The modern construction market is filled with thermal insulation materials of different composition and structure. The energy efficiency of the samples is reflected, among other things, in physical parameters. Let's look at how to calculate the thickness of insulation for walls: calculator, formulas for independent calculations. Let's get acquainted with the sources that must be taken into account during design. After reading the article, it will not be difficult to achieve the optimal result without harm to the home and increasing the cost estimate.

Comparison of thicknesses of materials with identical energy efficiency Source stroybobrov.ru

Calculation of pipeline insulation materials

It is not difficult to carry out insulation calculations for pipelines; for convenience, it is recommended to use special calculators. There are a number of actions that allow you to preliminarily determine the volume of materials. Before starting calculations, you should immediately decide what type of insulation will be used. Insulators differ not only in appearance, but also in installation conditions and properties.

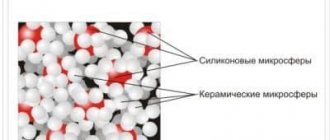

Painting agents can be used to insulate pipelines.

The quality of the materials is high, the layer is thin but durable, fully performing all functions. The calculation is done as follows:

- The formula for calculating the area of the cylinder is S=2πr(h+r), where r is the radius of the base of the pipe, h is the pipe length parameter, π is a constant, the approximate value for this case is 3.14.

- The resulting value is the coloring area. Next, according to the manufacturer’s instructions, determine the material consumption.

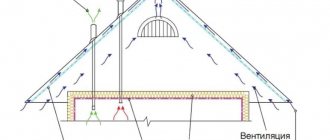

Scheme for calculating thermal insulation for a pipe.

When using conventional insulating materials, calculations are much simpler. It is necessary to determine the volume for the inside and outside of the pipe. To do this, use the formula V=πr2h, where:

- V is the volume of the pipeline;

- r — radius value (external or internal);

- h—pipe length;

- π is equal to 3.14.

The value of the internal and external radius is calculated separately, the resulting difference will be equal to the volume of the entire pipeline insulation material. Wrapping is an option for external insulation. In this case, the calculation is performed similarly using the first formula indicated, but it is necessary to take into account the thickness of the material, since it affects the quantity.

Laying insulation

The calculation of insulation depends on what kind of installation is used. It can be external or internal. External insulation is recommended for the protection of heating systems. It is applied along the outer diameter and provides protection against heat loss and the appearance of traces of corrosion. To determine the volume of material, it is enough to calculate the surface area of the pipe.

Thermal insulation maintains the temperature in the pipeline regardless of the influence of environmental conditions.

Internal laying is used for plumbing. It perfectly protects against chemical corrosion and prevents heat loss through hot water routes. Usually this is a coating material in the form of varnishes and special cement-sand mortars. The choice of material can also be made depending on what kind of gasket will be used.

Channel laying is most often in demand. For this purpose, special channels are preliminarily arranged, and the routes are placed in them. The channelless installation method is less commonly used, since the work requires special equipment and experience. The method is used in cases where it is not possible to carry out trenching work.

Features of insulation of wooden floors.

In pre- and post-war houses, the space between the joists was often filled with soil or debris. The procedure for insulating such a floor :

1. Remove the floor covering

2. Cover the space between the joists with waterproofing material

3. Pour expanded clay on top of the waterproofing material

4. Cover with a vapor barrier

5. Lay polystyrene foam or mineral wool

6. We mount a beam on top of the logs, onto which we attach the floor boards

If your floor design does not include logs, then the floor insulation technology will be as follows:

1. Clean the surface of the dirt floor from debris

2. If the soil has become deformed over time, it is recommended to put it in order

4. Apply a layer of sand and gravel mixture

6. Install reinforcing mesh

7. Fill the expanded clay with a thin layer of cement. Wait until the cement “sets”

8. Perform the main screed

9. Lay a vapor barrier

10. Install the subfloor

11. Install plank covering

Only two lengths

The length of the slabs has two standards. Thermal insulation with a density of 25 and 35 kg/m3 has a linear length of 1200 mm. The area of such a sheet is 0.72 m2. Insulation with a density of 45 kg/m3 has a slab length that is 2 times greater, equal to 2400 mm. The area also increases in direct proportion to 1.44 m2. Sheets of short length can be transported even in the cabin of a passenger car, and large ones can be transported in the trunk of the same car (just remember to secure the sheets longitudinally during transportation in order to avoid breakage of the plates under the influence of the oncoming air flow).

