Owners of corner apartments especially often face problems such as excessive dampness or cold. The heating system does not always work efficiently. Therefore, it is important to know how to insulate a wall in a corner apartment from the inside and minimize energy loss. With the right approach, it will be possible to significantly improve the indoor microclimate and make it more comfortable for living. In this material we will tell you how to properly install insulation and what is required for this.

Why insulate a corner apartment?

The layout of corner apartments in terms of energy consumption for heating is not the most optimal due to the presence of two external walls. And as a rule, in such conditions, even the presence of additional heating devices does not save residents from the cold. Before the heating season, when the temperature outside drops sharply, heat begins to quickly leave the room, which is why the apartment becomes cold, dampness and fungus appear. If the walls are not insulated, it will be uncomfortable to be in such a room.

Freezing corner in the apartment

When the central heating comes on, the situation improves slightly as it becomes warmer, but corner walls can freeze. This leads to damage to the plaster layer and peeling of the wallpaper. As a result, mold and various types of fungus begin to develop in such places. Such a microclimate causes discomfort and does not have the best effect on the health of residents. Due to the dampness and low temperatures, colds are becoming a common occurrence for many residents of corner apartments.

Heating

The first thing you need to do is make sure that your existing heating system is working efficiently. This is especially true for old cast iron batteries - if they do not warm up along the entire length, then they are probably simply clogged and need to be washed.

Another feature of the old heating systems installed in all Khrushchev buildings is a three-way valve at the junction between the riser and the pipe leading to the radiator. It is made in order to, if necessary, redirect the flow of hot water between the radiator and the jumper - in cold weather, as much as possible, direct all the coolant into the battery; in relatively warm times, on the contrary, let it flow further along the riser. In practice, these valves are a long-standing headache for plumbers. You need to make sure that they work properly in your apartment.

It is worth paying attention to the location of the radiators themselves and, if possible, move them closer to the corner of the external walls - the most problematic area.

And finally, make sure that the power of the heating devices is sufficient for the space of this area. According to standards, the number of sections in a radiator is set at the rate of one section per two square meters of area of the heated apartment. But for a corner apartment you can multiply this number by a factor of 1.3. For the northern regions, increasing coefficients are also provided - up to 2.

A little theory: dew point

In construction, the concept of “dew point” is used.

The dew point is the temperature at which condensation forms (moisture from the air turns into water droplets). In relation to the enclosing structures of a house, such a point can be located both on the surfaces of the wall from the outside or inside, and in its thickness.

During periods of high air humidity and low temperatures, the microclimate of the apartment contributes to the formation of condensation. Due to an incorrectly located dew point, mold and mildew begin to develop on the walls. It is better to insulate them from the outside. This approach will make the walls inside the room warmer and move the dew point to its outer edge. This will help get rid of mold and mildew. If it is not possible to thermally insulate the apartment from the outside, then it is possible to insulate the end wall from the inside. In this case, you need to select the insulation so that the dew point is in the thickness of the supporting structure.

Visual optimal dew point position

Insulating the walls will help make the room warmer and get rid of dampness. The microclimate will become much more comfortable, and residents will not have to worry about their health. However, it is important to properly insulate the room so that the result is as effective as possible.

Reducing humidity

If walls often get wet in interior rooms with high moisture (bathhouse, bathroom), then the problem is most likely in the ventilation system. Therefore, first of all, you should check the ventilation openings for the presence of unnecessary objects that may interfere with air circulation.

It’s easy to check how clogged the ventilation channels are: hold a burning candle to the vent and watch how the flame reacts: if it reaches towards the grate, then the channels are not clogged and there is a draft. When there is no flame response to ventilation, additional devices need to be installed in order to establish air circulation.

When the holes are not clogged, but the draft is still weak, additional slots can be made at the bottom of the door for air intake. If this does not help, a forced exhaust is installed in the ventilation duct. Such fans are turned on only when there are no people in the room, as they can seriously harm your health.

Experts advise installing fans with a built-in humidity controller in the bathroom. When humidity rises, the fan operates automatically, eliminating air oversaturated with dampness.

Which material to choose - mineral wool or polystyrene foam?

