Polystyrene foam is a modern material that is used for thermal insulation of living space both outside and inside. This is due to its environmental friendliness, low hygroscopicity, and budget price. When choosing, the thermal conductivity of the foam is also taken into account. It is this parameter that we will talk about in today’s article.

Large sheets of foam plastic for insulating the facade of a house Source drive2.ru

What is polystyrene foam and its performance characteristics

Polystyrene foam, or, as it is called, expanded polystyrene, is a slab that can vary in thickness. The main material of this raw material is foamed polymer. There is air inside the material in the granules and between them, which ensures the thermal conductivity of the insulation. Polystyrene foam consists of 95-98% of a specific gas, which, in fact, retains heat.

Foamed polystyrene with low thermal conductivity Source avexpro.ru

Due to the fact that there is enough air in the middle layers of the raw material, polystyrene foam has a minimum density and has a low specific gravity. Also, the internal air layer provides good sound insulation.

The finished density and other characteristics of the insulating material depend on the polymer itself and the processes that were used during the manufacture of the material. As a result of applying different conditions at the production stage, foam plastic of unequal density and varying degrees of resistance to mechanical stress may be obtained.

Table of thermal conductivity values for different materials Source otoplenie-gid.ru

Classification of expanded polystyrene

Regular foam

Thermal insulation material obtained by foaming polystyrene. As mentioned above, its volume is 98% air , which is sealed into granules.

This speaks not only of its excellent thermal insulation qualities, but also of its sound insulation properties. The main advantage of the material is the lack of ability to absorb moisture. In addition, it does not rot or biodegrade. Durable material, light weight and easy to use. It can be glued to any building material.

Expanded polystyrene is easy to burn, but it contains a substance called a fire retardant. This is what gives the foam the ability to self-extinguish. In addition, expanded polystyrene cannot be used to insulate facades. This is due to its low vapor permeability . And in order to carry out work with foam plastic under the roof, you should carefully consider the ventilation system.

Use depending on the brand of material

- PSB-S 15. The marking of polystyrene foam indicates that it can be used to insulate structures that are not subject to mechanical stress. For example, insulation of the roof, the space between the slings and the ceiling.

- PSB-S 25 and 25F. Common markings for polystyrene foam. It says that any surface can be insulated. Walls, facades, ceilings or flooring, roofing.

- PSB-S 35 and 50. This material can be used to insulate objects that are under constant high load.

Extruded polystyrene foam

Thermal insulation material, which has high effect and quality. It is most often used to insulate building envelopes. And the thermal conductivity coefficient ranges from 0.027 to 0.033 W/m K.

The structure of the material is cellular. And the complete closure of each cell provides absolute protection against water penetration. Therefore, this material is recommended for use where humidity is high or where the material can come into contact with water. This is insulation of the basement or foundation of a cottage. Even in conditions of insufficient waterproofing, extruded polystyrene foam will retain its thermal insulation qualities.

In addition, this material is highly resistant to various deformations. This feature allows it to be used as insulation for surfaces bearing heavy loads. For example, facades can be insulated with extruded polystyrene foam. Especially if the cladding material is very heavy.

As for the temperature. Expanded polystyrene is able to withstand sudden changes, from -120 to +175 degrees. At the same time, its structure remains intact and unharmed.

The disadvantages of this material are flammability, but, like polystyrene foam, its constituent elements can cause it to extinguish. Contact of polystyrene foam with complex carbohydrates can lead to destruction.

Main characteristics of thermal conductivity of foam plastic

Before you find out what the thermal conductivity of polystyrene foam will be, you need to understand what this parameter is.

Thermal conductivity is a quantitative characteristic of foam plastic (or any other material), which evaluates the ability of a particular body to conduct heat. The unit of change for this parameter is W/mS. In this case, each designation is characterized as follows:

- Watt is the amount of thermal energy;

- Meter—distance of heat conduction through oneself;

- C is a certain temperature for a certain time.

We suggest looking at an example of what thermal conductivity is. Let's assume we have a sheet of polystyrene foam PSB-S 50. Its density is 50 kg/m3. The heat transfer parameter of this raw material is set by the factory. Based on this, it can be determined that the thermal conductivity of 50 mm foam is 0.041 W/mS. It should be noted that such an indicator will only be subject to exposure to temperatures not exceeding 20-30 degrees.

On a note! It is possible to clearly notice the heat penetration parameter of polystyrene foam only when comparing its values with the values of other thermal insulation materials.

