Any heating boiler is connected to at least four lines:

1) Power supply . Required for the control and safety automation system located inside the boiler, for example: ignition control. 2) Fuel supply line . For gas boilers, these are connections to the low pressure line or to the pipes of the gas holder (liquefied gas storage) 3) Heating system lines . If the boiler is single-circuit, then there are only two pipes: forward and return lines (output and inlet to the heat exchanger). If the heater is double-circuit, then two more pipes are added: cold water inlet and heated water outlet. 4) Combustion products emission line . The boiler must also be connected to a chimney that provides unhindered smoke removal, and if the boiler is installed in a closed combustion chamber, it must also be connected to the heating unit with combustion air.

Each of these connections must be made in compliance with the rules and regulations governing each type of connection. The electrical part must meet the requirements of the PUE . The water and fuel lines are regulated by the relevant SNiPs, which specify everything from the type of connection used to the choice of sealing materials. These connections must ensure absolute tightness and the ability to maintain it under conditions of high pressure, which is especially important for coolant pipelines.

Fuel gas connections, as you might guess, in addition to tightness, should also be made taking into account the organization of protection of the fuel line from possible mechanical damage. Checking the tightness of the gas system at home is carried out by supervisory services by pumping air into the system under a certain pressure. After the control period (at least one week) has passed, the pressure will be checked again. The pressure difference between the start of the test and its completion should be minimal. Only in this case will a permit to operate the heating system be obtained.

Piping a gas boiler in the heating system

After the wall-mounted gas boiler has been installed and the heating device is placed on the wall, the first thing you need to do is connect it to the heating system. Depending on which model is installed, single-circuit or double-circuit, there are different piping schemes. We will look at the connection process using the example of a wall-mounted double-circuit gas boiler.

Photo 1: Connection diagram for a wall-mounted double-circuit gas boiler

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermal or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is quite enough for 1-2 distribution points (for example, a kitchen faucet and shower).

A modern wall-mounted gas boiler is very compact and already contains within itself the basic elements necessary for the operation of a heating system with forced circulation, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

At the bottom of any mounted double-circuit boiler there are 5 pipes. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas connection is usually located in the center and is colored yellow. All other lines can be located in any order, depending on the model of the gas boiler. Therefore, before starting tying, it is necessary to clarify the purpose of each of them in the operating instructions.

Photo 2: Piping diagram for a wall-mounted double-circuit gas boiler

The piping of a wall-mounted gas boiler is done with polypropylene or metal pipes. The cross-section of heating pipes is usually larger than DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through American nuts. Ball valves are installed on each line for the convenience of dismantling the gas boiler without draining the coolant and to isolate the boiler from the heating system if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or flax.

Coarse filters must be installed in the heating return line and in the DHW supply line. For ease of washing and cleaning, they are also cut off by shut-off valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed at the DHW supply.

Familiarization with technical characteristics

Below we discuss the main parameters of the products of the most popular “Logano” series. The information is provided in the form of a comparative table to make it easier to make a choice. All models are made of steel or cast iron, as these materials have the most suitable properties.

Logano G221 products presented.

Having made preliminary calculations of the heating system for the building, you can familiarize yourself with the technical data of the boilers.

| Products | Power in kilowatts | Efficiency in percent | Pressure in bars | Material |

| S111-2 | 12-45 | 86 | 2,5 | Steel |

| S121-2 | 21-38 | 85 | 2 | Steel |

| G221 | 20-40 | 78 | 3 | Cast iron |

| G221A | 25-30 | 80 | 4 | Cast iron |

The Logano S121-2 boiler is demonstrated.

Recommendation! When operating boilers operating on solid fuel, it is necessary to use firewood whose humidity does not exceed 20 percent. Otherwise, the power of the devices will be noticeably reduced.

Setting up and adjusting Buderus boilers

All heating units require regular balancing and adjustment of parameters. In most cases, a full range of such work is performed during boiler servicing. However, there are situations when unscheduled adjustments are required. For example, after an emergency stop, with a decrease in productivity, with repeated errors generated by automation or after upgrading the system.

