Foam wall insulation is a practical and convenient option that is popular. After all, the capabilities of foam are not limited to the insulation function; it also has waterproofing and soundproofing properties; the use of the product is quite wide. More information about the types of foam insulation for walls and their properties will be discussed in the article.

Technical characteristics of polyurethane foam

Let's look at what polyurethane foam is.

This material is considered one of the best for insulating aerated concrete and other surfaces. Foam of this type has both advantages and disadvantages, which can manifest themselves both during operation and in the future. Typically, the main components of foam are special combinations of polymers. Initially they are in a liquid state, but after being applied to the surface when interacting with air, the foam hardens almost instantly, filling the pores and forming a very dense and reliable layer.

Positive properties

Let's consider the main advantages of using polyurethane foam for wall insulation. There are quite a lot of them, which explains such a high degree of demand for the material among builders and people who started insulating walls.

Window insulation with polyurethane foam

- Very high degree of sound insulation. As a rule, foam today is even better than extruded polystyrene foam at isolating a room from extraneous sounds. This applies to both external and internal insulation. In both cases the effect will be achieved. Only natural cork material can compete with foam in terms of sound insulation.

- Absolute degree of environmental friendliness. This property allows you to use polyurethane foam for any purpose, even for sealing cracks in the walls in a children's room. The foam does not emit any toxic substances even when exposed to external factors.

- Polyurethane foam is relatively resistant to negative environmental factors; it is a non-flammable insulation material. She is practically not afraid of rain, wind, or extreme heat. The polymer composition gives the polyurethane foam greater stability, especially high if a protective layer of plaster is applied on top of it.

- Polyurethane foam is quite easy to work with. It has good adhesion - it adheres perfectly to almost any surface, it can even be applied to metal panels. Has the ability to expand several times. As a result, even a large crack can be filled with a small amount of liquid foam.

- The degree of thermal conductivity of foam is considered one of the minimum among other materials for insulating walls in a house. This allows it to retain heat in the room and keep air and moisture out. And fire resistance protects the house from fire.

Disadvantages of polyurethane foam

But there are also disadvantages to using polyurethane foam. Of course, there are not as many of them as advantages, but still they must be taken into account. This will allow you to avoid mistakes and make the right choice.

Sealing cracks with foam

- Polyurethane foam is not resistant to ultraviolet radiation. As a rule, after sealing cracks and cracks, additional materials should be applied on top or finished with slabs. This will protect the foam from exposure to sunlight, which causes the destruction of polymers in the structure.

- Another disadvantage is the cost. Now on the building materials market you can find many types of foam, which differ from each other in their characteristics. But usually even a small bottle of foam is not cheap. And when working with damaged walls and large areas, you will have to buy a lot of foam at once.

So, if you carefully weigh all the pros and cons, you can choose a good polyurethane foam that will serve for a long time and will firmly protect the inside of the house. Taking into account all the subtleties described above will not allow you to make a mistake.

How to choose material

There is a wide range of foam insulation materials on the market. European foam insulation intended for walls guarantees high quality, but has a high price. Domestic manufacturers have well mastered the production of licensed compounds and materials of their own design, which provide decent quality thermal insulation and a guaranteed service life at a significantly lower price. Experts highlight such manufacturers as

Their advantage over nameless Chinese crafts is their precisely known composition and quality control at all stages of production.

When choosing foam intended for insulating external walls, you should check whether the specific material is recommended for outdoor use, whether it matches the density of the equipment available and the final calculated density of the foam.

And if saving on equipment is even more or less reasonable - it will only be useful once, then it’s definitely not worth saving on materials.

Nowadays, issues related to energy saving are more relevant than ever; the constant increase in tariffs forces us to look for alternative options for saving heat.

Areas of application for Touch'n Seal Foam Kits (USA) for insulation

Currently, the construction market offers a fairly wide selection of insulation materials. At the same time, insulation based on foam, which is contained in cylinders, has rapidly begun to gain popularity.

Work using polyurethane foam and mineral wool for wall insulation can be carried out both inside the premises and along the entire facade.

Some important tips

Before you choose this material and start insulating walls with foam, you should take into account useful tips for choosing and working with insulation

Let's consider in what cases and how best to insulate walls.

For dealing with cracks on the exterior walls of a home, the polyurethane foam type is ideal. It can also be used to insulate the floor if it is an open veranda, and also for insulating the attic. But if you decide to make a room out of the attic where you plan to spend a lot of time, or the windows face the sunny side, then it is not recommended to use polyurethane foam there either.

