The main quality of a good home is the ability to retain heat for a long time without loss, and therefore you should be especially careful when choosing insulation. The modern market of thermal insulation materials includes about 15 types of insulation. We have selected 9 of the most effective ones that are suitable for any structure

Read in the article:

- Mineral (stone) wool

- Extruded polystyrene foam

- Liquid foam

- Cork insulation

- Foam glass

- Ecowool

- Sawdust

- Straw

- Hemp and flax

1

Mineral (stone) wool

Rock wool is one of the most common and sought-after insulation materials on the market, and there are several reasons for this.

High heat saving ability

. The thermal conductivity of stone wool varies from 0.035 to 0.042 W/(m*K). In other words, a 10 cm thick layer of this material retains heat as well as 25 cm of timber or 117 cm of brickwork.

Fire safety.

Stone wool does not burn or smolder, because the melting point of basalt fibers exceeds 1000°C.

Vapor permeability.

Thanks to its relatively loose, “airy” structure, stone wool allows water vapor to pass through, which is formed in the house as a result of human activity (showering, cooking, washing, etc.). This means there is no need to worry about mold formation.

Sound absorption ability.

The same fibrous structure makes mineral wool a good sound insulator. So, when covering facades with stone wool, you can solve two problems at the same time: the house will become both warm and quiet.

Resistance to aggressive environments.

Mineral wool insulation is not afraid of mold, mildew and aggressive chemicals. And of course, “foamed stone” does not arouse food interest among insects and rodents.

Light weight.

A package of slabs with a total area of 0.35 m² weighs from 10 to 70 kg (depending on the thickness of the material). Thanks to its relatively low weight, both transportation and installation are facilitated.

Minor shrinkage.

Unlike many loose materials, stone wool almost does not lose volume over time. And that means heat-saving properties.

Durability

. The material retains its performance characteristics for 70-100 years.

Mineral wool in rolls

Mineral wool in slabs

Requirements for external insulation

Despite the fact that the operating conditions outside and inside the house are strikingly different, the same materials can be used in both cases. However, when choosing insulation, preference should be given to those options that best meet the following requirements:

- increased resistance to shrinkage;

- resistance to mechanical damage;

- UV resistance;

- durability;

- ease of installation;

- resistance to insects and microorganisms.

Examples of insulation of walls made of brick and concrete

For wooden houses, the vapor permeability of the insulation is also important, because wooden walls must “breathe”. As a rule, finishing coatings for facades are designed for long-term use, and removing them every few years to replace thermal insulation that has become unusable is too troublesome and not always advisable. At the same time, if the insulation under the finishing becomes compressed, cracks, begins to rot, or is chewed off by mice, it will no longer be able to retain heat, which means it will not be possible to do without repairs. That is why it is so important that the selected material fully meets the specified criteria.

Insulation of a wooden house, diagram

Flaws

High price.

Basalt wool is quite expensive. One cubic meter of material costs from 1,500 to 6,500 rubles. (depending on density and a number of other factors). Such a high price tag is primarily due to the complexity of production and the need to use expensive equipment, in particular blast furnaces.

Use of environmentally unsafe materials.

Stone wool consists of more than 95% of stone itself, but it cannot be called an absolutely natural product. To prevent the boards from falling apart into fibers, manufacturers are forced to use binders, in particular formaldehyde resins. Of course, self-respecting companies use them in minimal quantities, but there is always the possibility of “running into” a low-quality product that emits toxic fumes.

There is only one way to minimize risks - by checking the documents for the products. The laws of the Russian Federation require manufacturers of heat-insulating materials to obtain a Fire Safety Certificate, as well as an Expert Opinion on compliance with current sanitary standards and rules.

Roll Size Chart

For comparison, we take insulation whose thickness does not exceed 50 mm. This is due to the fact that more massive rolled thermal insulation materials roll up much worse. The review involves fiber coatings. Manufacturers of insulation in rolls:

| Material grade | Width, mm | Length, mm | |

| Ursa M-11 | 1200 | The manufacturer offers two options: 7000 and 9000 | |

| Heat Knauf Dacha | 1220 | 7380 | |

| Isover Classic | 1220 | 8200 | |

| Isover Sauna | 1220 | 12500 |

To compare coatings by cost and determine the most suitable option, take into account the number of strips in the package.

Types of stone wool

Basalt-based insulation is available in several modifications. Rolled fabric (the width of which is usually 1.2 m, and the length varies from 7 to 12 m), from most manufacturers has a low density - only 35 kg/m³. This material can only be used for horizontal laying in areas without any load. Such solutions do not occur very often.

The large area of the rolled fabric allows it to be laid with a minimum number of seams, and therefore cold bridges

The most popular is stone wool in the form of slabs (dimensions 0.6-1 m by 1.2 m and thickness from 30-200 mm). The main factor determining the scope of their application is density. Depending on this, the material is divided into several grades.

P-75

(density 75 kg/m³). Used for insulating surfaces with minimal load, for example, interior partitions and ceilings.

P-125

(125 kg/m³). Suitable for thermal insulation of floors, interfloor ceilings and facades.

PZh-175

(175 kg/m³). Designed for thermal insulation of reinforced concrete and metal walls and ceilings.

PPZh-200

(200 kg/m³). The material of maximum density is used for insulating roofs and floors under screed.

How to calculate the thickness of insulation

If you look through SP23-101-2004 or a similar but later set of rules SP 50.13330.2012, you can see that calculating the thickness of the insulation is not so easy.

Each building is “individual”. When developing a project and approving it, such thermal calculations are made by specialists. And here a whole range of parameters are taken into account - the characteristics of the region (temperatures, length of the heating season, average number of sunny days), the type and area of glazing of the house, the thermal capacity of the floor covering, the thermal insulation of the roof and basement. Even the number of metal connections between the wall and the cladding matters.

But if the owner of a previously built house decides to insulate it (and the new standards introduced in 2003 are much stricter than the old ones), then he will have to choose between three parameters of the “standard thickness” of insulation - 50, 100 and 150 mm. And here the accuracy of calculations is not needed. There is a diagram that shows the equivalent dimensions of the thickness of different materials (in average form), the wall of which will meet the new requirements for thermal protection.

Only a house made of aerated concrete blocks with a thickness of 45 cm does not need insulation Source legkovmeste.ru

And then it’s simple. They take the thickness of a wall made of a certain material and see how much is missing from the standard. And then they calculate in proportion what thickness of the insulation layer of the outside wall of the house should be added. Taking into account that a wet façade also has a layer of plaster, and a ventilated façade has an air gap, plus the interior finishing of the façade walls, you can be sure of sufficient thermal protection.

And the issue of insulating the roof, floors and choosing good windows is decided separately.

It’s even easier to use one of the many online calculators. The figure here, of course, is approximate, but rounded up to the nearest standard insulation thickness, it will give the required result.

What is the best way to insulate facades – from the inside or the outside?

There are three options for positioning the insulation relative to the wall.

The first one is from the inside.

This method has few advantages. This is ease of installation (working indoors is more comfortable than outdoors) and there is no need to protect the insulation from harsh external influences. The disadvantages are much more significant. First of all, this is a loss of precious usable space. And the greater the thickness of the insulation, the less free space.

Another disadvantage is the risk of the walls getting wet. Stone wool is a vapor-permeable material. Water vapor passes through it unhindered, after which it begins to accumulate at the “cold wall-insulation” boundary or in the thickness of the wall. So, when choosing this installation method, you need to install a vapor barrier on the side of the room and organize effective (possibly forced) ventilation.

If you place the insulation outside

, the so-called dew point (water vapor condensation zone) will shift into the thickness of the mineral wool, from where the liquid will evaporate naturally. This means that the wall will no longer get wet.

In addition, external insulation protects the wall from alternate freezing and thawing, which has a beneficial effect on the “weather in the house.” And of course, if the mineral wool is located outside, there can be no talk of any loss of usable space.