Our center’s specialists are ready to carry out both one-time adjustments of your heating unit and take it for long-term maintenance. We are authorized to work with the entire Buderus model range, and our craftsmen have all the necessary licenses and certificates.

Boiler adjustment includes activities such as: warming up; checking the chimney and safety automation; control and debugging of the ventilation system, fuel supply and electrical network. We provide an official guarantee for all types of work.

For additional information on all types of services provided by our center, you can call our 24-hour hotline or come to our office.

__________________________________________________________________________

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. If the level of the sinusoid at the input is insufficient or the shape is not ideal, the devices quickly fail. To prevent frequent breakdowns and extend the service life of the unit, it is necessary to connect voltage stabilizers for gas boilers. To avoid shutdowns of heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

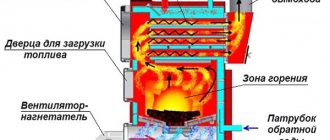

Installation of solid fuel units

These units are installed in a private house in dry rooms, the dimensions of which are directly proportional to the dimensions and power of the unit. The walls of the boiler room must be plastered or covered with sheet iron. Their connection diagram implies the presence of supply and exhaust ventilation, which will provide good draft.

The boiler is installed level on a horizontal foundation covered with a layer of sheet iron. The foundation should be 10 cm larger than the base of the unit along its entire perimeter. The safety zone on the firebox side is at least 40 cm.

There are installation standards for operational safety, which are specified in the installation requirements or are freely available in open sources of information. They must be followed!

Tools and materials

To connect to the heating system you need to purchase:

- two ball valves with a coupling-fitting connection with a diameter of 50 mm;

- two bends of the same diameter;

- pressure gauge;

- safety valve;

- automatic air vent;

- two ball valves with a diameter of 15 mm;

- three steel couplings with a diameter of 50 mm;

- transitions 57 x 32 mm with a wall of 3 mm;

- bends 57 x 3.5 mm;

- chimney with gate valve;

- pipes 57 x 3.5 mm;

- heat-resistant sealant;

- plumbing winding;

- circulation pump.

Harness

The unit's piping is equipped with a safety system, which consists of a heat accumulator, a three-way valve for mixing cold water, and a thermostat. What need to do:

- place the boiler on the foundation;

- connect the heating pipes with the obligatory use of ball valves, sealing the joints with plumbing tape;

- make grounding and connect the power cable;

- install a safety system (pressure gauge, safety valve, automatic air vent);

- assemble the chimney, sealing the joints of the elbows with heat-resistant sealant;

- fill the heat exchanger with water;

- check the location of the grate, ignition valve, cleaning plug, etc.;

- Reduce the pressure in the heat exchanger to operating level;

- install the dampers in the chimney and firebox to the required position;

- carry out laying firewood.

In general, any heating equipment can be connected to a heating system with your own hands if you use the right approach and have basic knowledge and skills.

The main stages of setting up Buderus boilers

- Checking and adjusting automation.

This includes not only diagnostics of the operation of the control system, but also of various sensors, including those for weather-dependent operating modes. - Setting up the burner device.

Our specialists will not only carry out all the necessary work, but will also check the correct selection of the burner for your type of boiler. Using special equipment, specialists will adjust the supply of air and fuel for optimal combustion. - Hydraulic balancing.

Proper operation of pressure sensors, pump, valves and auxiliary fittings will achieve maximum efficient and safe operation.

Commissioning of boilers by qualified specialists will ensure proper and safe operation of the entire heating system. The scope of work includes pressure testing when the heating unit is supplied in separate sections; filling the heating system; tightness control; checking the location of the flue gas guide plates (not for all models); turning on the burner and control system; flue gas temperature control; checking the flue gas exhaust system; control of operation in all modes.

Operating rules

All heaters are equipped with an automated control system. The owner can only initially set the necessary parameters, then the unit will independently process the information and follow the instructions received.

The user will need to follow a few simple rules:

- Carefully read the instructions for using the equipment.