When choosing insulation, you need to take into account the characteristics of the room. Any material must have the following properties:

- fire resistance;

- environmental friendliness (in the case of internal insulation, this factor plays a key role);

- ability to absorb moisture;

- high thermal insulation and breathability properties.

Mineral wool

Mineral wool is made from basalt and is the most popular material for wall insulation. It retains heat well inside the room, but easily allows air to pass through, which ensures good ventilation. The air in the room is always fresh and does not stagnate, which also allows you to get rid of high humidity. The material is highly elastic, which is convenient for installation. However, over time, basalt wool tends to deform, absorbing excess moisture. Therefore, when installing mineral wool, a sheathing is installed.

For basalt wool you will definitely need a frame

Other disadvantages include harm to the respiratory system. When used indoors, the degree of toxicity is not very high, but still the material is more suitable for outdoor use. Another disadvantage is considered to be increased weight.

Styrofoam

The main advantages of polystyrene foam are its cost and high thermal insulation ability. The material perfectly allows air to pass through, it is lightweight and convenient for installation work. It is non-toxic, which makes it excellent for interior decoration. The low weight will allow all work to be carried out independently without the involvement of builders. Particularly effective for internal insulation. However, there are also disadvantages. Polystyrene foam is highly flammable and is also not suitable for insulating wooden structures, since condensation will form on such surfaces.

Installation of foam plastic boards

Preventing the appearance of dampness

Following certain rules will help reduce dampness to a minimum and prevent its occurrence in the future.

- Laundry should be dried outside living rooms or with the hood turned on for air removal.

- When cooking, pots and pans should be covered with lids to prevent steam from escaping.

- In the bathroom, where the highest concentration of humidity is, as well as in the kitchen, hoods and ventilation openings should be regularly cleaned to remove excess debris, and these rooms should also be ventilated daily.

- In a private house, you can insulate the attic and also cover the walls with a waterproofing material, preferably with pores.

- All flammable substances that form a lot of moisture, in particular paraffin, should be used extremely rarely indoors.

- All rooms in the house should be ventilated daily.

- Correct errors in the heating system in a timely manner.

- Use a dehumidifier to reduce humidity. This household appliance can easily cope with the problem of dampness, and its compactness allows you to move the dehumidifier from room to room.

We recommend: Has minimalism taken the highest level in interior design?

Features of insulation of corner apartments of a panel house

The process of installing panel wall railings is different for finishing walls indoors or outdoors. Let's take a closer look at the main differences.

The nuances of installing thermal insulation from inside the room

In a panel house, when installing internal insulation, the material must be laid on bare walls, which is why it is better to carry out the procedure during a major overhaul. Installation work begins with the installation of a waterproofing layer, which is most often a polyethylene film with special breathable membranes. It is best to use a single piece of film over the entire surface of the wall. A metal frame is installed on the waterproofing layer. After installing the sheathing, sheets of insulating material are installed.

An example of internal insulation of an apartment corner with mineral wool over a steel frame

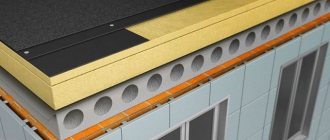

Installation from the outside of the panel

When carrying out work on the outside of the room, initially all foreign objects are removed from the surface of the walls, and their surface is thoroughly cleaned. The lathing is installed directly on the surface of the walls. Next, two layers of waterproofing are installed with a layer of vapor barrier between them. Sheets of the main insulation are installed on top. The outside is decorated with decorative cladding.

Defects in the floor connection

It has been noticed that residents of the last floors most often suffer from freezing corners. This happens because during the roofing process the workers did not properly insulate the connection between the roof and the walls. As a result, cold air leaks into the rooms through cracks in the joints of the walls.

Nuances of internal installation

Foam plastic is most often used for internal wall insulation in brick houses. Before installation work begins, any finishing is removed. The surface is carefully plastered and then treated with a primer. It is very important to apply the primer in an even layer so that cracks do not begin to form after drying.

The insulation sheets are installed on the still damp material. The insulation material is attached using construction adhesive. It is very important to pay attention to the components of the composition. The adhesive material should not emit toxic fumes.

Video: example of thermal insulation of an apartment with Penoplex slabs

Insulation from the outside

For exterior work, mineral wool is most often used. The start of work follows a similar algorithm. On the outside, the panels are protected with an additional layer of primer to resist weathering, and a decorative finish is applied over the protective layer.