The disadvantage is that the insulation has to be protected from atmospheric moisture and mechanical damage by covering it with plaster (wet facade) or cladding panels (hinged ventilated facade).

And finally, the third way. In this case, the insulation is laid on the outside of the wall and covered with facing bricks

. In this case, stone wool is reliably protected from external influences, there is no loss of usable area and other disadvantages described above. The only problem is that this solution is optimal only for buildings under construction. It is problematic to insulate an already finished house in this way, since increasing the thickness often requires strengthening (remodeling) the foundation.

Read more in the article “Pele’s Hair”

2

Video description

Visually about mineral wool insulation in the video:

Attention. In the “wet facade” system, the insulation is installed in only one (!) layer. A vertical surface made of two layers of “soft” slabs loaded with plaster behaves unpredictably, especially with changes in temperature and humidity conditions. Do not be fooled by arguments that the second layer of slabs overlaps the seams of the first and eliminates “cold bridges”.

The ventilated facade uses rigid mineral wool mats with a density of 80 kg/m3. If the surface of the mats is not laminated, then after attaching them to the sheathing, the surface is covered with either fiberglass or a vapor-permeable membrane.

The spacing of the lathing is chosen 2-3 cm less than the width of the mats. In addition to fastening to the sheathing, the insulation is additionally fixed to the wall with umbrella dowels.

The size of the air gap between the insulation and the cladding should be in the range of 60-150 mm.

Important. The size of 40 mm is standardized for non-ventilated air spaces.

To ventilate the layer in the cladding, inlet openings are installed in the base area and outlet openings are installed under the roof eaves. The total area of the holes must be at least 75 cm2 per 20 m2 of wall.

Ventilation grilles in the wall Source tproekt.com

Extruded polystyrene foam

Extruded polystyrene foam (EPP) is a progressive and modern material; it is quite closely related to the polystyrene foam familiar to each of us. Both insulation materials are made from polystyrene, but using fundamentally different technologies. And this causes significant differences in consumer properties.

Extruded polystyrene foam XPS

During the production of polystyrene foam, polystyrene granules are repeatedly treated with hot steam, which is why they increase in volume.

But at the same time, the micropores of the material increase. At first, the insulation copes with its duties perfectly. But over time, under the influence of moisture and other aggressive factors, it simply crumbles into individual grains. Although even polystyrene foam that has just “come off the assembly line” has rather low strength. It crumbles easily and has almost no resistance to bending.

In the case of extruded polystyrene foam, the granulated raw material is placed in a reactor where it is subjected to heat and pressure.

Then, when the polymer melts, the pressure is released, which leads to active foaming, and the resulting mass is passed through an extruder.

The result is a material consisting of closed cells with strong molecular bonds. This implies the main advantage of extruded polystyrene foam. It is approximately 5 times stronger than polystyrene foam.

Extruded polystyrene foam is an effective insulation material.

A 10 cm thick EPP slab retains heat as well as a 150 cm thick brick wall. A lightweight, usable roof system for pedestrian loads with plastic supports.

High strength allows the EPP to withstand quite significant loads, and this, in turn, provides a wide range of applications. This insulation is used not only for walls and ceilings, but also for foundations, blind areas, and used roofs. It is used to fill well masonry during the construction of brick houses. It is included in the design of many sandwich panels.

It is also worth noting that polystyrene foam is an exceptionally lightweight material.

It puts virtually no load on the walls and foundation, and also does not create problems during installation

.

The slabs lend themselves perfectly to mechanical processing, and glue and dowels are enough to secure them to the walls.

An important advantage of polystyrene foam is its almost complete waterproofness.

. Even when dipped, it absorbs less than one percent of the liquid.

But unfortunately, EPP has quite noticeable disadvantages.

The first, and probably the main one, is

extremely low vapor permeability.

In simple words, this material does not “breathe” well. You should not insulate the walls from the inside with it - settling condensation will lead to the formation of mold. Experts recommend using this heat insulator outside and covering it with plaster. You can also lay polystyrene foam boards inside frame structures, but it is extremely important to create an air gap for proper ventilation.

Like regular polystyrene foam, extruded polystyrene foam is “afraid” of certain chemical reagents.

For example, bitumen mastics, which are used as waterproofing. Under their influence, EPP becomes soft and sometimes even dissolves.

To avoid blowing through the seams, EPP boards should be laid in two layers, with bandaging

More details in the article “Foam plastic”

3

How to deal with the shortcomings of internal insulation

The Building Regulations do not recommend using insulation from the inside when designing the thermal insulation of premises. However, if internal insulation is necessary, the thermal insulation layer must be continuous and durable.

To prevent the occurrence of dampness, the place where the dew point is located should be isolated as much as possible from the effects of vapors.

For this purpose, a set of measures is provided:

1. Use of insulation with minimal vapor permeability. It is necessary that this characteristic of the material be less than that of the wall. The main rule is that the vapor permeability of layers in a multilayer structure should increase from the inside out. In this case, the moisture will gradually come out.

A - vapor barrier decreases from inside to outside; B - vapor barrier increases from inside to outside.

2. High-quality installation. It is recommended to lay the insulation with glue, and the adhesive is applied not pointwise, but over all surfaces (under the comb) in order to avoid leaving gaps.

Applying glue to the insulation under the comb.

3. Equipping the room with additional ventilation. High-quality air exchange will help avoid humidity. It is necessary to use mechanical ventilation systems or install control valves on windows.

Window ventilated valve.

4. Particular attention should be paid to cold bridges. When installing thermal insulation indoors, there is no opportunity to insulate the joints of external walls. Therefore, the insulator is laid over the adjacent walls. These projections can then be decorated with boxes.

5. Cover with a vapor barrier. If stone wool is used as insulation, then from the side of the room it must be hermetically sealed with a special vapor barrier membrane, and all joints are carefully sealed.

Installation of a vapor barrier membrane on top of the insulation.

Liquid foam

Externally liquid foam (penoizol)

looks like elastic white foam, more than 90% consisting of air bubbles, which, in fact, provides a heat-saving effect.

According to the companies using this material, 10 cm of such insulation is equal to 30 cm of ordinary board foam, 20 cm of mineral wool or 2.5 m of brickwork.

Such impressive characteristics are largely due to the fact that the material is applied under pressure. Increasing in volume, the foam penetrates into the smallest depressions, cavities and cracks, forming a continuous heat-insulating layer without cold bridges.

High adhesion allows the use of liquid polystyrene for internal insulation of vertical and inclined planes, for example, attic roofs

Foamed foam insulation can be used to insulate almost any enclosed space: layered brickwork, false wall cavity, attic floor, etc.

Penoizol is especially popular among companies reconstructing old houses. After all, in order to insulate a building, you do not need to remove the façade cladding or dismantle the ceilings.

Penoizol can also be used outside the home. For example, it is used to insulate the walls of wells. To do this, you just need to make permanent formwork, spaced 3-5 centimeters from the outer walls of the shaft, and foam the resulting space.

Although carbide foam contains organic resins, it effectively resists fire and is self-extinguishing. According to the current classification in the Russian Federation, this insulation belongs to the flammability group G1 (low-flammability)

So, we have looked at the advantages of liquid foam, and there are quite a few of them. But, studying construction forums, you might think that penoizol is perhaps the worst material for insulating private houses. Of course this is not true. Most of the negative reviews are due to the fact that unscrupulous companies, seeking to save money at any cost, use low-quality raw materials and work “carelessly.” And yet it should be noted that this technology does have drawbacks.

The first, and perhaps the main one, is the environmental unsafety of the material.

. Liquid foam contains formaldehyde, which emits toxic fumes. Yes, they weather over time, but finishing work cannot be carried out in the house for another two weeks after insulation. And that's the minimum. It is advisable to wait a month or a month and a half with the “inner stuff” so as not to risk your health. As for finishing facades and other outdoor activities, there are no strict restrictions. But we repeat – it’s better not to take risks.

