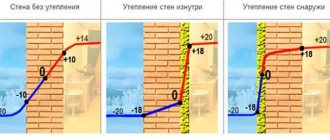

Properly selected and installed insulation allows you to improve the microclimate in the room, because... It helps keep you warm in winter and cool in summer. The formation of additional thermal insulation is economically beneficial, because Helps reduce heating and cooling costs.

Thermal insulation materials on the market differ not only in characteristics, but also in areas of application.

Insulation materials are an extremely popular product on the market of thermal insulation materials. Regardless of what field of construction you work in, insulation materials can be used in both civil, private, and industrial construction. We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia.

We offer an extensive line of Isoroc insulation. The material is based on mineral wool. Environmentally friendly raw materials, processed using modern equipment, fully comply with GOST standards. This means: you get European quality at an affordable price. The truth of these words is confirmed by the experience of leading developers: Isoroc thermal insulation was used in the construction of the largest construction projects in Russia:

More recently, another interesting fact was revealed. It turns out that the integrity of superthin basalt fibers is not damaged by the radiation environment. Therefore, Isorok mini-plates began to be used as thermal insulation for nuclear industry buildings.

ISOVENT-N

Isoroc Isovent-N is a mineral wool insulation based on stone fiber. The material is made from natural components of igneous rocks of the basalt group.

Non-flammable hydrophobized mineral wool slabs based on stone. Intended for use in civil and industrial construction as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including low-rise and cottage-type individual buildings; middle layer in three-layer lightweight masonry (layered, well); inner layer for two-layer insulation in curtain wall systems with an air gap; heat and sound insulation of technological equipment with a temperature of the insulated surface from minus 60 to +400°C.

ISOROC

The ISOROC company aims to solve a number of problems: saving energy, improving living conditions, improving the quality of thermal insulation of residential and non-residential buildings, as well as meeting the needs of Russian consumers of environmentally friendly insulation.

Why choose ISOROC?

IZOROC basalt insulation is created from environmentally friendly raw materials - natural stone, from which mineral fiber is obtained by melting. It has many unique properties - it does not burn, does not deteriorate from moisture, does not rot, does not collapse over time, and is chemically neutral, which allows the mineral fiber to maintain its integrity even when completely immersed in acids and alkalis. This material is absolutely harmless to human health and pets. Therefore, insulation made from it is a sought-after product - because its use increases the comfort of living in the house.

By the way, the insulation is made by pressing - adding a special synthetic binder to mineral fiber, and under pressure, at a temperature of 250 ° C, giving this mixture the shape of slabs. Unscrupulous competitors are spreading a rumor that the finished insulation emits a substance called phenol, which is toxic and can cause serious illness. However, phenol-formaldehyde resin, which is part of the binder for mineral fiber, loses its toxic properties during the production of insulation, undergoing a polymerization process. Therefore, in finished slabs it is in an inert (not active) state. Mineral wool insulation is capable of releasing no more than 0.003 mg/cub.m of phenol into the air, and this figure is within the MPC (maximum permissible concentration), while the maximum content of this substance in the atmosphere can be 0.035 mg/cub.m. But if you decide to buy ISOROC

, and if you doubt its environmental friendliness, ask the seller for a sanitary certificate for this product to once again make sure of its safety.

IZOROC insulation - which one to choose?

The ISOROC company produces sixteen types of mineral wool insulation. Which one should you choose to ensure high-quality insulation of your home and allow you to save on heating costs and save resources for a long time?

Of course, like any other insulation, ISOROC must be chosen based on the design features of your home. In what region is it located? What will its foundation, roof, walls be like? What's inside - joist floors, frame partitions, an attic or an attic? What will the façade finish be like? The answers to these and many other questions will help you correctly calculate the density and thickness of the insulation and select those types of thermal insulation that will allow you to maintain the thermal characteristics of the house without overpayment and additional time costs.

