By laying insulation under drywall, you can achieve the solution of several problems at the same time - providing optimal thermal insulation, leveling the walls and performing sound insulation.

If there is a need to build several additional partitions in an apartment or house, then it is cheaper and faster to build them using plasterboard, and insulating partitions from plasterboard will provide additional warmth and sound insulation.

Types of material

Today on the market you can find a huge number of insulating products that differ in their quality characteristics.

When choosing insulation for drywall, you first need to study the characteristics of each.

Insulation materials include the following materials:

Each of them has a specific structure and parameters.

To choose the right insulation, you must initially know the characteristics of each of them.

Features of polystyrene foam and polystyrene foam insulation

These products have been used in finishing work for quite some time. They have earned recognition due to their optimal cost and excellent quality characteristics.

Polystyrene foam or polystyrene help make the process of insulating buildings faster and better. Despite the large number of advantages, the materials also have disadvantages. These include the following characteristics:

In addition, polystyrene foam and expanded polystyrene act as vapor barriers. This negatively affects the insulation of rooms with high air humidity and high temperature conditions.

Mineral wool and its characteristics

There are several types of this material. These include the following products:

Each of them has certain advantages and disadvantages.

The most popular insulation is glass wool. It is made from natural raw materials - sand, borax, soda and limestone.

The advantages of mineral wool are its non-toxicity and fire resistance.

The advantages include the following characteristics:

The material is also an excellent sound insulator.

Disadvantages include the fragility of the fibers in the structure, as well as low heat resistance. Glass wool loses its properties when exposed to temperatures of 450 degrees.

Today, this type of insulation is effectively used to insulate internal plasterboard walls.

Basalt wool is less popular due to cost. It is made from basalt raw materials. It has excellent heat and sound insulation properties. It is also heat-resistant and stands out among similar materials for its environmental friendliness.

Stone mineral wool is a relatively new type of insulation. It is made from volcanic rocks. Thanks to this, it has a dense structure. The material is not able to absorb moisture and perfectly absorbs noise. Its main advantage is environmental friendliness.

Slag waste is the raw material for the production of slag wool. This type of thermal insulation agent is less popular than all others. This is due to its technical indicators. It is capable of absorbing moisture, cannot withstand exposure to low and high temperatures, does not absorb sounds so well and is not environmentally friendly. The only advantage is low cost.

Reflector in insulation of structures

This product has appeared on the market recently, but has already gained recognition. It is made using foil and a rubber base. Thanks to this, the material reflects heat well and does not let it pass through the wall. It is also unable to absorb moisture.

The main qualitative characteristics of the reflector include the following:

In addition, it is safe for human health. The rubberized base of the material increases its elasticity. This insulation for plasterboard partitions is also called isolon.

Coconut and cork plates

The products are made from coconut fiber and cork using special products. The materials are environmentally friendly and have good technical characteristics.

If you need to make high-quality heat and sound insulation of a structure, coconut and cork plates will be indispensable.

The structure quickly recovers after compression. The service life of cork insulation reaches 30 – 40 years. It is worth noting that the material does not rot or deform when exposed to alkalis, which cannot be said about coconut plates. They are able to absorb moisture during a certain cycle of exposure. A variety of bacteria form in the structure, with the help of which mold develops.

If coconut insulation is used, it is necessary to additionally make layers of hydro- and vapor barrier.

The cost of the material is quite high due to the use of natural raw materials in its production.

What not to do

Often, when trying to limit themselves from noise, many people use materials that are not the most suitable for this. First of all, this applies to polyurethane foam.

Not only does it provide poor protection from noise, but it is also not fire safe. The foam melts perfectly and releases a suffocating gas. The same can be said about polystyrene foam.

By creating a simple partition made of gypsum sheets to protect against noise, and not filling it with a noise absorber, they thereby turn it into a large resonator, which only worsens the situation.

Insulation from sound penetrating through technological openings - sockets, air ducts and the like - is required. If nothing special is done with the air ducts and ventilation ducts, then the outlet can be treated from the inside even with a simple sealant, which, although slightly, will reduce the amount of incoming noise.

When using roll sound insulators and membranes, you must not leave joints or gaps between the parts of the coating. It is necessary to glue them overlapping.

Installation of insulation

Whatever type of thermal insulation agent is used, high-quality insulation is only possible if it is installed correctly. The material is secured in the cells of the metal profile frame. It is for this reason that the insulation is initially given the required dimensions.

Initially, the insulation must be given the required size, because The material is secured in the cells of the metal profile frame.

After this, the sheets of thermal insulation are tightly inserted into the cells. In this process, the main thing is to eliminate the appearance of small gaps between the material and the metal profile. Heat will escape through them.

