No construction is complete without the use of insulating materials. Houses are often insulated using foamed polymers, the production method of which raises controversy about fire safety. Everyone knows about expanded polystyrene, synonymous with the brand Penoplex; Whether this material burns or not worries many owners who choose insulation for their home. Let's take a closer look at the properties of expanded polystyrene (EPS), examine its flammability and find out how dangerous it is in a fire.

Opinions about the dangers of polystyrene foam insulation vary widely Source lalafo.com

What is extruded polystyrene foam

The complex technical name of the insulation alarms many who prefer to use only environmentally friendly, low-flammable materials in insulating their homes. Modern technologies make it possible not to use freon as a foaming agent. Therefore, only CO2 or freons are now used for polystyrene foam granules. So we can well call it environmentally friendly.

The material has a number of characteristics that make it very attractive for private and low-rise construction, as well as for use on an industrial scale.

- The insulation does not have a biological component, so it does not rot or decompose. Such properties make it durable (service life ≥ 50 years).

- Eco-friendly insulation. Moreover, we can even talk about the environmental friendliness of its production.

- It has proven itself well in underfloor heating systems. The entire “warm floor” structure is mounted on top of penoplex 35. A low thermal conductivity coefficient will effectively save heat, due to which the cost of heating a house or apartment is significantly reduced.

- Wide range of applications. The insulation can be used both in a country house and at an airfield.

Technical characteristics of penoplex are presented in the table below.

“Velit” insulation made of porous concrete D-140

A very good and promising heat insulator, which is used to insulate house facades, flat roofs, floors, and ceilings. What does he imagine himself to be? Velit is porous concrete D-140 (for understanding, I can say that one cubic meter of this material weighs only 140 kg) is non-flammable.

It does not have a flammability class, it is simply not standardized by class, it is NG, which means non-flammable. Since this insulation is porous concrete, in principle it cannot burn, and there is nothing you can add here.

We study the flammability of penoplex

Penolex is a type of thermal insulation material, which is extruded polystyrene foam. Most people, when choosing suitable insulation for their home, are guided by the various characteristics of the material. Many are interested in low price, some prefer ease of installation, and only a small part think about environmental safety and fire resistance. What characteristics does penoplex have? Is it combustible or absolutely non-flammable? It’s strange, but there are a lot of opinions about this indicator, so it’s worth taking a closer look at the fire safety of penoplex.

Non-flammable penoplex or fire hazardous insulation?

Low fire resistance is considered one of the main disadvantages of this heat insulator. At facilities with high fire safety requirements, this insulation is not used. Expanded polystyrene without inhibitors is rarely used in the construction of any structures; it can ignite from a spark or the flame of a small match. Only modified, so-called “non-flammable penoplex” can be chosen for building a house. But in any case, you need to understand that in the event of a fire you will need to urgently leave the premises. When burning, foam releases the following dangerous substances: hydrogen bromide, hydrogen cyanide, phosgene. When these toxins enter the human body, they paralyze the lungs and nervous system, leading to rapid death.

Insulation of house walls

You should not use polystyrene foam for insulation of administrative, social and entertainment facilities. The fire at the Lame Horse club in Perm, which claimed several dozen lives, was largely due to the thermal insulation of the building made of foam plastic. The cause of death for most visitors is poisoning from toxic combustion products.

Pipes with flammability group G1

These pipeline systems have passed specialized tests and have a certificate of flammability group G1 - this ensures the possibility of their use in fire-hazardous premises, basements, risers, warehouses, automatic fire control systems and fire-fighting water supply systems.

Italian silent sewer pipes are the most cost-effective silent sewer!

- Noise absorption - 12 db

- Non-flammability - flammability group G1

- Pressure - adhesive connection - 10 atm

- Non-pressure - socket connection - 3 atm

Installed at the 2018 FIFA World Cup stadiums

Officially approved plastic pipe system in the field of automatic fire extinguishing. Designed specifically for sprinkler systems.