If you plan to fill a large space with foam or fill it, then the use of penoizol will be indispensable. But don’t forget about purchasing a special spraying apparatus, because... a regular bottle won't be enough.

If you need to repair cracks and other defects in the wall or provide thermal insulation in small areas, then it is better to insulate the house with polyurethane foam in cylinders. This non-flammable insulation is environmentally friendly and becomes quite dense after final hardening.

There is one more tip about applying foam. If it is necessary to repair external defects, then the technology of applying foam is direct - using a balloon or a special apparatus. But if defects are found in the thickness, then it is necessary to use a long hose to push the foam. Just before doing this, you should drill a couple of holes in the wall.

wall pie

Construction of a wall “pie” of a frame house:

- interior decoration;

- vapor barrier layer;

- insulation;

- frame stand;

- windproof layer;

- transverse lathing;

- vertical lathing;

- external finishing.

If you plan to insulate the premises from the inside, you need to carry out all the work in stages. One of the main issues that you should pay special attention to is the correct placement of the vapor barrier film in the thermal insulation “pie”.

Vapor barrier can be made from:

- reflective film;

- diffusion membrane;

- steam condensate film.

When installing a vapor barrier material, you need to take into account one important point: it must be mounted on top of the insulation on the room side. If you plan to insulate the wall with polyurethane foam, then you will not need a vapor barrier.

Types of foam insulation

Foam insulation may differ in its structure and composition. We can distinguish the main types of material for insulating walls and windows:

- Penoizol. It contains aldehydes, which are harmful to health, although manufacturers often claim the opposite. It dries much longer than polyurethane (complete drying time can reach three days). Typically used for insulating attics, load-bearing walls and structures. Can be purchased in the form of ready-made slabs or as a liquid composition.

- Ecowool and foam concrete. Can be purchased in liquid form, most often used for pouring foundations. They are practically not used when finishing facades due to their significant weight, which puts a large load on the walls. In addition, the high cost often speaks against this material.

- Polyurethane foam. Suitable only for sealing seams, joints, holes, since it does not allow moisture and steam to pass through, and this is a critical point for insulating material. When interacting with air, its volume increases twenty times, while there is a minimal amount of air bubbles inside. Can be purchased in convenient small-volume containers that have a significant shelf life.

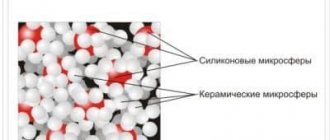

- PPU or polyurethane. The most common option, which is considered the most universal. Polyurethane insulation is very effective as thermal insulation for facades. It consists of two components; they must be mixed by machine immediately before application. The foam expands thirty to forty times from its initial volume, and small balloons form inside. Due to this, high-quality insulation of the house is achieved.

https://youtube.com/watch?v=Ju-v7ryNuC8

Advantages and disadvantages of polyurethane foam

Polyurethane foam (PPU) is a type of foam, that is, gas-filled plastic with a cellular structure. Getting on the insulated surface, the foam creates a uniform, homogeneous layer, which is an effective heat insulator. Insulation of a house with foam can be done both on the outside of the walls and on the inside; it can also be used for thermal insulation of the roof and foundation. The scope of application of polyurethane foam depends on its density. Thus, polyurethane foam with 90% closed pores is used to insulate country houses with a forced ventilation system, as it is vapor-tight. To ensure “breathable” walls, polyurethane foam containing 50% closed and 50% open pores is required.

Advantages of PPU insulation:

- High heat transfer resistance;

- Good adhesion to the insulated surface;

- Dense filling of voids;

- Low vapor permeability (in the case described above) and low water absorption;

- Additional sound insulation of walls;

- Simplicity and speed of insulation.

Disadvantages of polyurethane foam insulation:

- Low vapor permeability in case of insulation of a house without forced ventilation;

- Aging and deterioration of the properties of polyurethane foam over time;

- PPU is a flammable material, without additional coating it does not meet fire safety requirements;

- High price (up to 2500 rubles per square meter);

- Harmful effects on the health of workers when performing work;

- Excessive expansion of foam can cause damage to wall structures if they are insufficiently strong.