To secure elastic insulation to the surface, use special solutions or glue.

These types of materials include heat insulators made of balsa wood, coconut fiber and isolon. Their use in insulating a structure requires the presence of a rough surface for installation. It can be the back side of a sheet of drywall, a wall or a ceiling. If the insulation is mounted on GC, the surface of the sheets must be primed. This will increase the adhesion rate of the glue and the rough base. To increase the insulating properties of a structure, foam plastic is often used together with elastic insulation. This combination of materials has a positive effect on sound and vapor barrier performance.

Source

Soundproofing protection

There are special building regulations according to which the level of airborne noise insulation in residential premises must be at least 43 dB. If this indicator is higher than normal, this means that the interior partitions do an excellent job of soundproofing the room. It should be noted that this does not apply to low frequency sounds.

A thickened interior partition isolates the room from low-frequency sounds much better than a frame structure, with the same noise insulation indices. In addition, such structures made of ceramics, plasterboard, aerated concrete, and shell rock are capable of absorbing and reflecting any sounds.

The thickness of such structures is at least ten centimeters. They provide a fairly high sound insulation index (about 40 dB).

Excellent sound insulation in a private house or cottage is provided by standard types of interior partitions. Such designs perfectly isolate various noises, creating a comfortable and cozy indoor environment.

To improve the sound insulation of the room during the construction of partitions, it is necessary to additionally create an air gap or cover the walls with plasterboard.

Multilayer structures are no less effective. The outer hard layers of such structures are capable of reflecting various sounds, while the inner soft layers absorb them perfectly. Special slabs made of basalt fiber are most often used as internal soft layers. This building material is laid in a dense layer under the facing material. The use of a double layer of facing building materials, as well as special sound-proofing and heat-insulating materials in the process of erecting interior partitions can significantly increase the quality of sound insulation of premises.

Features of thermal insulation with plasterboard

Advantages of gypsum board cladding in terms of wall insulation in an apartment:

In apartment buildings, internal insulation is more affordable than external insulation; drywall is one of the most economical options. The panels are easy to process and undemanding in maintenance, they can be applied with any type of finishing, they form a perfectly flat surface without weighing down the load-bearing structures. GCRs are combined with most types of insulating (hard, soft) and finishing materials, which is important when creating interior design.

General recommendations

The measures described should never be redundant. Isolation from extraneous sounds in residential premises is very important for comfortable living, but if you overdo it in this matter, you can doom yourself to unreasonable costs and loss of usable space. Therefore, you need to understand that the partition between the kitchen and the living room has different requirements than the partition separating the bathroom or children's room.

The problem of high-quality sound insulation is not only technical; much depends on proper planning, predicting noise loads by determining the sources and paths of propagation of extraneous sounds. Much depends on the finishing materials. For gypsum plasterboard partitions made according to schemes from technical albums, painting and wallpapering are recommended, while tiling forces the use of hinged fasteners, increasing the number of layers and using the capabilities of damping materials.

Types of suitable insulation materials, their properties

The insulating structure is selected in accordance with the brand of plasterboard panels, they can be:

To insulate partitions and load-bearing structures, moisture-resistant wall variations that are fire-resistant and have increased strength are used. Additional insulators vary in density, consistency, thermal conductivity, and thickness.

Slab materials are optimal for walls; compared to roll insulation, they are much easier to install. The parameters of the products are suitable for placement in the grooves of the sheathing; you don’t have to waste time on adjustment. It is only important that the slabs are positioned closely, without gaps. Glass wool, basalt wool, polystyrene foam, and isolon can be mounted on walls under drywall.

Styrofoam

The granular substance is based on polystyrene, is characterized by low weight and low density, and is molded into slabs of varying thickness. The popularity of the solution is due to ease of installation and low cost; the disadvantages are fragility and insufficient sound insulation, and the need for additional ventilation. Rodents are interested in the material; additional protective measures will be needed.

Foam plastic - insulation for drywall

Minvata

Basalt wool is more expensive than glass wool and polystyrene foam, but it is in great demand due to its optimal performance properties. The natural insulating resource is made from molten rocks and is characterized by being hypoallergenic, fire-resistant, environmentally friendly and durable. The texture is formed from thin stone fibers alternating with layers of air, which ensures thermal insulation.

Unlike other categories of mineral wool, basalt does not absorb water, so it can be used in rooms with high humidity. In addition to the price, the disadvantage is the large thickness of the slabs, which “eats up” useful space.

Glass wool

A flexible, soft solution with a small thickness, kept in the budget segment, and has low thermal conductivity. This option is dangerous for use in everyday life, since glass fibers upon contact with mucous membranes and skin provoke severe burning and itching. During installation, you need to use a respirator, special clothing, safety glasses, and gloves.

