Purpose and features

Penoplex is made from polystyrene granules, which, according to technology, are exposed to high pressure and temperature. Under the influence of a foaming catalyst, polystyrene granules produce a foamy mass with a finely porous structure. It is shaped into slabs and used for soundproofing and thermal insulation work.

Material properties:

- low thermal conductivity - 0.027-0.031 W/m;

- moderate level of fire resistance - categories G3, G4;

- resistance to moisture, low susceptibility to getting wet - water absorption for 28 days is 0.5% by volume;

- optimal compressive elasticity - 25-35 kg/m³;

- recommended for use in a wide temperature range - from −50 to +75 °C;

- high vapor permeability, equal to two layers of roofing material.

Penoplex is an environmentally friendly building material that is not subject to rotting and the influence of precipitation.

Important! The material does not react with acids, alkalis, ammonia, water-dispersion paints, lime and alcohol. May interact with formaldehyde, gasoline and oil paints.

Penoplex successfully solves issues related to improving the quality of long-term indoor stays. Areas of application of the material:

- protection of the foundation of residential and industrial buildings;

- thermal insulation of basements, garages and outbuildings;

- sound and heat insulation of walls, floors and interfloor ceilings;

- insulation of balconies and roofs;

- soundproofing work in cottages and hotels, factories and dachas, baths and saunas.

conclusions

Extruded polystyrene foam is considered a highly effective sound insulation material. Therefore, you can safely use it instead of expensive mineral slabs and other similar materials.

For information

Extruded polystyrene foam has a durable, integral microstructure that looks like closed cells filled with gas molecules. This is a chemical substance with strong intermolecular bonds, which are tens of times stronger than in polystyrene foam. Individual cells are impenetrable due to the fact that, unlike polystyrene foam, they do not have micropores, which prevents the penetration of water or gas from an adjacent cell

The process of soundproofing structures

Properly installed thermal insulation using Penoplex allows you to create a reliable barrier to external noise, cold and moisture for several decades, leaving them behind the wall. Thanks to the tight joining of the slabs, it is possible to create a reliable thermal insulation environment for the enclosing structures. This increases the period of operation of the structure and its ability to withstand loads.

Features of soundproofing walls

Due to the small thickness of the slabs, Penoplex is suitable for covering walls and ceilings indoors. It slightly reduces the usable area, but at the same time creates an excellent sound insulation effect.

For Penoplex, it is necessary to take care of the evenness of the surface on which the material will be mounted. The base must be thoroughly cleaned of old layers, paints and flaking materials. Prime concrete walls with compounds containing quartz sand - they will improve the adhesion of the glue to the wall. For interior work, you don’t even need to install a frame—the slabs are attached directly to the base using glue.

Work progress:

- Apply markings on the wall for the installation of Penoplex.

- Use a utility knife to cut the slabs according to the dimensions of the walls.

- Prepare the glue according to the instructions - pour the mixture into water, mix with a mixer and leave for 10 minutes, then mix again.

- Using a spatula, apply the prepared glue to the surface of the foam board, covering 40-50% of its area.

- Fasten the material to the wall surface in the required order, trying to leave minimal gaps between the elements. The plate must be pressed tightly to the base, making light rotational movements.

- When the adhesive has hardened, secure the slabs with disc dowels.

- Tape the joints with aluminum tape. If the distances turn out to be voluminous, you can fill them with polyurethane foam.

- The top of Penoplex must be plastered using mesh or fiberglass.

Important! To insulate the facade, Penoplex is fixed to a frame made of a metal profile.

Soundproofing the floor

Penoplex laid on the floor will relieve residents from the noise of neighbors below and will additionally insulate the room. Even when combined with a concrete screed, the product will not create additional load on the floor and will not cause damage to the overall structure.

Article on the topic: What is Penolon substrate used for?

Penoplex insulation technology will depend on the base surface. If the apartment has an old wooden floor covering, it will have to be dismantled, the logs strengthened and stiffeners created. Then all the cracks are blown with foam and sealed with construction tape.