Floor insulation.

The modern choice of building materials allows residents of the first floors (and not only the first) to insulate the floor as efficiently as possible, based on the capabilities of their wallet:

1. Foam plastic for floor insulation.

2. Penoplex for floor insulation.

Has low thermal conductivity, high sound insulation properties, and a fairly long service life

3. Expanded clay for floor insulation.

4. Mineral wool for floor insulation.

The material is sold in rolls or plates. It has high heat and sound insulation properties. Resistant to chemicals and does not melt at high temperatures.

5. Gypsum fiber sheets for floor insulation.

Convenient for installation. Has fire-resistant characteristics.

To calculate a warm, water-based floor, you can use the heated floor calculator.

Floor insulation. Preparatory work.

If you still need to insulate the floor, you should first determine the scale of the work. If you have a cold basement underneath, then you may have to insulate the floors not only on the apartment side, but also on the basement side. The choice of material and method of floor insulation must be approached very responsibly, weighing the pros and cons. Eliminating errors can result in serious physical and material costs.

Attention! Before starting work, be sure to notify the building authorities about this; it is possible that the use of the materials you have chosen is not compatible with communications located in the basement.

Penoizol

This is a liquid version of polystyrene foam, which has the same pros and cons as the solid version. Its advantage is that it can be poured into hard-to-reach places and, after hardening, forms a monolithic coating without seams.

Penoizol

The disadvantages include the fact that you need to think about the method of supplying penoizol for pouring; on high floors this can be a problem. In most cases, penoizol is used during the construction of private houses; when insulating floors in apartment buildings, it is more convenient to use polystyrene foam and penoplex.

The required thickness of the penoizol layer is the same as that of solid foam.

How to calculate the thickness of insulation for walls

The first step in calculating the thickness of thermal insulation is determining the thermal resistance that must be compensated for by the thermal insulator. Let's consider examples based on the listed data. Here you need to use the formula R=d/k, where the layer thickness is divided by the thermal conductivity coefficient.

Climatic zones within Russia Source infourok.ru

Here are some options (odds are taken as an average):

- Moscow. 15 cm thick reinforced concrete slab without finishing. In fact, R=0.15/1.7=0.088. 3-0.088=2.911 units are missing.

- Krasnodar. Log house made of logs with a cross section of 20*20. Drywall inside. R=0.2/0.14=1.43. You need to compensate 2.3-1.43-0.16=0.71 sq.m*℃/W.

- Anadyr. Gas foam concrete wall 30 cm thick. The facade is brick, inside there are tiles and plaster. R=0.3/0.145=2.068. The total thermal resistance is: 2.068+0.93+1.05+0.3=4.348 sq.m*℃/W. There are only 4.7-4.348 = 0.352 units missing here.

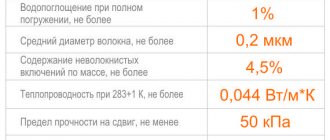

The next step is to select a thermal insulation material based on efficiency, installation method, and cost. The thickness is determined by the first criterion: d=R*k. Let's look at examples:

- Moscow. Ecowool should be laid in a layer of 2.911*0.034=0.01 m, polystyrene foam 2.911*0.029=0.084 m, expanded polystyrene foam 2.911*0.038=0.11 m. For concrete walls, it would be optimal to use 8.4 cm thick EPS without taking into account finishing materials.

Insulation of a monolithic house under construction with penoplex Source remontuem.if.ua