Glass wool - insulation for drywall

Izolon

One of the new insulation options, formed as a result of polyethylene foaming under the influence of propane. It is characterized by low density and weight, as it is saturated with air bubbles. Izolon perfectly protects against heat leaks, exhibits high sound insulation with an acceptable thickness, and with its help you can save the usable area of the apartment. Some brands have foil vapor protection.

Types of noise protection partitions

For interior screens or barriers between the kitchen and one room, the lowest Rw value is approximately 43 dB, between other areas and the bathroom it is about 47 dB. However, not only this parameter is important for good sound insulation.

Low-frequency noise created by functioning electrical appliances is also important. The sound background is quite irritating, although not loud. For example, when comparing a partition monolithic structure and a light frame that have an equal index value, the monolithic structure reflects low-frequency waves an order of magnitude better. For maximum protection from unpleasant sounds, a lightweight structure is installed, filling it inside with a sound-absorbing layer.

We list the types of partitions with sound insulation:

- Frame partitions made of building materials with special layering. The outer side is designed to reflect noise, and the back is to absorb. They reduce noise pressure and its saturation to a level that is not dangerous for the human nervous system.

- Sound-absorbing structures made of building materials that absorb sound wave energy. Also designed to reduce noise and its intensity.

- Soundproof structures - absorb and isolate noise at the same time. They completely block sounds, preventing them from either entering or leaving the apartment. These are, for example, multi-layer barriers, where noise reflected from plasterboard cladding is absorbed by a soft inner layer.

The level of silence in the room depends on how hard the outer and soft inner layer of the material is. Experts say that plasterboard screens are superior to glass partitions and monolithic products in terms of ease of installation and savings in usable space.

In offices/panel houses, the internal and load-bearing walls do not have good sound insulation. Monolithic partitions for offices made of gypsum tongue-and-groove slabs perfectly transmit sound. There are two ways out here - replace the sound insulation of tongue-and-groove slabs with multilayer gypsum plasterboards with a layer of sound insulator, or sew up, for example, in an office with soundproof partitions, and gypsum plasterboard on top. The second method is simpler, but it will “eat up” valuable centimeters of space. Sound insulation can be improved through upholstered furniture, draped curtains, acoustic mobile partitions, and carpet.

Which way to choose - from the inside or the outside?

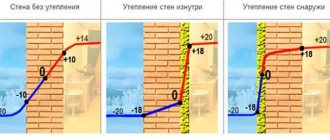

If the thermal insulation material is placed outside, that is, the facade of the house is directly insulated, the dew point (condensation forms along this boundary during temperature changes) falls precisely on the additional layer. In this way, the impact of temperature changes and changes in air humidity on the load-bearing wall is neutralized, resulting in an extended service life of the building.

If insulation is carried out from the inside using mineral wool covered with gypsum board or similar cladding, the dew point moves. Usually this boundary is between the wall and the insulation, in such conditions there is a high risk of fungi and mold growing. If internal thermal insulation of partitions and walls in an apartment is carried out, two conditions must be taken into account - the presence of a protective layer on the side of the facade and the total thickness of the wall. The best option is to strengthen the load-bearing structures on both sides.

Technology for installing insulators under drywall

As a result of preliminary preparation of the walls, clean, dry surfaces should be formed, free from any unevenness in the form of holes, cracks and fungal infection. Pockets of mold are cleaned and treated with an antiseptic, and the defects are carefully puttied.

The blanks are fixed with flat cutters at the boundaries of the wall, then vertical slats are mounted in increments of 60 cm (the insulation must fit tightly into the resulting grooves).

The method of fixing the material depends on its essence. Foam boards are installed using special dowels and glue, the joints are additionally reinforced with construction tape, and the cracks in the area where they meet horizontal surfaces must be filled with silicone sealant. To fix the mineral wool, you will need foam glue: it is distributed around the perimeter of the slab and applied a little in the center.

The vapor barrier layer can be formed from dense polyethylene film or construction foil. Next, they begin covering the cake with plasterboard using self-tapping screws. The cracks are filled with putty, cleaned to prevent cracking of the putty, and the top is covered with paint or special tape. If the base was laid with a metal profile lathing, in order to prevent the occurrence of cold bridges, tapes from the main heat insulator must be placed in its cavity.

The service life of the solution considered is determined by the type of insulation used. On average, it varies between 20-30 years. As the material ages, it loses a third of its beneficial properties due to caking and drying out, so it should be promptly replaced with a new one.

Source

Material characteristics

Moisture-resistant gypsum boards are painted green.