Certified according to established fire safety standards in most countries of the world, as well as by VNIIPO EMERCOM of the Russian Federation for use in fire control systems and fire-fighting water supply systems. Does not require washing, flame retardant.

Penoizol - polystyrene foam based on urea-formaldehyde

In addition to polystyrene, other polymers are also used in the production of foam plastics. Material based on urea-formaldehyde has become widespread. It is more often called penoizol. The production of penoizol is quite complex, and in our country it was not widely used in construction until the 90s of the last century.

The process of making penoizol consists of creating foam and enveloping the cells with karmamide resin. The material hardens within 2-3 days and acquires excellent characteristics - the material is quite dense and has low thermal conductivity.

Penoizol is produced in the form of standard slabs, but is most often used in construction work in a liquid state - during the preparation process at the workplace. This has great advantages in terms of installation work:

- Filling the hardest-to-reach places with thermal insulation

- There is no need for preliminary calculations for the purchase of materials

- No additional fasteners

However, the use of penoizol during the construction process requires special equipment. It is clear that in this case, only specialized teams can carry out the insulation work.

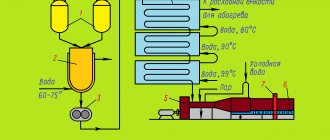

Spraying penoizol requires special equipment

Safe for me, safe for you

It is impossible not to compare both materials in terms of their impact on the environment and interaction with it. Who to give preference: penoplex or technoplex?

The fire hazard of the materials is the same. They belong to the category of substances that support and spread combustion. When they burn, a gas that is unsuitable for breathing is released into the atmosphere. Because of this, they are not recommended for use as insulation without taking additional measures to ensure fire safety, for example, treating them with thermite.

The chemical and biological activity of these insulation materials is the same due to the use of the same source material: they are not afraid of contact with most building materials and solutions, are not attacked by insects and rodents, do not rot or spread fungus.

Both materials are destroyed under the influence of ultraviolet radiation, so their use without shelter is not recommended.

Mineral wool

This is a very good thermal insulation material. Mineral wool is a non-flammable material and this is its undoubted advantage, which is widely advertised by manufacturers.

Mineral wool with a foil layer has class G1. Combustion occurs not so much on the surface of mineral wool, but in its depth. Visually, there is practically no damage on the mineral wool sample. Mineral wool with the addition of sedimentary basalt rocks emits acrid smoke formed due to the combustion of formaldehydes included in the composition.

Method of obtaining

Foams are a class of polymers (plastics) that contain air cells between the chains of an organic matrix. If the microcavities are connected to each other, the product is called a foam plastic.

Foams are produced by mixing large polymer molecules or medium oligomer molecules with solid blowing agents, low-boiling liquids or an inert gas.

There are technologies in which gas is formed during a chemical reaction of organic raw materials. The foamed product is shaped by cooling or special curing techniques.

There is a modification of expanded polystyrene obtained by polymerization of the monomer. The resulting polymer is mixed with additives that form pores. The resulting mixture is passed through an extruder.

The result is a high-density foamed styrene polymer. Extruded polystyrene foam, often called penoplex. This is a product with good thermal insulation ability. It can be used to insulate houses even in the Far North.

Among foam products, polyurethane foam, also known as foam rubber, is very popular. It is obtained by foaming a liquid reaction mixture of monomers with the addition of organosilicon components, foaming agents (water or freon), and substances with high surface activity.

By varying the process conditions, polymers of varying rigidity can be obtained. They have conditionally non-flammable properties. Foamed polyurethane products with a reinforced matrix are used as insulation materials.