In addition, the relatively high hygroscopicity of liquid foam should be taken into account. Some companies add moisture-repellent agents (hydrophobizers) to the raw materials, and this minimizes the problem. But it doesn't solve it completely. Therefore, it is impossible to use liquid foam to insulate foundations and other areas that have direct contact with the soil.

Due to its low density, penoizol is categorically not suitable for insulating floors under screed. And the last problematic factor is shrinkage. Foam applied under pressure “deflates” over time. As a rule, it is insignificant - only 1-4%. But the heat-saving properties of the material are somewhat reduced.

To ensure that foam settlement is not critical, it should be applied in compliance with certain rules. So, in one pass, the material is applied to a height of no more than 3 m. But it is better to limit it to a height of 1 m. And only when the foam has slightly set, work can be resumed.

Read more in the article “Light foam”

4

Why external insulation and not internal

The most understandable argument for a non-specialist sounds very convincing, although this is a secondary factor - insulation from the inside “takes away” the useful volume of residential and office premises.

Builders are guided by the standard according to which insulation must be external (SP 23-101-2004). Insulation from the inside is not directly prohibited, but it can only be carried out in exceptional cases. For example, when work on the outside cannot be carried out due to the design features or the facade “belongs” to a house that is classified as an architectural monument.

Cork insulation

Cork insulation is made from granulate - a piece of bark from which a panel of acceptable sizes can be cut does not exist in nature. No synthetic glues are used; the binder is the lingin contained in the bark. However, environmental friendliness is not the main advantage of the material.

Cork oak bark is an amazing raw material. Structurally, it resembles a honeycomb: each cubic centimeter contains hundreds of thousands of tiny cells. They are filled with air, which makes up almost 90% of the total volume. This makes cork the most effective natural heat insulator. It has the same thermal conductivity coefficient of 0.037–0.04 W/m K (at t = 25°C) as mineral wool.

A 30mm thick cork panel retains heat as well as a 40cm thick brick wall or a 15cm thick timber wall

The building material of the cells is the aforementioned lignin, which not only glues the granules together, but also provides elasticity to the material, as well as suberin, a waxy substance impermeable to water. Yes, despite its wood origin, cork is completely impervious to moisture

. Wet insulation is as effective as dry insulation.

It is also worth noting that there is practically no protein in cork, which serves as a breeding ground for harmful microorganisms.

But it contains a lot of tannin - tannin. This is what explains the durability of the material. By insulating your house with cork panels, you can forget about the problem forever - their lifespan is calculated in centuries. And these are not nice words from manufacturers: there are buildings with a centuries-old history that still have cork finishes to this day.

Another undeniable advantage of cork is its lightness.

One cubic meter weighs on average from 100 to 120 kg, which means it will be quite easy to install. And the load on the foundation will be minimal. This is especially important for wooden and frame structures that rest on piles or a monolithic strip foundation.

Despite its woody nature, cork is almost not subject to fire. When in contact with a flame, it does not light up, but only slowly smolders

Depending on the thickness (which varies from 5 to 30 cm), the slabs can be used to insulate walls, floors and roofs. This is a universal insulation. But why hasn’t this material displaced all other insulation materials from the market? The main limiting factor is price. Unfortunately, cork is a rather expensive material. The price for 1 m² 5 cm thick is 2277 rubles. (as of February 2022) But for effective thermal protection you need a layer at least 10 cm thick. Obviously, the cork “costs a pretty penny.” But, nevertheless, she is in demand.

Insulation of walls with cork

Cork in roof insulation

Cork in a green roof design

Read more in the article “Tested!”

5

But there are exceptions! Insulation from plant materials.

Environmentally friendly insulation made from flax and hemp fibers have unique properties and, using them, you can deviate from generally accepted rules. Thermal insulation made from plant materials does not require the use of vapor barrier. Such thermal insulation can be used both internally and externally in almost any structure. If additional wall insulation is performed, then vapor barrier is not used at all. This is especially important when insulating wooden walls. This method of insulation allows you to maintain a favorable microclimate for a person in a wooden house, while significantly improving the heat-saving characteristics of the structure. If a frame house or roof is insulated with flax insulation or hemp insulation, then instead of a vapor barrier, special vapor barrier cardboard is used. Flax and hemp are natural antiseptics, they are not afraid of moisture and can remove moisture from the structure through their capillary fibers; this is their main difference from other non-organic insulation materials. Linen and hemp insulation are absolutely safe for humans, are not afraid of rodents, are durable and will last more than 70 years.

Mode of production

The material is obtained as follows. At the first stage, a mixture (charge) is prepared from finely ground silicate glass and a carbon-containing gas former, which can be coal coke, anthracite, limestone or marble. Then the mixture is sent to a tunnel furnace, where at a temperature of about 900–1000°C the glass particles are softened to a viscous-liquid state, and gaseous CO2 and CO released as a result of carbon oxidation foam the glass mass, forming closed pores in it. The final product can be presented in the form of granules and crushed stone of different fractions, slabs, blocks. Let's talk about the most popular forms of foam glass in private housing construction.

Thanks to its exceptional properties, foam glass (otherwise known as cellular glass) can provide excellent heat and sound insulation of various building structures: roofs, walls, ceilings, etc.

Types of materials in rolls

There are two groups of insulation materials, characterized by flexibility, low density and rigidity:

- Based on expanded polystyrene, polyethylene. Such materials are characterized by a closed-porous structure, which is achieved by foaming the raw materials. As a result, most of the volume is a gaseous medium. By foaming polyethylene, a flexible coating of small thickness is obtained. Roll insulation of this type is characterized by low thermal conductivity, wear resistance, and lasts a long time.

- Mineral wool is presented in varieties: glass and slag wool, basalt or stone wool. These are natural insulating coatings characterized by low thermal conductivity. Disadvantages include low strength, tendency to sag during operation, and hygroscopicity. The last of the properties is the reason for the short service life of the coating. This insulation is suitable for walls, floors, ceilings, attics, basements, and roofs. If you provide protection from moisture in areas with high loads, you can avoid deformation of the coating.

Foam insulation is divided into types, taking into account differences in the production method:

- physically stitched;

- chemically cross-linked;

- gas-foamed.

The first 2 options are characterized by similar properties, but are manufactured using different technologies. In addition, insulation materials are divided into types, taking into account differences in structure: foam with additives (fire retardants), foil. The last option has improved properties. It not only reduces heat loss, but also reflects thermal radiation, returning it back to the room.

Glass wool

The material is based on glass industry waste and sand. Raw materials are exposed to high temperatures (+1450°C). During the melting process, the finest fibers appear. To obtain a thermal insulation material, a binder is added to glue the fiberglass together. Then molding occurs. In order for the binder component to obtain the desired properties, it must undergo a polymerization process. At the last stage, the material acquires a yellowish tint as a result of dyeing

This type of thermal insulation layer protects different types of objects. Glass wool is a universal coating option. However, when working with it, you need to use personal protective equipment (respirator, goggles, gloves, closed clothing) . This is due to the fact that the insulation contains particles that are characterized by small mass and can be released into the environment under the influence of external factors. Dust enters the respiratory tract, settles on the skin and mucous membranes, which provokes tissue irritation.

To slightly improve the strength indicators, the rolled material is reinforced. The disadvantages, in addition to the release of abrasive particles, include relatively low thermal conductivity. In terms of this parameter, the insulation is inferior to its foam counterparts. Another disadvantage is hygroscopicity. The vast majority of mineral coatings strongly absorb moisture.

Advantages of glass wool:

- good sound insulation properties;

- sufficient level of strength;

- the material is lightweight, which means it will not weigh down the structure;

- installation does not require special skills;

- flexibility;

- vapor permeability;

- fire safety;

- elasticity, due to which the insulation can restore its original shape;

- small width means glass wool will not hide the space;

- resistance to mold and fungi;

- insulation is unattractive to rodents.

