Our company provides services for replacing coolant in heating systems of country houses with washing and cleaning internal surfaces of scale and other contaminants. Flushing is a mandatory step, as it stops corrosion processes and prevents fresh antifreeze from becoming contaminated and immediately losing its performance properties.

We use modern equipment, our craftsmen complete the work in a short time.

Types and properties of heat-carrying liquids

The working fluid of any water system - the coolant - is a liquid that takes a certain amount of energy from the boiler and transfers it through pipes to heating devices - radiators or underfloor heating circuits. Conclusion: the efficiency of heating depends on the physical properties of the liquid mediator - heat capacity, density, fluidity, and so on.

In 95% of private houses, ordinary or treated water is used with a heat capacity of 4.18 kJ/kg•°C (in other units - 1.16 W/kg•°C, 1 kcal/kg•°C), which freezes at a temperature of about zero degrees. The advantages of traditional heating fluid are availability and low price, the main disadvantage is the increase in volume when frozen.

The ice that forms in the cold literally splits pipes, boiler heat exchangers and radiators. To prevent the destruction of expensive equipment due to defrosting, 3 types of antifreeze made on the basis of polyhydric alcohols are poured into the system:

- Glycerin solution is the oldest type of non-freezing coolant. Pure glycerin is a transparent liquid of high viscosity, the density of the substance is 1261 kg/m³.

- An aqueous solution of ethylene glycol - dihydric alcohol with a density of 1113 kg/m³. The starting liquid is colorless and is inferior in viscosity to glycerin. The substance is toxic, the lethal dose of dissolved glycol when taken orally is about 100 ml.

- The same, based on propylene glycol - a transparent liquid with a density of 1036 kg/m³.

- Compositions based on the natural mineral - bischofite. We will analyze the characteristics and features of this chemical separately (below in the text).

Reference. Any non-freezing heating fluid contains a dye that gives the chemical a distinctive color. Poisonous ethylene glycol is usually colored red or yellow, propylene glycol is green (less often blue). Glycerin antifreeze is given a pink tint or left transparent. This classification is not mandatory and is not always observed.

Anti-freeze products are sold in two forms: ready-made solutions designed for a certain subzero temperature (usually -30 ° C), or concentrates, which the user dilutes with water himself. Let us list the properties of glycol antifreezes that affect the operation of heating networks:

- Low crystallization temperature. Depending on the concentration of polyhydric alcohol in an aqueous solution, the liquid begins to freeze at a temperature of minus 10...40 degrees. The concentrate crystallizes at 65 °C below zero.

- High kinematic viscosity. Example: for water this parameter is 0.01012 cm²/s, for propylene glycol - 0.054 cm²/s, the difference is 5 times.

- Increased fluidity and penetrating ability.

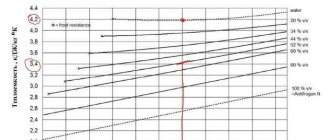

- The heat capacity of non-freezing solutions lies in the range of 0.8...0.9 kcal/kg °C (depending on concentration). On average, this parameter is 15% lower than that of water.

- Aggressiveness towards some metals, such as zinc.

- The substance foams when heated and quickly decomposes when boiling.

In order for antifreezes to meet operational requirements, manufacturers add additive packages to glycol solutions - corrosion inhibitors and other elements that maintain antifreeze stability and reduce foaming.

Example of an automatic make-up system

There is a lot of equipment on the market to solve the issue of recharging heating systems. Do you want an automatic, trouble-free, reliable installation? It can be “assembled” from the following elements:

- containers with screw caps;

- dosing pump;

- pressure switch;

- rigid suction line with level sensor;

- air valve for releasing air;

- a fitting for pouring coolant into a container, equipped with a plug (prevents solid particles from entering the container);

- injection valve for connection to the circulation system;

- flexible tube;

- low level sensor to signal the absence of liquid in the make-up tank;

- an electric stirrer that prevents possible separation of the coolant into fractions.

A correctly installed unit from the above components will be highly effective in maintaining the required pressure in the heating circuit, and is also fully compatible with the room air conditioning circuit. The installation will automatically “eliminate” all normal losses in systems: connections, pump seals, fittings. It is not at all capricious with regard to the coolant: it works well with both water and glycol-containing liquids.

This unit operates according to the following principle:

- Through the fitting or neck, water/glycol and water in the appropriate proportion/ready solution are poured into the container.