Flammability class

The closest analogue of polyurethane is classified as flammability class G2. This fact can be completely trusted, since the insulator contains nitrogen. But the assurance that polystyrene foam has the same flammability and belongs to the same class is most likely an advertising ploy. According to the generally accepted classification, this insulation is defined as follows:

- NGA, G1 and G2 are non-flammable, slightly and moderately flammable materials; the fire safety characteristics of penoplex can hardly be attributed to these classes;

- G3 - insulation materials with normal flammability parameters; this class includes polystyrene foam with the addition of fire retardant and other components;

- G4 is a conventional polystyrene foam insulation with highly flammable properties.

Some manufacturers claim that they have switched to the production of a brand of penoplex with a G1 flammability class, but this is physically impossible. The first two groups include materials that do not splash into droplets when burning. Polystyrene heat insulator does not have such qualities. Supporting videos of a suspended sample cannot serve as real evidence, since the penoplex droplets flow downwards through natural gravity.

You can compare the flammability of various thermal insulators with polystyrene foam in this video:

How dangerous is penoplex?

Misunderstandings often arise between sellers and buyers. When a buyer is interested in whether penoplex is a flammable material or not, the seller can say that the insulation is a fire-resistant building material. He will be right if the slabs belong to classes G1-G3, and a fire-retardant impregnation is added to them, making the material self-extinguishing.

However, even in this case, the polymer will not withstand fire: the surface will melt and combustion products will enter the air. And, although the technology for producing EPS has been improved, and flammable gas has been replaced with carbon dioxide, the health hazard still remains. When burning, among other things, soot and hydrogen chloride are released, and their inhalation can cause an attack of suffocation, and in rare cases, pulmonary edema.

Therefore, foamed EPS can be classified as non-flammable only conditionally, implying its good fire resistance. Buyers often take the name literally and believe that the seller is deceiving them, although they interpret the same concept in different ways.

Expanded polystyrene emits smoke in any case Source yandex.net

Manufacturers

There is fierce competition in the construction market, however, not as many companies are involved in the production of technoplexes as the consumer would like. Let's consider the list of the main suppliers of extruded insulation on the Russian market.

TECHNONICOL. The company is among the TOP 100 largest enterprises in Russia, and has several production lines in the country. The manufactured products attract buyers with a relatively low price and high quality.

URSA. A relatively young brand that appeared on the market in 2003. At the beginning of its development, the company was engaged in the production of mineral wool from fiberglass. After merging with the Spanish company URALITA, lines for the production of extruded polystyrene began operating. Now it is one of the leading European brands, actively developing the Russian building materials market.

RAVATHERM. The trademark belongs to a Belgian company with production lines in the Moscow region. Finished products are subject to multi-stage quality control, so they invariably have high technical characteristics.

It is worth noting that the products of these enterprises have international certificates and are absolutely environmentally safe.

Let's summarize

If you want to buy expanded polystyrene boards for building a house, you should understand that the material does not have high fire resistance. Or you will have to purchase expensive, but fire-resistant insulation. This applies to a greater extent to the upper structures: the attic, attic and roof. When purchasing, ask the seller for a certificate, GOST compliance and technical specifications. You can reduce the risk by observing fire safety measures: the insulation should be located far from the source of fire, for example, a fireplace; you should not use this heat insulator in saunas and baths.

Description

Density

High-quality EPS has a homogeneous structure and closed pores of a much smaller size than conventional polystyrene foam (no more than 0.2 mm). Due to its increased compressive density, EPS can be used where foam plastic is too soft. Extruded polystyrene foam can withstand a load of 35 tons per 1 m2!

Installation work

Another advantage that this material structure provides is the ability to process it comfortably. Many people know how difficult it was to cut foam plastic. The balls crumbled, scattered and became magnetized to hands, tools and surfaces. And even with careful handling, the slab could crack and break in the wrong place.

House insulation with Penoplex

Extruded polystyrene foam is free of all these disadvantages. It is easy to cut with a regular hacksaw. The cut is precise and even. And the slabs are laid directly on the base - no additional layers of steam and waterproofing are required. The joints are sealed with polyurethane foam. EPS does not emit toxic substances or unpleasant odors. Working with it does not require special equipment for installers.