When choosing, not only positive/negative qualities are taken into account, but also coating parameters. Glass wool is characterized by the following properties:

- the thermal conductivity value is in the range of 0.039-0.047 W/(m*K);

- water absorption coefficient of glass wool for partial immersion – 15%;

- This type of insulation is used at temperatures of -60…+250°C;

- upon contact with water during the first day, the coating will absorb water in the amount of 1.7% of the total volume of thermal insulation material;

- sound absorption rate: from 35 to 40 dB.

In terms of thermal conductivity, glass wool is similar to the following insulation materials: mineral wool, expanded polystyrene.

Izolon

This is foamed polyethylene foam, which is characterized by a closed-porous structure. Available in the following varieties: simple, with a foil layer on one or both sides. Izolon is a fairly dense, but at the same time soft insulation. Its characteristics:

- the average thermal conductivity is 31 W/(m*K);

- density – 33 g/m³, with a decrease in the value of this parameter, thermal conductivity increases;

- the water absorption coefficient is 1%, which indicates that the insulation has no tendency to absorb moisture;

- the material does not allow steam to pass through;

- the ability to perform its main task (reducing the intensity of heat outflow) at low temperatures - down to -60°C, while the insulation does not lose its properties, does not break, does not deform;

- service life is about 100 years;

- resistance to negative factors is noted: precipitation, high loads;

- no toxic substances are released during combustion;

- the material is environmentally friendly;

- Izolon insulation protects the object from noise, and a decrease in the intensity of sound waves is noted even with a minimum thickness of the material.

If we consider the foil coating, we should highlight its ability to reflect heat. The insulation reflects 97% of the heat back into the room. Isolon is not deformable. This means that under the influence of moderate loads it retains its properties.

Plates in rolls

In this case we are talking about materials with increased rigidity, which are formed into rolls. These include basalt wool. This material is characterized by a fibrous structure and is superior to glass wool in terms of hygroscopicity and thermal conductivity. In addition, basalt wool in rolls is almost no different in density from isolon (30 kg/m³). Thermal conductivity of the material is 0.039 W/(m*K). In terms of water absorption coefficient, the insulation is inferior to foam analogues (15%). The main advantage of this coating is its non-flammability.

Granular foam glass

Foam glass in the form of granules is the optimal heat insulator for floors on the first floor of a building. Unlike, for example, expanded clay concrete, the material is not hygroscopic, which means there are no conditions for wood to rot. The vapor permeability of expanded clay is 0.21 mg/(m•h•Pa), and foam glass is 0.001–0.005 mg/(m•h•Pa), moreover, it has half the density, so when producing heat-insulating backfill, You can get by with a layer half as thin. But as for the price, there is a clear advantage of expanded clay, which costs significantly less than granulated foam glass: 1450–2750 rubles. versus 6,000-12,000 rubles. per cubic meter.

Main types of insulation materials

Several types of insulation materials are suitable for insulating a country house from the inside. To help you figure out which one to choose, their characteristics will be discussed in more detail below.

So, this list of thermal insulation materials includes:

- Basalt and glass wool, which can be purchased in mats or rolls.

- Ecowool, made from cellulose fibers, in bulk or formed into mats.

- Expanded polystyrene in slabs.

- Sprayed materials - penoizol or polyurethane foam.

Before moving on to detailed descriptions of the characteristics, you should immediately study their comparative description, which may help you take the first step towards the correct choice of insulation:

| Illustration | Name of material | The main advantages of insulation | Significant material shortcomings |

| Glass wool | — affordable price with fairly high performance characteristics; — high vapor permeability | - hygroscopic; - low-flammability (G1), - inferior in environmental qualities to basalt wool; - there is a tendency to gradual caking. | |

| Basalt wool | — non-flammable (NG); - durable; — has high thermal insulation characteristics; - excellent vapor permeability | - relatively hygroscopic, but the improved material has pronounced hydrophobicity. - much more expensive than glass wool. | |

| Extruded polystyrene foam | — low moisture absorption, — high thermal insulation qualities; - light; - non-toxic under normal conditions; - durable; - resistant to ultraviolet rays; - high mechanical strength. | - flammable at high temperatures; — upon thermal decomposition, it emits extremely toxic gas; — almost complete absence of vapor permeability. | |

| Polyurethane foam | — not afraid of moisture; - has the highest thermal resistance. | — low-flammability (G1); — almost complete absence of vapor permeability; - difficult to apply - requires special equipment and certain work experience. | |

| Ecowool | - environmentally friendly material; - excellent heat insulator; - durability, biological resistance. | — low-flammability (G1); - hygroscopic; — a tendency to caking is possible (with the “dry” method of use). |

The main physical and operational characteristics of these insulation materials are as follows:

| Name of material | Density, kg/m³ | Thermal conductivity coefficient, W/(m×°C) | Vapor permeability, mg/(m/h/Pa) | Moisture absorption, kg/m² |

| Glass wool | 15÷40 | 0,039÷0,046 | 0,4÷0,6 | 0,55÷1,0 |

| Basalt wool | 30÷50 | 0,035÷0,042 | 0,4÷0,6 | 0,1÷0,5 |

| Extruded polystyrene foam | 35÷45 | 0,030÷0,035 | 0,0÷0,013 | 0,01÷0,05 |

| Polyurethane foam | 30÷80 | 0,024÷0,030 | 0,0÷0,005 | 0,01÷0,05 |

| Ecowool (mats) | 33÷75 | 0,038 ÷ 0,045 | 0,3÷0,5 | 0,3÷0,8 |

It should be noted that improved types of these insulation materials are being produced that have improved performance characteristics. Their parameters will be presented below.

Glass wool

Glass wool is made from fibers obtained by melting quartz sand (glass scrap) and some additives. The average fiber length is 30÷50 mm. The resulting mats have fairly high dimensional stability and vibration resistance.

Glass wool is a good insulation material, but its use for thermal insulation in residential premises is not always welcome

Glass wool has good soundproofing qualities, chemical resistance, and high thermal insulation properties. The operating temperature range of the material is from - 60 to + 180 °C. When this temperature is exceeded, the fibers themselves remain intact, but the resinous binder undergoes destructuring, so the fibrous structure can sinter or disintegrate.

Glass wool is used mainly for insulating non-residential premises, since its fibers are particularly brittle, and it is undesirable for them to enter the air of inhabited rooms.

Mouse “paths” and nests made in a layer of glass wool

In addition, mice may well settle in layers of glass wool, making nests and passages in it. Therefore, it can be used in country houses if measures are taken to protect the structure from rodents.

The rodent problem can be very serious!

How to achieve good thermal insulation at home and at the same time try to avoid close proximity to rodents - read the article “What kind of insulation mice do not gnaw” , which can be found on the pages of our portal.

Now let’s look at several brands of glass wool, which in terms of their quality and performance characteristics can safely be considered standard.

"Isover"

Isover brand glass wool is always high quality.

One of the most famous brands of fiberglass-based mineral wool is Isover. This insulation is produced in slabs and rolls, and can have different densities. For example, if thermal insulation is laid under thick plaster, then rigid slabs with increased density are selected - these are “Isover OL-E” and “Isover OL-A”.

Isover glass wool is made from quartz sand with the addition of soda and limestone, and synthetic phenol-formaldehyde resins are used as a binder for the fibers. After mixing the finished fibers with a binder, they are subjected to heat treatment with pressing, due to which the mats acquire the necessary rigidity. Isover brand materials are famous for their durability.

The main characteristics of these insulation materials are given in the table:

| Insulation brand | Block size, mm | Thickness range, mm | Thermal conductivity coefficient, W/(m×°C) | Density, kg/m³ | Compressive strength at 10% deformation, kPa |

| "Isover OL-A" | 600×1200 | 20÷140 | 0,035 | 65 | 15 |

| "Isover OL-E" | 600×1200 | 50÷150 | 0,034 | 50 | 10 |

"URSA"

The most innovative technological developments are used in the production of URSA fiberglass insulation.

Another well-known brand of insulation of this type is URSA. The technologists of this company managed to minimize the characteristic disadvantages of glass wool. The material is characterized by excellent durability, strength of the fibers, and the special structure of the mats and slabs extremely simplifies their installation when insulating building structures.