In general, ISOROC produces both universal thermal insulation (which is suitable for insulating various house structures - walls, floors, pitched roofs, etc.) and insulation that has a narrow purpose. For example, ISOFAS for “wet” facades, or ISORUF for roofing. The company also produces thermal insulation for creating engineering systems - for example, ISOSHELL-C for pipelines. Cost of ISOROK insulation

largely depends on its density and compressive and peel strength. Another parameter that affects the price is the thickness of this material, which can vary from 30 mm to 200 mm. Therefore, from the ISOROK line you can choose a product for any budget.

Installation of ISOROK insulation

Mineral fiber basalt slabs are lightweight and have a standard size of 600x1200 mm. Therefore, they are very easy to install - after all, one person can lift the insulation to any height and secure it, without the use of construction equipment. If necessary, ISOROC slabs can be cut with any sharp tool. They are inserted inside frame structures when insulating roofs or walls, or laid on the base of the floor. When installed on walls without sheathing or on a roofing base, the insulation is attached using glue or disc dowels. In some cases, it is recommended to use vapor and waterproofing materials, which will extend the life of the insulation and allow it to maintain its performance properties.

In our store you can purchase ISOROK insulation with delivery

and at wholesale price.

We sell any home insulation

from Russian and foreign manufacturers.

If you don’t know how to choose insulation for walls

, facades, floors, roofs or foundations, contact our specialists - they will help you solve the issue efficiently and most economically.

ISOFLOOR

ISOROC's assortment includes various thermal insulation building materials. Including Isoflor. This building material can be used to solve a wide range of problems. From us you can purchase Isoflor both wholesale and retail. We are a product manufacturer. Therefore, our price for Isoflor does not contain any unreasonable markups. It is significantly lower than most resellers. In this section you will learn useful information about the properties of building materials and the terms of cooperation with us.

Mineral wool Izorok – reviews

Still, it is important to know what people who have already dealt with it think about the material. Here are some reviews found on the forums:

Fedor, Voronezh : “We used Isovent for the facade - excellent, elastic slabs, although the size was a little unusual. There were no problems during installation - everything was quick and easy. I liked that there is no dust from such slabs and the edges do not even crumble after cutting. For me, this is an indicator that everything will fit perfectly in the sheathing, and the insulation will not be blown out through the gap.”

Alexander, Moscow : “I am an inexperienced builder, so I spent a lot of time studying reviews about different materials. As for the insulation, I couldn’t choose a brand for a long time, so I decided to look at everything in the store and immediately feel it. I liked Izolight-L from the inexpensive series, especially since it didn’t give off “fluff” like Rocklight.”

Peter, Kaluga : “I have used Isorok more than once, but only this year I had the opportunity to work with the Ultralight variety. It seems to me that this is the worst decision of the company, since there is stratification. When laid, the mats broke up into bundles of fibers. We had to correct everything during the installation process - we threw the slabs onto a film backing and, as if on a stretcher, delivered them to the attic one by one. In principle, it turned out well - I compacted it between the lags, and then carefully pulled out the film.”

ISORUF V

The use of rigid Izoruf V slabs as an insulating material (alone or together with Izoruf N slabs for the bottom layer) seems to be the most rational option for thermal insulation of a load-bearing roof. Before the advent of this material, a layer of rigid insulation had to be first placed on the roof structure, followed by a cement screed, and only after that could waterproofing be installed. This inevitably led to a heavier structure and forced the construction of more powerful supporting structural elements. The total cost of construction increased.

Product line

The density of Isoflor allows it to be laid under a concrete screed or decorative floor.

The Isoroc line of wall insulation contains several subtypes, focused on the characteristics of the surfaces being protected and various areas of application. It includes the following items:

- Izolight-L;

- Isovent;

- Isofrol;

- Izoruf in packs;

- Isorok in slabs (in cylindrical shapes).

Samples of Izolight-Lux products have a density of 60 kg/cubic meter. meter and are used to insulate surfaces of various orientations. At the same time, large loads and deformation stresses in the layers of products of this type are unacceptable. The next model in the series, Isovent-L, has a significantly higher density (up to 90 kg/cubic meter) and is used for arranging ventilation for building facades.