But most often Penoplex is combined with concrete floors under screed. Stages of work:

- Clean the surface from old coating, glue and mortar residues.

- Remove all dirt and dust, seal cracks and defects with putty or construction foam.

- Prime the surface of the concrete floor.

- Mark and cut the slabs taking into account protruding communications, pipes, etc.

- Pour a layer of sand or sand-cement mixture, about 1.5-2 cm thick, onto the concrete surface. The powder is done in stages, no more than for 2-3 slabs at a time.

- Lay Penoplex sheets on top of the embankment, lightly pressing them against the sand layer. Thus, the base is leveled and the mixture is distributed evenly.

- Cover the entire surface with insulation.

- Lay reinforcing mesh cards overlapping on top.

A concrete screed prepared using a certain technology from cement mortar is poured on top of the mesh.

Soundproofing ceilings

Insulating the ceiling in the room will eliminate temperature changes inside, which will prevent the formation of fungus and mold. The surface is prepared in the same way as in previous cases - it is necessary to get rid of the old coating, fill the voids and prime the ceiling.

Stages of insulation work:

- Prepare the adhesive composition.

- Cut the slabs into segments corresponding to the area and configuration of the ceiling.

- Apply a small amount of glue to each slab - in a continuous strip along the perimeter and several dots on the inner area.

- Press the part tightly against the surface of the ceiling, trying to press it into the base. Thus fill the entire surface of the ceiling.

Important! The insulated ceiling can be finished with plasterboard, decorative panels or a layer of plaster.

Characteristics of foam plastic

Polystyrene is one of the few that is not capable of releasing substances harmful to the human body. Expanded polystyrene is a type of plastic that, when burned, emits vapors identical to wood. Thanks to manufacturing technology, this material has the property of quickly fading. Water is not capable of destroying it, much less causing the proliferation of microorganisms. Therefore, polystyrene may come into contact with food. Expanded polystyrene can come into excellent contact with asphalt mixtures, fertilizers, paints, and soap.

It has been proven that the external environment does not destroy the composition of polystyrene foam. But water wears away stones. Therefore, excessively long exposure to ultraviolet radiation can significantly reduce its resistance to moisture and air currents. It would be best to cover the foam structure with a special material.

Thanks to the perfection of technology, a fire retardant was introduced into the composition of the foam. Due to this, he gained the ability to resist fire for 4 seconds. A sheet of polystyrene foam 3 cm thick can protect the room to a fairly good extent. If you increase the foam layer, you can achieve a very high level of noise absorption. The insulation is made from several sheets of expanded polystyrene, sealing the outer layer with a rigid facing material. This design can absorb almost 100% of noise.

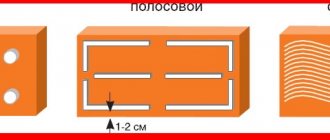

Wall soundproofing diagram.

But it is worth remembering that polystyrene foam is afraid of contact with chemical compounds (ethyl alcohol, acetone, white spirit, gasoline, kerosene). This is explained, first of all, by the structural features of the foam, which contains cells filled with air.

When using penoplex and expanded polystyrene in construction, a number of positive aspects can be highlighted. These include:

ease and ease of processing; use without additional precautions; non-susceptibility to deformation.

Soundproofing technology

In order for as little noise as possible to penetrate into the room and more heat to be retained, special attention must be paid to the layer-by-layer arrangement of the floor. Sound insulation technology when laying Penoplex on the floor involves the formation of the following layers:

- concrete floor slab;

- insulation layer with Penoplex;

- waterproofing layer;

- reinforcing mesh;

- concrete screed;

- decorative flooring - ceramic tiles, linoleum, laminate, carpet.

Article on the topic: Acoustic panels for walls: what they are, efficiency, technical characteristics and cost

In some cases, they opt for frame sound insulation made from wooden beams. The bars will serve as stiffeners and create a kind of cells, inside which prepared and cut Penoplex slabs will be installed.