The variety of URSA brand insulation is extremely large. In private construction practice, it is recommended to use the URSA GEO line of materials, as they are maximally adapted to such conditions and safe for human health.

Some insulation products from the URSA GEO line are presented in the table below:

| Insulation type “URSA GEO” | Thermal conductivity coefficient, W/(m×°C) | Vapor permeability coefficient, mg/(m×h×Pa) | Recommended scope of application |

| "M-11" | 0.04 | 0.64 | One of the most popular types, universal use |

| "Mini" | 0,041 | 0.64 | The same universal material, but made in mini rolls, which can be convenient for individual areas of insulation |

| "A private house" | 0,041 | 0.64 | The name speaks for itself - convenient to use in the construction of private houses |

| "Universal plates" | 0,036 | 0.51 | Material in slabs, intended mainly for wall insulation |

| "Light" | 0,044 | 0.64 | Lightweight type, universal use. Mainly - for use in horizontal unloaded structures (for example, a floor on joists or an attic floor) |

| "Pitched Roof" | 0,035 | 0.64 | Convenient packaging - slabs in a roll. The main purpose is roof insulation. |

| "Noise protection" | 0,04 | 0.64 | Material for sound insulation, for example, internal interior partitions, sound absorption class “B”. |

| "Framework" | 0,035 | 0.64 | For use in frame structures of walls or ceilings. |

Insulation based on basalt wool

Such insulation materials are made from a melt of gabbro-basalt rocks, and are considered the best option for insulating walls and other surfaces from the inside of private houses. The thermal conductivity of basalt fibrous materials is comparable to glass wool, but they have much more suitable qualities for use in residential premises. For example, “stone” fibers are not as brittle as glass, and slabs usually have a higher density, which means that the strength properties of basalt insulation are significantly higher.

An excellent solution for insulating walls in a country house - basalt wool slabs

Basalt wool is produced in slabs and rolls, which can be additionally stitched and equipped with a foil layer, which enhances the insulating effect. The general characteristics of basalt wool were presented in the table, and specific qualities for its individual varieties will be shown below.

Basalt wool slabs are much superior in their strength characteristics to their fiberglass counterparts

There are many well-known brands of basalt insulation materials, foreign and domestic produced, on the domestic market. The most popular ones include Technonikol, Rockwool and Knauf .

"TechnoNIKOL"

Among domestic products, it is gratifying to highlight insulation of the TechnoNIKOL brand.

The table shows popular brands of basalt wool, which are ideal for thermal insulation of a private country house.

| Material grade | Thermal conductivity coefficient, W/(m×°C) | Compressibility, %, no more | Vapor permeability, Mg/(m×h×Pa) | Moisture absorption, kg/m² | Density, kg/m³ |

| "Rocklight" | 0,037÷0,041 | 30 | 0.3 | 2 | 30÷40 |

| "Technolight" | 0,036÷0,041 | 20 | 0.3 | 1,5 | 30÷38 |

| "Heat roll" | 0,036÷0,041 | 55 | 0.3 | 2 | 25÷35 |

| "Technoacoustic" | 0,035÷0,040 | 10 | 0.3 | 1,5 | 38÷45 |

"Rockwool"

The “trend setter” in the production of basalt insulation

can rightly be called the most eminent in the production of basalt insulation. She is a kind of “trend setter”, constantly modifying her products, bringing them to perfection. Thus, “Rockwool” basalt wool was assigned the NG category, that is, the material is recognized as absolutely non-flammable thanks to improved manufacturing technology.

This manufacturer produces a very wide variety of basalt-based insulation materials. But in our case, for insulating walls in a country house, the optimal choice would be “ROCKWOOL LIGHT BUTTS” or “ROCKWOOL LIGHT BUTTS SCANDIC”.

"ROCKWOOL LIGHT BUTTS SCANDIC" - universal slabs that are ideal for insulating a private home

The main parameters of insulation of the “ROCKWOOL LIGHT BUTTS” type are given in the table:

| Name of the main operational parameters of the material | Indicators |

| Thermal conductivity coefficient (W/m×°C): | |

| — calculated at t = 10 °С | 0,036 |

| — calculated at t = 25 °С | 0,037 |

| — operational under conditions “A” (normal conditions) | 0,039 |

| — operational under conditions “B” (conditions of high humidity) | 0,041 |

| Flammability group | NG |

| Fire safety class | KM0 |

| Vapor permeability (mg/(m×h×Pa), not less | 0.03 |

| Moisture absorption when partially immersed | no more than 1kg/m² |

| Dimensions of insulation board | 1000×600 mm |

| Slab thickness | 50 or 100 mm |

Video: ROCKWOOL basalt mineral wool is an excellent material for wall insulation

"Knauf"

Famous for its “German quality”

“ Knauf ” is a German company that is well known to Russian consumers, as it specializes in the production of various building materials of guaranteed quality. Basalt insulation materials from this brand are no exception.

For insulation, you can choose material from the “Insulation” line - but they are considered professional-class insulation, which, naturally, is reflected in the price. For private housing construction, a special line of products is provided, with the very characteristic names TeploKNAUF Cottage, House and Dacha. The characteristics of these insulation materials are shown in the table:

| Name of material | Flammability group | Thermal conductivity coefficient, W/(m×°C) | Slab (mat) size | Thickness of the slab (mat) |

| "TeploKNAUF Cottage" | NG | 0,037 | plate 1230×610 roll 6148×1220 | 50 |

| "TeploKNAUF House" | NG | 0.040 | plate 1230×610 | 50 |

| "TeploKNAUF Dacha" | NG | 0,044 | roll 7380×1220 | 50 |

| Note: for slab insulation, the line has been expanded with the “Cottage+” and “House+” types. Their difference is in the thickness of the material, which is 100 mm |

It should be noted that even the highest quality mineral wools have a common drawback - they are fiber-binding components that can release fumes harmful to humans into the environment. However, nowadays, leading manufacturers make bold statements that they completely abandon the use of formaldehyde resins, using innovative technologies for forming the fibrous structure of insulation. Of course, such materials should be given preference.

In high-quality insulation, the emission of fumes harmful to humans is reduced to almost zero.

Extruded polystyrene foam

Everyone is familiar with a very popular insulation material - polystyrene foam, which is widely used in private construction. But you need to be extremely careful with its use, since it has a number of very serious disadvantages, due to which it was completely abandoned in many European countries.

Such negative properties of polystyrene foam include:

- High flammability of the material. Moreover, during combustion, it actively melts and spreads, as well as the release of toxic smoke, which is deadly to human life.

- With prolonged use, polystyrene foam also begins to release toxic fumes into the environment (its chemical structure cannot be classified as stable organic compounds). Such fumes, containing toxic free styrene, can penetrate even concrete walls.

- In addition, ordinary polystyrene foam is easily chewed by mice, and if it has a thickness of 80–100 mm, then they can easily make their home in it.

Instead of polystyrene foam, it is recommended to use extruded polystyrene foam, which belongs to the category of low-flammable, self-extinguishing synthetic insulation.

Glass wool

If you are going to use rigid synthetic insulation for your dacha, then not ordinary white foam, but extruded polystyrene foam

Extruded polystyrene foam has a fine-cell structure and is obtained by melting polystyrene granules when heated to high temperatures, introducing a foaming agent into the melt, and then giving the desired shape by pressing it through the extruder nozzles. . Moreover, it is important to note that if earlier foaming took place using freons, which were not harmless to humans, today they have been replaced by freon-free compounds based on ordinary carbon dioxide.

Unlike polystyrene foam, extruded polystyrene foam, due to its density and lack of vapor permeability, does not attract rodents as a permanent place of residence, and they can only gnaw on it in several places.

Extruded polystyrene foam has a low coefficient of moisture absorption and thermal conductivity, high compressive strength, excellent frost resistance and chemical resistance. In addition, the material is not subject to rotting, so it is excellent for both indoor and outdoor use.