Stages and elements for insulation

To reduce heat loss, it is not enough to insulate only the walls of the house. Sources of significant heat loss are floors, roofing and foundations, so complete insulation of a country house should include the following steps:

- Roof insulation. Polyurethane foam is applied to all horizontal, inclined and vertical surfaces, and hard-to-reach places are filled.

- External and internal wall insulation. A frame made of wooden blocks can be mounted on the outer surface of the wall to secure the finishing coating; the cavities between the wall and the finishing coating are filled with polyurethane foam. Insulation is possible without an additional frame, since the polyurethane foam layer can be finished with siding or lining. The insulation of the inside of the walls is similar: a frame for plasterboard sheets is mounted, and the voids are filled with polyurethane foam.

- Insulation of floors and ceilings. To insulate the ceiling, PPU foam is filled into the cavity between the suspended or plasterboard ceiling and the ceiling structure. When insulating the floor, PPU foam fills the gaps between the flooring joists.

- Insulation of the foundation - applying polyurethane foam to the concrete surface.

Equipment for insulation

Insulation of a house with polyurethane foam can be done either by specialists from a construction company or by the owner himself; for this there are the following types of spraying installations:

- Disposable for rigid polyurethane foam with closed cells;

- Portable for low density polyurethane foam with open cells;

- For pouring rigid polyurethane foam with closed cells into the cavity.

External insulation work must be carried out in dry weather. For interior and exterior work, the use of personal protective equipment is required: goggles, respirator, overalls and gloves.

Other types of wall insulation

One of the materials used in repairs and construction is penoizol. It is often sold not in liquid form, but as ready-made hardened panel sheets, similar to basalt insulation for walls. This is a fairly reliable material for insulating aerated concrete; it is characterized by a fast hardening time (about 3 days) if used in the form of a liquid solution. Finished sheets do not require hardening.

But it should also be understood that penoizol has a certain degree of danger to human health, just like extruded polystyrene foam. If it is used in sheets, then there are harmful formaldehydes that are released at high temperatures. It is not recommended to use this foam material inside living rooms.

Insulation of walls with ecowool

Polyurethane foam is another non-flammable insulation material. This material is two-component, but it is not harmful to humans. The main thing is to follow the correct installation technology on the wall surface. As a rule, polyurethane foam insulates the room very well, including from air.

For this reason, care should be taken in advance to ensure sufficient air flow into the rooms from the ventilation. Otherwise, the room will not have a normal microclimate. It is polyurethane foam that can expand 2-3 times more than regular polyurethane foam. This makes the consumption of material for sealing cracks much less. But be sure to use plaster over polyurethane foam.

Ecowool or foam concrete is also often used. It is difficult to say which insulation is better. These materials are not bad in quality, but in terms of fire safety they are very flammable. This is especially true for ecowool. Working with such insulation is not so easy; in addition, they are heavy.

Other advantages

- The hardened structure of the material with pores also seems to be an excellent material for sound insulation.

- The material is light enough, it will not exert any noticeable load on building structures.

- Many of these insulating materials, after final polymerization, become completely safe for people, animals and nature. They do not become infected with fungi or mold, and they are not of interest to mice, rats or insects.

- Most of the insulating foam has excellent contact with the structural and metal elements of the building, not only forms a thermal insulation layer for them, but also creates good protection against rust. Most materials of this type exhibit excellent waterproofing properties, preventing vapor or water from penetrating. When insulating walls, roofs or ceilings, it eliminates the need to install special gaskets.

Cylinder assembly

It is best to carry out insulation with this type of insulation in small areas, because its use in large areas is not always economically feasible.

The reason here is that polyurethane foam is sold mainly in small volume containers, approximately 200 and a maximum of 750 ml.

The largest of them are inexpensive, but they are enough to process only 1 square meter. m of any surface, but taking into account that the layer will be applied no thicker than 8 cm.

After insulation with this material, the thermal insulation of the surface will be several times lower in comparison with the use of the other two types of foam. The reason is that in such insulation half of the cells remain open, whereas in the same polyurethane foam the number of closed pores reaches 90%.

The process of foaming polyurethane foam occurs due to the fact that it is supplied to the surface under high pressure.

In addition, this process intensifies after the material reacts with moisture in the air.

The use of this insulation is common for sealing both window frames and during the installation of doors. It is also advisable to insulate the walls of a small area, for example, a loggia or closed balcony.

This insulation has a more complex composition than classic polyurethane foam.

It is produced in the form of slabs, which is somewhat similar to classic polystyrene foam.