Moisture absorption

The dense structure increased the moisture resistance of the material (against the background of vulnerable mineral wool, water absorption of 0.2 looks like an error). In the first 10 days, the side cells on the cut collect a minimal amount of moisture. Then water absorption stops, water does not pass inside.

Thermal conductivity

In the battle to retain heat, even a slight difference in thermal conductivity matters. For different brands of expanded polystyrene, this figure ranges from 0.037 to 0.052 W/(m* °C). Extruded polystyrene foam has an indicator of 0.028 - 0.03 W/(m* °C)!

Chemical resistance

XPS has proven to be resistant to:

- various acids (organic and not);

- salt solutions;

- ammonia;

- cement and concrete;

- lime;

- alkalis;

- alcohol dyes, alcohol;

- carbon dioxide, oxygen, acetylene;

- freons (fluorinated hydrocarbons);

- paraffin;

- water and water-based paints;

- bacteria and fungi.

Other properties

The thickness of the produced slabs can be from 2 to 12 cm.

For ease of installation, three types of edges are available:

- Straight.

- With the selected quarter (marked with the letter S).

- Tenon - groove (letter N on the marking).

The outer surface can be smooth or corrugated (indicated by the letter G on the marking).

The color range of extruded polystyrene foam is varied. There are no uniform standards yet, so each manufacturer produces slabs of different sizes, thicknesses and different colors to indicate different quality EPS.

The properties of EPS do not change even after 1000 freezing-thawing cycles, or after prolonged immersion in water. Extruded polystyrene foam remains unchanged even in conditions of -60 +85 °C!

Orange slabs

Cons and weaknesses:

- Penoplex is vulnerable to solvents, some gases (methane), petroleum jelly, tar, gasoline, oil and fuel oil.

- Susceptible to destruction upon contact with polyvinyl chloride (siding).

- Flammability. It corresponds to the level of flammability of wood, but all foam plastics emit toxic substances when melted that suffocate a person faster than carbon monoxide.

- The material must be protected from direct exposure to ultraviolet radiation (not used open).

- There are temperature restrictions when insulating baths, saunas and fire pits. The surface should not be heated above +75 °C.

- Just like polystyrene foam, extruded polystyrene foam can be damaged by rodents. They don't eat it, but grind it up and build nests in it.

There are no ideal materials, therefore, knowing about its shortcomings, you need to be able to adjust technologies to suit them. For example, in order to protect residents in case of fire, it is not recommended to use EPS for internal insulation of ceilings, and plastering should be done on top of the insulation layer.

To protect the wall from rodents, Penoplex slabs can be covered with fine mesh.

Types, characteristics and properties of polystyrene foam

There is no insulation in the world that is more hotly debated than polystyrene foam. Flammable, toxic, unreliable - all sorts of complaints are made against it.

But what is the reality? How dangerous is it from the point of view not of the average person, but of officially existing norms and standards?

Types of expanded polystyrene. Chemical composition

Depending on the manufacturing technology, expanded polystyrene (EPS) is divided into several types:

- Pressless. Denoted by the abbreviations EPS (foreign production) or PSB (domestic). This is “ordinary” polystyrene foam, most often used for wall insulation. The modified PPS is designated PSB-S; it has a lower fire hazard.

- Extruded (extruded). Abbreviated XPS (EPS), it has high compressive strength. It is used to insulate the bottom of a “Swedish” foundation slab, laid under concrete floors or cement-sand screeds, etc.

- Press (for example, PS-1 or PS-4).

- Autoclave (including autoclave-extrusion).

The last two types are not widely used. From a chemical point of view, EPS consists of foamed polystyrene. In turn, polystyrene is obtained from styrene (chemical formula C8H8), classified according to GOST 12.1.

007-76 to hazard class 3 (moderately dangerous).