For the Isoflor modification, the density indicated by the manufacturer is close to 140 kg/cubic meter. m. This insulation is used as an intermediate link in three-layer reinforced concrete structures. Can be used in sandwich panels. For thermal insulation of roofs and concrete floors, another type of insulation material called Izoruf is used. It is produced with the markings H, B or NL, and its average density is 110 kg/cubic meter. meter. Blanks of this material or mats without a piercing shell are marked as “MP”, and if it is present – “MP (ST)”.

Isorok insulation in slabs has two modifications with a material density of 75 and 100 kg/cubic. per meter respectively. They are optimally suited for protecting any horizontal surfaces, but do not allow the load to exceed the maximum level. Isorok Cylinders, marked CF, are considered as a separate category of heat insulators. Various samples of these products differ in the diameter of the cylindrical blanks (ranging from 18-273 mm) and are used for insulating cold water and hot water pipes.

ISORUF-NL

Thermal insulation is the most important stage in the construction of a facility for any purpose, and today many types of materials are offered for this work, each of which has certain characteristics and properties. The Isoroc company, which has been working in the field of manufacturing heat and sound insulating materials for a long period, offers Isoruf slabs for the installation of a reliable and effective thermal insulation structure. Izoruf can be classified as a unique energy-saving material that is made using the latest technology.

Main advantages

The Izorok line of insulation, which has a large number of varieties, is characterized by the following indicators:

- low level of thermal conductivity, allowing to reduce the cost of heating the facility;

- good sound insulation;

- high strength indicators;

- resistance of insulation boards to deformation and other mechanical influences;

- good water-repellent qualities;

- fire resistance and environmental friendliness of the product.

Another attractive aspect of this material is its resistance to aggressive environments.

Resistance to fungal formations is explained by the inorganic origin of the starting material, and fire resistance is due to the presence of fire retardant additives in it.

PP-60/-80

PP-60/-80 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded thermal and sound insulation of pitched roofs, floors, ceilings, internal partitions, light frame structures, three-layer lightweight walls of low-rise buildings made of brick, aerated concrete and other blocks, for thermal insulation of equipment and pipelines with an insulated surface temperature of - 60 C to + 400 C.

Material Specifications

Insulation is available in the form of slabs of various sizes or rolls, differing in a number of operating parameters. The following technical characteristics of Isoroc insulation are especially important for the user:

- The density of the source material reaches 150 kg/cubic meter.

- Compression resistance up to 55 kPa.

- The inverse indicator or tensile strength is within 15 kPa.

- Thermal conductivity, expressed as 0.075 W/(m K).

- Moisture absorption – no more than 5%.

The last characteristic refers to the ability of the fibers of a substance to absorb moisture - hygroscopicity.

P-125

P-125 are non-flammable mineral wool slabs based on stones with water-repellent and dust-removing additives. Designed for use as unloaded heat and sound insulation of horizontal, vertical and inclined building envelopes of all types of buildings, including: in three-layer lightweight masonry (layered, well); frame walls and partitions; attics and interfloor ceilings, for thermal insulation of equipment with a temperature of the insulated surface from -60 °C to + 400 °C.

Scope of application of ISOROK thermal insulation

Due to their performance properties, ISOROC insulation materials can be used for thermal insulation of structures of various types .

Low thermal conductivity and good moisture resistance determine the use of ISOROC mineral wool materials for insulation of external walls (facades of various types) and roofs . Technical thermal insulation provides fire protection for ventilation ducts and other utilities.

Good vapor permeability and effective noise absorption make basalt mineral wool a good option for insulating internal walls and interfloor ceilings . At the same time, it not only reduces heat loss, but also creates a favorable indoor microclimate.

ISOVENT-SL

Isoroc ISOVENT-SL is a non-flammable hydrophobized mineral wool slab based on stone. Designed for use as heat and sound insulation of horizontal, vertical and inclined building envelopes, including: in three-layer lightweight masonry (layered, well); suspended facades with an air gap (ventilated facades) with single-layer insulation and as an outer layer with a two-layer insulation scheme, for thermal insulation of equipment with a temperature of the insulated surface from -60 to +400 ° C.

