending on:

- Type of wall material from which the base is made (different anchorage lengths);

- Type of thermal insulation (in systems made of polystyrene, connectors with a plastic or steel stud are used, in systems with mineral wool only with a steel stud);

- The thickness of all insulation layers (surface layer, thermal insulation material, adhesive).

Fasteners for thermal insulation boards can be divided depending on the type of material. For polystyrene, plastic connectors made entirely of plastic are sufficient.

Plastic fasteners are required for mineral wool slabs, but with a steel stud. Both types of fasteners are available in two versions - screw-in or hammer-in.

Fastening is carried out at least 24 hours after the completion of fastening of the insulating boards. First, the necessary wiring and location of individual connectors are drawn on the wall. Then holes are drilled in the marked places with a depth slightly greater than the length of the connector.

After blowing compressed air through the holes, fasteners are placed in them and then hammered or screwed in. When the fastening is correctly installed, the surface of the slab should be flush with the thermal insulation layer.

General description of insulation for building facades

Modern and high-quality facade insulation systems are multi-layer materials for universal use.

Layers of such building materials provide high-quality ventilation and insulation of walls, prevent condensation and freezing of the building, allow you to decorate the house and consist of the following elements:

- facade thermal insulation with minimal heat loss;

- windproofing and waterproofing protecting walls from wind and moisture;

- load-bearing subsystem for strengthening decorative facade materials;

- decorative cladding materials for exterior finishing of the house.

Complete systems contribute to the comprehensive protection of the external walls of the house, which ensures that heat loss through the walls of the building is minimized.

On this website https://giddizajn.ru you can study ready-made instructions and all the pitfalls that you will encounter during installation work

To carry out the necessary procedures for insulating surfaces, it is necessary to competently approach the choice of building materials and functional systems of various types.