It is typical that, depending on the technology for processing the feedstock (styrene), the resulting polystyrenes can be safe - they are used to make yogurt cups, food utensils, etc.

Main characteristics of expanded polystyrene

The main characteristics of expanded polystyrene include high thermal insulation performance, very low vapor permeability and close to zero water absorption.

Main characteristics of teaching staff.

Like any other material, the thermal insulation properties of EPS depend on its density. The water throughput capacity also depends on it. The much denser XPS is superior in this regard to its “softer” counterpart.

Comparative table of characteristics of PPP and EPS.

Due to its strength and “hydrophobicity”, it is EPS that is best used for insulating the basement of a building (foundations, windings, underground parts of walls).

Low vapor permeability creates a number of nuances for using this insulation in rooms with high humidity conditions. In industrial premises this issue is solved by increased air exchange (ventilation), in residential premises - by installing windows with a slot ventilation function.

One of the most common myths is the use of EPS as sound insulation. The basis for this myth was the relatively high soundproofing properties of mineral wool.

Since cotton wool and PPS are the main competitors for the consumer’s wallet, the average person often views them as almost equivalent materials, with the only difference being that mineral wool does not burn and is therefore more expensive.

In fact, mineral wool insulation, in addition to higher soundproofing properties and non-flammability, is also distinguished by its hygroscopicity (absorb moisture) and high vapor permeability.

EPS and EPS do not contain substances attractive to microorganisms, insects and rodents. However, mold and mildew may form on the surface of these materials.

Mice and other rodents can also make burrows in the body of EPS and EPS, but in general these materials are much less attractive to them than natural ones.

Thus, the “inedibility” of polystyrene foam, as well as its “attractiveness,” are myths.

The destruction of PPS is a process of chemical transformation of its structure due to oxidative processes. The cause of the latter is high temperature (80 degrees and above), as well as direct exposure to oxygen.

Therefore, expanded polystyrene is not used for thermal insulation of hot objects (for example, heating pipes) and must be protected from the external environment (most often by a reinforcing layer over a mesh).

As an example, “Two methods of reinforcing plaster when installing a wet façade on polystyrene foam.”

The average durability of PPS is usually taken to be 10 - 15 years. After this period, the polystyrene foam becomes brittle and the process of self-shedding begins.

This does not mean that its thermal insulation properties will become zero in the 16th year of operation.

This means that the warranty period of suitability is 10-15 years (it varies from manufacturer to manufacturer).

It is noteworthy that for mineral wool, many manufacturers indicate an identical warranty period. Protective measures (for example, the reinforcement layer mentioned above) increase the service life of this material. Thus, the unreliability of teaching staff in terms of shelf life is another myth.

Fire hazard

Source: https://rems-info.ru/penopolistirol-kharakteristiki.html

Differences between polystyrene foam and polystyrene foam

Expanded polystyrene is produced differently. I melt the granules and process them. The result is a denser “coupling” formed at the molecular level. No air bubbles form between the “clusters” of polystyrene beads.

Secondly, there are some differences in the characteristics. This logically follows from different production methods. Expanded polystyrene has its advantages compared to polystyrene foam. Namely:

- increased strength. Since this material is a single mass of molten polystyrene granules, its strength is significantly higher. Foam plastic, as everyone has noticed, crumbles easily. And if you bend it, the sheet will simply break. This will never happen with polystyrene foam. Technically speaking, polystyrene foam is 6 times less flexurally strong than expanded polystyrene.

- permeability. Polystyrene foam, as already mentioned, has air bags. As a result, this material can absorb more moisture than its older brother. The same applies to sound permeability; for foam plastic this indicator is much worse, which means that noise can penetrate into rooms more freely.

- density. Expanded polystyrene is almost five times denser than polystyrene foam. This makes it a little heavier, but still keeps the weight at a minimum. But the increased density makes polystyrene foam several times stronger.