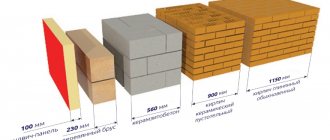

If individual construction is planned

When building a house, it is important to take into account the technical characteristics of all components (wall material, masonry mortar, future insulation, waterproofing and steam-removing films, finishing). To understand which walls will best retain heat, you need to analyze the thermal conductivity coefficient of not only the wall material, but also the mortar, as can be seen from the table below: To understand which walls will best retain heat, you need to analyze the thermal conductivity coefficient of not only the wall material, but also the mortar, as can be seen from the table below:

To understand which walls will best retain heat, you need to analyze the thermal conductivity coefficient of not only the wall material, but also the mortar, as can be seen from the table below:

| Order number | Wall material, mortar | Thermal conductivity coefficient according to SNiP |

| 1. | Brick | 0,35 – 0,87 |

| 2. | Adobe blocks | 0,1 – 0,44 |

| 3. | Concrete | 1,51 – 1,86 |

| 4. | Foam concrete and cement-based aerated concrete | 0,11 – 0,43 |

| 5. | Foam concrete and lime-based aerated concrete | 0,13 – 0,55 |

| 6. | Cellular concrete | 0,08 – 0,26 |

| 7. | Ceramic blocks | 0,14 – 0,18 |

| 8. | Cement-sand mortar | 0,58 – 0,93 |

| 9. | Mortar with added lime | 0,47 – 0,81 |

Important. From the data given in the table it can be seen that each building material has a fairly large spread in the thermal conductivity coefficient.

This is due to several reasons:

- Density. All insulation materials are produced or installed (penoizol, ecowool) of varying densities. The lower the density (more air is present in the insulating structure), the lower the heat conductivity. And, conversely, for very dense insulation materials this coefficient is higher.

- The substance from which it is produced (base). For example, brick can be silicate, ceramic, or clay. The thermal conductivity coefficient also depends on this.

- Number of voids. This applies to bricks (hollow and solid) and thermal insulation. Air is the worst conductor of heat. Its thermal conductivity coefficient is 0.026. The more voids, the lower this figure.

Mortar conducts heat well, so it is recommended to insulate any walls.

Comparison of thermal conductivity of polystyrene foam with other materials

Obviously, when changing the thickness of polystyrene foam brand PSB, the thermal conductivity index varies in the range - 0.037-0.043 W/mS. For example, if you compare it with raw materials such as mineral wool, then the differences in indicators will not be significant.

Also, to determine the optimal parameter, not only sheet heat insulators with various fillers are taken into account, but also the building materials used to construct the walls of the structure.

It’s not for nothing that red brick is so often used in laying the walls of a house. This is due to the fact that it has a fairly high level of heat transfer of 0.7 W/mS. This is almost 19 times more than expanded polystyrene foam. That is, in order to do without a heat insulator, it is necessary to build a wall with a thickness of at least 80-85 cm. In the case of sand-lime brick, it will be necessary to build meter-long load-bearing structures.

Wood is also often used to build houses. It competes with foam a little better than red brick. The thermal conductivity of wood is 0.12 W/mS. It turns out that this is three times more than polystyrene foam. It turns out that if you build a wall from solid wood, then you will need a log house up to 23 cm thick so that the thermal conductivity indicator is equivalent to PSB with a thickness of 5 cm.

Comparison of styrene with penoplex

Polystyrene foam and penoplex are relatively identical materials, made using the same granules. The only difference is the gluing technology, which gives unexpected results when comparing indicators.

The fact is that during the production of penoplex, styrene beads are processed under pressure at high temperatures. The result is a plastic mass that, when frozen, is homogeneous and durable. The air bubbles that remain inside are evenly distributed throughout the entire part of the stove.

When forming foam, the material pre-loaded into the mold is simply doused with steam. As a result, it gets a “popcorn” structure, and, as a result, the bonds between loose granules are much weaker.

Based on this, it can be noted that the thermal conductivity of extruded polystyrene foam is better and corresponds to 0.028-0.034 W/mS. Thus, only 30 mm of this material will be needed to replace 40 mm of conventional foam.

The structure of penoplex differs from polystyrene foam Source pgsstore.ru

Important! In cases where there is no need for high strength of the insulated wall, then you can safely give preference to budget polystyrene foam. True, you should first determine its optimal thickness, depending on climatic factors and operating conditions.

Lifetime

Most manufacturers indicate a service life of 20-30 years. This is the warranty time during which the useful properties of the material are within acceptable limits. Recent studies by European scientists have shown surprising and encouraging results. When demolishing houses built 40-50 years ago using polyurethane foam, scientists found that its properties remained virtually unchanged. The structure and texture remained the same as originally. Further laboratory studies only confirmed the durability of this material.

Environmental friendliness

An important parameter that modern builders are paying more and more attention to. During the production process, polyurethane foam goes from liquid to solid in 30 seconds

After this, harmful fumes from its surface stop. If it is heated to 450 Cº, carbon dioxide and carbon monoxide will begin to be released. However, the same thing can be observed when wood is heated. Polyurethane foam does not emit compounds harmful to the human body

Features of choosing foam sheets for insulation

First of all, when you buy polystyrene foam, focus on the quality certificate. Whether the thermal conductivity indicator will correspond to the real value that we discussed above completely depends on it.

It happens when a manufacturer manufactures a product using GOST and its own specifications. In such situations, technical characteristics, including the heat transfer rate, may vary.