GKLs are available in thicknesses of 12.5 mm for walls and partitions and 9.5 mm for ceiling cladding. Standard sheet sizes are 2.5 * 1.2 m. According to additional characteristics, the material is divided into:

It is still recommended to lay a layer of thermal insulation between the wall and the gypsum board

GCR has a low level of thermal conductivity, tens of times lower than that of concrete. The value of the indicator ranges from 0.14-0.15. It is thanks to this value that the sheets do an excellent job of retaining heat indoors without the use of an additional layer of insulation.

However, thermal insulation with a thermal conductivity coefficient of 0.03 is usually laid under gypsum boards. A decrease in thermal conductivity is possible when installing gypsum boards on frame guides. This design significantly increases the thermal insulation properties of walls and ceilings.

Insulation of walls with plasterboard from the inside is used both in office or utility rooms, and in living rooms. Such insulation is most relevant where it is difficult to install external layers of thermal insulation, especially in corner rooms.

Often gypsum boards are mounted on a metal frame

Experts consider installing a thermal insulation system from plasterboard sheets to be one of the simplest and fastest methods. Any technology has its own specifics, and insulating walls from the inside with plasterboard is no exception.

Depending on the area of the room and the required level of thermal insulation, you should choose one of the installation methods.

Methods for fastening the installation of gypsum boards:

The sheet is glued directly to the wall using gypsum or cement-polymer mortar. With this method, the gypsum board itself is used as insulation. This installation method does not reduce the area of the room. The disadvantage is the inability to lay thermal insulation material. The wall covering must be absolutely durable without peeling.

GKL sheets are attached to metal guides or a wooden frame beam. The service life of a metal base is much longer than a wooden one. In addition, wood is prone to deformation, especially during temperature changes. The air chamber between the wall and the sheet, even without laying insulation material, provides a good level of thermal insulation

Frame with insulation

With this installation method, thermal insulation material is laid in the chamber between the wall and the gypsum board sheets. The height of the guides in this case is equal to the thickness of the insulation material.

Using the frame method using insulation material, the movement of convection air currents is prevented and the level of thermal insulation is increased.

Finishing

When the plasterboard sheets are installed on the frame, we proceed to cleaning the working surface from the debris and dust that has accumulated on it.

The joints of adjacent plasterboard sheets and the places where screws are installed must be puttied. After the solution has completely dried, the surface should be treated with sandpaper. This will completely level the ceiling, getting rid of unevenness.

Now we begin to decorate the plasterboard ceiling. This stage is greatly simplified, since there is no need to plaster the surface. The surface is painted or covered with wallpaper. Drywall can also be treated with decorative plaster. Here you need to proceed from your own preferences and financial capabilities. An extensive selection of possible finishing options allows you to create a unique and stylish floor. Having learned to install a simple single-level structure, in the future it will be much easier to master multi-level ceilings.

Compliance with safety regulations

- This is the basis for any type of repair work, so take this recommendation seriously. Probably the most basic and uncomplicated step when installing drywall, which, however, will require help in the form of a couple of extra hands.

- UD – profile. This profile is placed around the perimeter of the room. It is fixed to the walls of the room. Determining the quantity of the required profile is very simple - you just need to calculate the perimeter of the room.

- CD profile or, as it is also called, the main profile. Drywall is fixed directly onto it. The longitudinal guides are attached in such a way that the profile fits at the junction of two adjacent sheets of drywall.

When filing the ceiling, it is recommended to use special screws. They have a special thread shape that allows you to securely fix the drywall. In this case, immediately before filing, the sheets are cut to the required size.

For these purposes, a knife with a replaceable blade or a regular saw with fine teeth is suitable. With this approach to work, first you will have to carefully prepare the rough ceiling: eliminate all flaws, putty and treat the surface with a primer. It starts with installing the guides.

They are placed exactly along the line that outlines the perimeter of the room

The whole process is as follows: Before hemming the ceiling with plasterboard, you need to pay attention to the edges of the sheets. They should be even

This will make future puttying easier.

You can hem drywall using a screwdriver and self-tapping screws, which must have a flat head. Drywall for interior work, both in an apartment and in a private house, is used more and more often as it goes on. This is not surprising, because it is an environmentally friendly material that can easily be laid with your own hands, creating perfectly smooth surfaces. In order for the consumption of sheets during repair to be optimal, you need to know how to properly line the ceiling with plasterboard.

More on this and much more below. Many people worry about the consequences of flooding from neighbors above and, knowing about moisture-resistant plasterboard, wonder whether it should be used on the ceiling. VGKL is less hygroscopic and has additives to protect against mold and mildew, but it will not save you from a serious disaster. Ordinary drywall will also withstand slight moisture; it will soon dry and return to its original qualities. GKL slabs are attached to the frame and it seems that a wooden house is an ideal building for installing a plasterboard ceiling.