The corner apartment of a brick house is insulated from the outside

A brief overview of foam brands for insulating walls from the inside

In building materials stores you can see a fairly large assortment of foam brands. Let's look at the most common of them. Regardless of the brand, there can be two types of marks on the box: “PS” and “PSB”. The first indicates that the material was made using the pressing method, the second - the non-press method.

A popular brand of polystyrene foam is C-15. This type is produced using a non-press method. Due to its high density, it is excellent for both indoor and outdoor use. However, foam plastic of the S-25 PSB brand is best suited for insulating corner apartments. This is a higher density material that can also be used for floor insulation. The S-35 PSB grade is characterized by excellent resistance to extreme weather conditions. It is characterized by high fire resistance, as well as the ability to easily withstand mechanical damage. The densest variety is the S-50 PSB. This is a fairly expensive material, which is usually used in cases of frequent hail and constant strong wind.

For internal insulation, only the first two options are used.

A brief overview of mineral wool brands for insulating walls from the inside

There are four most popular varieties of mineral wool: P-75, P-125, PPZh-200 and PZh-175. For interior work, only the first two varieties are used. Cotton wool P-75 is the lightest and has a relatively low density. P-125 is more rigid and is used for interior decoration in cold climates. The last two types, due to their increased density, are used only for outdoor work.

The best manufacturers of insulation materials are: Isover, Isorok, Ursa, and Rockwool.

Advantages of expanded polystyrene

Scheme of insulating a brick wall from the inside with polystyrene foam.

In other words, this is the well-known foam plastic.

Easy to install, lightweight and budget option, available to anyone who wants to insulate their home from the inside. For greater fire resistance and less fragility, we recommend choosing extruded polystyrene foam. Choose the thickness and density of the sheets depending on the purposes of insulation.

Necessary materials: expanded polystyrene, polystyrene foam, glue for expanded polystyrene, mounting disc dowels, metal profile for drywall, drywall, self-tapping screws for drywall.

Necessary equipment: a knife, metal scissors, a wide spatula-comb for applying glue and a small handy spatula, a bucket for diluting glue, metal scissors, a hammer drill with a drill suitable for “fungi” and self-tapping screws, a nozzle for mixing glue or just a rod.

Alternative modern insulation materials

There are many non-standard alternative ways to insulate corner apartments. They are distinguished by the use of modern innovative materials.

Polyurethane foam

PPU insulation meets all requirements for vapor barrier, water absorption and absence of seams. Therefore, even if there is a dew point inside the layer, it will remain “conditional”, since there is no condensation in vapor-tight materials. This results in a completely sealed thermal insulation layer from the room side.

Wall insulated with polyurethane foam

Keramoizol

Keramoizol

A modern building material characterized by increased thermal insulation. Sold in liquid form. For maximum effective insulation, 6 layers are laid on the wall in a direction perpendicular to each other.

Astratek

Astratek

Astratek is a liquid insulation material. It can be applied to the surface with a spray or brush, and after drying it forms a durable and elastic substance with a porous structure. Such insulation perfectly allows air to pass through, but effectively retains heat inside the building.

Liquid thermal insulation using Mascoat paint as an example

Mascoat

The paint from a well-known American manufacturer has increased thermal insulation properties and also repels moisture very effectively. Its efficiency is 5 times higher than mineral wool. 1 mm. The effectiveness of paint is not inferior to a layer of mineral wool half a centimeter thick. It is applied to the wall surface in the same way as ordinary paint. Can be used simultaneously for decorative finishing.

Polyph

This material is made from a polyethylene base. Its thermal insulation properties are slightly lower than those of previous options, but the material also has its advantages. A durable polyethylene film made by foaming is covered on the inside with a thin layer of foil. Sheets of paper are glued on top on both sides. Externally, the material resembles wallpaper and is often used as a preparatory finish before gluing it. The main disadvantage is that it can only be used on dry walls. It may not be suitable for a corner apartment, since such rooms are characterized by high humidity.

Polyform installation

Video - How to eliminate freezing of corner walls?