Being in this form, it is more protected from external factors for storage and transportation.

But to bring it into a liquid state at the point of use, a special device is used. It not only melts penoizol, but also mixes it with resin. When insulating walls using such insulation with your own hands, you use a special construction gun.

Foaming begins inside this device and then it is applied to the surface, where it hardens after 15 minutes. For the material to completely harden, you need to wait several days.

Due to the fact that it has a long period of complete hardening, brick-type walls are most often insulated with foam insulation. The material is also often used for thermal insulation of formwork, as well as for insulation of frame houses.

Good to know: due to the fact that the composition of penoizol includes urea and formaldehyde, a significant number of people believe that this insulation is harmful to health. In fact, this is not so, all these components are removed, so the material is harmless to people.

Features of application

Thermal insulation by spraying polyurethane foam needs protection from the sun's harmful rays. That is, a light-proof finish must be applied on top of the applied layer. It is also undesirable to use flammable polyurethane foam for insulating wooden buildings. Despite the presence of fire retardant compounds in the mixture, the manufacturers failed to achieve absolute fire safety.

Another disadvantage of polyurethane foam is the toxic substances released from the foam during the polymerization process. So during work you need to use a good respirator and generally take care of your own safety. Well, the cost of insulation with polyurethane foam is very high, per 1 sq. m it ranges from 550-680 rubles with a layer of 5 cm. But polyurethane foam has a low thermal conductivity of about 0.019-0.028 W/m∙K and, if properly sprayed, can last at least 20-30 years. You can read more about working with such material in this article about polyurethane foam.

Main application steps

If you carry out insulation yourself by spraying polyurethane foam, you will need special equipment with a compressor and a pneumatic gun for the work. Ideally, this should be an automated foam generator that controls all mixing and supply parameters.

After this, you will need to order from the manufacturer a two-component composition for preparing PPU thermal insulation. In further work, follow the instructions:

1. Mix the first ingredient with a construction mixer to evenly distribute foaming agents, regulators, fire retardants and polyesters.

2. In a separate container, prepare a hardener - the second component of thermal insulation. If a precipitate appears in it, heat it to +70 °C, stir again and filter.

3. The combination of two ingredients must be carried out in a completely dry room, where foreign objects or substances cannot enter the mixture.

4. The finished thermal insulation is fed by a compressor into a special sleeve and applied from a gun to the surface to be treated under pressure.

Typically, the proportions of two-component mixtures are kept at 1:1, but the dosage should be checked with the manufacturer. The process of spraying insulation itself, judging by reviews, does not require any skills or complex training. Before insulation, you just need to clean the base from dust and loose pieces, and dry it thoroughly. Immediately after this, polyurethane foam is applied in a layer of 10-15 mm. A second pass is performed on an already frozen base.

Ecowool

This insulation is completely different from polyurethane foam, since it consists of natural components (cellulose), and is 40 percent cheaper. True, its thermal conductivity is higher - 0.032-0.041 W/m∙K. In our review, we will look at ecowool, which involves spraying using a wet-glue method. This is the most expensive, but also the most effective method of its use. The lucky ones living in areas where there are their own manufacturers of thermal insulation made from paper raw materials can count on the minimum price. To apply dry ecowool and the adhesive component, it is enough to dilute it with water in the correct proportion and use a pneumatic gun to spray it in a continuous layer over the surface. According to reviews, you can do without glue, but it is more reliable.

The density of ecowool is approximately 52-65 kg/m3, which guarantees its normal operation as insulation. But unlike polyurethane foam, it does not have proper moisture resistance, so it requires additional protection. However, with slight moisture (up to 14%), ecowool does not lose its properties - it “acts” like wood, releasing excess moisture rather than accumulating it. A really serious drawback is the flowability and shrinkage of the insulation - every year, cellulose insulation loses up to 1.2% of its original volume. Over 5-10 years of service, ecowool will sag by 6-12%, so manufacturers and craftsmen in their reviews recommend making a thicker layer.

When to use spray-on insulation:

1. Since spraying allows you to create a continuous layer, it is ideal for processing non-standard surfaces with protrusions, non-rectangular cells and irregularities.

2. This type of coating is indispensable for thermal insulation of any building structures with a large number of metal elements. Spraying polyurethane foam provides them with reliable protection from moisture penetration and subsequent corrosion.

3. For insulation of pipes and containers for various purposes.

Is it possible to insulate walls with foam?