It is much easier to make lathing in it than in a room with floors made of concrete slabs. This is true, but provided that some nuances are taken into account. Wood is very mobile, it moves over time and cracks form.

The following will provide tips on how to take this feature into account in order to perform the installation correctly. The sheet can be attached to the ceiling without an assistant. To do this, it is enough to tighten the profile or block to the sheathing with two long screws, leaving a gap of several centimeters.

The sheet is laid on this support, and its free edge begins to be attached to the sheathing.

- It was puttied with gypsum putty twice, with a break for drying. I used ABS Saten, which, by the way, left a very pleasant impression with the absence of lumps and the long life of the mixture;

- The seam was roughly sanded with a #80 mesh in an oscillating sander;

- Then the grinding area was cleaned of gypsum dust with a brush;

- Fiberglass was glued onto PVA glue diluted with water in a ratio of 1:1. To make stickers easier, it had to be cut into meter-long pieces;

Insulation material

When installing mineral wool, use a vapor barrier.

Internal insulation of plasterboard partitions is made using various materials. The most common thermal insulators for laying under drywall are:

Foamed polyethylene film covered with aluminum foil is ideal as a vapor barrier cushioning material that prevents the formation of condensation inside the partition. To learn how to insulate walls with plasterboard, watch this video:

Using film will retain 95% of heat. At the same time, sound insulation in the room will significantly improve.

Vapor barrier film

Such raw materials are quite popular among people doing repairs. However, you should consider all the pros and cons.

Flaws

- Since polyethylene does not allow air to pass through, creating a greenhouse effect on the surface, the craftsmen came up with a trick. Some experts recommend walking over the surface of the polyethylene with a needle roller. Thus, according to repairmen, the surface begins to breathe and provides the desired effect. Other experts say that this idea is wrong. In any case, the pores created in this way will not perform the required function, allowing moisture to pass in both directions and not retaining it inside.

- Experts say that the film cannot be confidently positioned as a vapor barrier. The raw material is not specially prepared to perform the function of retaining steam in its coating.

Based on the above, it can be understood that plastic film is not the best option. But, if temporary repairs are required or there are no funds, polyethylene film can be considered as an alternative to professional materials.

Advantages and disadvantages

When installing gypsum board on a frame, the area of the room will be slightly reduced.

The main advantage of using plasterboard sheets as insulation is the high efficiency of the material.

In this case, the surface of the sheets does not require additional leveling and is ready for laying the final decorative layer of decoration.

How to putty plasterboard for painting Which is better: GVL and plasterboard on walls Proper insulation of walls in a foam concrete house Insulation of walls with polystyrene foam or mineral wool Insulation of external walls with sawdust How to properly insulate walls made of aerated concrete from the outside

Do-it-yourself finishing of walls and ceilings with plasterboard: step-by-step instructions

The frame can also be metal. For this purpose, a galvanized metal profile with characteristics specified in accordance with the design requirements is used. Today, the profile for gypsum plasterboard is considered the best material, as it has all the necessary qualities for the reliability of the structure. The installation itself takes place using the necessary types of profiles and fastening materials, with the obligatory use of a special tool for working with drywall. At the initial stage, it is necessary to make a level mark. At this stage, you should take into account the communication device and, of course, all light sources. It is also worth choosing and purchasing finishing and painting materials in advance, so that not only finishing, but also painting of plasterboard ceilings is successful. At the same time, prepare several profiles (bearing, starting and longitudinal ones must be in your arsenal), a crab so that with its help you can effortlessly connect the profiles, dowels, putty, painting material and self-tapping screws.

Particular attention should be paid to the purchase or manufacture of boxes that are necessary for finishing pipes (if any). Subsequent rough finishing of plasterboard surfaces includes the use of starting and finishing putty, reinforcing tape, perforated corners in the presence of external corners, arched corners in the presence of bends, etc.

d...Also, plasterboard sheets can be glued using putty or liquid nails. The main thing is to first seal all the cracks in the wall and prime the surface.

The layer of putty or adhesive applied to the sheet should not exceed 5 mm.

Additional information on the topic:

- What screws to use to attach drywall to the partition profile

- Plasterboard structure extending from wall to ceiling

- Installing a pedestal sink on a plasterboard wall

- How to install a corner profile when covering the walls of a house with plasterboard

- Sealing tape for drywall profiles - what you need

Insulation of plasterboard partitions. Material selection

Today, the choice of insulation for plasterboard structures is simply huge. In this material we will consider the most common of them.

The following materials are distinguished:

To achieve maximum sound insulation in gypsum partitions, builders most often use mineral wool. It is important to remember that this soundproofing material comes in different shapes, sizes and thicknesses.