- The pump of the make-up installation is connected to the network and pumps coolant into the system at low output, thereby ensuring its uniform filling.

- When the pressure in the system reaches the set value, pumping automatically stops.

- When the pressure drops, the relay turns on the pump, returning the system to stability.

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at subzero temperatures. We list other positive aspects of using antifreeze in closed water heating systems:

- coolants do not contain calcium and magnesium salts, which form scale inside the heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not sour, the fittings last longer;

- the boiling point of antifreeze 103-106 °C delays the moment of vaporization and airing in case of overheating of a solid fuel boiler;

- When the temperature drops below the freezing threshold, glycol solutions turn into a gel mass.

Note. The paragraph about scale implies that the “anti-freeze” is diluted with demineralized distilled water.

Let's clarify the last 2 points. Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT boiler supply, the steam phase penetrates the chamber with the impeller, water pumping stops, and the boiler completely overheats. A higher boiling point of antifreeze will delay the moment of the accident.

Unlike water, glycol hardened in the cold does not expand and does not destroy pipe walls. In the event of freezing, the only unit that will suffer is the forced circulation pump. The crystallizing gel will jam the impeller and the motor will burn out.

Unfortunately, there are plenty of disadvantages to non-freezing substances:

- Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless.

- The heat capacity of the “anti-freeze” is 15% less. To deliver the required amount of heat to the batteries, the liquid flow will have to be increased.

- The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump.

- Good turnover is a double-edged sword. Glycols penetrate through the slightest leaks, from which plain water cannot flow.

- Coolants and additives decompose during operation, losing their frost-resistant properties and forming flakes of sediment. The maximum service life of 1 refill is 5 years, then the heating is flushed and replaced.

- When using antifreeze, many gas boiler manufacturers void the warranty of the purchased product.

Glycol liquids are poorly compatible with electric boilers. Instructions for the use of various antifreezes categorically do not recommend filling systems operating in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the “Galan” type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze can release flammable gas that breaks through the automatic air vent. Example: the heat source is an electric boiler, the heaters are Chinese-made aluminum radiators. Heating glycol causes a complex chemical reaction and gas formation.

What to consider when choosing antifreeze

When buying antifreeze, pay attention to the following indicators:

- temperature range at which the coolant performs its functions - the wider it is, the better;

- heat capacity, that is, the amount of coolant consumed to pump a unit of time to transfer the required amount of heat, while losses should be minimal;

- viscosity coefficient, on which the speed of its circulation, heat transfer, etc. depends;

- corrosive activity in relation to the materials of the elements from which the heating system is assembled;

- safety for nature and people;

- low viscosity - the higher the indicator, the lower the efficiency;

- inertness to foaming, on which the efficiency of the pump depends.

Attention! The composition should not contain substances that make polymers and other materials brittle and lead to their destruction.

Inertness to foaming is one of the main quality indicators

New mineral coolants

We decided to highlight the description of these liquids, since they are made based on the natural mineral - bischofite. The substance is a magnesium salt of hydrochloric acid, the full name is magnesium chloride hexahydrate. The manufacturer declares the following characteristics of the finished antifreeze, designed for a minimum temperature of minus 30 degrees:

- the color of the aqueous solution is light yellow, the density is 1117...1250 kg/m³;

- boiling threshold - 116 °C, freezing point - minus 30 °C;

- specific heat capacity - 0.77 kcal/kg •°С (3.23 kJ/kg•°С);

- thanks to the additives, there is no foaming and no aggressive effect on various seals - silicone, paronite, EPDM and BMS rubber;

- the substance is not toxic;

- In terms of viscosity and fluidity, the drug is very close to glycol chemicals.

Reference. The product appeared on the market after 2010. The price of liquid as of 2022 is about 1 USD. e. per liter of finished coolant (-30 ° C).

Compared to traditional glycol analogues, mineral antifreeze benefits due to its high boiling point, cost and health safety. The negative point is the increased density and low heat capacity, 23% worse than that of water.

The practical use of the coolant has revealed a number of shortcomings, as evidenced by reviews from homeowners:

- The fluidity of the solution is extremely high. There have been cases where antifreeze penetrated through the soldered joint of polypropylene pipes.

- Upon contact with air, the liquid fraction quickly evaporates, leaving a noticeable salt build-up. Similar phenomena are observed in heat exchangers and pipelines where air bubbles have penetrated.

- The substance reacts with bare metal on welds. Stalactites of iron and salt form inside the system, reducing the flow area and clogging the mud traps.