If a corner of your house freezes , the following guide will help:

- It is the façade that needs to be insulated, not the inside of the wall. If a house has many defects in the form of cracks and gaps, then heat-insulating plaster cannot be used.

- The brickwork is embroidered and filled with mortar. As a rule, such plaster contains polystyrene foam granules. It expands and fills empty pores.

- Next, you can begin covering the facade with cladding material. It is also often thermally insulating.

It all depends on what exterior finishing (siding) is chosen. There are quite a lot of materials that have an aesthetic appearance.

Penofol

Penofol is a combination of polyethylene foam and aluminum foil. This is a whole series of materials (including single-sided, double-sided, laminated, with an adhesive layer). Moreover, it can be used both in combination with other heat-insulating materials, and independently.

By the way, penofol is popular for insulating a bathhouse from the inside, and there is much more steam there than in an ordinary living room.

Penofol - alternative insulation

Do-it-yourself choice of material for insulating walls from the inside, insulation technologies

The first requirements when choosing materials for internal wall insulation are their high density, low vapor permeability, and a minimum number of joints during installation. The most common insulation materials for internal use are materials based on polystyrene foam, polyethylene, warm plaster, ceramic compounds, mineral wool and many others, and we will consider the most acceptable types of materials and technologies for their installation when doing insulation with your own hands.

Internal wall insulation with mineral wool is one of the most common, but not ideal, types of insulation, since wool over time can begin to absorb moisture and contribute to the appearance of dampness, however, if the work is carried out carefully, the joints are processed and the wall and insulation are impregnated with antifungal compounds, its service life is quite long and can reach 10 years.

When insulating with mineral wool, the wall is equipped with a metal frame, the cells of which are filled with mineral wool slabs, carefully compacted and covered with sheets of plasterboard on top. The disadvantage of this method of insulation is the reduction in the area of the room.

Striving for comfort, many apartment residents refuse central heating and install electric heated floors; Reviews from those who have already used heated floors eloquently indicate increased comfort and warmth along with savings.

Instructions for installing heated floors are in this article. Features of installation and proper installation.

Insulating walls from the inside with expanded polystyrene is also popular, since sheets of expanded polystyrene have a low specific gravity and high resistance to moisture, and their small thickness does not require prior placement of the frame on the wall. Fastening to the prepared wall can be done using construction glue, dowels, liquid nails, making sure to treat the joints with polyurethane foam.

Insulating internal walls with penoplex, or expanded polystyrene foam, is considered one of the most reliable ways to protect a room from dampness. This material is absolutely environmentally friendly, has high strength and wear resistance, is fireproof, easy to install and relatively inexpensive.

Penoplex is glued or nailed to the prepared wall and requires the creation of a reinforcing layer to give the structure greater strength, as well as additional leveling of the surface - only after this can you begin finishing the walls.

Internal wall insulation with foam plastic is also carried out using a frameless method by gluing foam panels to the wall using ceramic tile adhesive.

The surface of the foam is covered with a layer of glue and a reinforced mesh with an overlap of 10-15 cm is placed on top of it with slight indentation, which is eventually covered with a layer of plaster for painting or wallpapering, or ceramic or tiles are mounted directly on the insulation.

Before insulating the walls of an apartment from the inside, it is necessary to select the insulation material to match the materials from which the walls or ceilings are made:

- insulation of a brick wall from the inside can be done using polystyrene foam, expanded polystyrene and mineral wool;

- Internal insulation of walls made of foam blocks is best done with polystyrene foam, penoplex or expanded polystyrene;

- to insulate the internal walls of a wooden house, it is better to use penoplex or expanded polystyrene;

- You can insulate concrete walls from the inside using any of the described insulation materials.

Many owners of their own country home are interested in insulating the floor in a private house, especially if there is no basement or cellar. Find out the features and methods of floor insulation in a private cottage or country house.

If the house is cold or the climate is harsh, you should also think about how to insulate the walls of the apartment from the inside. Find out here about the methods and features of insulating walls from inside a living space.

When choosing materials for internal insulation, it is important that they meet the following requirements:

- high temperature resistance, fire safety;

- low thermal conductivity - the selected material should not release heat from the room in winter and should not contribute to heating the apartment in summer;

- environmental friendliness or health safety;

- durability, strength and ability to retain shape and volume;

- high resistance to moisture.