The most common type of mineral wool can be called rolled “mats”. They have the following widths: 40, 60 and 120 cm. This is exactly the width of the horizontal step of the plasterboard frame. Rolled “mats” come in the following thicknesses: 50, 75, 100 mm. This is exactly the thickness of the metal profile for mounting plasterboard walls.

It is important to remember that when laying mineral wool in the profile of a plasterboard structure, at least a minimum air space must remain.

In addition, mineral wool can be in the form of slabs. Dimensions: 60x100 cm. The thickness is the same as that of rolled “mats”.

Also, some builders use basalt mineral wool (ROCKWOOL) as insulation for plasterboard partitions.

Good advice

- By insulating walls with gypsum, you can avoid the cost of purchasing some building materials. The vapor barrier layer must consist of a special membrane whose density ranges from 90 to 150 micrometers.

- Using hardware, choose a product with a wide head. It will serve as a reliable fixation for the drywall sheet.

- It is not recommended to choose drywall that is too low in cost. Such savings may later result in unscheduled repairs, since the quality of the material may be much lower than expected.

- When insulating a wooden house, you need to place an additional layer of insulation made of non-combustible material between the surface of the wall and the drywall.

- Sheets of material are installed exactly end-to-end, regardless of their thickness. Neglecting this advice may result in the wall surface not being very smooth even under a layer of plaster.

- When using wooden beams as sheathing material, make sure that it is not damaged by insects. It is better to treat the wood with an antiseptic compound before installation.

- The type and dimensions of the material must be in accordance with the purpose of the room where the drywall is installed.

- All corners of the material are secured with special care when laying the insulation. Otherwise, any carelessness will lead to damage to the sheet section.

The basic principles of working with plasterboard when insulating walls in a home from the room side are outlined above. Regardless of the material of the walls of a residential building, thermal insulation and cladding of the wall surface using plasterboard should be carried out as carefully and efficiently as possible. Otherwise, the result will not be able to meet expectations, which threatens premature repair of the plasterboard wall.

How to install mineral wool correctly

Before laying mineral wool, you need to have a respirator, construction gloves, and a hat.

When the frame is completely assembled, the mineral wool is cut into strips of certain sizes using a drywall knife. The cut strips are laid tightly along the frame posts. If the ends are joined, it is better to overlap from 10 to 15 cm.

Coconut cork and combination board

If it is important to achieve maximum sound insulation of a plasterboard partition, you can use balsa wood and coconut fiber boards. You can combine these soundproofing materials. Then you can achieve the maximum permissible sound insulation effect.

Expanded polystyrene boards are perhaps one of the best thermal insulation materials used in insulating plasterboard partitions. Expanded polystyrene boards come in different sizes and densities. Usually these are 120x60 and 100x50 cm with a thickness of 2 to 5 cm. They differ in density into soft, semi-rigid and hard. They are connected using grooves.

They also speak well of polystyrene foam as an insulating material. High heat transfer, a wide range of sizes and shapes, allows you to insulate any wall made of plasterboard construction.

If a decision is made to carry out insulation exclusively with the help of mineral wool, then Rockwool will be an indispensable insulation. After all, it is no worse than the same polystyrene foam. As an advantage, it is worth emphasizing the fact that Rockwool can have a heat reflector. It should be remembered that ROCKWOOL mineral wool comes in both slabs and rolls. If it is a roll, then it can have a thickness of 30,40, 50 cm; length 5, 8, 10 m, standard width 1 m. If it is a slab, then dimensions: 100x60 cm with a thickness from 5 to 20 cm. This insulation is able to withstand large temperature differences and has good water-repellent and fire-resistant characteristics.

Polymer heat reflectors are used to maintain temperature in a particular room. They are usually sold in rolls with dimensions: 2-5 mm thick. width - 1 m. length - 30 m. The thickness of the heat reflector foil itself can also be different.

Application of new developments

Competition in the construction market forces manufacturers to look for ways to improve product quality. To achieve this, work is being done in the following directions:

- creation of acoustic drywall;

- use of special filler with noise-absorbing properties for partitions;

- elastic pads under the frame, reducing the sound of impacts;

- filling partitions and creating false walls;

- spraying cellulose fibers inside partitions.

Acoustic drywall

and Aku-Line have mastered the production of acoustic plasterboard, which reduces the noise level when finishing interior partitions and when covering walls. Increased sound insulation of the partition is achieved due to a large number of holes, creating a reflection of a passing sound wave directed at the wall surface. In addition, a non-woven fabric is glued to the cardboard on the reverse side, which absorbs sound.