It is widely used for insulating walls outside and inside.

Apply using a special apparatus or a pistol. The material fits well on vertical, horizontal and inclined surfaces. Features of wall insulation:

- The walls become thicker, which leads to greater resistance from environmental influences.

- The material can withstand temperatures up to +80.

- Vapor permeability.

- Resistant to various damages. It will not crumble from impact or become deformed.

- The material does not burn.

The following objects are insulated:

- window openings;

- walls from the street;

- foundation;

- balcony, attic;

- pipelines;

- attic spaces.

After application there are no seams or joints. The foam hardens in 1 to 3 days, depending on the number of layers applied.

Inside

Warming indoors is carried out as a last resort.

Only when it is not possible to carry out work, if the apartment is on the upper floors. This is indicated in SNiP 23-101-2004. When insulating walls indoors, you should take care of waterproofing, because the dew point shifts. The walls will be wet, which will lead to the appearance of fungus and destruction of the supporting structure.

Outside

Insulating the outside is the right solution. The main factor is not the violation of the dew point. The walls will be warm and dry.

Benefits of insulating from the outside:

- High energy saving data.

- Inside, the footage remains the same.

- No condensation.

- Sound insulation performance improves.

Disadvantage: foam insulation requires the use of equipment.

Even with the inflated cost of the materials, the equipment used, and the work of the craftsmen, this pays off in savings (payment for heat), silence, and comfort.

Foam cost

If you buy a cylinder at retail, then on average you can pay 300-500 rubles per piece. But this type of insulation is rarely purchased separately. Usually its cost is included in the cost of work:

- polyurethane foam - about 100 rubles per linear meter;

- penoizol - 700−2000 rubles per cubic meter;

- polyurethane - 3000−5000 per cubic meter.

The price of the material also plays a big role in its selection.

But you shouldn’t skimp on high-quality thermal insulation if you need to insulate your home for a long time for a comfortable stay. Foam insulation is suitable for most walls, including panel, block and aerated concrete. Therefore, they can be safely used as insulation for apartments and private houses. What type of foam to choose is a purely personal matter for everyone. But first, it still doesn’t hurt to find out more about the selected composition, read reviews, and get advice from a salesperson at a hardware store. It is not recommended to use loose-fill insulation, which easily catches fire, unlike the foam fireproof version. And it is not the most convenient to use, the only exception being the floor surface.

Insulation with liquid foam is a better solution, because if desired, this procedure can be carried out independently, without the help of specialists

If you do everything correctly and be careful, you will be able to quickly insulate any surface that needs it.

Useful video

21.03.2017 1,

Why do you need to insulate your house? Most likely, this question will cause confusion among many ordinary people.

A residential building must be insulated. If you reliably insulate a residential building, you will be able to create a stable internal microclimate at any time of the year. Thus, how comfortable the homeowner and all members of his family will live will not depend on temperature changes and the vagaries of nature. By also insulating the house, you will ensure reliability of all elements of the structure and increase their durability.

Before starting to build a private house, it is worthwhile to think through the issue regarding the insulation of not only the walls and ceiling, but also the entire structure. These activities can be carried out not only at the construction stage, but also during the operation of the building (this is best done in the warm season).

Advantages and disadvantages of foam insulation

Thermal insulation with foam has its advantages:

- Fast processing of even large areas.

- Does not require the installation of lathing, additional profiles, hydro- and vapor barrier films and membranes.

- Does not rot, does not contribute to the growth of mold and fungi.

- It is classified as highly flammable, does not burn, but melts.

- When interacting with metal, it creates a dense anti-corrosion coating.

- Seamless uniform surface with good heat-saving characteristics.

Foam is not a new method of insulation. But, unfortunately, it is not as studied as mineral wool or polystyrene foam - it is difficult to talk about such indicators as environmental friendliness and durability. However, there are several disadvantages inherent in this particular type of insulation:

- Afraid of direct sunlight.

- Does not withstand constant contact with water.

- The original product is not cheap and requires special application conditions.

- A special suit made of tarpaulin, gloves and a respiratory mask with goggles are required.

- Due to the low level of vapor permeability, a thermos effect is created inside the room, so a forced ventilation device is needed.

In search of reliable and safe insulation, builders sometimes use the most unconventional materials and methods. The effectiveness of foam spraying has been proven and does not require large investments or labor costs.

The main thing is to be careful when working and not to leave treated surfaces without a final protective coating.