Also, when planning your own wall insulation, it is advisable to consult with specialists who could recommend the optimal thickness of the material.

Non-standard method of insulation - electric

A new, but quite effective way to insulate walls in a corner apartment is to use the principle of heated floors. Panels with electric heaters are mounted indoors on the surface of the walls and connected to the electrical network. The control unit is installed in a separate accessible place. For proper installation, it is very important to wait for frost, and then turn on the equipment until the walls are completely dry. Only after this is an additional thermal insulation layer laid and decorative finishing is performed.

This method of insulation is very effective, but has one big drawback. In cold weather, you will need to regularly maintain a stable temperature to prevent the formation of dampness and condensation. This will lead to additional energy costs. The purchase of an insulation system itself will require considerable expenses, and after that you will have to pay for regular operation. However, this approach allows you to create an ideal microclimate inside the corner room in cold weather.

How and with what to insulate an old wooden house from the inside

Old wooden structures can be insulated in several ways. The first involves reducing the thermal conductivity of walls and seams by placing flax, tow or other synthetic sealants in the appropriate areas.

The second method (more expensive) involves working with mineral wool, which requires additional installation of hydro- and vapor barrier layers.

Its implementation is carried out with the initial filling of joints and cracks, followed by treatment with antiseptics and installation of sheathing. Next, finishing is carried out using plasterboard or other decorative sheet materials.

In the first case, the budget option would be to use a cement (clay) mixture with sawdust, and in the second, at a minimum, laying sheets of plywood with a thickness of at least 9 mm, followed by foaming the joints with polyurethane foam.

Let's watch a video about insulating a wooden house:

What are the conclusions?

The procedure for insulating the walls of a corner apartment is not considered complicated, but has many nuances. It is very important to choose high-quality insulation material that will provide high thermal insulation and a comfortable indoor microclimate. Internal insulation is a simple method that you can do yourself, which is why it is more popular. However, if there is increased humidity in the walls and the formation of mold on their surfaces in the apartment, it is better to call specialists for external insulation. You can also consider using effective and cheap alternative methods.

More

The principle of eliminating the problem

Eliminating freezing of a house or a separate part of it is not so simple.

As a rule, the most common places for such problems to occur are the corners of the building.

They are the ones that are most susceptible to various deformations and may contain voids that arise due to the junction of two walls. The only way to get rid of wall freezing is to shift the dew point back towards the street. A similar effect can be achieved in one single way - complete thermal insulation of surfaces.

Such a procedure requires a huge investment of time and effort, and also costs a lot of money. However, this is the only way to be sure of achieving a positive effect. In addition, complete insulation of the house will not only make it warmer, but will also make it possible to save money on heating.

You can insulate a freezing wall using ecowool or polyurethane foam.

For those who do not want or cannot shell out a tidy sum for thermal insulation of the entire building, there is a more economical solution. It consists of spot insulation of corners or walls. A similar option is not as effective as creating a dense monolithic thermal insulation layer, but can also be beneficial. In some cases, insulating a small part of the wall is quite enough to remove condensation from its inner surface.

You can achieve the desired effect in several ways, which look like this:

- use of polyurethane foam;

- use of special heat-protective plaster;

- direct insulation with thermal insulation materials.

Each of these methods is capable of eliminating wall freezing, but the effect of spot thermal insulation is quite small and cannot guarantee complete insulation of the room.

Vapor permeability

In a residential building, the vapor permeability of walls should increase towards the street. The main reason lies in the different humidity levels inside and outside the house in winter. The reasons for high humidity in the house are:

There are people living in the house who breathe, cook, wash floors and dishes, and do laundry.

All these habitual operations make the air more humid. And when the windows are closed, the exchange of air is difficult and is carried out only by the forces of the ventilation system. From the course of physics, we know that heated air is capable of holding more moisture compared to cool air. For this reason, condensation occurs from “excess” moisture as the air cools.

Foggy windows and dampness in the corners of a building are a practical example of this. But water vapor leaves the house not only through ventilation, but also through the pores of the wall. If the wall outside is more permeable to steam, then it can pass through it without difficulty. Otherwise, having encountered an obstacle, water vapor begins to condense directly in the wall, which leads to its dampness.