Choosing the optimal foam thickness Source lazurit64.ru

Therefore, in order for the purchased material to be used with the expected effect, you need to ask the seller in the store to provide a document confirming the technical characteristics of the material of the particular brand you have chosen.

Note! The correspondence of the document to the type of polystyrene foam can be found by special symbols, which are usually printed on the side of each sheet of material.

Why is thermal insulation needed?

The relevance of thermal insulation is as follows:

Heat loss through the walls of a typical multi-storey residential building is 30-40% . To reduce heat loss, special thermal insulation materials are needed. The use of electric heaters in winter contributes to additional energy costs. It is more profitable to compensate for these costs by using high-quality thermal insulation material, which ensures heat retention in winter and coolness in the summer heat. At the same time, the cost of cooling the room with air conditioning will also be minimized.

In the case of industrial buildings using a metal frame, insulation helps protect the metal surface from corrosion, which is the most detrimental defect for this type of structure. And the service life of a brick building is determined by the number of freeze/thaw cycles. The impact of these cycles is perceived by the insulation, because the dew point is located in the thermal insulation material, and not in the wall material.

Such insulation allows you to increase the service life of the building many times.

Protection against increasing noise levels is achieved by using such noise-absorbing materials (thick mattresses, sound-reflecting wall panels).

The use of a thermal insulation system makes it possible to reduce the thickness of external walls, while increasing the internal area of the building.

Why is it important to remember about vapor permeability?

When you decide to use polystyrene foam as insulation for the walls of your own home, it is advisable to remember the vapor permeability of this material. The lower this indicator, the better for the operation of the heat insulator.

The fact is that many insulation materials do not resist the penetration of steam. Over time, it turns into moisture and is deposited in layers of material. This causes the latter to deteriorate and lose its quality characteristics. Thermal conductivity also suffers: the foam plastic begins to transmit thermal energy through itself and release it to the street.

Fire resistance

Being a combustible material, polystyrene foam has good fire resistance, since the spontaneous combustion temperature is +4910 C. This indicator is 1.8 times higher than that of wood, for which +2600 C is enough. In the absence of fire within 4 seconds, the combustion dies out. During combustion, the material releases about 1000 MJ/m3 of energy, while wood - 7000-8000 MJ/m3 - which means that when burning polystyrene foam, the temperature increase will be much lower.

Manufacturers offer self-extinguishing polystyrene foam made with the addition of fire retardants. However, experiments show that the self-extinguishing effect is lost over time, and in the design the material, which was initially classified as belonging to the G2 flammability group, after some time already corresponds only to the G4 class (research carried out at the Research Institute of Industrial Safety and Emergency Situations of the Ministry of Emergency Situations of Belarus).

At the same time, it should be recognized that the products released during the combustion of different brands of polystyrene foam are still poorly studied.

Features of application and numbers in markings

Foam insulation can be used for indoor and outdoor conditions. This can be determined by the thermal conductivity coefficient. For example, if the product name contains the number “15”, then such sheets are suitable for gluing to vertical structures indoors. The thickness of this raw material is insignificant, and therefore will not use up useful space.

Low thermal conductivity foam for outdoor conditions Source 27del.ru

There is also a coefficient with the number “25”; this is a higher quality insulation, used only for thermal insulation of walls on the outside of the house. It is also often used in attics or basements where an enhanced level of thermal insulation is required. Expanded polystyrene with this coefficient can be used to insulate interfloor ceilings and roof slopes in multi-storey apartment buildings and the private sector.

Foam plastics, which are labeled with the number “35,” have the lowest thermal conductivity value. They try to insulate buried foundations, runways, highways and other capital industrial structures with such materials. It is irrational to use such insulation boards for a home.

Positive and negative properties of polyurethane foam

For a more convenient understanding of the essence, properties and scope of the material, you need to have an idea not only of the physical and chemical properties, but also know its positive and negative sides.

Positive

- Polyurethane foam has good adhesion. It adheres to wood, metal, and concrete surfaces without any problems. It does not require additional fasteners. Due to its elastic structure and method of application, polyurethane foam fits well on uneven substrates. Before applying it, the surface does not require additional treatment with primer or paint.

- PPU has a low cost. It is produced directly on the construction site by mixing two components. There are no costs for additional transportation and manufacturing.

- Polyurethane foam is a lightweight material that does not load building structures.

- In addition to heat and sound insulation, polyurethane foam strengthens load-bearing walls, making the structure stronger and more durable.

- It is practically unaffected by extremely low and high temperatures. PU foam is not destroyed by cyclic freezing and thawing.

- The polyurethane foam coating has a monolithic structure. There are no gaps for the appearance of cold bridges. The wind doesn't blow through it.

Negative

- Polyurethane foam quickly degrades under the influence of ultraviolet rays. Therefore, it does not remain open, but requires protection. It can be covered with a layer of paint or plastered. The use of various cladding panels is also suitable.

- Polyurethane foam is a non-flammable material. Still, it is not recommended to use it in places of possible contact with open fire. If this is technically impossible, then the polyurethane foam is covered with fire-resistant plasterboard.