How to avoid mistakes when working with Penoplex

Experienced craftsmen advise adhering to the following recommendations in order to obtain a good sound and heat insulation effect:

- Before you begin soundproofing, you should assess the noise level and identify noise “bridges” in order to pay special attention to them during installation.

- When insulating walls, the slabs are laid in rows, starting at the bottom and moving up.

- To improve the adhesion of the slab to the base, it is necessary to walk over the surface of the Penoplex with a toothed roller or rub it with sandpaper.

- If the slabs are fastened with dowels, it is necessary to carefully calculate the length of the nail. To do this, it is necessary to add the actual difference in the surface of the fastener to the thickness of the plate and glue and add 2 cm to the depth of the hole for the dowel.

- The dowel attachment points should be staggered relative to each other.

- To strengthen the surface of Penoplex, a reinforced fiberglass mesh is attached to the slabs. It is applied to a layer of glue and leveled with a spatula until it is completely immersed in the glue.

- When foaming the joints between the slabs, gaps should not be made, otherwise the insulation effect will be minimal.

- Manufacturers offer several types of slabs, varying in thickness and characteristics. It is necessary to choose the modification that is best suited for a particular type of work.

Installing foam boards on the ceiling

When choosing this option for noise protection, installation will indeed be easy. It’s even easier than believing in its effectiveness. You can try to resolve the issue this way, and on your own.

Step one. The plaster covering the ceiling can settle, that is, be unstable and unreliable. Then the ceiling surface needs to be cleaned by removing from the base:

Cleaning the ceiling surface

The ideal option is to reach the base, to the floor slabs. Then the panels will be able to be mounted on the base itself much more successfully, and they will become more secure.

When performing work, the owner uses:

So the result will be a well-cleaned, stable surface suitable for installing soundproofing material on it.

Step two. There may be many defects on the ceiling surface. Usually this:

All of them are carefully sealed. Special places are the joints between the slabs. In such areas, flaws will certainly appear.

Step three. Surface adhesion should be high. In addition, it is necessary to initially prevent the spread of mold colonies. For this purpose, the ceiling is degreased by applying a special primer (preferably in two layers). This composition has antiseptic properties.

The primer composition is easier to apply with a roller. If hard-to-reach areas are being treated, then a brush is used.

Step four. Penoplex boards, also called extruded polystyrene foam, are attached to the prepared surface. The process can be significantly simplified, since the following are used:

An adhesive composition is prepared to fix this material to the ceiling. More often, a dry construction mixture for the appropriate purpose is used. It was developed specifically for fastening polystyrene foam. Adhesive foams produced in plastic pipes can also be used.

Glue is applied to the back sides of slabs and panels, and in different ways. The choice depends on the type of adhesive composition itself.

For example, an adhesive solution, if it is prepared from dry construction mixtures, is laid out pointwise, forming slides. In addition, the composition can be distributed evenly over the entire surface using a notched trowel.

You can use a special polymer glue. It is applied around the perimeter in strips, as well as in the center, so that the mass is parallel to the long sides of the panels.

Applying glue to penoplex

The glue has been applied, now you need to pause for 2-3 minutes. Next, you will need to press the attached panel tightly to the ceiling in the place where it will be located. You should hold the stove for at least 1 minute. This time will be enough for initial fixation. But if necessary, the duration of the clamp will be longer.

Step five. For final fixation, mushroom dowels are used. Drill holes in the floor slab (directly through the foam) to attach these dowels. A standard panel is usually secured with 4-5 of these fasteners.

Step six. All subsequent installation work is carried out in the same way. The ceiling plane must be completely covered with sound insulation. The panels are connected, their locking parts are joined. The result should be a completely monolithic coating. For this purpose, the seams that still remain between the installed slabs are filled with polyurethane foam. After the foam hardens, the excess is cut off.