There are several well-known brands of similar insulation on the Russian market, and it is recommended to choose material from trusted manufacturers, since thermal insulation of unknown origin most likely will not meet all the requirements for efficiency and operational safety.

"Styrodur"

Plates of extruded polystyrene foam "Styrodur"

Solid extruded polystyrene foam "Styrodur" is used in various fields of construction. It is great for insulating not only walls, floors and attic floors, but even the foundations of houses.

Styrodur insulation has the following physical and operational characteristics:

— average material density 25÷45 kg/m³;

— thermal conductivity 0.025÷0.033 W/(m×°C);

— water absorption – no more than 0.1÷0.5% of the volume;

— maximum temperature of use — +75 °С.

— vapor permeability 0.008-0.009 Mg/(m×h×Pa).

This material is produced in the form of light green slabs. They are equipped with tongue-and-groove lamellas, which allow you to create a seamless coating for the wall surface, without leaving “cold bridges”. The insulation is non-toxic, odorless and does not generate dust, so it is well suited for internal insulation of the walls of a house or cottage.

"Penoplex"

“Penoplex” is perhaps the most popular insulating material from the category of polystyrene foam.

Another, more popular insulation material from this series among domestic consumers is “Penoplex”, which has several varieties that eloquently speak about its purpose - these are “Wall”, “Foundation”, "Roof" and universal - "Comfort". Two types are suitable for wall insulation - “Wall” and “Comfort”.

The dimensions of the insulation boards are shown in the table below:

| Slab dimensions, mm | "Penoplex" ("Comfort") | "Penoplex S" ("Wall") | "Penoplex K" ("Roof") | "Penoplex F" ("Foundation") |

| - width | 600 | 600 | 600 | 600 |

| - length | 1200, 2400 | 1200 | 1200 | 1200 |

| - thickness | 40, 50, 60, 80, 100 | 20, 30, 40, 50, 60, 80, 100 | 20, 30, 40, 50, 60, 80, 100 | 20, 30, 40, 50, 60, 80, 100 |

The main technical and operational characteristics of Penoplex are as follows:

— thermal conductivity coefficient – 0.030 W/(m×°C);

— water absorption – no more than 0.2÷0.4% of the volume;

— vapor permeability – 0.007÷0.008 Mg/(m×h×Pa);

— flammability category — G1;

— operating temperature range – from -50 to +75 °C;

— durability declared by the manufacturer is 50 years.

- "Penoplex S", intended for insulation of internal and external walls, contains fire retardants, which make the material resistant to fire (G1). Thanks to its high thermal insulation properties, low moisture absorption, resistance to temperature changes and the presence of a locking connection, this type of insulation is able to create reliable thermal protection for the premises of the house.

- “Penoplex F”, used for insulating the foundation, is produced without the addition of fire retardants, since they are not necessary, because part of the insulated base is in the ground, which reduces the risk of any fire to zero. Therefore, due to the lack of fire resistance (the material usually belongs to category G4), such insulation cannot be used to insulate wooden floors and walls.

- "Penoplex K", although it has a specific purpose - for roof slopes, can be used in all areas of building insulation, therefore it is one of the most popular types.

- “Penoplex Comfort” is a material of increased versatility, designed specifically for use in residential construction, so it is also well suited for thermal insulation of cottage walls.

Polyurethane foam

Polyurethane foam is a highly effective insulation material that is sprayed onto walls using special equipment. In order to achieve the desired thermal insulation effect, polyurethane foam can be applied to the wall in one layer of the required thickness or in several layers. When sprayed, the foam expands and fills all gaps, technological gaps and cracks, forming a completely sealed coating. The material has high adhesive qualities, so you can do without preliminary preparation of the wall surface before applying it.

Fine-cell air-filled structure of hardened polyurethane foam

This insulation is used for thermal insulation of walls both outside and inside the building and is used for this purpose even in regions with very harsh winter conditions. Like any insulation, polyurethane foam requires covering it with finishing materials. Its weak point is its instability to ultraviolet rays.

To insulate walls with sprayed polyurethane foam, special equipment and appropriate qualifications of the craftsman are required.

The main performance characteristics of this sprayed insulation are indicated in the table above, but in addition to them we can add that polyurethane foam, due to its low moisture absorption, retains its thermal insulation properties even at very high air humidity.

Spraying of insulation can be carried out on a wall built from any material - the adhesive qualities will not suffer from this at all. To better distribute the material over the surface and maintain the required layer thickness, the wall is divided into separate zones by attaching vertical guides. After the polyurethane foam expands and hardens, its excess, which extends beyond the installed sheathing, is cut off using a regular sharp construction knife.

Basalt wool

Ecowool

Ecowool has not yet become as popular as mineral wool, polystyrene foam or polyurethane foam, but recently it is increasingly used for insulating various elements of buildings. The material is made from cellulose fibers and is sold in bulk or in formed slabs. The crushed insulation is installed using the “dry” or “wet” method.

The basis of ecowool is specially processed cellulose fibers

The “dry” method is more often used to insulate horizontal surfaces - this is an attic floor or floors, but sometimes hollow walls are also insulated using this technology. The “wet” method of application allows the material to be used on any surface, but this will require special equipment.

Ready-made slabs are installed in the same way as other types of mineral insulation.

Ecowool consists of environmentally friendly ingredients and will not emit fumes harmful to humans. In addition, due to the presence of boric acid in the material, ecowool has the ability to “preserve” surfaces, protecting them from the formation of mold colonies.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Insulation applied using the “wet” method does not lose its heat-insulating qualities throughout the entire period of operation. At the same time, ecowool forms an airtight, seamless coating on the surface, therefore it protects the premises of the house well from cold and overheating.

When laid using the “dry” method and compaction is not good enough, the material may shrink, but its layer, if necessary, can be increased by adding and distributing additional insulation.

During the production process, dry insulation material is necessarily treated with fire retardants and has category G1, that is, it is slightly flammable and self-extinguishing. It does not produce a lot of smoke and does not emit combustion products with toxic substances. Cellulose, which is the basis for this insulation, is a “breathable” material, so moisture will not be retained inside it.

If a private house in which year-round living is planned is insulated with ecowool, manufacturers guarantee a return on costs within two to three years.

The most reputable brand in this area is “Termex” - this trademark belongs to a Finnish company that supplies ecowool to the Russian market in loose form.

Packaging of dry loose ecowool "Termex"

This material has a good thermal conductivity indicator - 0.040 W/(m×°C), final density, depending on the application technology, from 35 to 79 kg/m³. Ecowool “Termex” is characterized by high sound insulation properties - with a layer of 25 mm, noise absorption reaches 9 dB.

The insulation is made exclusively from environmentally friendly materials; flame retardants and antiseptics that are safe for humans are also used for their processing.

Thermex insulation goes on sale packaged in 13 kg bales and comes in two types: Seina-Termex and Puhallus-Termex. Both materials are certified by the Finnish Ministry of the Environment in accordance with the high environmental standards of the European Union and have all the positive characteristics mentioned above.

The table below shows the main options for using ecowool when insulating various structures:

| Methods of applying (laying) material | Dry backfill | "Wet" spraying | Filling left cavities in walls or insulated roof slopes | |

| Insulated areas | This method is used for open horizontal surfaces - attic floors and subfloors for sheathing. | Spraying insulation onto any vertical surfaces between the sheathing guides, for further sheathing. | - located at an angle of less than 60 degrees relative to the horizontal. | — located at an angle of more than 60 degrees relative to the horizontal. |

| Minimum consumption, kg/m3 | 26-36 | 42-65 | 32-65 | 55-65 |

“Wet” method of insulation with ecowool

Insulation using the “wet” method will require special equipment.

Ecowool is applied to vertical surfaces using the “wet” method, which is vaguely reminiscent of spraying polyurethane foam.