- In case of overheating, antifreeze turns into a slurry of unknown color.

User responses about this type of “anti-freeze” can be read on the well-known construction forum: https://www.stroimdom.com.ua/forum/showthread.php?t=157650

Taking into account the experience of users, we do not dare to recommend mineral antifreezes for use in heating systems of private houses. Perhaps over time, manufacturers will eliminate the above problems and the magnesium chloride solution will be able to compete on equal terms with glycols.

Wiring diagram

Developing, drawing, designing and approving a heating scheme for a new building or at least moving a radiator to another location is the subject of a separate article, not even several articles.

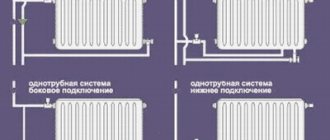

Therefore, we believe that we are only talking about the reconstruction of heating in a city apartment and all the batteries remain in their places. Methods for connecting heating radiators

In this case, the general heating scheme of the house remains as is, and we only need to choose the method of connecting the radiators to the riser. There are four options, see fig. Bottom connection - for hidden wiring

It is important not to forget about TWO ball shut-off valves for each radiator, for supply and return; they are highlighted in color in the left picture. In the event of a leak, this will allow you to disconnect one battery without affecting the entire system

For steel and metal-plastic with aluminum radiators, do not forget about propylene inserts to avoid electrocorrosion. They are also highlighted and labeled on the left.

Choosing an “anti-freeze” for heating

Tip number one: buy and fill in antifreeze only in extreme cases - for periodic heating of remote country houses, garages or buildings under construction. Try to use water - regular and distilled, this is the least troublesome option.

When choosing a frost-resistant coolant, follow the following recommendations:

- If your budget is limited, take ethylene glycol from any well-known brand - “Teply Dom”, Dixis, Spektrogen Teplo Coolant, Bautherm, Termo Tactic or “Thermagent”. The cost of the concentrate -65 °C from Dixis is only 1.3 USD. e. (90 rubles) per 1 kg.

- If there is a danger of antifreeze getting into household water (for example, through an indirect heating boiler, double-circuit boiler), or you are very concerned about the environment and safety, buy harmless propylene glycol. But keep in mind: the price of the chemical is higher; a ready-made Dixis solution (minus 30 degrees) will cost 100 rubles (1.45 USD) per kilogram.

- For large heating systems, we recommend using premium class HNT coolant. The liquid is made on the basis of propylene glycol, but it has an increased service life of 15 years.

- Do not buy glycerin solutions at all. Reasons: sedimentation in the system, too high viscosity, tendency to foam, a large number of low-quality products made from technical glycerin.

- Electrode boilers require a special liquid, for example, HNT-35. Before use, be sure to consult with a representative of the manufacturer.

- Do not confuse automobile antifreezes with chemicals used in heating systems. Yes, both formulations are glycol-based, but the additive packages are completely different. Engine coolant is not compatible with residential water heating.

- For open and gravity-flow heating systems, it is better to use water, or, in extreme cases, propylene glycol diluted at minus 20 °C.

- If the heating distribution is made with galvanized pipes, there is no point in purchasing glycol mixtures. The substance will deal with zinc, lose the package of additives and quickly degrade.

Clarification. It is not profitable to use frost-resistant liquid for an open heating system. Hot antifreeze will evaporate into the atmosphere through the expansion tank, the antifreeze will have to be constantly topped up, and money will be spent. It is unacceptable to pump in ethylene glycol, since its vapors are toxic.

There is a lot of debate about the harmfulness of ethylene glycol compounds, including on the pages of construction forums. Without denying the harmful effects of the chemical on human health, let us draw attention to a convincing fact.

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

Homeowners whose closed systems are installed well have been using inexpensive glycol for years without any problems. Let's listen to the expert's opinion in the video:

What determines the prices of services for replacing antifreeze in heating systems?

To calculate how much it costs to replace antifreeze with flushing, our technicians need to obtain a number of initial data. First of all, this is the type of system, the total volume of coolant, the degree of contamination of the working elements. The location of the facility is also important - we serve the entire Moscow region, and by prior agreement we travel to the regions for large orders.

In our company you will receive a full package with quality guarantees for all work performed and high-quality antifreeze poured into the system. Managers will provide you with any necessary additional information and accept a request for service at the phone number indicated on the website.