Information about the manufacturer Isorok

Izorok products are manufactured in compliance with European standards.

The date of appearance of the Russian brand “Izorok” is considered to be 2000, when a large association was created on the basis of the Tambov Mineral Insulation Plant. The further development of this production was supported by investments coming from a number of foreign companies.

Over time, Isorok mineral wool has become a very popular product, in demand in most areas of construction technology.

To expand the volume of mineral wool production, the association needed:

- significantly expand its production areas;

- acquire modern equipment that allows you to automate the work process;

- master new technologies for waste-free production of insulation products.

Thermal insulation Isorok is made on the basis of the finest fibers from a melt of mineral rocks, the individual components of which are held together by a special binder. The need to comply with all the subtleties of the technological chain stimulated the concern's engineers to constantly improve this process. Today it belongs to the undisputed leaders of the Russian market of insulation materials.

All samples of Isoroc mineral wool thermal insulation are manufactured in compliance with European standards. Since its production is organized in Russia, prices are attractive for domestic consumers.

Installation features

Under the screed, Izorok slabs are laid tightly next to each other, without gaps.

Features of the installation of Izorok slabs and rolls for surfaces of various classes are manifested in the requirement to adhere to certain rules. They depend on the conditions in which this material is supposed to be used as a heat insulator. However, in any case, its use is permissible only in combination with vapor and waterproofing.

Cement floor screed

Installation of insulation on a floor base begins with preparatory operations, which include the following steps:

- The screed is cleaned of accumulated layers of dirt.

- All cracks found on the floor are sealed, followed by leveling its surface.

- A waterproofing layer is installed, on top of which Izorok mats are laid.

When laying them, you will need to ensure that the workpieces are positioned close to one another without noticeable gaps.

Another waterproofing layer is laid on top of the thermal insulation, on which a reinforcing mesh is then placed. The laid reinforcement is filled with cement screed. When carrying out this work, it is important to take into account that the total thickness of the coating increases noticeably.

Insulation of external walls of frame structures

For external walls, a metal frame is formed under mineral wool.

Before purchasing Izorok slabs, their total volume is calculated based on the fact that two layers of protective material are formed. Work on their installation is carried out in the following sequence:

- A sheathing based on wooden slats or a metal profile is attached to the walls.

- During installation, the distance between the individual elements must match the dimensions of the insulation boards.

- The laying is organized in such a way that the slabs in the layers are arranged in a checkerboard pattern, with the blanks of the second row completely covering the joints of the previous one.

To fix the outer sheets on the walls, fungal-type piece hardware is used, hammered in at 5 points. Waterproofing is installed on top of the insulated surface, providing reliable protection for the coating being formed.

Insulation of flat roofs

For roof insulation, Isorok material with a high density is selected, laid on a base of reinforced concrete slabs or metal profiles. Work order:

- A vapor barrier layer is installed to prevent moisture from entering between the layers of the heat insulator.

- The edges of the protective film must be folded under the insulation, which does not allow vapors to penetrate into it.

- With multi-layer installation, the joints of the slabs are located with a slight offset.

- For the top layer, a material of higher density is selected than for the bottom coating.

- Waterproofing is installed on top of the insulation.

Isoroc insulation is a reliable and high-quality material used in a wide variety of production areas. Due to the ease of installation and accessibility, this type of heat insulator is constantly in demand among professionals and people engaged in construction at an amateur level.

Do-it-yourself installation of ISOROC insulation

Installation diagram of Izorok mineral wool on the facade

The general principles of working with the material consist of several simple recommendations:

— slabs of material are laid in several layers with overlapping joints, excluding cold bridges;

- protected on the warm side by a vapor barrier, and on the cold side by a waterproofing film;

— the material must be additionally secured to vertical walls to prevent slipping;

— it is necessary to provide access to remove moisture from the surface of the film by creating a ventilation gap.