Before application, dry loose insulation is treated with a special composition containing adhesives, so it will have excellent adhesion to the wall surface. It does not expand like polyurethane foam, so it is sprayed at once or in several layers to the desired thickness. Since a wall insulated with ecowool must necessarily be covered with finishing material, vertical guides (wooden or made of galvanized metal profile) are fixed on its surface to the thickness of the future layer, which will become both a kind of “beacons” and the basis for installing the finishing.

Extruded polystyrene foam

Leveling the insulated ecowool surface before installing the finishing

After drying, the cotton wool sprayed between the guides is trimmed with a special roller, thereby creating a flat surface. The sheathing elements act as “beacons” during rolling.

Filling the closed space of an insulated wall

Filling the cavity left in the wall with ecowool

Another way of laying ecowool when insulating walls is to fill the empty space in the wall with it. The material is supplied by a compressor through holes drilled in the upper part of the wall. The advantage of this option is that the wool does not fly apart, but flows directionally into the insulated space. Inside the wall, ecowool clogs all the cracks and gaps, forming a seamless “slab” that will not be affected by either temperature changes outside or strong winds.

Foam glass slabs

A wide range of foam glass slabs and blocks designed for insulating various structural elements.

Foam glass slabs are a universal insulation material. In addition to excellent thermal insulation properties, they have high vapor and water resistance and exceptional strength. Foam glass has established itself as a material suitable for the construction of energy-efficient buildings using Passivhaus technology. In practice, it has been proven that if you lay 50 mm thick slabs with a thermal conductivity of 0.052 W/m•°C and a compressive strength of 16 kg/cm² between the base of the house and a brick wall, then with a temperature difference between the street and the room of 35°C (– 15 and +20°C, respectively) no condensation forms in the lower part of the wall, and its temperature is 16.3°C.

In comparison with other insulation materials, the service life of foam glass is practically unlimited, and over time it will not deteriorate its performance, and the slabs will not change their geometric dimensions, thereby eliminating heat loss through breaks in the insulating circuit. Foam glass provides noise absorption up to 56 dB, is environmentally and hygienically safe (does not emit toxic substances), and is immune to chemical influences.

The strength and load-bearing capacity of foam glass is such that a number of blocks laid under brick walls of seven floors can withstand this load without causing settlement and preventing the formation of cold bridges

One of the serious advantages of foam glass insulation is that it does not support combustion (which cannot be said about materials based on polystyrene foam) and does not deform at temperatures up to 450°C. And finally, “glass” will obviously not be to the taste of rodents and will not be harmed by microorganisms.

Slabs are produced with dimensions of 600 × 450 mm and thicknesses from 50 to 80 mm (in increments of 10 mm). For thermal insulation of building envelopes, products with a density of 150–250 kg/m³ are used. The material is easy to install: despite its rigidity, it can be easily machined (cutting, drilling) and glues well. To fasten the slabs and seal the seams between them, you should use compounds selected and recommended by the foam glass manufacturer, taking into account the characteristics of the base.

The slabs are glued outside the house directly to the insulated surface. If it is necessary to use two layers of insulation, the first of them is additionally fixed with dowels, and the second is laid with offset joints, also placing it on glue. Due to the excellent adhesive properties of foam glass, plastering work can be carried out without the use of reinforcing meshes and primers.

Read more in the article “Glass Formula”

6

Wall insulation technology

Thermal insulation of the facade can be performed in different ways, depending on the type of insulation. But for all options, a prerequisite is high-quality preparation of the base, because not a single insulation can stop the processes of destruction of wall materials. Let's consider methods of insulation with mineral wool and polystyrene foam boards, as the most popular in frequent construction.

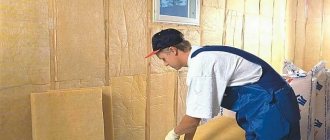

Insulation with mineral wool

External walls are cleaned of dirt, peeling plaster or paint. Repair cracks and problem areas, and be sure to treat areas affected by fungus. There is no need to eliminate minor irregularities - the mineral wool insulation is mounted using a frame, so all defects will be hidden inside. Finally, the walls are coated with a waterproof primer with antiseptic properties so that mold does not develop under the layer of thermal insulation.

Step 1. The beams for the frame are cut to the required length, treated on all sides with antiseptic impregnation and dried in air.

Advice. The cross-section of the beams should be selected taking into account the thickness of the heat-insulating layer. That is, if slabs with a thickness of 50 mm are laid in one row, the thickness of the frame should be 5-6 cm, with a two-layer laying - no less than 11 cm. In the first case, a beam with a section of 50x50 mm is suitable for the racks, in the second - a board 40x110 mm installed on the edge.

Step 2. Markings are made on the walls for the frame guides strictly according to the level, holes are drilled for fasteners and the beams are installed. The distance between the posts should be 10-15 mm less than the width of the insulation board. During the installation process, the location of the elements is controlled at the building level; if necessary, wooden supports are used under the beams so that all the racks are in the same plane.

The pitch of the sheathing corresponds to the width of the insulation

Step 3 . The insulation is inserted into the cells of the frame. To do this, the plates are slightly squeezed along the edges, pressed between the racks and released. The material expands on its own and tightly fills the space. The insulation must be inserted so that there are no gaps between the plates.

Unpacking mineral wool

Cutting mineral wool

Laying mineral wool slabs in two layers

Step 4. After filling all the cells on top, the insulation must be covered with a windproof, moisture-proof membrane. The membrane is laid with the marked side out, the canvases are positioned horizontally, starting from the bottom. A construction stapler is used to fix the membrane. The top sheet is overlapped by 8-10 cm, and it is recommended to glue the joints with tape.

Membrane fixation

Step 5 . Wooden counter battens 30-40 mm thick are stuffed on top of the membrane to provide an air gap. If this is not done, condensation will accumulate on the insulation, the moisture will saturate the wooden frame and the structure will quickly become unusable.

Fastening counter battens

After this, all that remains is to install the finishing coating, for example, siding or corrugated sheeting. The finishing must completely cover the thermal insulation layer so that precipitation does not fall on the slabs. Only under such conditions will the material last long and effectively.

The last step is decorative finishing of the facade

Insulation with polystyrene foam

This method of insulation is noticeably different from the previous one. First, the base must be leveled so that the material fits snugly to the surface. Secondly, installation is carried out without sheathing; the slabs are attached with glue and mushroom dowels.

Step 1. The prepared walls are covered with a primer with quartz sand, for example, Betokontakt. If the base is porous, the primer is applied in 2 layers.

Step 2. Determine the lower limit of thermal insulation and draw a horizontal line along the perimeter of the house. Drill holes for dowels according to the markings in increments of 20-30 cm and secure the starting strip.

The plank is secured with dowels

Starting bar fixed

Step 3. To fix the insulation you will need special glue. You can use mounting adhesive in cylinders, for example, TYTAN STYRO 753, or a dry adhesive mixture (Ceresit CT 83). The mixture is diluted in clean water according to the manufacturer’s instructions, mixed until smooth with a mixer at low speed.

Preparing glue for foam plastic

Take the first sheet, apply glue on the back side in a continuous strip around the perimeter and in the center. Next, apply the insulation to the wall, resting the bottom edge on the starting profile, check the location with a level, and press it firmly to the base.

Applying glue

Step 4. Secure the entire row, tightly joining the sheets together. The next row begins with half a sheet to offset the vertical seams. Excess glue that appears at the joints is carefully removed with a spatula.

Installation of foam boards

Filling gaps with foam

Surface grinding

Step 5. When the glue has hardened, each sheet must be secured with disc dowels. To do this, carefully drill holes in the wall through the insulation, insert dowels and carefully hammer them in with a hammer. One sheet requires 5 fasteners - in each corner and in the center.

Fixing slabs with dowels

Step 6. Next, mix the adhesive solution, apply a continuous layer to the insulation, lay a fiberglass reinforcing mesh on top and embed it in the solution. Openings and corners are additionally reinforced with corner profiles.