Instructions for use

If your system previously ran on water, switching to antifreeze will not be easy. Theoretically, radiators with a boiler can be emptied and filled with cold-resistant coolant, but in practice the following will happen:

- due to lower heat capacity, the output of batteries and the efficiency of heating rooms will decrease;

- due to viscosity, the load on the pump will increase, coolant flow will drop, and less heat will reach the radiators;

- antifreeze expands more than water, so the capacity of the old tank will not be enough, the pressure in the network will rise;

- To improve the situation, you will have to increase the temperature on the boiler, which will lead to excessive fuel consumption and increased pressure.

Addition. After filling the liquid, the old connections sealed with flax and paint are guaranteed to flow.

In order for heating to function normally using a chemical coolant, you need to calculate in advance or remake the existing system according to the new requirements:

- Select the capacity of the expansion tank at the rate of 15% of the total volume of liquid (water was 10%);

- The pump performance is assumed to be 10% more, and the generated pressure is assumed to be 50% more. Let us explain with an example: if previously there was a unit with a working pressure of 0.4 Bar (4 meters of water column), then use a 0.6 Bar pump for antifreeze.

- In order to operate the boiler in optimal mode and not raise the temperature of the coolant, it is advisable to add 1-3 (depending on power) sections to each battery.

- Pack all joints with dry flax or use high-quality pastes - sealants such as LOCTITE, ABRO or Hermesil.

- When purchasing shut-off and control valves, consult with the seller about the resistance of rubber seals to glycol mixtures.

- Pressure test the system again by filling the pipes and heating equipment with water.

- When starting the boiler unit at negative temperatures, set the minimum power. Cold antifreeze needs to be warmed up slowly.

Advice. The total amount of coolant is easy to calculate - the cross-sectional area of the pipe is multiplied by its length, the capacity of the boiler and radiators is indicated in the product data sheets. Find out how to properly place and connect the expansion tank in our separate publication.

The concentrated coolant must be diluted with water, ideally with distillate. Do not rely on an excessive reserve of frost resistance - the more water you add, the better the heating will work. Recommendations for preparing coolant:

- For heating elements, electric and gas double-circuit heat generators, prepare the mixture at minus 20 degrees. A more concentrated solution may foam upon contact with the heater, and carbon deposits will form on the surface of the heating element.

- In other cases, mix the components at freezing point according to the table below. Proportions are indicated per 100 liters of coolant.

- If there is no distillate, first conduct an experiment - dilute the concentrate in a jar with plain water. If you see a precipitate of white flakes - a product of the decomposition of inhibitors and additives, this water should not be used.

- A similar check is done before mixing antifreeze from two different manufacturers. It is unacceptable to dilute ethylene glycol with propylene composition.

- Prepare the coolant immediately before pouring.

The maximum service life of any antifreeze substance in pipes and heating radiators is 5 years. At the end of the specified period, the liquid is drained, the system is flushed twice and filled with fresh antifreeze.

Where to put

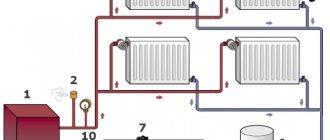

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Finally, about coolants for electrode boilers

Electric water heaters of this type operate on the principle of a “soldier’s boiler” consisting of two blades connected to a 220 volt network. Water simultaneously serves as a coolant and electrolyte; heating occurs due to its conductivity, which depends on the content of magnesium and calcium salts.

This is why electrode boilers do not work with distillate and significantly lose power with under-salted water. According to the passport of the Galan heater, the resistance of the working fluid should be no more than 3200 Ohms per 1 cm.

If you pour regular ethylene glycol into an electrolysis heat generator, the substance will enter into a chemical reaction, foam and lose additives against corrosion and scale formation. The problem can be solved in 2 ways:

- A special antifreeze designed for electrode-type units is purchased. Special additives that resist foaming are dissolved in the working environment.

- A saline solution of the required concentration is prepared, as shown in the video below. Such water will begin to crystallize at a lower temperature, although it cannot be compared with antifreeze in terms of frost resistance.

You should pay attention to the preparation of tap water - pass it through a filter and let it sit for 1-3 days. A good solution is to buy a corrosion inhibitor separately and add it to the coolant for the heating system in advance.

How to prevent a reduction in the service life of the coolant and avoid the formation of corrosion in the system?

First of all, this will be facilitated by the correct choice of coolant intended for use in your specific system. Indicators such as the predominant metal, approximate temperatures, type of equipment, etc. are important.