- thermal conductivity. Since polystyrene foam is denser, its thermal conductivity is lower.

In almost all characteristics, polystyrene foam is inferior (albeit slightly) to its older brother. In addition, polystyrene foam costs a little more. But in principle, both materials are excellent insulators and are widely used in thermal insulation work.

Foamed polystyrene what is it

Penoplex is produced by the company of the same name. It creates insulating material using a special technology: extruded polystyrene is foamed under high pressure. The same applies to the technology for creating Technoplex, according to open sources. It is produced by TechnoNIKOL. As for the remaining details of the process of creating Penoplex and TechnoNIKOL insulation, nothing is reported about them. True, fragmentary data leads us to the following thoughts:

- Polystyrene granules, which act as the main raw material, are mixed with the gasifier. The mixture is heated to a high temperature and pressed through small holes. In this case, polystyrene granules must be highly purified.

- As the mixture passes through the micro-hole nozzle, the flow begins to break up into microscopic threads. In this case, the polymer molecules are pulled out and form a connection with each other. And thanks to pressure, they begin to harden.

- When the polypropylene comes out of the nozzle, it begins to foam and forms a porous material with thousands of small bubbles.

It turns out that based on the technology of creation, it cannot be said that Penoplex or TechnoNIKOL is better. They are almost the same, the difference lies in composition and strength. According to the TechnoNIKOL company, the composition of their products, namely Technoplex, is enriched with amphora carbon or graphite. In this case, the rolling rollers can better form the material into its final shape and thickness.

So, Penoplex is made by extrusion. And Technoplex, thanks to the inclusion of graphite nanoparticles, increases the strength of the material, and its thermal conductivity coefficient decreases even more. Both the first and second materials are environmentally safe. They are safe and non-flammable. The materials will not dissolve in water or soil.

Conventional production technology involves the use of light freons mixed with carbon dioxide as a vapor-forming gas. As for new creation methods that are much better. For their implementation, liquid and powder gas-forming agents are used.

Production technology

Modern polystyrene foam is produced in the form of slabs, which are produced using a non-press method. Foaming polystyrene is taken as a base and placed in large molds. Next, using the thermal shock method, foam blocks are formed. They are cooled using water, vacuum or naturally.

Foam production

Advantages and disadvantages

Like any other material, extruded polystyrene foam has advantages and some disadvantages. It is worth familiarizing yourself with them before purchasing and using them.

Advantages of extruded polystyrene foam:

- Moisture absorption within 0.2%. This indicator means almost complete waterproofness.

- Minimum thermal conductivity. At a standard temperature of 25°C it is about 0.032 W/m*K. If we compare the heat conductivity, the indicators are as follows: 55 cm of brick equals 3 cm of polystyrene foam.

- Withstands deformation well. Can be used for laying under a blind area, or after the foundation.

- Does not react with inorganic chemical reagents.

- Withstands significant temperature changes, the indicators do not change at air temperatures from -50 to +75°C.

- According to the documentation, the material can be used for at least half a century. During this time, the characteristics will not change.

- Environmentally friendly substance. It is used not only as insulation, but, for example, for the production of lightweight disposable plates or other types of cheap tableware. Children's toys are made from it.

- Has minimal weight. A small thickness is enough for good insulation.

In addition to numerous positive characteristics, some disadvantages can be identified:

- comparison with other types of insulation shows that the price of the material is high;

- highly flammable. During the combustion process, harmful substances and black smoke are released;

- destroyed under the influence of infrared rays. To maintain performance characteristics, it must be hidden from direct sunlight;

- Manufacturers assure that rodents will not grow inside the insulation. Indeed, they do not live inside, but often make channels for movement;

- solvents destroy the structure.

In addition to the listed disadvantages, low vapor permeability can be added to them. Sometimes this is a plus, but if you insulate a wooden house, fungi and mold may develop. As a result, an unpleasant odor appears in the home and dampness is constantly felt.