Surface treatment after installing penoplex

We can assume that the installation of the foam layer on the ceiling is complete. All that remains is to finish the newly formed surface.

First option. Plastering the ceiling. Fiberglass mesh is used for reinforcement.

Second option. Coverings are installed in the form of:

Reviews of sound insulation made of polystyrene foam

Mikhail, 42 years old: “I have long wanted to bring my large loggia into decent shape and turn it into a separate full-fledged room. The first thing was to insulate it - I chose Penoplex, 5 cm thick. The slabs weigh a little, but take up a lot of space in the room, so before purchasing you need to take into account the considerable dimensions and provide space for installation work. It was easy to lay the material; I cut it with a regular knife and installed it myself. All work took exactly one day. There was less noise after insulation, now I’m waiting for winter to evaluate the thermal insulation properties of Penoplex.”

Alexey, 29 years old: “Our apartment is located on the first floor. As far as I can remember, the floors have always been cold, no carpets or rugs helped. The construction supermarket suggested choosing Penoplex for insulation. The material turned out to be light, but very durable. The repairmen laid the slabs in just a few hours. But it took much longer to form a cement screed on top of the Penoplex. We chose laminate as a decor, and now we are enjoying the results - the floors have become warmer, and thanks to the spectacular laminate, there is no longer a need for carpets.”

Answers to initial questions

It remains to answer the questions that were asked initially and related to the main purpose of penoplex installed only on the ceiling.

Penoplex is a sound insulator: is it true?

It is worth immediately noting that the ability of the designated material to perform the functions of a thermal insulator is not questioned here. The highest reliability of penoplex was noted; it is beyond doubt. Therefore, the designated material is widely used in the construction industry. The following help to use penoplex as insulation:

But our extruded polystyrene foam was not originally intended as a soundproofing material. So special qualities, such as providing sound insulation, although they are inherent to it to some extent, but only with an impeccable installation method.

Can penoplex really protect an apartment from airborne noise?

Research shows that no significant benefit in this sense can be expected from penoplex. Although the designated material is porous and lightweight, it has significant elasticity and rigidity. So the slab of extruded polystyrene foam becomes a kind of membrane. And if you “shake” it with sound vibration, it turns into an additional “speaker”.

Thanks to the results obtained during laboratory research, it became clear that the special structure of the material enhances frequency resonance in a considerable range - from approximately 200 Hz to 500 Hz. These are the average speech range indicators. So in this frequency range they can o. In other words, airborne noise will be amplified, presenting a significantly increased indicator - approximately from 12 dB to 15 dB.

Can penoplex somehow help in the fight against impact noise?

You can conduct a simple experiment yourself: just tap a section of extruded polystyrene foam with your finger or pencil. It is easy to see that this material can be used in the form of a drum. Its sound, even under light shock loads, is quite resonant. Naturally, penoplex will also not muffle stronger impact sounds. They will be transmitted through massive building structures, and such a coating will only strengthen them.

Impact noises should subside when these waves are transmitted through different parts of the building structure. The greater the massiveness and density of the next material, the lower the amplitude of the shock wave. Plates placed on the ceiling become another transmission link for the propagation of impact noise. In this case, the resonance phenomenon will most likely intensify.

Such noise is reduced by installing special materials with a very high density. For example, Texound sheets are used.

What happens if extruded polystyrene foam is installed on the floor in the apartment of neighbors above

That is, penoplex is mounted on the side of the noise source. In this situation, the picture will change dramatically. A certain damping layer is formed, which takes on the main shock load.

The ratio of layer density will also have a positive effect on the situation. Shock vibrations, when they begin to be transmitted from lightweight polystyrene foam to a dense concrete slab, will noticeably change their strength. The impact noise level will be significantly reduced.

So the indicated properties of extruded polystyrene foam should certainly be taken into account if it is intended for soundproofing a room. A special effect is shown by its installation when a floating insulated screed is constructed. This system does not have a rigid connection either with the walls or with the floor slab.