Preventive measures and compliance with operating rules are also important:

- Do not allow the system to overheat - high temperatures contribute to the deposition of scale primarily on heat exchangers, and the efficiency of the heating system and hot water supply as a whole depends on them;

- Do not allow the system to remain idle for long periods of time - even if you do not live in the house, carry out an annual heating start-up, avoiding liquid stagnation;

- Do not carry out self-service - dirt may enter the system, which will reduce performance;

- Do not add water to the antifreeze - this will also reduce the performance of the system, increase the risk of freezing, and increase the intensity of corrosion formation.

It is important to remember that the higher the density (content, concentration of propylene glycol) of the coolant, the less intensively the system will be contaminated, and the less often it will require flushing and comprehensive cleaning of its elements. Emergency repair costs will be minimized.

And how to do it

But leaving aside for now the questions of who should do what and be responsible for what, let’s consider purely technically how it is possible, for example, to replace old pipes with plastic ones. This will allow you to remove worn-out pipes clogged with deposits, installing new ones, and thus help solve the problem of how to increase the heat transfer of a heating pipe - due to the passage of more coolant.

In this case, what your neighbors have will be critical for completing the work. If the neighbors above have already replaced the metal riser pipe with a polypropylene one, then you should install the same one.

It is best if you can agree with them on the possibility of connecting to their junction. In this case, you are dismantling the heating in the apartment, i.e. cut out all the old pipes, cut out an adapter from plastic to metal from a neighbor, determine locally the required length of pipes that need to be laid. Then the metal scrap is pulled out from the ceiling, a propylene pipe is inserted in its place and soldered through a propylene coupling to the neighbor’s pipe.

Connecting a metal and polypropylene pipe using a special coupling

In cases where your neighbors have metal left and they do not allow you to make a joint at their place in order to go through the ceiling, you will have to cut your pipe under the ceiling and cut a thread on its remains. A transition coupling for polypropylene is placed on it, and the corresponding pipe is already connected to it.

If you want the heating replacement in the apartment to be complete, i.e. If you are planning to replace radiators, then you need to start work with them.

There are quite a lot of them, and of very different types, but regardless of this, there are general rules, the implementation of which will allow you to get a good result:

- all radiators in the apartment must be placed equally, on the same level;

- the battery must be positioned strictly vertically;

- its top should be five cm below the window sill and six cm above the floor;

- when attaching a radiator, there should be one mounting bracket per square meter of its surface;

- the front surface of the battery should protrude beyond the edge of the window sill.

Correct installation of a heating radiator

Installation of polypropylene pipes

Main stages

The following stages of work can be distinguished:

- Before starting installation work, it is necessary to cut segments of polypropylene pipes of the required size. If a foil-coated pipe is used during installation, you will have to remove the outer and inner layers of foil at the junction with the fitting.

- Removing burrs from the end of the pipe.

- Make a mark with a marker at the fitting entry point to the fitting entry depth. In this case, you need to leave a small gap, which will avoid narrowing at the junction of two pipe segments using a fitting.

- Place marks at the junction of the pipe and fitting. This will help avoid distortion during the connection.

- The fitting and the end of the pipe are put on the heated nozzle at the same time to heat them evenly. Thick parts need to be heated at the very beginning.

When connecting, you need to pay attention to how the segments are inserted. If one of them fits too loosely, it must be replaced with a new one. Otherwise, it will not be possible to achieve a good seal of the pipe, and in the near future a leak will form in this place.

After the parts have been heated up as required, they are connected to each other. In this case, you need to use the marks made earlier and try to align them with each other. The parts must not be rotated during installation. Hardening of the heated material takes no more than 10-30 seconds. Therefore, in the first seconds of connection you need to be very careful. After the parts are properly connected, they need to be fixed to cool for the period of time recommended by the manufacturer.

Connection of heated pipes

It’s better not to take the easy way out when repairing heating equipment.

antigenic particles to an antifreeze filler that has already been in use for several years . It is also possible to do this when the old liquid is not drained, only adding new liquid to the heating equipment. This antifreeze treatment method is not effective and can lead to serious consequences. It is best not to skimp on materials for heating work; this applies primarily to replacing antifreeze.

Stop warming the street

Whether the radiators will be changed during the heating reconstruction process or not, but since they will still have to be removed for some time, it is highly advisable to cut off the outflow of heat to the outside. To do this, you need to cover the wall behind the batteries with heat-insulating mats aluminized on both sides. How such a bedding works in terms of heat can be read in the article on floor insulation; here it is enough to note that in a block Khrushchev house with radiators in niches, double heat shields behind the radiators are equivalent to covering the walls with 20 mm plywood.