Thermal conductivity

EPS and EPS have low, and therefore good, thermal conductivity. The extruder, due to its denser structure, is slightly ahead in this parameter. A 50 mm sheet insulates a room better than a half-meter thick concrete wall. This is an effective material, on par with mineral wool.

Note: UV protection and adhesion

Polystyrene foam is afraid of ultraviolet radiation. It must be covered with another material on top: plaster, if we are talking about a facade, or a roofing covering together with a waterproofing membrane, if the roof is insulated.

EPS and EPS are very smooth, so in order to improve the surface in terms of adhesion, before applying the glue, you need to damage the top layer with very rough sandpaper or scratch it with a hacksaw. Otherwise, over time, the plaster will slip and fall off.

Another reliable option is to glue a reinforced mesh onto the insulation with alkaline glue, and then apply plaster on it.

Styrofoam

In accordance with the generally accepted classification, it has a flammability class of G1, G2. However, it has the ability to smolder slowly, releasing very toxic smoke containing styrene.

Numerous tests carried out with polystyrene foam allow us to draw the following conclusions:

- polystyrene foam has the property of self-extinguishing, which means that in the absence of a constant source of flame it will not burn;

- Most types of foam plastic during the combustion process are deformed only in the part where the open flame was exposed;

- has the ability to smolder, emitting toxic smoke;

- The height of the open fire during combustion reaches a maximum after 3–5 seconds, and then the process of smoldering and self-extinguishing begins.

Test results

Most of the tests to which penoplex was subjected confirm the fire hazard. The test results are as follows:

- in the absence of a constant source of fire, the insulation begins to self-extinguish;

- deformation of the heat insulator appears only in the place where it was exposed to fire;

- the maximum height of the flame fades during the first 5 seconds, then the burning slows down, the material begins to smolder;

- the insulation is toxic; it emits toxic smoke.

The fire hazard of polystyrene insulation lies in two aspects: the danger of combustion itself and the release of toxic substances. The second factor has a greater impact, since statistics report that only 1/5 of those injured in fires were victims of fire. According to the results of tests carried out at the VNIIPO of the Ministry of Internal Affairs of the Russian Federation, the toxicity of the samples is close to the limit values for the class of highly hazardous materials. This fact confirms the requirements for this heat insulator in some European countries. There, a penoplex thickness of 35 mm is defined as the maximum. In Russia, the requirements are less stringent; in some facilities, insulation reaches 30 cm.

Features of various substances

It is known that substances can be in different states of aggregation, which are important to take into account when determining the flammability group. GOST provides for classification based on quantitative indicators

If a substance can burn, the flammability group G1 is more optimal for fire safety than G3 or G4.

Flammability is of great importance for finishing, thermal insulation, and building materials. On its basis, the fire hazard class is determined. Thus, plasterboard sheets have a flammability group of G1, stone wool has a NG (does not burn), and polystyrene foam insulation belongs to a flammability group of G4, and the use of plaster helps reduce its fire hazard.

Gaseous substances

When determining the flammability class of gases and liquids, standards introduce such a concept as a concentration limit. By definition, this is the maximum concentration of a gas in a mixture with an oxidizer (air, for example), at which a flame can spread from the point of ignition to any distance.

If such a limit value does not exist and the gas cannot spontaneously ignite, then it is called non-flammable.

Liquid

Liquids are called flammable if there is a temperature at which they can ignite. If a liquid stops burning in the absence of an external heating source, then it is called slow-burning. Non-flammable liquids do not ignite at all in the air atmosphere under normal conditions.

Some liquids (acetone, ether) may flash at 28 ℃ and below. They are considered especially dangerous. Liquids that ignite at 61…66 ℃ and above are classified as flammable (kerosene, white spirit). Tests are carried out in an open and closed crucible.

Solid

In the field of construction, the most relevant is the determination of the flammability group of solid materials. It is preferable to use substances of the flammability group G1 or NG, as they are the most resistant to ignition.