- When installing a heating system yourself, you need to purchase the necessary materials, tools and consumables.

- Always follow safety precautions.

- After installing the boiler, you need to check the operation of the system in order to eliminate possible problems in a timely manner.

- If the installation was carried out by craftsmen from a special service, then the owner must sign the work acceptance certificate.

- Set up the system. Set the basic parameters and enjoy a pleasant microclimate.

It is better to heat Buderus boilers with wood. If there is such a need, install grate bars, after which it is possible to use coal as fuel. Choose the brand specified in the instructions. Suitable options: DPK, TPK, SSPKO. Each type of boiler will have its own fuel consumption rate. Study the Swedish stove with fireplace and hob at the link.

Connecting a Buderus wall-mounted boiler

The peculiarity of wall-mounted boilers is that it is, as they say, a boiler room in miniature. Inside one housing are the boiler itself and the hot water supply circuit, sometimes together with a small storage tank, a circulation pump and, of course, automatic control. Sometimes a small expansion tank is also placed inside. Naturally, all these units are combined and connected to each other at the factory. But nevertheless, the boiler itself still needs to be correctly and reliably connected to the gas, chimney and pipes of the heating and hot water circuits. All connection operations are described in the installation instructions, and theoretically can be performed independently if you have the necessary skill. But do not forget that during the initial connection and commissioning you will still need to have an agreement in hand with a certified installation organization.

When replacing a wall-mounted boiler, which at first glance is quite simple, it is also worth remembering that the boiler is high-risk equipment, and its poor connection can lead not only to failure, but also to much more dire consequences.

It is better to entrust any questions regarding connecting gas boilers to professionals. There is an unimaginable number of subtleties, which, by the way, are well known to our specialists both theoretically and practically, and if you do not want to encounter unexpected heating accidents, we recommend that you contact us to solve connection problems.

The efficiency and safety of a gas boiler largely depends on its correct connection to the heating system. This process, also called strapping, consists of several stages. Due to the fact that gas is a very dangerous fuel, some work must be carried out by certified gas service employees, but much can be done with your own hands.

Connecting a wall-mounted gas boiler is a complex of works that includes: piping in the heating system, connecting to the gas and electrical networks, and installing a chimney. In this article we will try to talk about each of the stages.

A little about the manufacturer

Buderus is a large manufacturer of heating equipment and other climate control systems. While producing heating equipment, Buderus also supplies components, accessories and additional equipment:

- pumps;

- chimney equipment;

- various fittings and fittings;

- expansion tanks and other components, both self-made and from well-known European manufacturers.

Buderus is a German company that actively promotes innovative equipment on the domestic market, which makes it possible to significantly save energy resources and reduce emissions into the atmosphere.

The company sets itself the following main objectives in the production of equipment:

- reducing the cost of operating installed systems;

- increasing equipment efficiency;

- caring for ecology and the environment.

Solving these problems, Buderus offers energy-efficient heating equipment - solid fuel boilers of its own production, as well as a full range of services for installation, connection, startup, adjustment and maintenance of this equipment.

Advice! Buderus is a reputable company that respects its existing and potential clients. People who use the equipment and services of this company always recommend it to friends and leave only positive reviews about the quality of equipment and service.

Buderus boiler connection diagrams

There are standard classic diagrams, illustrated in the installation instructions for Buderus boilers of one series or another. However, in practice, the diagrams almost always undergo changes to optimize the wiring, adjust to the geometry of the furnace room and the relative position of individual components of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, no matter how diverse the areas and layouts of buildings are, their heating systems are just as different. Departures from standard schemes can also be caused by:

- connecting the pool heating heat exchanger,

- placing a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, solid fuel boiler or fireplace insert with a water circuit.

Complications of the circuit cannot be avoided when implementing the connection scheme for Buderus cascade boilers, when the system is designed to use several gas boilers operating together or alternately. A modern approach to building such systems is the use of special units - hydraulic arrows, which ensure equalization of temperatures and pressure of the coolant in several circuits connected to it.