In an alternative option for insulating the wall behind the radiator, heat-insulating material (1) and aluminum foil (2) are used separately.

Installing the shielding mat is simple: we cut holes in it for the hooks of the battery suspension, apply thin “sausages” of construction silicone or mounting adhesive using an “envelope” to the side adjacent to the wall, put it on the hooks and press it to the wall.

An indispensable condition: the mat must be organic, made of synthetic or natural fibers. The use of open mineral wool mats in residential premises is unacceptable - it is harmful to health.

Selection of pipes and method of their installation

Before installing a pipeline in an apartment with your own hands, you need to decide on the material. This is necessary in order to select the necessary connecting elements, as well as choose the installation method.

- Polypropylene pipes occupy a leading position in terms of installing water supply in an apartment or house. This is due to their technical features, as well as their low price. Only one drawback sometimes raises doubts about the advisability of carrying out installation work with this material. This disadvantage lies in the impossibility of disconnecting the pipeline after its installation. The polypropylene material is soldered together using special couplings and a soldering iron.

- Metal-plastic tubes are not inferior to polypropylene in all respects except cost. For installation of metal-plastic, special threaded type couplings are used. This allows you to disassemble the plumbing to make changes if necessary. Suitable for cases where there is no finance to purchase a soldering iron for soldering polypropylene.

- Polyethylene or HDPE pipes have an even lower cost than polypropylene, and special plastic fittings are used for their installation. This type of material is easy to install, but is not suitable for high temperatures, so often if installation is carried out with such material, it is only for supplying cold water.

When the optimal material option for installing the water supply system has been selected, you need to understand the method of connecting the pipes. For polypropylene, the soldering connection method is used. To carry out work with a soldering iron, it is not necessary to buy one, since you can borrow money from familiar craftsmen.

The soldering method is based on connecting two polypropylene products using special plastic fittings or couplings. The principle of joining or soldering is based on heating the outer and inner parts of the products, after which they are joined.

conclusions

What to fill the heating system with - water or antifreeze - must be decided based on the specific operating conditions and the presence of a real threat of water freezing in the heating circuit.

The process itself cannot be called too complicated, although it is quite labor-intensive and requires the invitation of an assistant.

The biggest danger that can threaten an individual heating system is freezing during the winter when there is a power outage. To avoid such situations, many use antifreeze for the heating system of a country house, which protects the boiler and pipes from deformation.

The construction market offers various brands of antifreeze for heating systems, the composition of automotive antifreeze liquids is similar, the most famous of which is Antifreeze. Therefore, many homeowners have a reasonable question: is it possible to use Antifreeze as an antifreeze for the heating circuit of an individual home and is it profitable from a financial point of view?

To get answers to this question, you should consider the physicochemical characteristics of Antifreeze and compare it with special liquids designed to protect the heating system from freezing.

Rice. 1 Popular brands of antifreeze: Warm House, Dixis, Thermagent

Floor insulation for hidden wiring

Removing heating pipes out of sight is tempting from an aesthetic point of view. To prevent hidden heating wiring from subsequently causing the righteous anger of heating engineers with accompanying sanctions, it is advisable to prepare the floor accordingly. If the decorative flooring is laid on joists and additional floor insulation is not required, then the pipes are simply laid between the joists, and removable access hatches are installed above their connections.

Otherwise, the pipes must be laid in the floor. Methods for floor insulation are described in the corresponding article. and for this case we can recommend the following:

- We lay pipes.

- We form an additional warm screed from foam concrete. We fence the pipe connections until the concrete hardens with boards according to the required dimensions (see at the end).

- We lay 12-18 mm plywood flooring directly over the warm screed, gluing the joints with liquid nails or assembly adhesive. We cut out openings in the plywood above the pipe joints.

- We restore the finished flooring. We cut out the hatches for access to the pipes larger than the openings in the plywood - they will simply be removed.

Note: It is advisable to use sheets of tongue-and-groove plywood. But if there are no wild parties in the apartment, you can also install a simple one - it is much cheaper.

The second method is somewhat more expensive, but it is easier to work with and provides access to the pipes along their entire length. To do this, we use foam concrete or aerated concrete slabs with cement-sand mortar as a warm screed. The rest is the same.