Acoustic plasterboard "Knauf"

Sound-absorbing filler inside partitions

Sound insulation of plasterboard partitions also requires the presence of a sound-absorbing filler between them. The same companies are developing it. Expanded polystyrene is widely used - a foamed thermoplastic made from fused granules with air cavities. The material also successfully copes with the function of thermal insulation. The addition of a fire retardant can increase the fire resistance of polystyrene foam. Judging by customer reviews, domestic polystyrene foam is a very poor thermal insulator.

Mineral wool slabs have high protective properties against sound propagation. produces a wide range of acoustic stone wool slabs, among which 4 cm thick products are often used for soundproofing walls. For effective dispersion of sound waves, the homogeneity of the slabs, which acoustic mats have, is of great importance.

Acoustic mats "Rockwool"

Partition materials with improved soundproofing properties are more expensive than usual, but with their help they achieve complete sound insulation. In addition, you can use filler of a smaller thickness, which will reduce costs and loss of room volume.

Membranes made of thin fabric with a fleecy coating are a high-quality sound absorber. The layer can be from 2.5 to 12 mm thick.

Polyester or polyurethane foam panels are used for internal filling and to create false walls. Some of them may be a fire hazard due to the content of flammable substances.

The cheapest filler for plasterboard walls is polystyrene foam. It reduces noise to some extent, but its efficiency is low.

Spraying sound-absorbing coatings

Spraying cellulose fibers with an adhesive composition is often used due to its low cost and the possibility of mechanizing the process. The method is used to correct acoustics indoors for entertainment and public purposes.

How does cellulose spraying occur?

Ready-made Sonaspray coatings have a texture like fur coat plaster. It can be coarse or uniform, depending on the size of the cellulose flakes. Since the coatings look impressive, dyes of a wide variety of shades are added to the solution. The coating can be painted after it has been applied.

The ability to spray a foamed cellulose solution on the surface of walls and ceilings made of building materials eliminates the need to create a frame that is used to hold gypsum board cladding. The manufacturability and cost-effectiveness of the process allows the team of specialists to ensure a productivity of 300 m² per day.

If you have the necessary equipment, the sound insulation of a plasterboard interior partition can be improved by applying cellulose from the inside.

Insulation of plasterboard partitions with mineral wool

It is not difficult to properly insulate and soundproof plasterboard partitions. Drywall itself has good soundproofing characteristics. You can increase the heat and sound insulation in a room by sewing it in two layers.

Mineral wool is considered one of the most used insulation materials. Important: before installing the metal frame on the profile guides, it is necessary to glue self-adhesive insulating tape to the floor, ceiling and walls.

Self-adhesive tape is made of polystyrene components and has a thickness of 3-4 mm. It is glued to effectively absorb sound from the ceiling, walls, floor, and even from the profile frame itself.

Electrical tape is also applied to the U-shaped brackets. It (insulating tape - ed.) is nailed to the wall, after which the rack profiles are aligned and screwed to the brackets. Then the distance from the indentation from the wall to the metal frame is measured. Rolled mineral wool is cut into strips 10-15 cm larger than the size we need. It is recommended to overlap the mineral wool on top by 10-15 cm, as this will allow the insulation to be more firmly fixed between the frame and the wall.

Having secured the first layer, you can begin installing the second. It is worth remembering that the second layer should be overlapped (10-15 cm). Remember, the denser the mineral wool is, the better the sound insulation will be. However, do not forget about the minimum gap (2-3 mm).

After the mineral wool is well placed in the metal frame, everything is sewn up on both sides with plasterboard sheets.

Sheathing rules

When forming soundproofing partitions, two types of drywall are used. The first is a standard sheet 16 mm thick, the main material for the construction of non-permanent vertical planes. The second type is acoustic plasterboard, which has a network of dot embossing or through perforations. The essence of the work of such a material is to create a heterogeneous environment in which mechanical vibrations propagate less well, as well as to reduce the contact area between the skin layers.

Acoustic (perforated) plasterboard

It is believed that the covering of gypsum board partitions with good sound insulation must necessarily be multi-layered. However, this rule misses the point, because simply increasing the thickness of the shell is not enough to prevent noise penetration. We will share one universal recipe that has shown good results in practice.

The first layer of plasterboard is sewn to the profiles in increments of about 20 cm, while the sheathing must be separated from the frame with an elastic tape, for example, made of polyethylene foam. Next, a layer of foam rubber up to 10 mm thick is attached to the formed plane with PVA glue. The joints between the divider sheets must be placed either horizontally or along the line of the profiles. The second layer of plasterboard is sewn on so that it is attached not to the supporting system, but to the inner layer of drywall in the space between the studs. Typically, the fastening consists of two vertical rows of self-tapping screws in a checkerboard pattern at a distance of 15–20 cm from each other. It is important to follow two rules: the total number of fasteners for the second layer must be twice as high as when attaching the internal one to the frame, and the distance of the second layer fasteners from the rack profiles must also be maintained at least 150 mm.