The degree of flammability is determined not by one category, but by several:

- "G"

flammability - "B"

flammability - "D"

smoke generating ability - "T"

toxicity

The combination of these categories determines the fire hazard class “KM”

For a clear example, we present the data in the table:

| Fire hazard properties of building materials | Fire hazard class of building materials depending on groups | |||||

| KM0 | KM1 | KM2 | KM3 | KM4 | KM5 | |

| Flammability | NG | G1 | G1 | G2 | G3 | G4 |

| Flammability | — | IN 1 | AT 2 | AT 2 | AT 2 | AT 3 |

| Smoke generating ability | — | D 2 | D 2 | D3 | D3 | D3 |

| Toxicity of combustion products | — | T2 | T2 | T2 | T3 | T4 |

Now we see, if we are only interested in flammability, let’s say G1, we can purchase materials for finishing KM2, and the fire inspector will insist that the requirement for materials correspond to KM1, i.e. the flammability was not higher than B1, and you will have to dismantle and purchase new material. Although G1 appears here and there, the fire hazard class may be different

Pay attention to this

This is interesting: Ignition temperature: described in general terms

About labeling and legislative subtleties

Until 2009, flammable PPS, to which flame retardants were added, received the G1 marking. In May 2009, federal law FZ-123 “Technical Regulations on Fire Safety Requirements” came into force. He changed the method by which building materials were distributed into flammability groups.

Based on the totality of their characteristics, all polystyrene-based insulation materials are now classified no higher than G3. This is due to the fact that, according to the new rules, materials of groups G1-G2 cannot form melt drops.

Expanded polystyrene boards are approved for use in construction Source 1-teplodom.ru

Advantages and disadvantages

Now it’s worth considering what the advantages of one and the other materials are. After all, each of them was invented for a reason and is in demand among consumers.

Styrofoam

The main positive qualities of polystyrene foam include:

- Using it as wall insulation both inside and outside the building.

- Its relatively low price is why it is in demand among consumers.

- The material is quite moisture resistant.

- Has little weight.

- Easy to use and install. In addition, it is easy to cut using a knife or other cutting object.

- Good insulation for foundations.

- Polystyrene foam can be cut at various angles, and any shapes can be cut out of it.

- The material can be painted and plastered.

Polystyrene foam is a good insulation material for foundations. The disadvantages of the material include:

- The thickness of the material used should not exceed 3 cm.

- To better attach the material to the wall, it must be perforated, for example, with a needle roller.

- It is necessary to take care of the fireproof coating for the material.

- When installing foam sheets, it must be completely coated with glue.

- When leveling the sheet, it is necessary to use a moisture-proof putty.

It can be seen that the material has both positive and negative sides. Therefore, before purchasing, you need to weigh the pros and cons so as not to get into trouble.

Expanded polystyrene

Its main advantages are:

- It does not transmit heat well, meaning it remains indoors.

- It does not allow moisture to pass through well, which means that even if the material is exposed to rain for several hours, it will remain dry.

- Despite its artificial origin, it allows the house or any other structure to breathe.

- Not subject to rotting.

- Not affected by fungus.

- Durable. Can last about 50 years.

- The material is good to use as a sound insulator. Because it has a homogeneous structure that muffles and absorbs sounds.

The disadvantages of this material include:

- Price. This material is not the cheapest. This is why many consumers buy polystyrene foam.

- This material is destroyed under the influence of certain solvents.

- Expanded polystyrene is susceptible to destruction by rodents. It is quite easy for them to build passages and houses in the material.

- Just like polystyrene foam, polystyrene foam is a flammable material. Therefore, it is necessary to take care of safety. Cover it with a special solution.

It can be seen that the positive aspects of expanded polystyrene are quite attractive, in some cases even better than those of polystyrene foam. However, the main and sometimes decisive disadvantage is the high price of the material.