The photo shows the fastening of corners and strengthening of openings before plastering work

Fixing the mesh

When the solution has dried, the surface is sanded, dusted and plastered with a thin layer. Now all that remains is to paint the facade or apply decorative plaster.

Painting applied decorative plaster

Ecowool

As the name suggests, the majority of this insulation (about 81%) is recycled paper. The remaining 19% comes from antiseptics against pests and fire retardants that protect against fire. The material is extremely simple to manufacture, so it is inexpensive.

A layer of sprayed ecowool 150 mm in energy saving corresponds to a brick wall 4.5 bricks thick.

But what is more important is that paper insulation (aka ecowool) copes with its responsibilities perfectly. Just 15 cm of paper mixture corresponds in terms of heat conservation to a brick wall 4.5 bricks thick! In this case, the layer turns out to be homogeneous, without seams and voids. It is also important that it “breathes” perfectly, and therefore does not need a vapor barrier.

Another advantage of ecowool is that it can also serve as a sound insulator. A 100 mm thick layer reduces the noise level by approximately 60 dB.

Fire safety.

For material that is shredded paper, this issue is of great importance. As practice shows, cellulose insulation does not ignite upon contact with fire, but only smolders and quickly fades, having lost a heat source. But still, it’s worth dwelling on fire retardants in more detail.

Some manufacturers use ammonium sulfates and phosphates, which emit a pungent and unpleasant odor. But this is not the main problem. The trouble is that over time these additives lose their fire-retardant properties. Therefore, it is better to purchase material impregnated with borax (borax). This fire retardant does not have the disadvantages described above.

Borax protects not only from fire, but also from pests. Rodents cannot tolerate this substance, so they will not settle in the insulation layer.

Water resistance.

It would seem that the paper is not “friendly” with her. First of all, we note that it is impossible to allow any insulation to get wet - this has a very bad effect on its properties. But if an accident does occur, the cellulose fibers will retain some of the moisture that gets on it in the upper layers, from where it will quickly evaporate, so that the material will not be critically damaged.

Cellulose insulation is used to protect walls, attics, attics, roofs and floors on joists.

But it cannot be placed under a screed - under the weight of the piled material, the loose material will become dense, which will reduce its beneficial properties to zero. The consistency of ecowool resembles fluff

. Ecowool is supplied in a compacted state (briquettes), which means that it must first be loosened. If manual installation is intended, this can be done with any convenient tools in a large container. Then the paper pulp is poured into the cavities of frame walls and ceilings. It is very important to observe the application density: for horizontal structures it is 35–40 kg/m³, for vertical structures it is 60–70 kg/m³. Obviously, this work requires a lot of time and effort. It is much faster and easier to apply the material using a special blow molding machine. It loosens the insulation itself and delivers it under pressure over a distance of up to 200 m horizontally and 40 m vertically. At the same time, ecowool penetrates into the smallest cavities and forms a uniform heat and sound insulating layer. The application density can be adjusted.

What type of insulation is best to use for walls inside the house?

Manufacturers of building materials today offer a wide selection of thermal insulators. However, not all materials are suitable for insulation from the inside. Each material has distinctive features that must be taken into account when choosing an insulator.

Expanded polystyrene

One of the best materials for insulating walls inside a house, providing effective thermal insulation, is polystyrene foam. There are foamed and extruded polystyrene foam.

Foamed polystyrene foam.

Extruded polystyrene foam.

For internal insulation, you can use both materials, but it is better to give preference to extruded polystyrene foam. It has greater density and is produced only by large manufacturers, whose quality control ensures the production of environmentally friendly material.

Expanded polystyrene retains heat well and does not allow moisture to pass through, which is why its popularity in internal insulation is constantly growing.

Compared to other insulators, polystyrene foam stands out:

- minimal water absorption;

- ease of installation;

- light weight;

- the ability to easily cut into desired shapes;

- resistance to loads.

Expanded polystyrene is available in the form of slabs of various thicknesses. For insulation inside the building, you can use thin slabs to save space as much as possible. The material does not absorb water and reliably isolates the dew point area. But for this it is necessary to carefully process the joints of the slabs and the junctions with the wall.

The use of slabs with stepped edges eliminates the appearance of cracks and gaps. Installation is carried out using an adhesive composition with additional fasteners using disc-shaped dowels. The glue must be applied to the slabs continuously, using a comb, so that there are no gaps between the wall and the insulation.

Installation of polystyrene foam on internal walls.

The outside of polystyrene foam must be finished with a layer of plaster using reinforcing mesh. The plaster layer is puttied, after which it is ready for installation of finishing materials.

The disadvantage of such a wall is the inability to hang heavy objects and insufficient sound insulation, since polystyrene foam does not have very good sound insulation properties.

Stone wool

Stone wool has high vapor permeability and is not very suitable for insulating walls inside a house. The problem is that it can absorb moisture from the room. When using this insulation, the main rule is violated - the vapor permeability of layers in a multilayer structure should increase from the inside out.

Even the use of a vapor barrier membrane is not always able to solve the problem. In the absence of artificial ventilation, this will certainly lead to moisture condensation on the vapor barrier layer. Which, in turn, will contribute to the formation of mold and fungi on the inner finishing layer.

If you need to insulate internal walls using stone wool, insulation manufacturers advise installing a load-bearing frame. Insulation boards must be laid between the frame supports, and a vapor barrier membrane must be installed on top of the frame and insulation.

Installation of stone wool.

Next, an additional one is packed on top of the first frame to create an air gap between the vapor barrier and the drywall. This will prevent the finishing material from getting wet.

Some builders use rolled wool, which is completely unsuitable for vertical walls. Such installation is cheaper and is carried out quickly, but the design becomes ineffective, since the rolled material is subject to shrinkage.

Stone wool has some undoubted advantages:

- fire safety;

- effective heat and sound insulation;

- environmental friendliness;

- durability.

We have discussed some brands of stone wool, the manufacturers of which allow the use of these insulation materials indoors, below.

Polyurethane foam

Polyurethane foam is well suited for internal thermal insulation. The cellular structure gives the material good thermal conductivity characteristics. The polyurethane foam cells are filled with air, all cells are hermetically sealed. The product reliably resists moisture without allowing it to pass through or absorb it.

A special feature of the innovative material is the method of application to the walls. It is sprayed as a two-component foam that hardens in a few seconds.

Application of polyurethane foam indoors.

The material differs from other insulation materials in its characteristics:

- high adhesion to any surface;

- tight connection with the wall;

- solidity of the coating;

- simplicity and speed of application;

- possibility of applying plaster.

Bringing into working condition - foaming - occurs at the processing site. The starting material has a small volume. Therefore, you will not need to spend money on its delivery and storage.

Flaws

So, it would seem that there are no obvious problems. So why is this insulation not popular among us? There are several reasons.

Let's start with the fact that in Russia there are no standards for the composition of paper insulation, so the manufacturer can regulate the quality of the product itself. It is unnecessary to say what this sometimes leads to.

During installation, there are also moments of risk. Workers interested in saving material may apply it in a looser layer than necessary. This means strict control is needed.

Although ecowool does not burn, it smolders, which means that when insulating attics and attics, you will have to insulate chimney pipes with non-combustible materials.

And finally, the most noticeable drawback is the price. The material itself is cheap, but workers’ services and equipment depreciation will also have to be paid for. The average cost of 1 m³ on a turnkey basis varies from 1,700 to 5,200 rubles.

Read more in the article “Boo...smears”

7

Recommendations for carrying out insulation work

Insulation work is best carried out in the summer, when air humidity is minimal.

The walls for insulation in the room must be perfectly dry. You can dry them after additional plastering and finishing work on leveling the surfaces using construction hair dryers and heat guns.

Stages of surface insulation:

- Cleaning the surface of decorative elements - wallpaper, paint.

- Treating walls with antiseptic solutions, priming the surface with deep penetration into the layers of plaster.

- In some cases, when installing polystyrene foam and electric heating elements, the walls are pre-leveled using waterproof plaster for bathrooms.