Which insulation is better for drywall?

To create comfortable living conditions, it is important to choose the right insulation for the walls, not the heating system. This allows you not only to retain heat, but also to save on utility bills. It is worth noting that the use of drywall is best suited for this process. It allows you to create a pleasant microclimate, while perfectly leveling the walls and creating an almost ready-made surface for finishing. Let's consider the thermal insulation qualities of drywall and what filler to choose for it in order to create warmth and comfort in the house.

Ceramic brick: expensive classics

Ceramic brick is a time-tested classic, seriously displaced on the market by other materials. Today, you rarely see a brick house under construction in a new village. What about interior partitions? Does it make sense to take ceramics?

Alexander: Brick has one significant drawback, which negates many of its advantages: the material is small-piece, and therefore its installation will be long, labor-intensive and cost a pretty penny. And the second point: the thickness of the brick is 12 centimeters, plus a centimeter of plaster on each side. As a result, we come to a partition 14 centimeters thick. In a situation where every square centimeter in a room is precious, this is too much.

Sometimes, in order not to waste vital space and save material, builders use one trick: they lay a brick on its edge and build a partition that way. The reliability of such a design raises questions. In this case, mandatory reinforcement and additional fastening of the partition to the load-bearing wall with anchors are necessary.

For interior partitions, it is better to take solid brick - you can hang anything on it. Other advantages are that it is not afraid of moisture, it is an environmentally friendly material, and it allows you to create a beautiful radius wall (however, drywall can do the same). If you are a fan of loft interiors, you can do without finishing.

Thermal insulation properties of plasterboard

The use of plasterboard slabs allows you to create high thermal and sound insulation not only due to the pores that form inside it, but also due to the air layer that is located behind the slab. Therefore, for a relatively warm climate, you may not need to use additional insulation. As for the gypsum board itself, the level of thermal insulation is determined by the thermal conductivity coefficient. For example, drywall has a thermal conductivity coefficient of only 0.15, which is significantly lower than reinforced concrete. This allows you to not only create warmth in the winter, but also coolness in the summer.

It is worth noting that the method of installing drywall affects the level of thermal insulation. To achieve greater effect, it is recommended to use a frame option rather than glue. The resulting layer under the frame creates additional insulation of the walls. But, one way or another, to create a warm atmosphere you will need insulation.

Primary requirements

Interior partitions are intended to divide the general space of a building into separate small spaces (rooms), while they are not load-bearing structures. Therefore, to make such a structure, you can use various materials: wood, plasterboard, sand-lime brick and others.

Sound insulation, environmental friendliness, home safety, etc. depend on how well the work on installing interior partitions is done. These indicators are also influenced by the type of material used to build a given structure.

Interior partitions must meet a number of requirements and have excellent technical and operational characteristics.

- High strength and reliability. Partitions should not create even the slightest danger for residents of the house and their guests throughout the entire life of the structures.

- The surface of the structure and the points of connection with other structures should not have any damage, cracks, crevices, etc.

- There are special requirements for partitions in bathrooms and laundry rooms. In addition to the main characteristics, the design must have increased resistance to the penetration of moist air and steam. When choosing a material, moisture resistance indicators should be taken into account. And when installing the partition, certain rules must be followed to prevent moisture from entering the structure. The best option for such structures is a special waterproof cladding material.

- For interior partitions installed on the second and subsequent floors, as well as in the attics of houses with wooden floors, an important factor is the weight of the structure. This is explained by the fact that floors made of wood can withstand only minor loads.

- To provide lighting to a room located in the back of the house, you should use a translucent structure made of special glass blocks. You can also install a partition with glass inserts.

- In stationary interior partitions, which have increased thickness, various communication systems are often installed, for example, a chimney, water pipes, electrical wiring, etc.

- Interior partitions that divide rooms with different temperature conditions must have excellent thermal insulation properties.

- To ensure reliable sound insulation of the room, when installing lightweight interior partitions, it is necessary to use special soundproofing building materials. Massive structures do not require additional equipment and are able to cope with this task independently.

Insulation of walls from the inside

The first thing you need to decide is where exactly the insulation will take place. For private houses, it is better to choose insulation from the outside; this is a more effective option. If the process is carried out in an apartment, then internal insulation will have to be carried out. The following materials are used for drywall:

So, in order to choose the right insulation for drywall, you need to decide what the price of insulation is, where exactly the building will be insulated (inside or outside). Isolon and basalt wool are best suited for internal insulation. The latter option is more common, it is easier to purchase at different prices, and it is completely safe during operation.

Source